oil type NISSAN LATIO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 24 of 4331

A/T FLUID

AT-19

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

13. Flush each steel line from the cooler side back to

ward the A/T by spraying Transmission Cooler Cleaner

in a continuous stream for 5 seconds.

14. Blow compressed air regulated to 5 - 9 kg/cm 2

(71 - 128 psi) through each steel line from the cooler side

back toward the A/T for 10 seconds to force out any remaining A/T fluid.

15. Ensure all debris is removed from the steel cooler lines.

16. Ensure all debris is removed from the banjo bolts and fittings.

17. Perform "A/T FLUID COOL ER DIAGNOSIS PROCEDURE".

A/T FLUID COOLER DIAGNOSIS PROCEDURE NOTE:

Insufficient cleaning of the cooler inlet hose exte rior may lead to inaccurate debris identification.

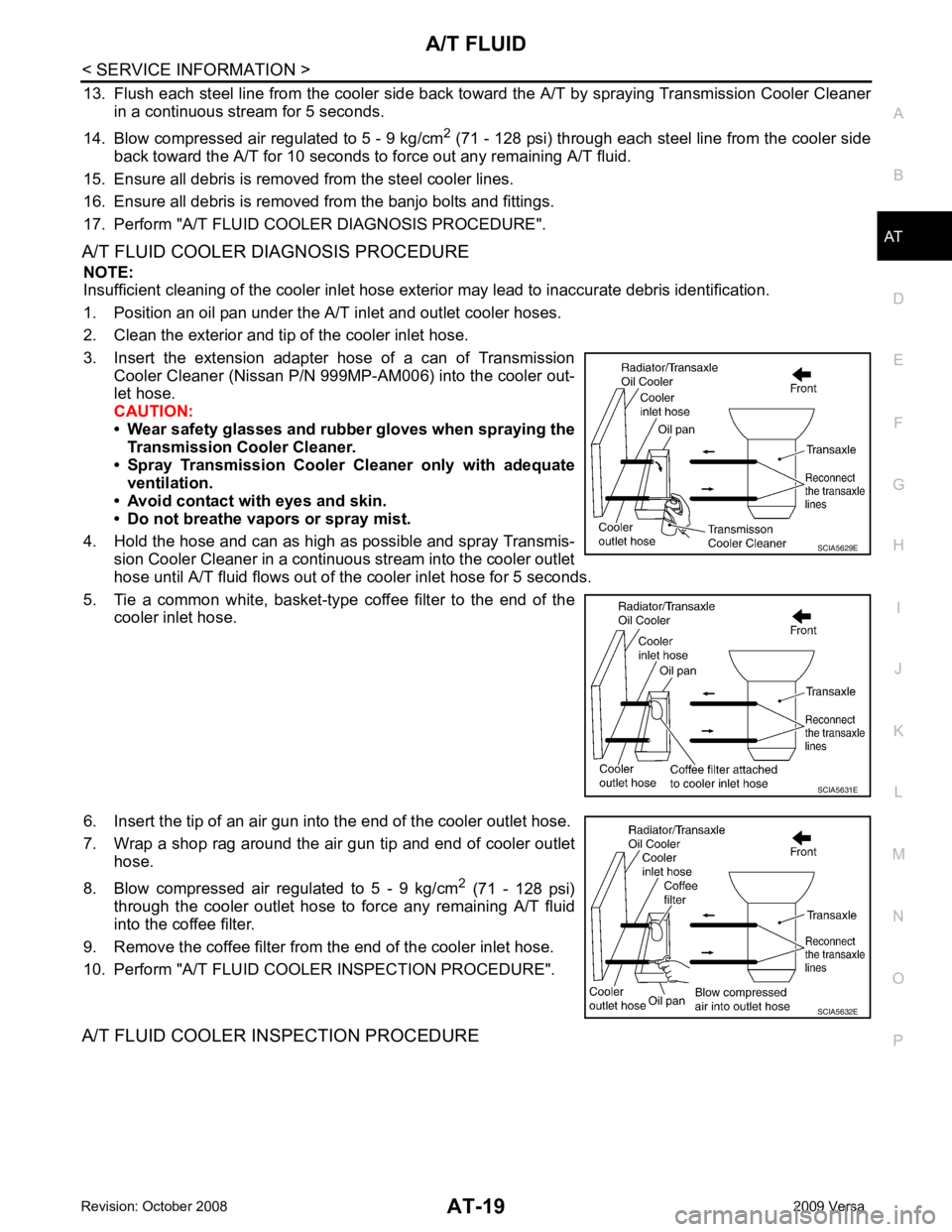

1. Position an oil pan under the A/T inlet and outlet cooler hoses.

2. Clean the exterior and tip of the cooler inlet hose.

3. Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the

Transmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breathe vapors or spray mist.

4. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until A/T fluid flows out of t he cooler inlet hose for 5 seconds.

