heater NISSAN LATIO 2010 Service Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 3162 of 3745

ENGINE MAINTENANCE (MR18DE)MA-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

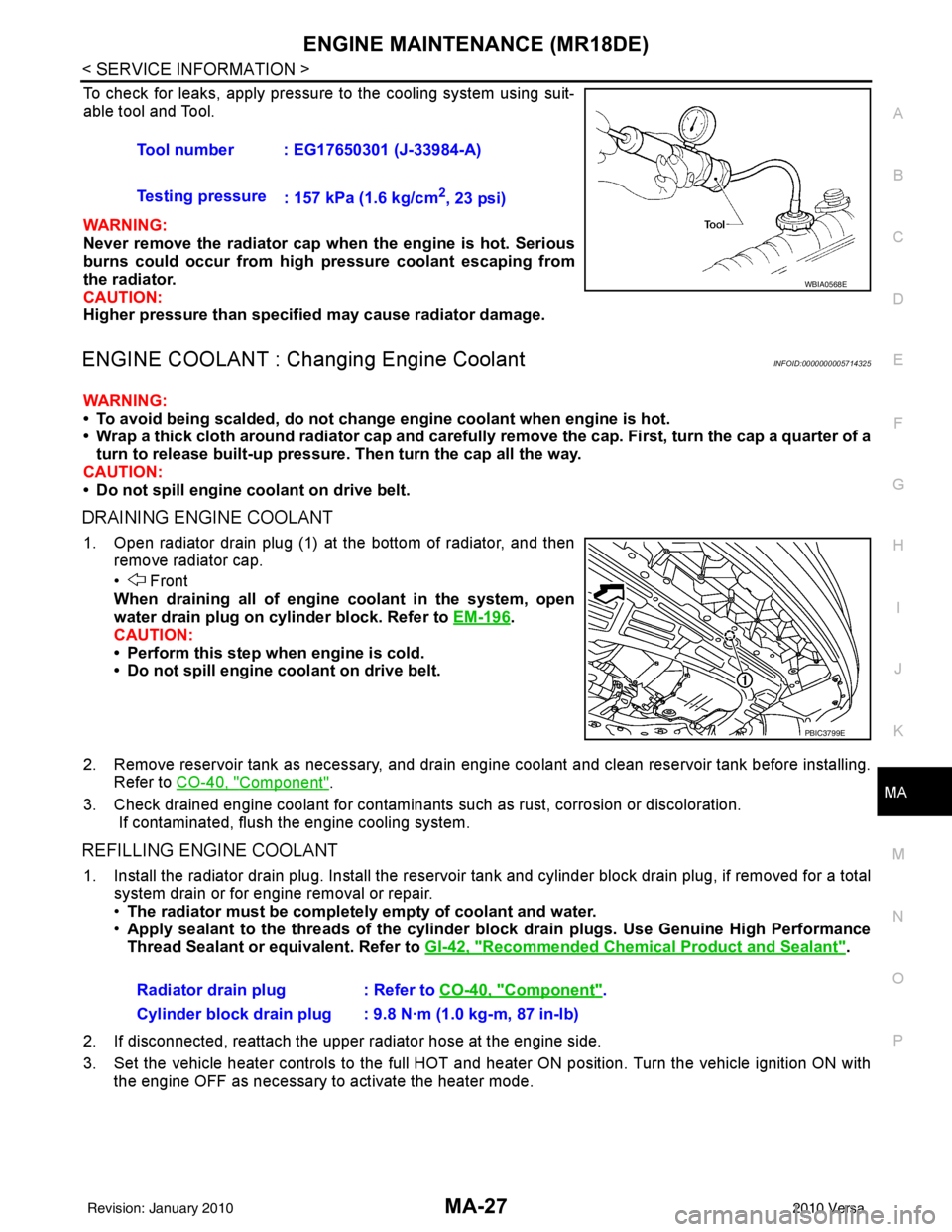

To check for leaks, apply pressure to the cooling system using suit-

able tool and Tool.

WARNING:

Never remove the radiator cap wh en the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

ENGINE COOLANT : Chang ing Engine CoolantINFOID:0000000005714325

WARNING:

• To avoid being scalded, do not change engine coolant when engine is hot.

• Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

CAUTION:

• Do not spill engine coolant on drive belt.