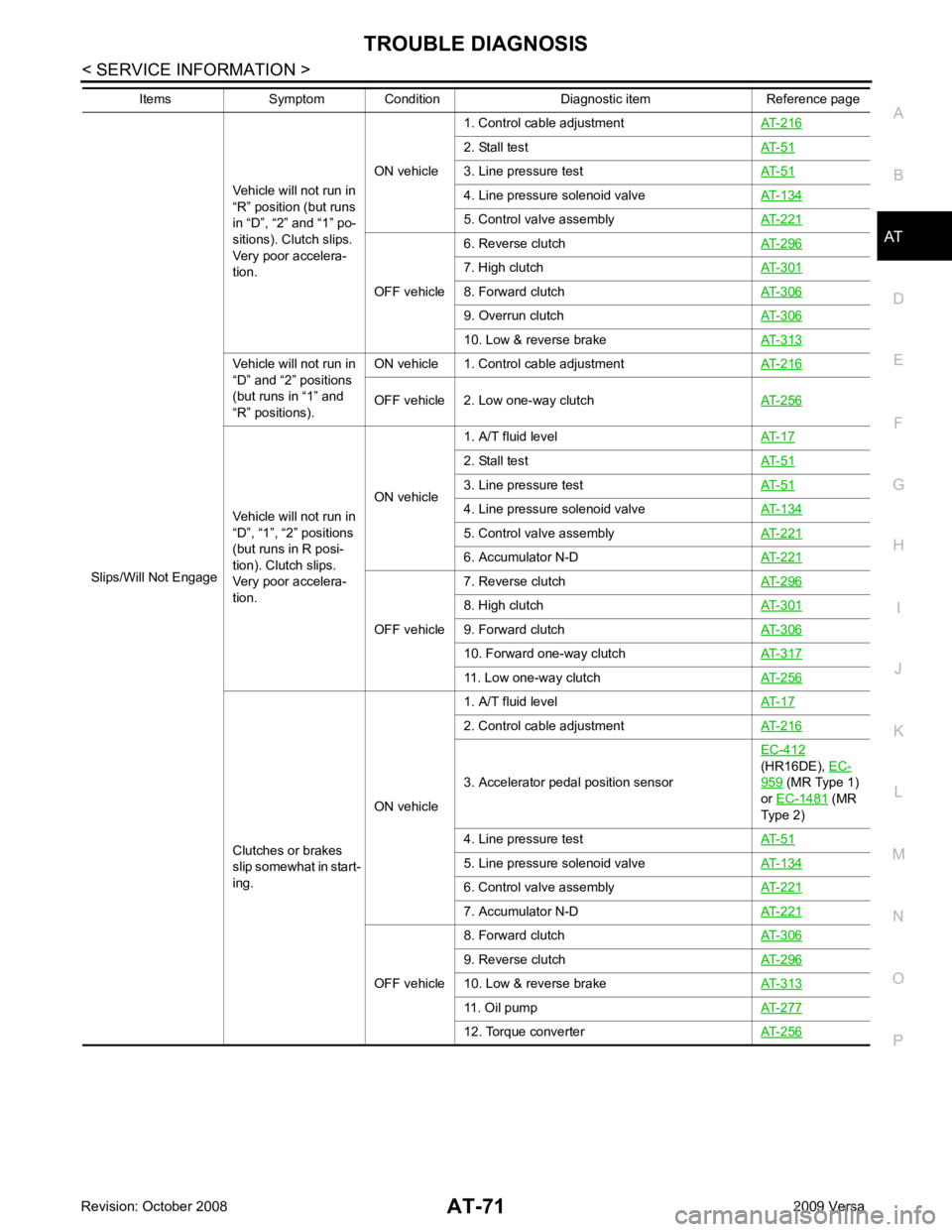

5. Tie a common white, basket-type coffee filter to the end of the cooler inlet hose.

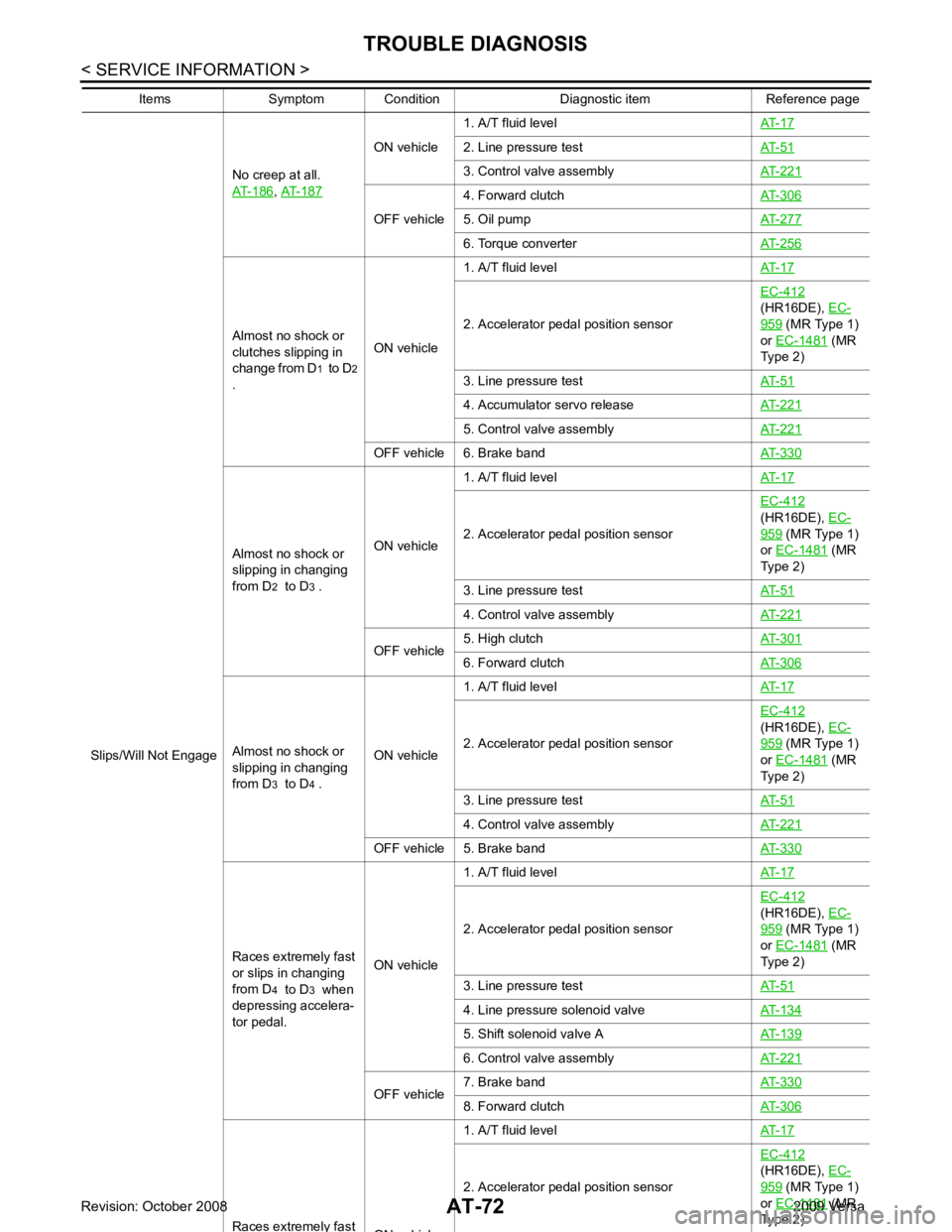

6. Insert the tip of an air gun into the end of the cooler outlet hose.

7. Wrap a shop rag around the air gun tip and end of cooler outlet hose.

8. Blow compressed air regulated to 5 - 9 kg/cm 2

(71 - 128 psi)

through the cooler outlet hose to force any remaining A/T fluid

into the coffee filter.

9. Remove the coffee filter from the end of the cooler inlet hose.

10. Perform "A/T FLUID COOL ER INSPECTION PROCEDURE".

A/T FLUID COOLER INSPECTION PROCEDURE SCIA5629E

SCIA5631E

SCIA5632E

Page 76 of 4331

AT

N

O P

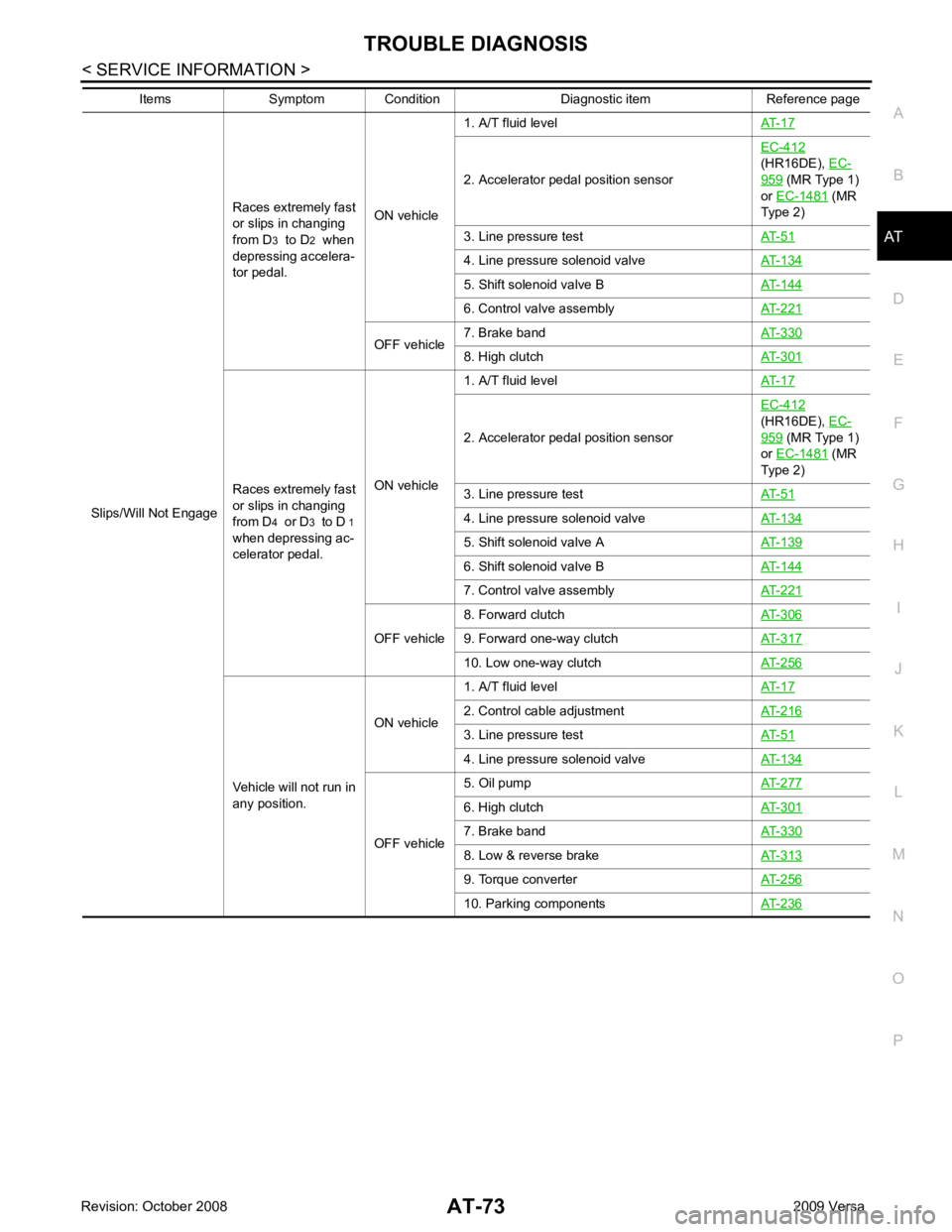

Slips/Will Not Engage

Vehicle will not run in

“R” position (but runs

in “D”, “2” and “1” po-

sitions). Clutch slips.

Very poor accelera-

tion. ON vehicle

1. Control cable adjustment

AT-216 2. Stall test

AT-51 3. Line pressure test

AT-51 4. Line pressure solenoid valve

AT-134 5. Control valve assembly

AT-221 OFF vehicle

6. Reverse clutch

AT-296 7. High clutch

AT-301 8. Forward clutch

AT-306 9. Overrun clutch

AT-306 10. Low & reverse brake

AT-313Vehicle will not run in

“D” and “2” positions

(but runs in “1” and

“R” positions). ON vehicle 1. Control cable adjustment

AT-216OFF vehicle 2. Low one-way clutch

AT-256Vehicle will not run in

“D”, “1”, “2” positions

(but runs in R posi-

tion). Clutch slips.