DRAINING ENGINE COOLANT

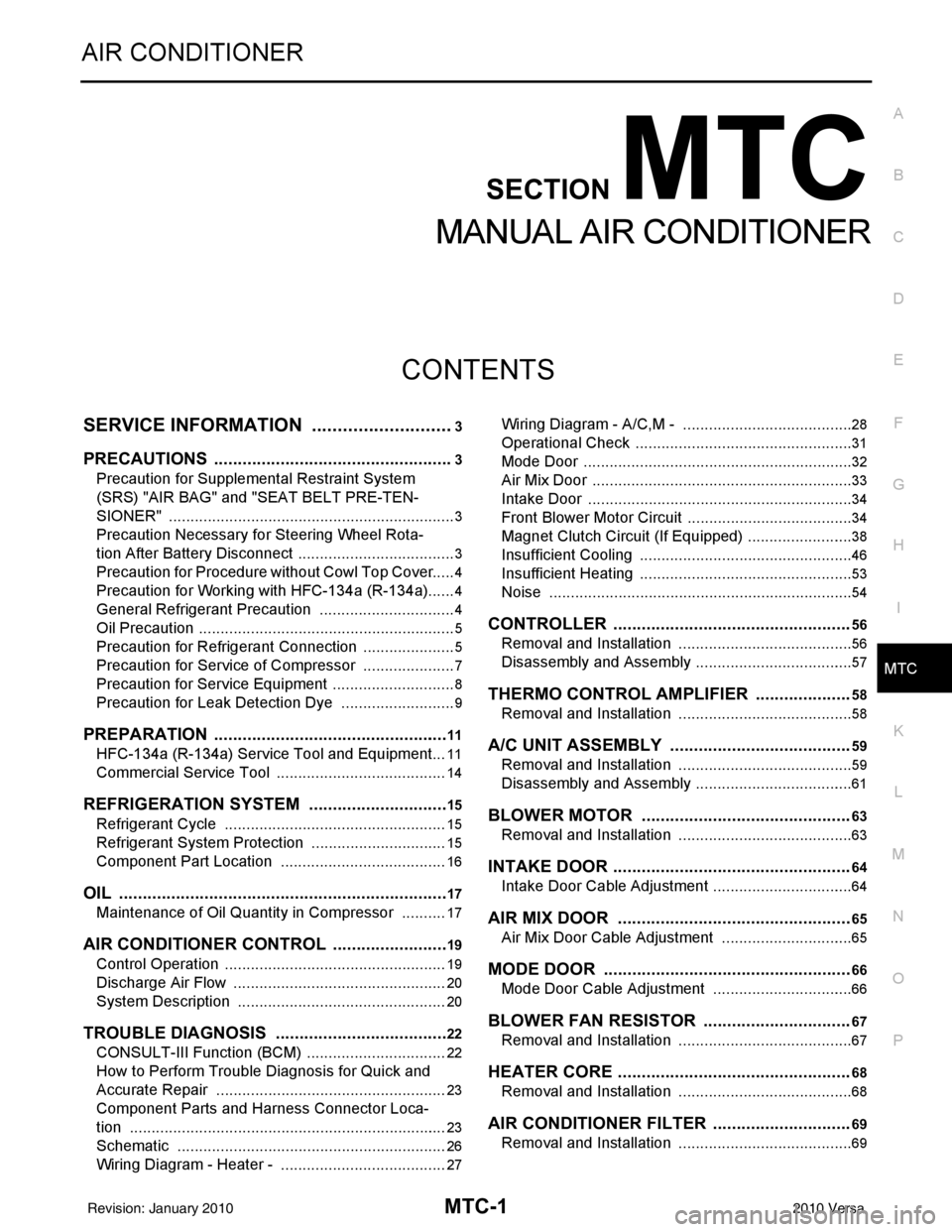

1. Open radiator drain plug (1) at the bottom of radiator, and then remove radiator cap.

• Front

When draining all of engine coolant in the system, open

water drain plug on cylinder block. Refer to EM-196

.

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engi ne coolant and clean reservoir tank before installing.

Refer to CO-40, "

Component".

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be completely empty of coolant and water.

• Apply sealant to the threads of the cylinder blo ck drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, "

Recommended Chemical Product and Sealant".

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode. Tool number : EG17650301 (J-33984-A)

Testing pressure

: 157 kPa (1.6 kg/cm

2, 23 psi)

WBIA0568E

PBIC3799E

Radiator drain plug : Refer to CO-40, "Component".

Cylinder block drain plug : 9.8 N·m (1.0 kg-m, 87 in-lb)

Revision: January 20102010 Versa

Page 3280 of 3745

MTC-1

AIR CONDITIONER

C

DE

F

G H

I

K L

M

SECTION MTC

A

B

MTC

N

O P

CONTENTS

MANUAL AIR CONDITIONER

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Working with HFC-134a (R-134a) ......4

General Refrigerant Precaution ................................4

Oil Precaution ............................................................5

Precaution for Refrigerant Connection ......................5

Precaution for Service of Compressor ................ ......7

Precaution for Service Equipment ....................... ......8

Precaution for Leak Detection Dye ...........................9

PREPARATION ..................................................11

HFC-134a (R-134a) Service Tool and Equipment ....11

Commercial Service Tool ........................................14

REFRIGERATION SYSTEM ..............................15

Refrigerant Cycle ................................................ ....15

Refrigerant System Protection ................................15

Component Part Location ................................... ....16

OIL ......................................................................17

Maintenance of Oil Quantity in Compressor ....... ....17

AIR CONDITIONER CONTROL .........................19

Control Operation ................................................ ....19

Discharge Air Flow ..................................................20

System Description .................................................20

TROUBLE DIAGNOSIS .....................................22

CONSULT-III Function (BCM) ............................. ....22

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ......................................................

23

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

23

Schematic ...............................................................26

Wiring Diagram - Heater - .......................................27

Wiring Diagram - A/C,M - .................................... ....28

Operational Check ...................................................31

Mode Door ...............................................................32

Air Mix Door .............................................................33

Intake Door ..............................................................34

Front Blower Motor Circuit .......................................34

Magnet Clutch Circuit (If Equipped) ..................... ....38

Insufficient Cooling ..................................................46

Insufficient Heating ..................................................53

Noise .......................................................................54

CONTROLLER ..................................................56

Removal and Installation .........................................56

Disassembly and Assembly .....................................57

THERMO CONTROL AMPLIFIER ....................58

Removal and Installation .........................................58

A/C UNIT ASSEMBLY ......................................59

Removal and Installation .........................................59

Disassembly and Assembly .....................................61

BLOWER MOTOR ............................................63

Removal and Installation .........................................63

INTAKE DOOR ..................................................64

Intake Door Cable Adjustment .................................64

AIR MIX DOOR .................................................65

Air Mix Door Cable Adjustment ...............................65

MODE DOOR ....................................................66

Mode Door Cable Adjustment .................................66

BLOWER FAN RESISTOR ...............................67

Removal and Installation .........................................67

HEATER CORE .................................................68

Removal and Installation .........................................68

AIR CONDITIONER FILTER .............................69

Removal and Installation .........................................69

Revision: January 20102010 Versa

Page 3306 of 3745

TROUBLE DIAGNOSISMTC-27

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

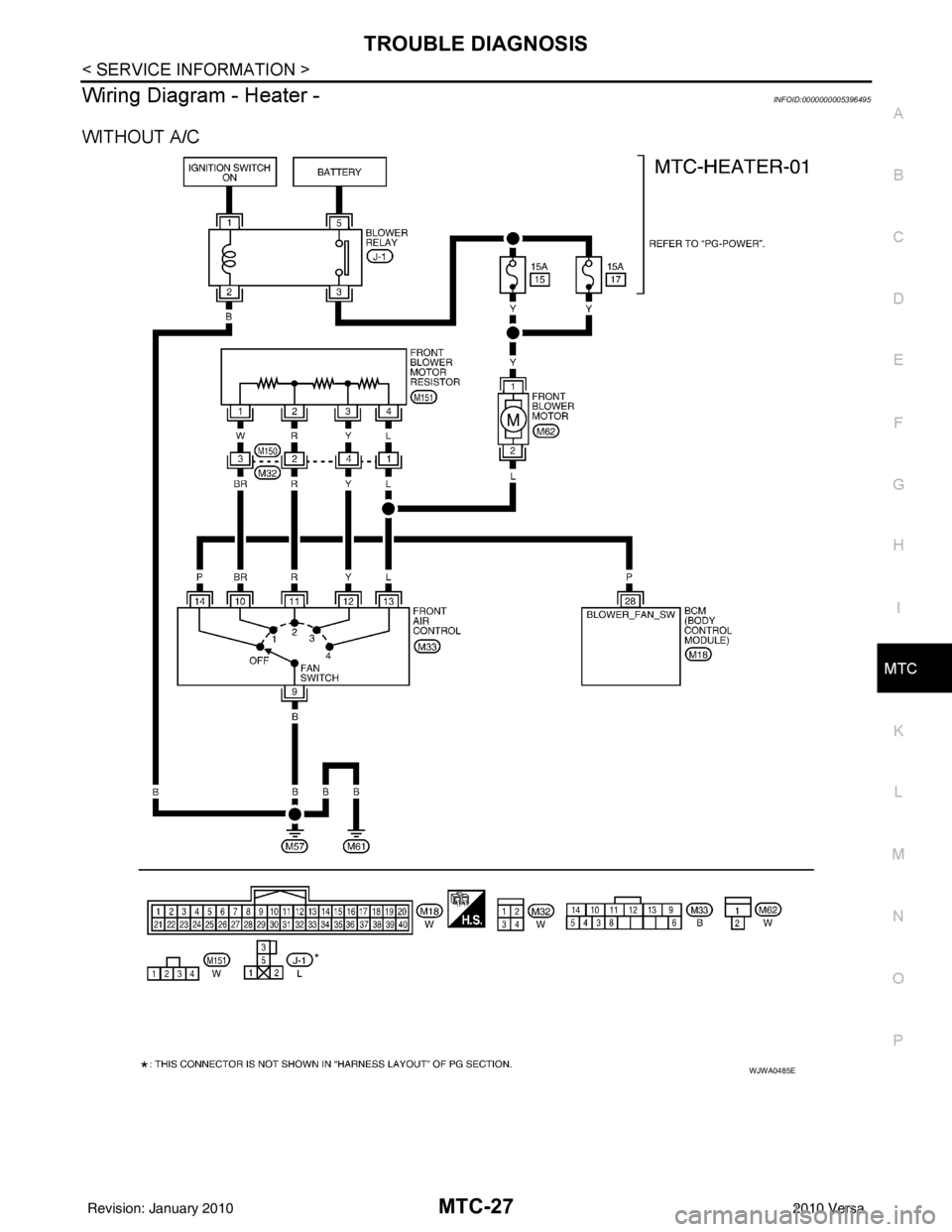

Wiring Diagram - Heater -INFOID:0000000005396495

WITHOUT A/C

WJWA0485E

Revision: January 20102010 Versa

Page 3333 of 3745

MTC-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

YES >> GO TO 6.

NO >> Adjust or replace air mix door cable. Refer to MTC-65, "

Air Mix Door Cable Adjustment" .

6.CHECK AIR DUCTS

Check ducts for air leaks.

OK or NG

OK >> GO TO 7.

NG >> Repair air leaks.

7.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses. The inlet hose should be hot and the outlet hose should be

warm.

Is the inlet hose hot and the outlet hose warm?

YES >> GO TO 8.

NO >> Both hoses warm: GO TO 9.

8.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check engine control temperature sensor. Refer to EC-690, "

Component Inspection" (MR18DE) or EC-163,

"Component Inspection" (HR16DE).

OK or NG

OK >> System OK.

NG >> Repair or replace as necessary. Retest.

9.CHECK HEATER HOSES

Check heater hoses for proper installation.

OK or NG

OK >> GO TO 10.

NG >> Repair /replace as necessary. Retest GO TO 7.

10.BACK FLUSH HEATER CORE

1. Back flush heater core.

2. Drain the water from the system.

3. Refill system with new engine coolant. Refer to CO-12, "

Changing Engine Coolant" (HR16DE) or CO-36,

"Changing Engine Coolant" (MR18DE) .

4. Start engine and warm it up to normal operating temperature.

5. Touch both the inlet and outlet heater hoses. The inlet hose should be hot and the outlet hose should be

warm.

Is the inlet hose hot and the outlet hose warm?

YES >> System OK.

NO >> Replace heater core and refill engine coolant. Refer to MTC-68, "

Removal and Installation" .