Very poor accelera-

tion. ON vehicle

1. A/T fluid level

AT-17 2. Stall test

AT-51 3. Line pressure test

AT-51 4. Line pressure solenoid valve

AT-134 5. Control valve assembly

AT-221 6. Accumulator N-D

AT-221 OFF vehicle

7. Reverse clutch

AT-296 8. High clutch

AT-301 9. Forward clutch

AT-306 10. Forward one-way clutch

AT-317 11. Low one-way clutch

AT-256Clutches or brakes

slip somewhat in start-

ing. ON vehicle1. A/T fluid level

AT-17 2. Control cable adjustment

AT-216 3. Accelerator pedal position sensor

EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

4. Line pressure test AT-51 5. Line pressure solenoid valve

AT-134 6. Control valve assembly

AT-221 7. Accumulator N-D

AT-221 OFF vehicle

8. Forward clutch

AT-306 9. Reverse clutch

AT-296 10. Low & reverse brake

AT-313 11. Oil pump

AT-277 12. Torque converter

AT-256Items Symptom Condition Diagnostic item Reference page

Page 77 of 4331

,

AT-187 ON vehicle

1. A/T fluid level

AT-17 2. Line pressure test

AT-51 3. Control valve assembly

AT-221 OFF vehicle

4. Forward clutch

AT-306 5. Oil pump

AT-277 6. Torque converter

AT-256Almost no shock or

clutches slipping in

change from D 1 to D 2

. ON vehicle1. A/T fluid level

AT-17 2. Accelerator pedal position sensor

EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

3. Line pressure test AT-51 4. Accumulator servo release

AT-221 5. Control valve assembly

AT-221 OFF vehicle 6. Brake band

AT-330Almost no shock or

slipping in changing

from D 2 to D 3 . ON vehicle 1. A/T fluid level

AT-17 2. Accelerator pedal position sensor

EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

3. Line pressure test AT-51 4. Control valve assembly

AT-221 OFF vehicle

5. High clutch

AT-301 6. Forward clutch

AT-306Almost no shock or

slipping in changing

from D 3 to D 4 . ON vehicle 1. A/T fluid level

AT-17 2. Accelerator pedal position sensor

EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

3. Line pressure test AT-51 4. Control valve assembly

AT-221 OFF vehicle 5. Brake band

AT-330Races extremely fast

or slips in changing

from D 4 to D 3 when

depressing accelera-

tor pedal. ON vehicle1. A/T fluid level

AT-17 2. Accelerator pedal position sensor

EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

3. Line pressure test AT-51 4. Line pressure solenoid valve

AT-134 5. Shift solenoid valve A

AT-139 6. Control valve assembly

AT-221 OFF vehicle

7. Brake band

AT-330 8. Forward clutch

AT-306Races extremel y

ON hi l 2. Accelerator pedal position sensor

EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

Items Symptom Condition Diagnostic item Reference page

Page 78 of 4331

AT

N

O P

Slips/Will Not Engage

Races extremely fast

or slips in changing

from D 3 to D 2 when

depressing accelera-

tor pedal. ON vehicle1. A/T fluid level

AT-17 2. Accelerator pedal position sensor

EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

3. Line pressure test AT-51 4. Line pressure solenoid valve

AT-134 5. Shift solenoid valve B

AT-144 6. Control valve assembly

AT-221 OFF vehicle

7. Brake band

AT-330 8. High clutch

AT-301Races extremely fast

or slips in changing

from D 4 or D 3 to D 1

when depressing ac-

celerator pedal. ON vehicle1. A/T fluid level

AT-17 2. Accelerator pedal position sensor

EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

3. Line pressure test AT-51 4. Line pressure solenoid valve

AT-134 5. Shift solenoid valve A

AT-139 6. Shift solenoid valve B

AT-144 7. Control valve assembly

AT-221 OFF vehicle

8. Forward clutch

AT-306 9. Forward one-way clutch

AT-317 10. Low one-way clutch

AT-256Vehicle will not run in

any position. ON vehicle

1. A/T fluid level

AT-17 2. Control cable adjustment

AT-216 3. Line pressure test

AT-51 4. Line pressure solenoid valve

AT-134 OFF vehicle

5. Oil pump

AT-277 6. High clutch

AT-301 7. Brake band

AT-330 8. Low & reverse brake

AT-313 9. Torque converter

AT-256 10. Parking components

AT-236Items Symptom Condition Diagnostic item Reference page

Page 79 of 4331

ON vehicle

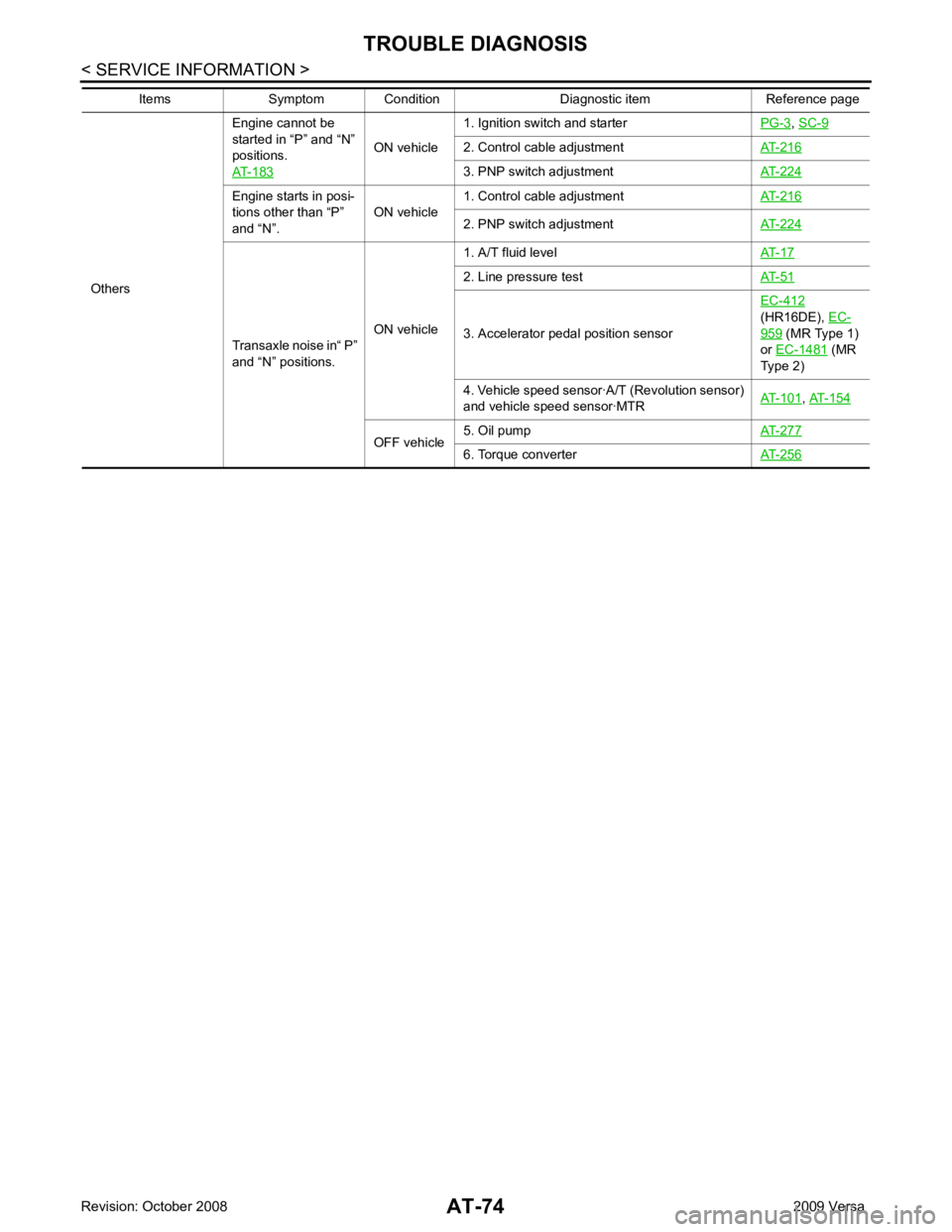

1. Ignition switch and starter

PG-3 ,

SC-9 2. Control cable adjustment

AT-216 3. PNP switch adjustment

AT-224Engine starts in posi-

tions other than “P”

and “N”. ON vehicle

1. Control cable adjustment

AT-216 2. PNP switch adjustment

AT-224Transaxle noise in“ P”

and “N” positions. ON vehicle1. A/T fluid level

AT-17 2. Line pressure test

AT-51 3. Accelerator pedal position sensor

EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

4. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTR AT-101 ,

AT-154 OFF vehicle

5. Oil pump

AT-277 6. Torque converter

AT-256Items Symptom Condition Diagnostic item Reference page

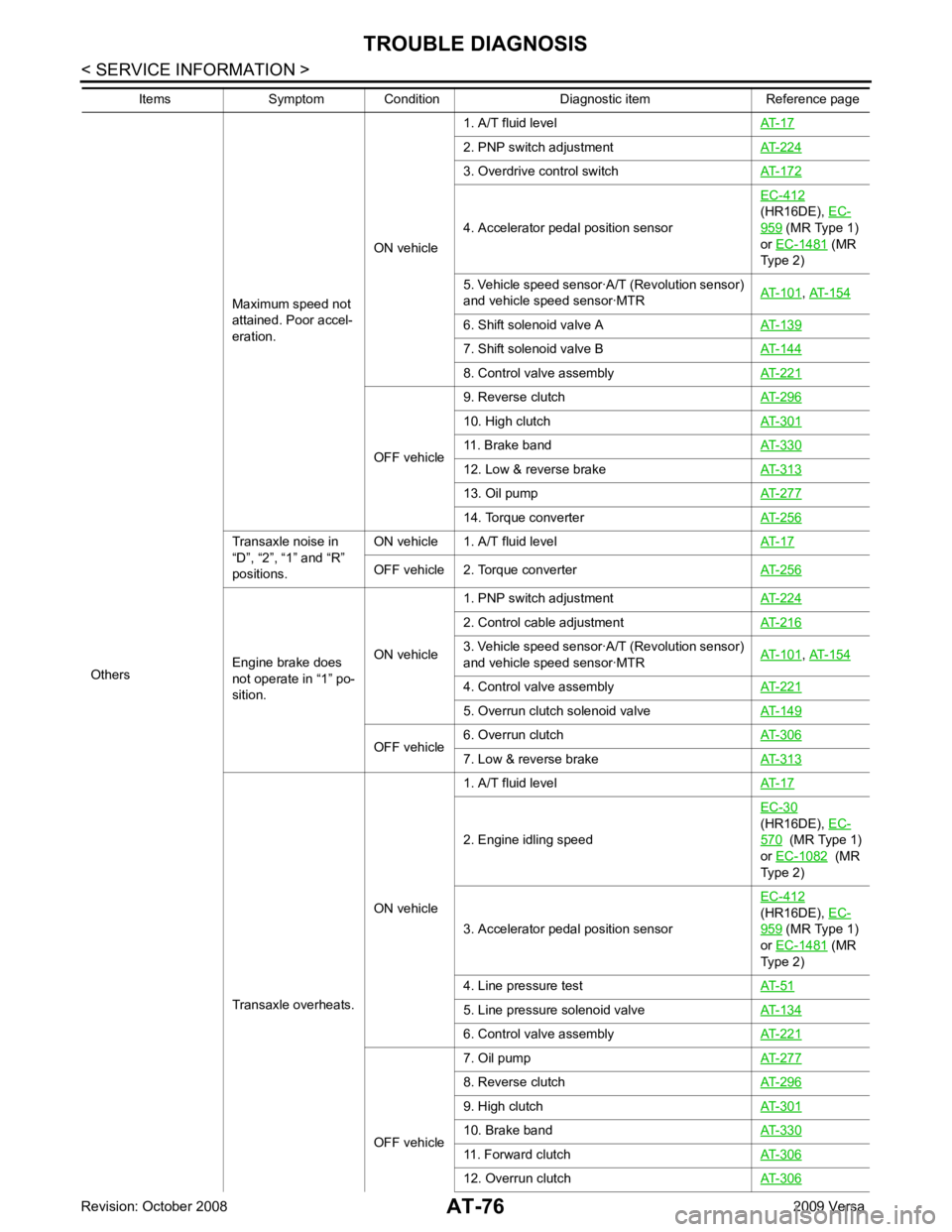

Page 81 of 4331

2. PNP switch adjustment

AT-224 3. Overdrive control switch

AT-172 4. Accelerator pedal position sensor

EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

5. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTR AT-101 ,

AT-154 6. Shift solenoid valve A

AT-139 7. Shift solenoid valve B

AT-144 8. Control valve assembly

AT-221 OFF vehicle

9. Reverse clutch

AT-296 10. High clutch

AT-301 11. Brake band

AT-330 12. Low & reverse brake

AT-313 13. Oil pump

AT-277 14. Torque converter

AT-256Transaxle noise in

“D”, “2”, “1” and “R”

positions. ON vehicle 1. A/T fluid level

AT-17OFF vehicle 2. Torque converter

AT-256Engine brake does

not operate in “1” po-

sition. ON vehicle1. PNP switch adjustment

AT-224 2. Control cable adjustment

AT-216 3. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTR AT-101 ,

AT-154 4. Control valve assembly

AT-221 5. Overrun clutch solenoid valve

AT-149 OFF vehicle

6. Overrun clutch

AT-306 7. Low & reverse brake

AT-313Transaxle overheats.