NoiseINFOID:0000000005396505

SYMPTOM: Noise

INSPECTION FLOW

Revision: January 20102010 Versa

Page 3338 of 3745

A/C UNIT ASSEMBLYMTC-59

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

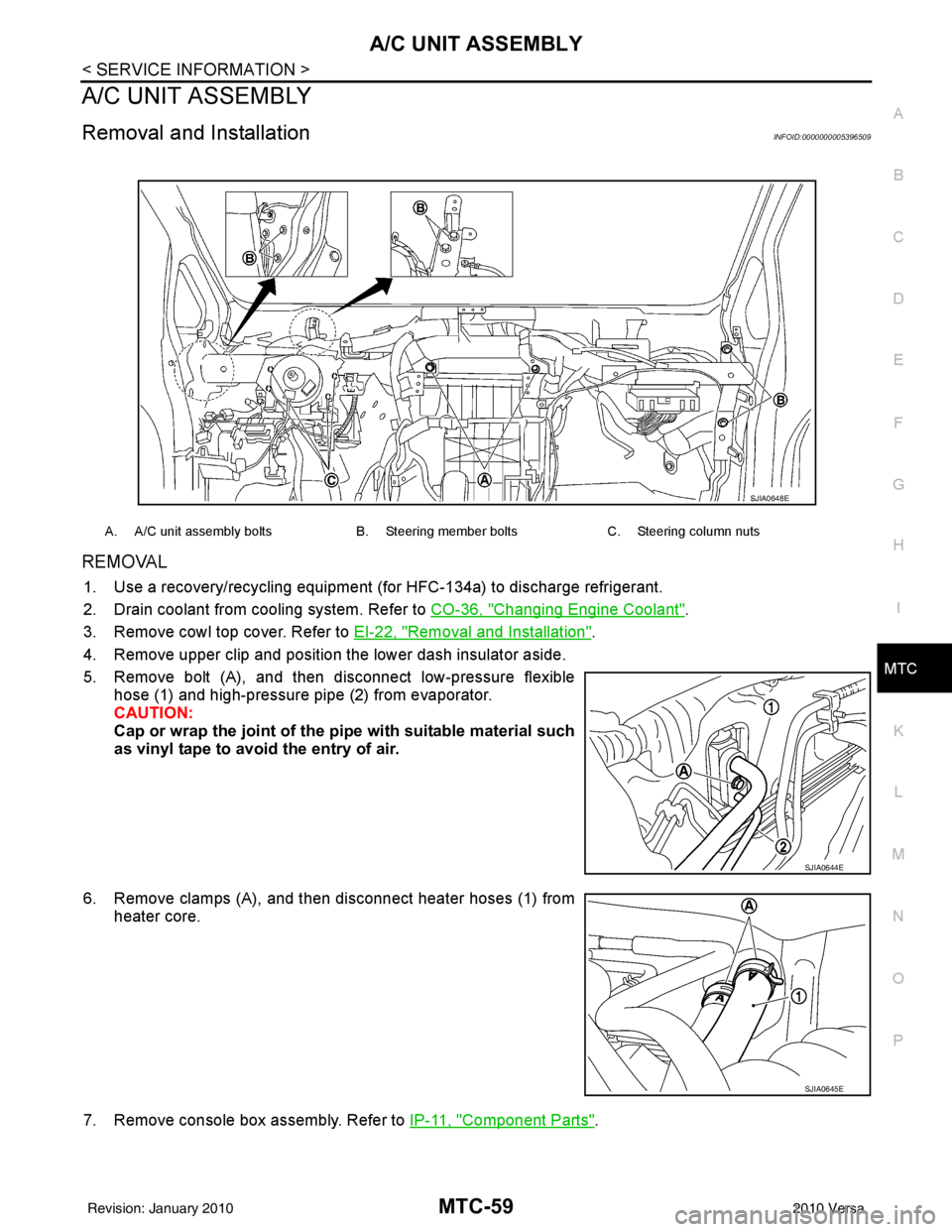

A/C UNIT ASSEMBLY

Removal and InstallationINFOID:0000000005396509

REMOVAL

1. Use a recovery/recycling equipment (f or HFC-134a) to discharge refrigerant.

2. Drain coolant from cooling system. Refer to CO-36, "

Changing Engine Coolant".

3. Remove cowl top cover. Refer to EI-22, "

Removal and Installation".

4. Remove upper clip and position the lower dash insulator aside.

5. Remove bolt (A), and then disconnect low-pressure flexible hose (1) and high-pressure pipe (2) from evaporator.

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

6. Remove clamps (A), and then disconnect heater hoses (1) from heater core.

7. Remove console box assembly. Refer to IP-11, "

Component Parts".

A. A/C unit assembly boltsB. Steering member boltsC. Steering column nuts

SJIA0648E

SJIA0644E

SJIA0645E

Revision: January 20102010 Versa

Page 3340 of 3745

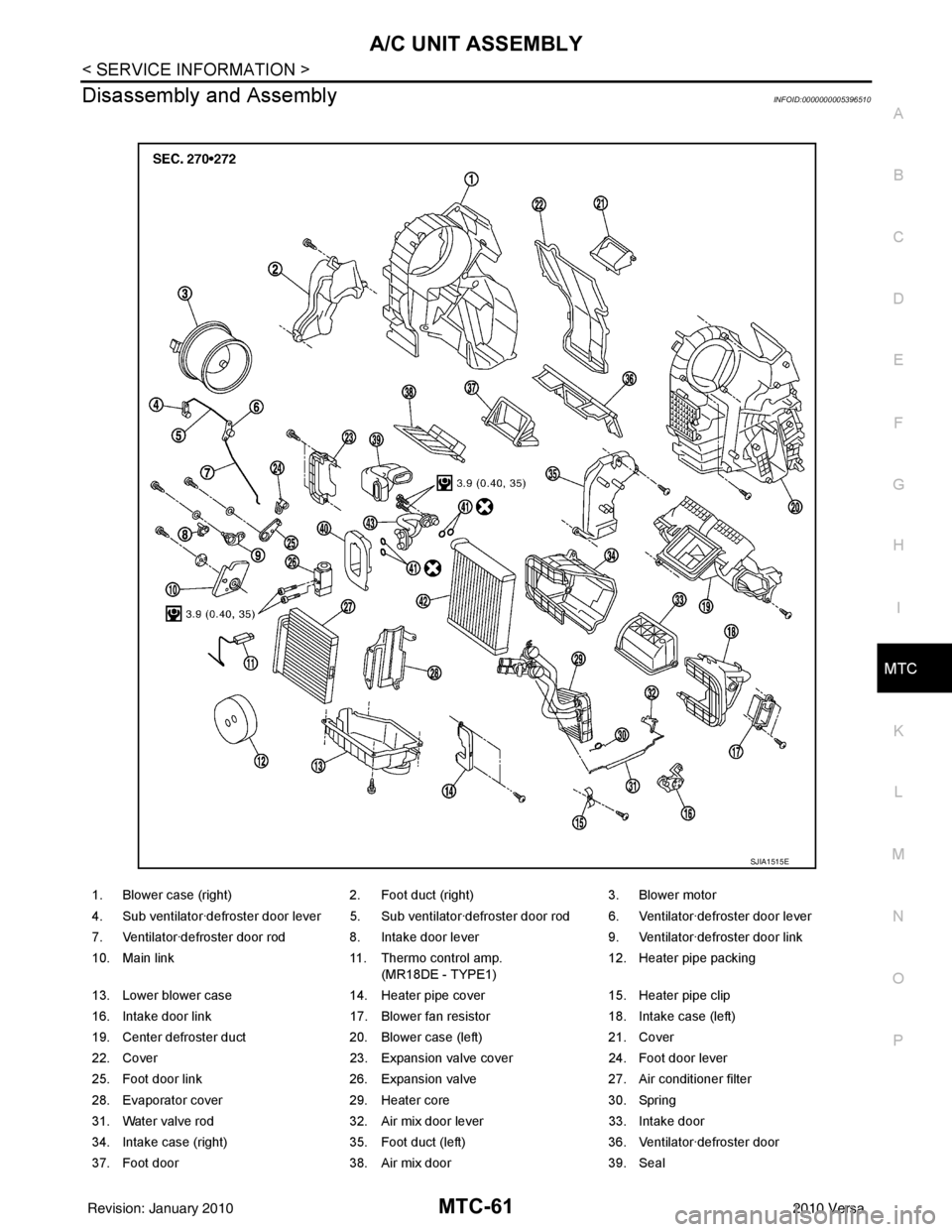

A/C UNIT ASSEMBLYMTC-61

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

Disassembly and AssemblyINFOID:0000000005396510

1. Blower case (right) 2. Foot duct (right) 3. Blower motor

4. Sub ventilator·defroster door lever 5. Sub ventilator·defroster door rod 6. Ventilator·defroster door lever

7. Ventilator·defroster door rod 8. Intake door lever 9. Ventilator·defroster door link

10. Main link 11. Thermo control amp.

(MR18DE - TYPE1) 12. Heater pipe packing

13. Lower blower case 14. Heater pipe cover 15. Heater pipe clip

16. Intake door link 17. Blower fan resistor 18. Intake case (left)

19. Center defroster duct 20. Blower case (left) 21. Cover

22. Cover 23. Expansion valve cover 24. Foot door lever

25. Foot door link 26. Expansion valve 27. Air conditioner filter

28. Evaporator cover 29. Heater core 30. Spring

31. Water valve rod 32. Air mix door lever 33. Intake door

34. Intake case (right) 35. Foot duct (left) 36. Ventilator·defroster door

37. Foot door 38. Air mix door 39. Seal

SJIA1515E

Revision: January 20102010 Versa

Page 3347 of 3745

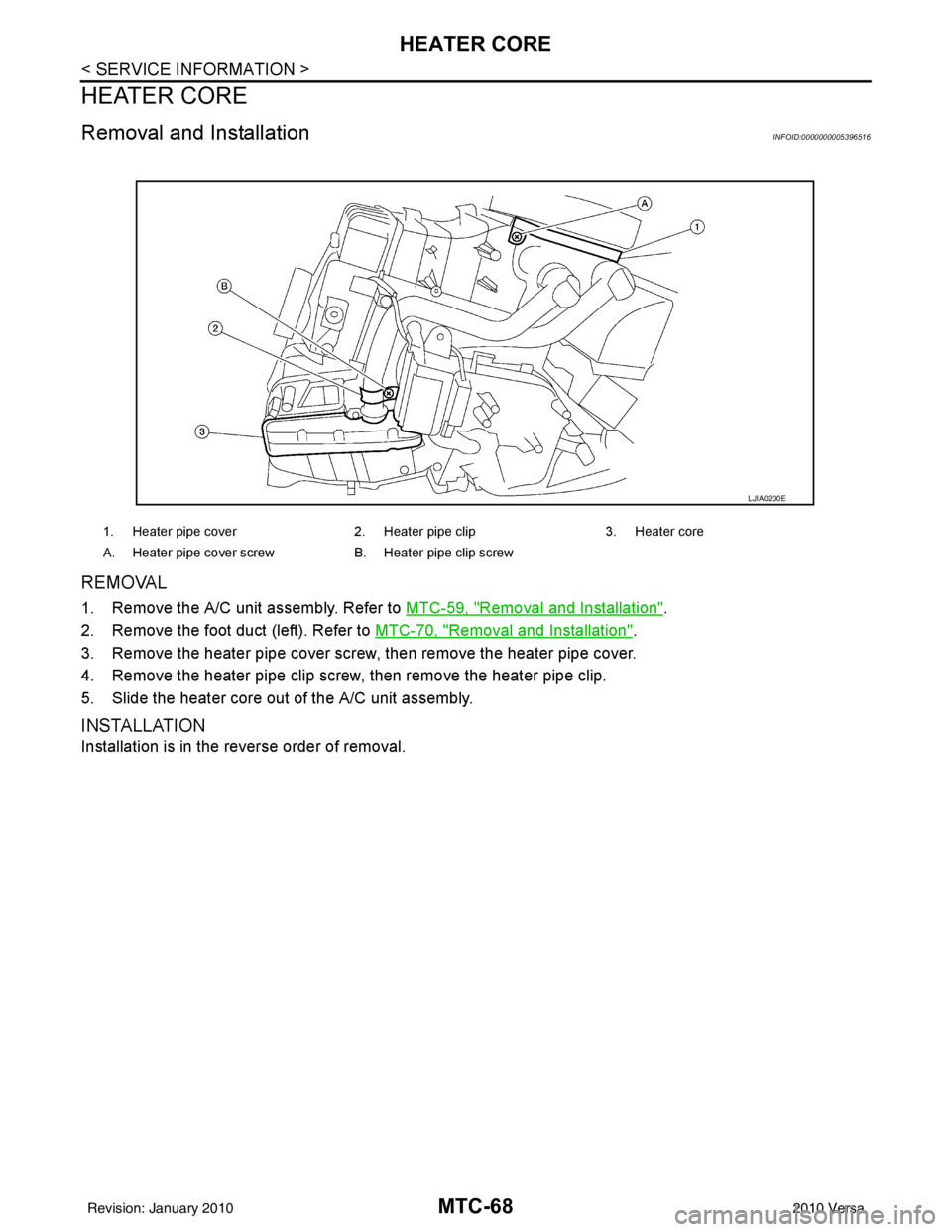

MTC-68

< SERVICE INFORMATION >

HEATER CORE

HEATER CORE

Removal and InstallationINFOID:0000000005396516

REMOVAL

1. Remove the A/C unit assembly. Refer to MTC-59, "Removal and Installation".

2. Remove the foot duct (left). Refer to MTC-70, "

Removal and Installation".

3. Remove the heater pipe cover screw, then remove the heater pipe cover.