ON vehicle1. A/T fluid level

AT-17 2. Engine idling speed

EC-30

(HR16DE), EC- 570 (MR Type 1)

or EC-1082 (MR

Type 2)

3. Accelerator pedal position sensor EC-412

(HR16DE), EC- 959 (MR Type 1)

or EC-1481 (MR

Type 2)

4. Line pressure test AT-51 5. Line pressure solenoid valve

AT-134 6. Control valve assembly

AT-221 OFF vehicle

7. Oil pump

AT-277 8. Reverse clutch

AT-296 9. High clutch

AT-301 10. Brake band

AT-330 11. Forward clutch

AT-306 12. Overrun clutch

AT-306Items Symptom Condition Diagnostic item Reference page

Page 194 of 4331

AT

N

O P

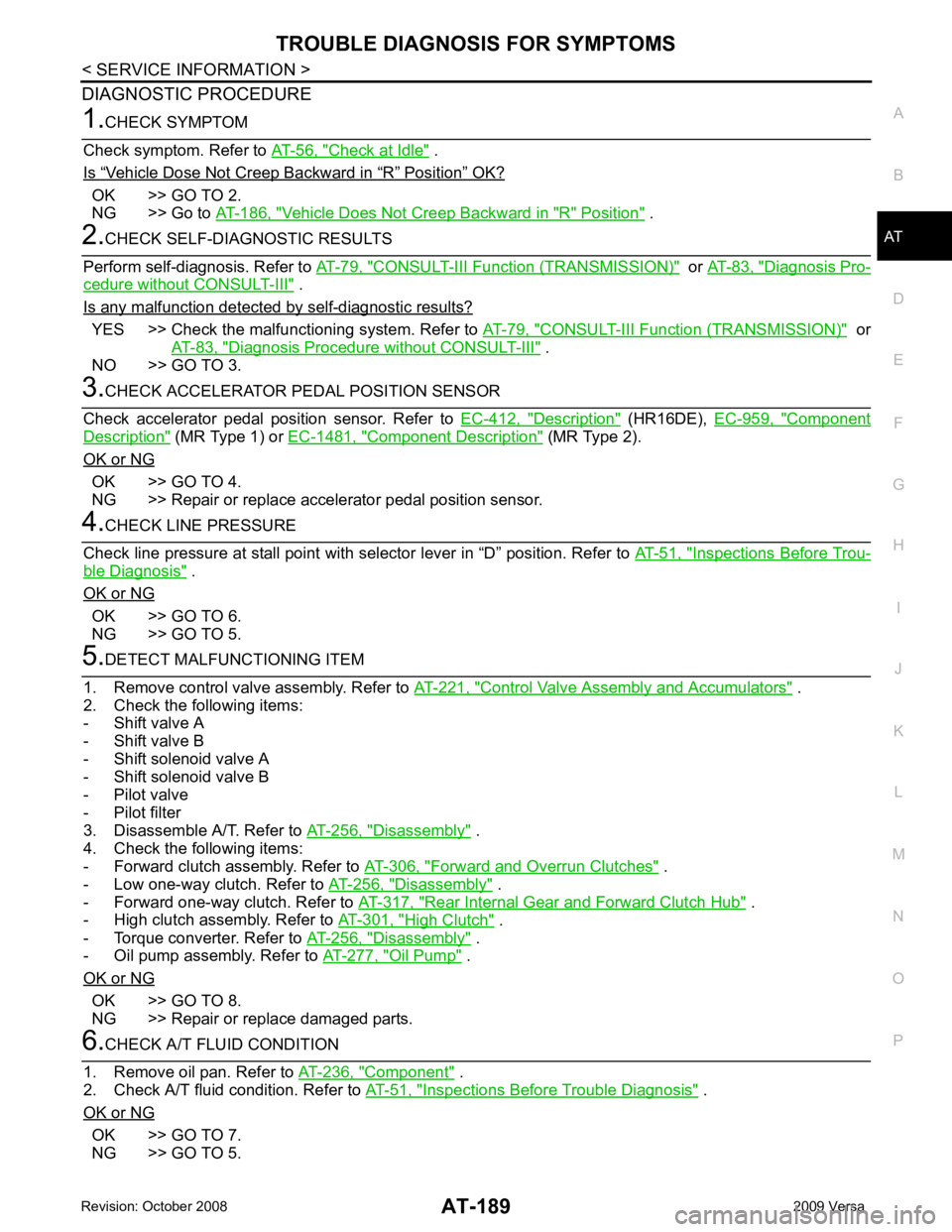

DIAGNOSTIC PROCEDURE Check at Idle " .

Is “ Vehicle Dose Not Creep Backward in “ R ” Position ” OK?

OK >> GO TO 2.

NG >> Go to AT-186, " Vehicle Does Not Creep Backward in "R" Position " .

CONSULT-III Functi

on (TRANSMISSION) " or

AT-83, " Diagnosis Pro-

cedure without CONSULT-III " .

Is any malfunction detected by self-diagnostic results? YES >> Check the malfuncti

oning system. Refer to AT-79, " CONSULT-III Functi

on (TRANSMISSION) " or

AT-83, " Diagnosis Procedure without CONSULT-III " .

NO >> GO TO 3. Description " (HR16DE),

EC-959, " Component

Description " (MR Type 1) or

EC-1481, " Component Description " (MR Type 2).

OK or NG OK >> GO TO 4.

NG >> Repair or replace accelerator pedal position sensor. Inspections Before Trou-

ble Diagnosis " .

OK or NG OK >> GO TO 6.

NG >> GO TO 5. Control Valve Assembly and Accumulators " .

2. Check the following items:

- Shift valve A

- Shift valve B

- Shift solenoid valve A

- Shift solenoid valve B

- Pilot valve

- Pilot filter

3. Disassemble A/T. Refer to AT-256, " Disassembly " .

4. Check the following items:

- Forward clutch assembly. Refer to AT-306, " Forward and Overrun Clutches " .

- Low one-way clutch. Refer to AT-256, " Disassembly " .

- Forward one-way clutch. Refer to AT-317, " Rear Internal Gear and Forward Clutch Hub " .

- High clutch assembly. Refer to AT-301, " High Clutch " .

- Torque converter. Refer to AT-256, " Disassembly " .

- Oil pump assembly. Refer to AT-277, " Oil Pump " .