4. Remove the heater pipe clip screw, then remove the heater pipe clip.

5. Slide the heater core out of the A/C unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

1. Heater pipe cover 2. Heater pipe clip3. Heater core

A. Heater pipe cover screw B. Heater pipe clip screw

LJIA0200E

Revision: January 20102010 Versa

Page 3374 of 3745

REFRIGERANT LINESMTC-95

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

Check all around the service valves. Ensure service valve caps are secured on the service valves (to

prevent leaks).

NOTE:

After removing A/C manifold gauge set from service va lves, wipe any residue from valves to prevent any

false readings by leak detector.

• Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in

the cooling unit. Wait a minimum of 10 minutes ac cumulation time (refer to the manufacturer’s recom-

mended procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use c aution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7-10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. Mode control dial position: VENT (Ventilation)

c. Intake door lever position: Recirculation

d. Max. cold temperature

e. Fan speed: High

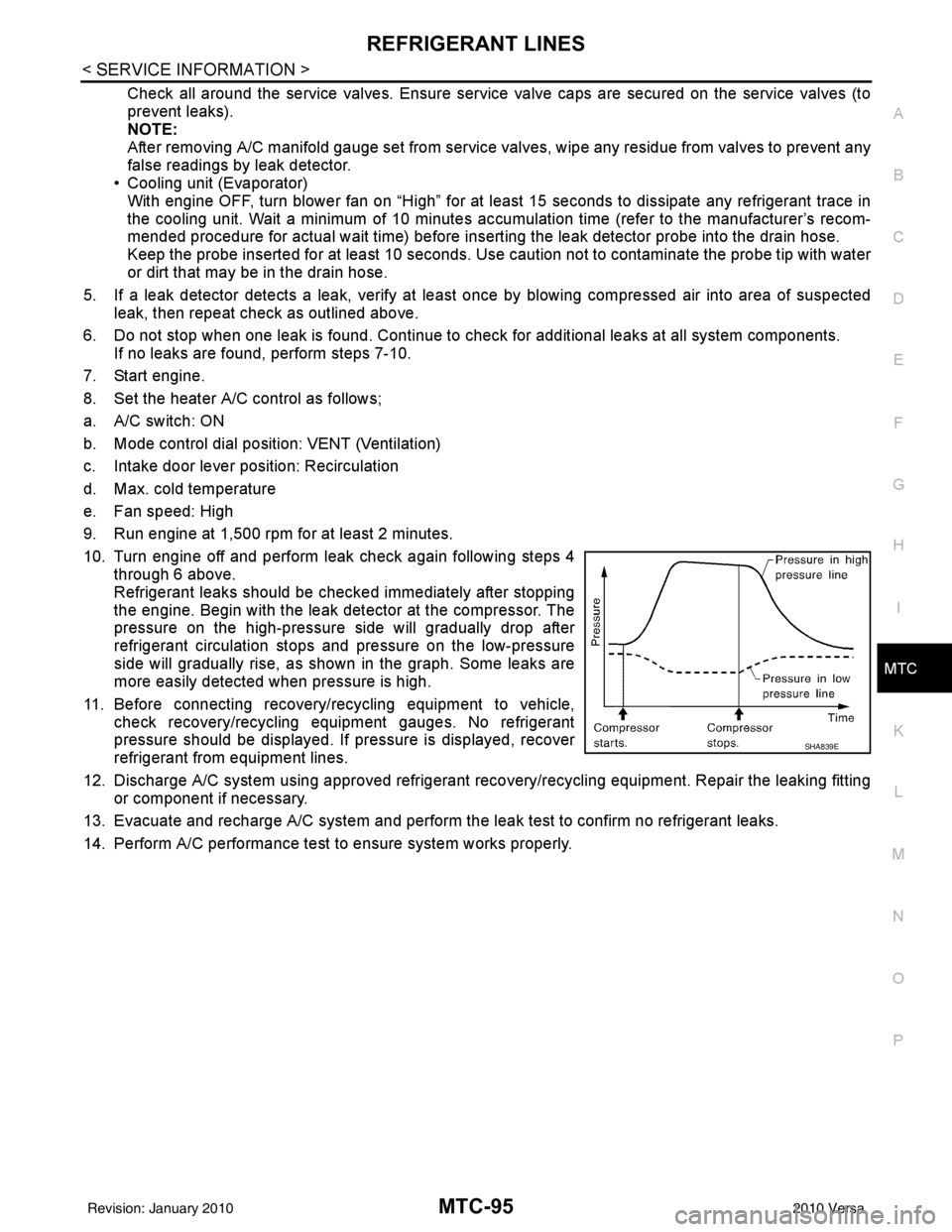

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Turn engine off and perform leak check again following steps 4 through 6 above.

Refrigerant leaks should be chec ked immediately after stopping

the engine. Begin with the leak detector at the compressor. The

pressure on the high-pressure side will gradually drop after

refrigerant circulation stops and pressure on the low-pressure

side will gradually rise, as shown in the graph. Some leaks are

more easily detected when pressure is high.

11. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges. No refrigerant

pressure should be displayed. If pressure is displayed, recover

refrigerant from equipment lines.

12. Discharge A/C system using approved refrigerant recovery/recycling equipment. Repair the leaking fitting or component if necessary.

13. Evacuate and recharge A/C system and perform the l eak test to confirm no refrigerant leaks.

14. Perform A/C performance test to ensure system works properly.

SHA839E

Revision: January 20102010 Versa

Page 3442 of 3745

HARNESSPG-59

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

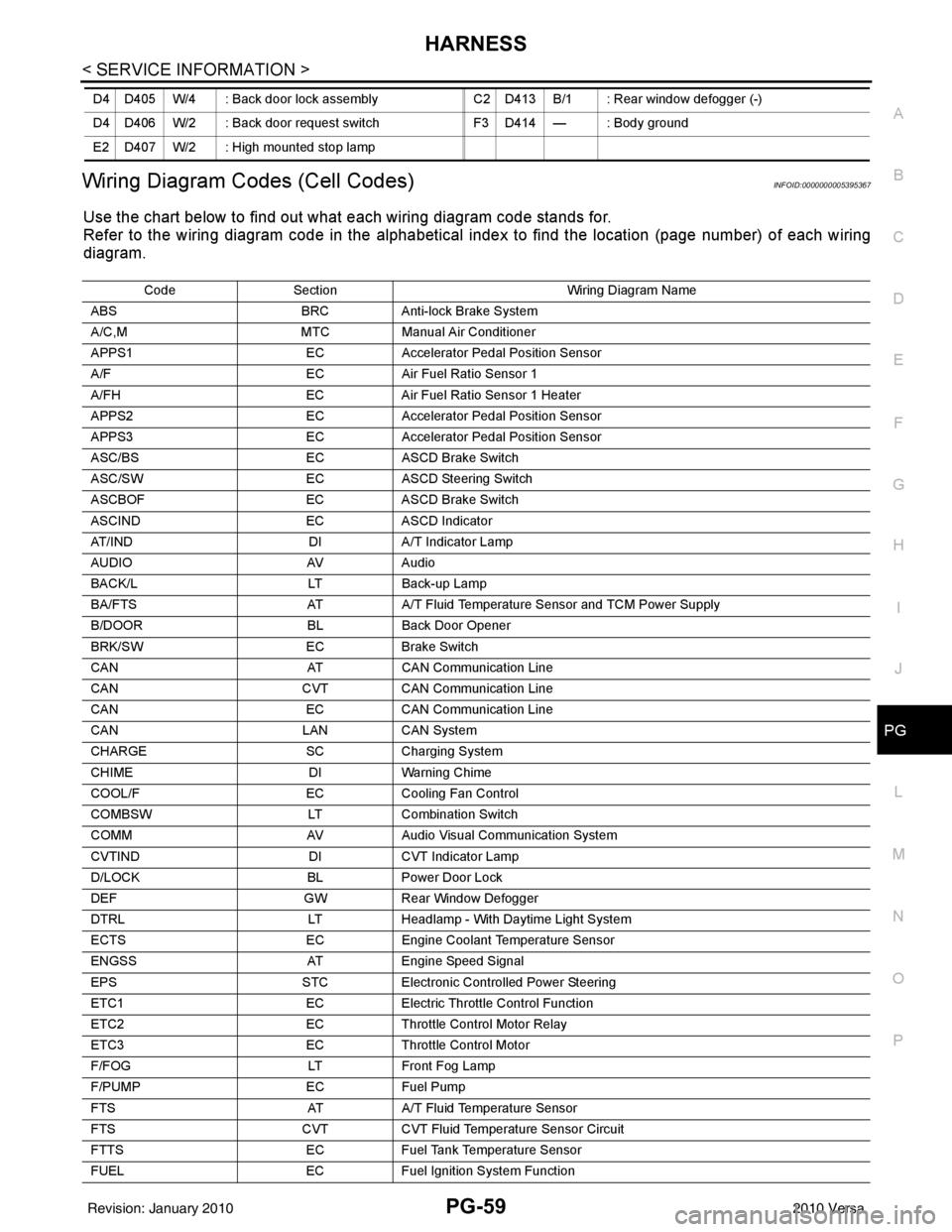

Wiring Diagram Codes (Cell Codes)INFOID:0000000005395367

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

D4 D405 W/4 : Back door lock assembly C2 D413 B/1 : Rear window defogger (-)

D4 D406 W/2 : Back door request switch F3 D414 — : Body ground

E2 D407 W/2 : High mounted stop lamp

Code Section Wiring Diagram Name

ABS BRC Anti-lock Brake System

A/C,M MTC Manual Air Conditioner

APPS1 EC Accelerator Pedal Position Sensor

A/F EC Air Fuel Ratio Sensor 1

A/FH EC Air Fuel Ratio Sensor 1 Heater

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

BACK/L LT Back-up Lamp

BA/FTS AT A/T Fluid Temperature Sensor and TCM Power Supply

B/DOOR BL Back Door Opener

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN CVT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

COOL/F EC Cooling Fan Control

COMBSW LT Combination Switch

COMM AV Audio Visual Communication System

CVTIND DI CVT Indicator Lamp

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - Wi th Daytime Light System

ECTS EC Engine Coolant Temperature Sensor

ENGSS AT Engine Speed Signal

EPS STC Electronic Controlled Power Steering

ETC1 EC Electric Throttle Control Function

ETC2 EC Throttle Control Motor Relay

ETC3 EC Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor

FTS CVT CVT Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUEL EC Fuel Ignition System Function