OK or NG OK >> GO TO 8.

NG >> Repair or replace damaged parts. Component " .

2. Check A/T fluid condition. Refer to AT-51, " Inspections Before Trouble Diagnosis " .

OK or NG OK >> GO TO 7.

NG >> GO TO 5.

Page 197 of 4331

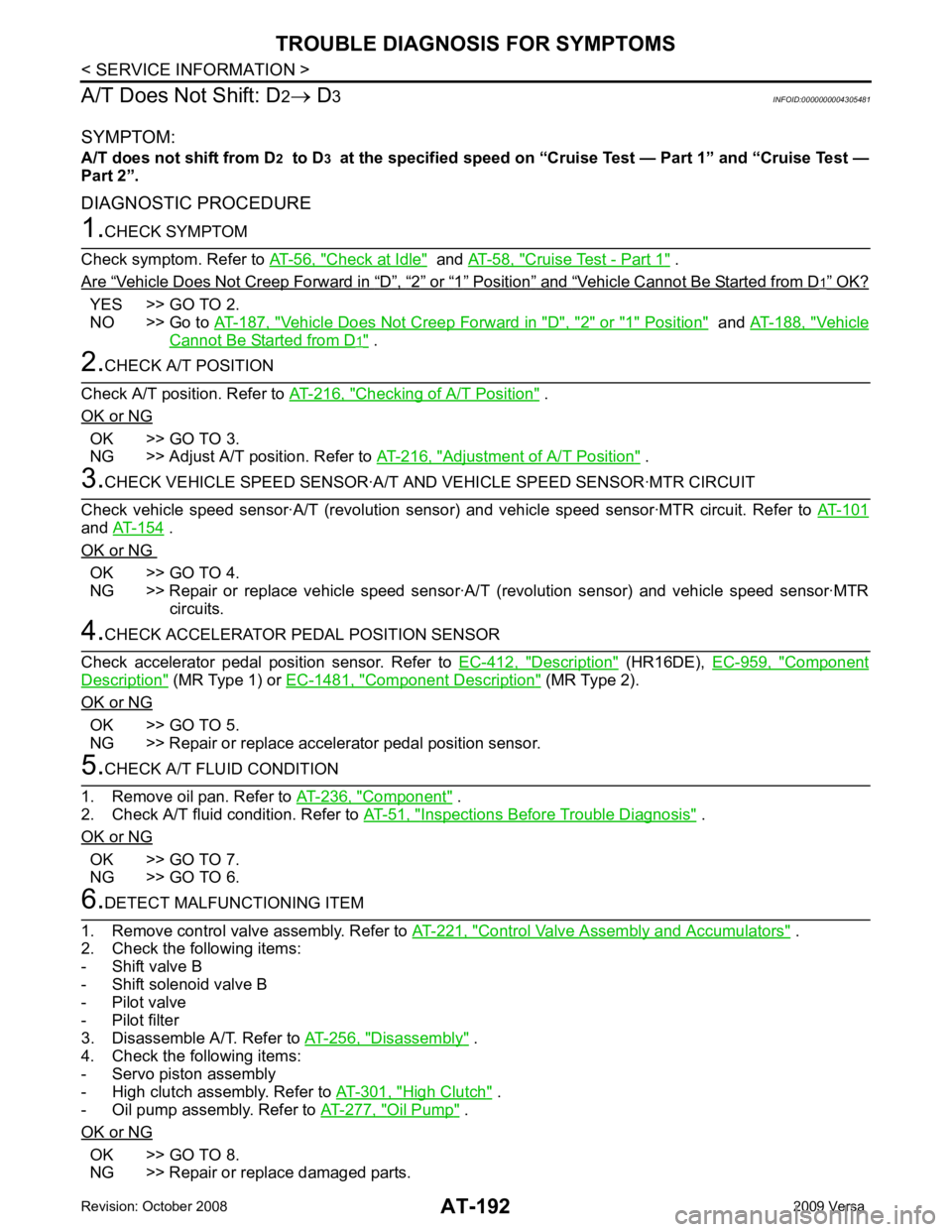

Check at Idle " and

AT-58, " Cruise Test - Part 1 " .

Are “ Vehicle Does Not Creep Forward in “ D ” , “ 2 ” or “ 1 ” Position ” and “ Vehicle Cannot Be Started from D OK?

YES >> GO TO 2.

NO >> Go to AT-187, " Vehicle Does Not Creep Forward in "D", "2" or "1" Position " and

AT-188, " Vehicle

Cannot Be Started from D .

Checking of A/T Position " .

OK or NG OK >> GO TO 3.

NG >> Adjust A/T position. Refer to AT-216, " Adjustment of A/T Position " .

and

AT-154 .

OK or NG OK >> GO TO 4.

NG >> Repair or replace vehicle speed sensor·A/T (revolution sensor) and vehicle speed sensor·MTR circuits. Description " (HR16DE),

EC-959, " Component

Description " (MR Type 1) or

EC-1481, " Component Description " (MR Type 2).

OK or NG OK >> GO TO 5.

NG >> Repair or replace accelerator pedal position sensor. Component " .

2. Check A/T fluid condition. Refer to AT-51, " Inspections Before Trouble Diagnosis " .

OK or NG OK >> GO TO 7.

NG >> GO TO 6. Control Valve Assembly and Accumulators " .

2. Check the following items:

- Shift valve B

- Shift solenoid valve B

- Pilot valve

- Pilot filter

3. Disassemble A/T. Refer to AT-256, " Disassembly " .

4. Check the following items:

- Servo piston assembly

- High clutch assembly. Refer to AT-301, " High Clutch " .

- Oil pump assembly. Refer to AT-277, " Oil Pump " .

OK or NG OK >> GO TO 8.

NG >> Repair or replace damaged parts.

Page 209 of 4331

AT-204< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

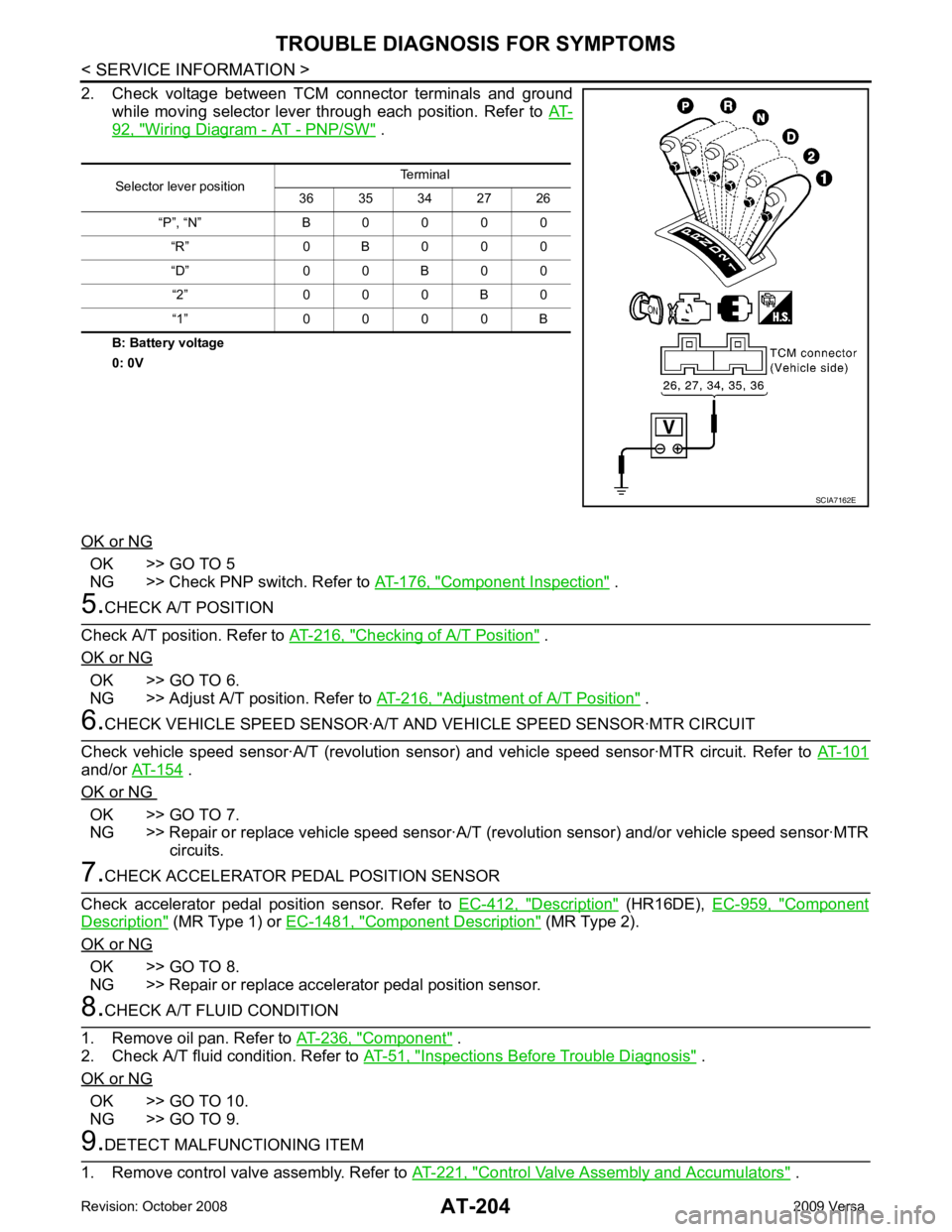

2. Check voltage between TCM connector terminals and ground while moving selector lever through each position. Refer to AT-92, " Wiring Diagram - AT - PNP/SW " .

B: Battery voltage

0: 0V

OK or NG OK >> GO TO 5

NG >> Check PNP switch. Refer to AT-176, " Component Inspection " .

5.

CHECK A/T POSITION

Check A/T position. Refer to AT-216, " Checking of A/T Position " .

OK or NG OK >> GO TO 6.

NG >> Adjust A/T position. Refer to AT-216, " Adjustment of A/T Position " .

6.

CHECK VEHICLE SPEED SENSOR·A/T A ND VEHICLE SPEED SENSOR·MTR CIRCUIT

Check vehicle speed sensor·A/T (revolution senso r) and vehicle speed sensor·MTR circuit. Refer to AT-101and/or

AT-154 .

OK or NG OK >> GO TO 7.

NG >> Repair or replace vehicle speed sensor·A/T (revolution sensor) and/or vehicle speed sensor·MTR

circuits. 7.

CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-412, " Description " (HR16DE),

EC-959, " Component

Description " (MR Type 1) or

EC-1481, " Component Description " (MR Type 2).

OK or NG OK >> GO TO 8.

NG >> Repair or replace accelerator pedal position sensor. 8.

CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-236, " Component " .

2. Check A/T fluid condition. Refer to AT-51, " Inspections Before Trouble Diagnosis " .

OK or NG OK >> GO TO 10.

NG >> GO TO 9. 9.

DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-221, " Control Valve Assembly and Accumulators " .

Selector lever position

Terminal

36 35 34 27 26

“P”, “N” B 0 0 0 0 “R” 0 B 0 0 0

“D” 0 0 B 0 0 “2” 0 0 0 B 0

“1” 0 0 0 0 B SCIA7162E

Page 842 of 4331

![NISSAN LATIO 2009 Service Repair Manual BRC-2< SERVICE INFORMATION >

[ABS]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004784402

The NISSAN LATIO 2009 Service Repair Manual BRC-2< SERVICE INFORMATION >

[ABS]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004784402

The](/img/5/57359/w960_57359-841.png)

BRC-2< SERVICE INFORMATION >

[ABS]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004784402

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution for Brake System INFOID:0000000004307251

CAUTION:

• Refer to MA-14 for recommended brake fluid.

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• To clean or wash all parts of master cylin der and disc brake caliper, use clean brake fluid.

• Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic sys-

tem.

• Use flare nut wrench when re moving and installing brake

tube.

• If a brake fluid leak is found, the part must be disassembled

without fail. Then it has to be replaced with a new one if a

defect exists.

• Turn the ignition switch OFF an d remove the connector of the

ABS actuator and electric unit (c ontrol unit) or the battery ter-

minal before performing the work.

• Always torque brake lines when installing.

• Burnish the brake contact surf aces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage. Refer to BR-32, " Brake Burnishing Proce-

dure " .

WARNING:

• Clean brake pads and shoes with a waste cloth, then wipe with a dust collector. SBR686C