Revision: January 20102010 Versa

Page 3443 of 3745

PG-60

< SERVICE INFORMATION >

HARNESS

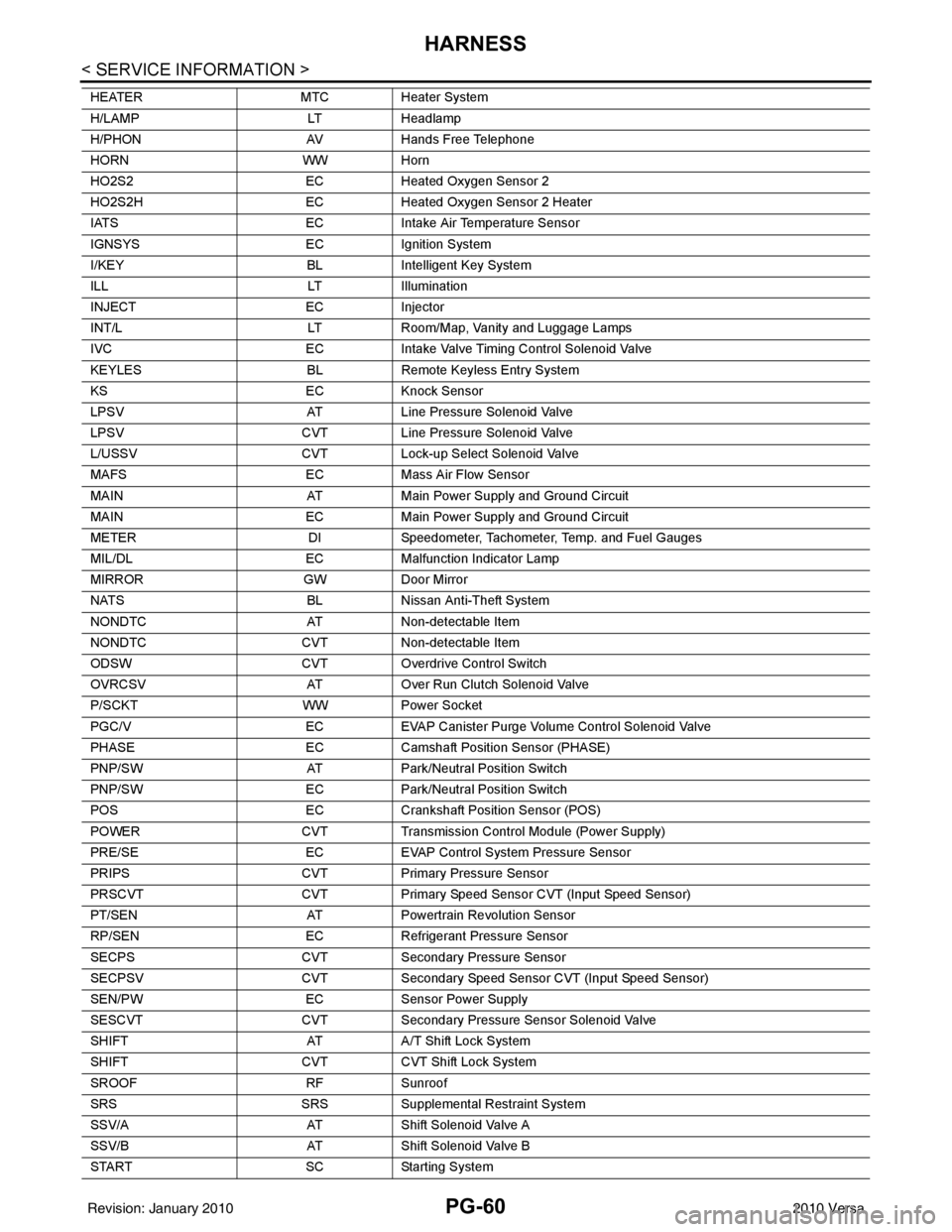

HEATERMTC Heater System

H/LAMP LT Headlamp

H/PHON AV Hands Free Telephone

HORN WW Horn

HO2S2 EC Heated Oxygen Sensor 2

HO2S2H EC Heated Oxygen Sensor 2 Heater

IATS EC Intake Air Temperature Sensor

IGNSYS EC Ignition System

I/KEY BL Intelligent Key System

ILL LT Illumination

INJECT EC Injector

INT/L LT Room/Map, Vanity and Luggage Lamps

IVC EC Intake Valve Timing Control Solenoid Valve

KEYLES BL Remote Keyless Entry System

KS EC Knock Sensor

LPSV AT Line Pressure Solenoid Valve

LPSV CVT Line Pressure Solenoid Valve

L/USSV CVT Lock-up Select Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Circuit

MAIN EC Main Power Supply and Ground Circuit

METER DI Speedometer, Tachometer, Temp. and Fuel Gauges

MIL/DL EC Malfunction Indicator Lamp

MIRROR GW Door Mirror

NATS BL Nissan Anti-Theft System

NONDTC AT Non-detectable Item

NONDTC CVT Non-detectable Item

ODSW CVT Overdrive Control Switch

OVRCSV AT Over Run Clutch Solenoid Valve

P/SCKT WW Power Socket

PGC/V EC EVAP Canister Purge Volume Control Solenoid Valve

PHASE EC Camshaft Position Sensor (PHASE)

PNP/SW AT Park/Neutral Position Switch

PNP/SW EC Park/Neutral Position Switch

POS EC Crankshaft Position Sensor (POS)

POWER CVT Transmission Control Module (Power Supply)

PRE/SE EC EVAP Control System Pressure Sensor

PRIPS CVT Primary Pressure Sensor

PRSCVT CVT Primary Speed Sensor CVT (Input Speed Sensor)

PT/SEN AT Powertrain Revolution Sensor

RP/SEN EC Refrigerant Pressure Sensor

SECPS CVT Secondary Pressure Sensor

SECPSV CVT Secondary Speed Sensor CVT (Input Speed Sensor)

SEN/PW EC Sensor Power Supply

SESCVT CVT Secondary Pressu re Sensor Solenoid Valve

SHIFT AT A/T Shift Lock System

SHIFT CVT CVT Shift Lock System

SROOF RF Sunroof

SRS SRS Supplemental Restraint System

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

Revision: January 20102010 Versa