warning light NISSAN LATIO 2010 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 3563 of 3745

SC-24

< SERVICE INFORMATION >

CHARGING SYSTEM

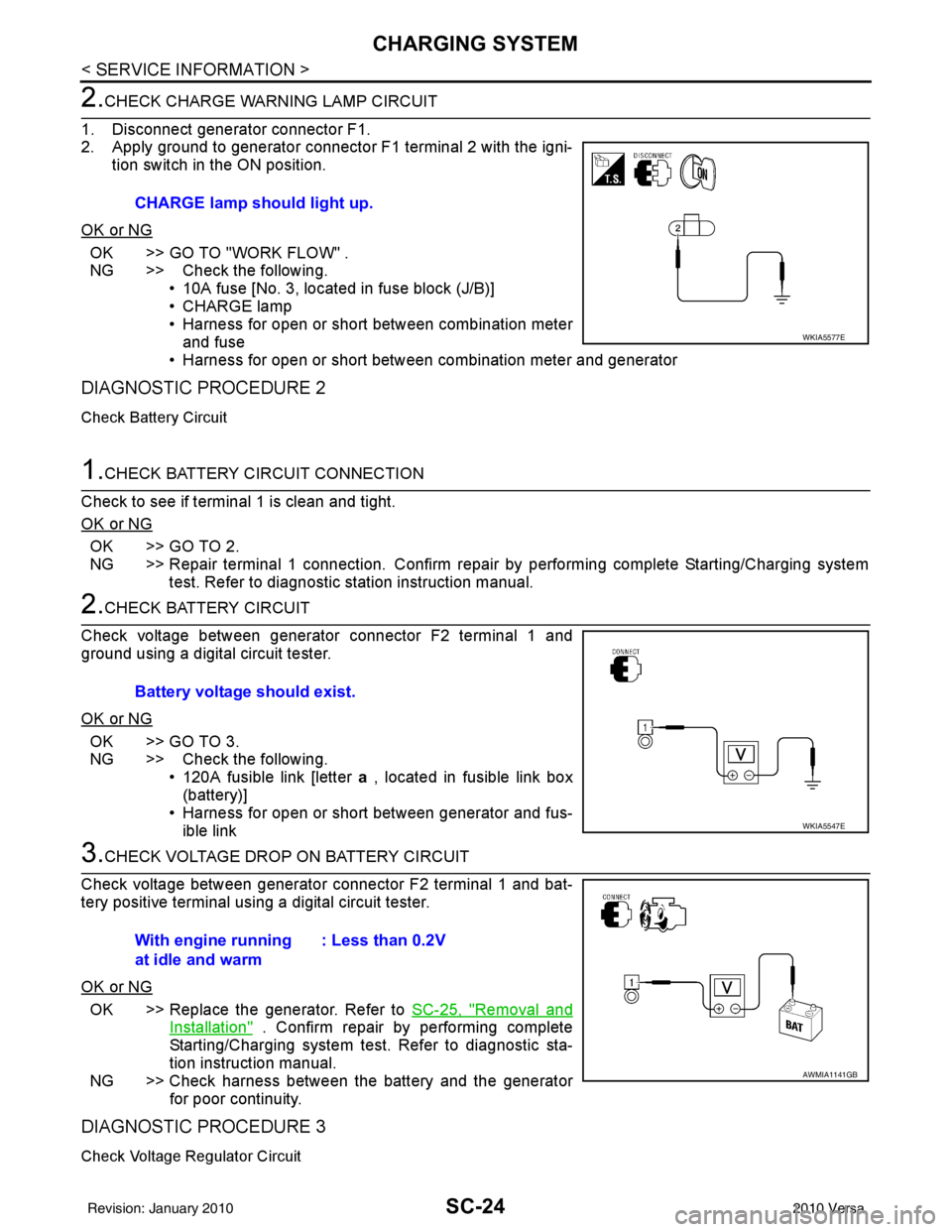

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector F1.

2. Apply ground to generator connector F1 terminal 2 with the igni- tion switch in the ON position.

OK or NG

OK >> GO TO "WORK FLOW" .

NG >> Check the following. • 10A fuse [No. 3, located in fuse block (J/B)]

• CHARGE lamp

• Harness for open or short between combination meterand fuse

• Harness for open or short between combination meter and generator

DIAGNOSTIC PROCEDURE 2

Check Battery Circuit

1.CHECK BATTERY CIRCUIT CONNECTION

Check to see if terminal 1 is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair terminal 1 connection. Confirm repair by performing complete Starting/Charging system test. Refer to diagnostic station instruction manual.

2.CHECK BATTERY CIRCUIT

Check voltage between generator connector F2 terminal 1 and

ground using a digital circuit tester.

OK or NG

OK >> GO TO 3.

NG >> Check the following. • 120A fusible link [letter a , located in fusible link box

(battery)]

• Harness for open or short between generator and fus- ible link

3.CHECK VOLTAGE DROP ON BATTERY CIRCUIT

Check voltage between generator connector F2 terminal 1 and bat-

tery positive terminal using a digital circuit tester.

OK or NG

OK >> Replace the generator. Refer to SC-25, "Removal and

Installation" . Confirm repair by performing complete

Starting/Charging system test. Refer to diagnostic sta-

tion instruction manual.

NG >> Check harness between the battery and the generator for poor continuity.

DIAGNOSTIC PROCEDURE 3

Check Voltage Regulator Circuit

CHARGE lamp should light up.

WKIA5577E

Battery voltage should exist.

WKIA5547E

With engine running

at idle and warm : Less than 0.2V

AWMIA1141GB

Revision: January 20102010 Versa

Page 3621 of 3745

SRS-28

< SYMPTOM DIAGNOSIS >

TROUBLE DIAGNOSIS

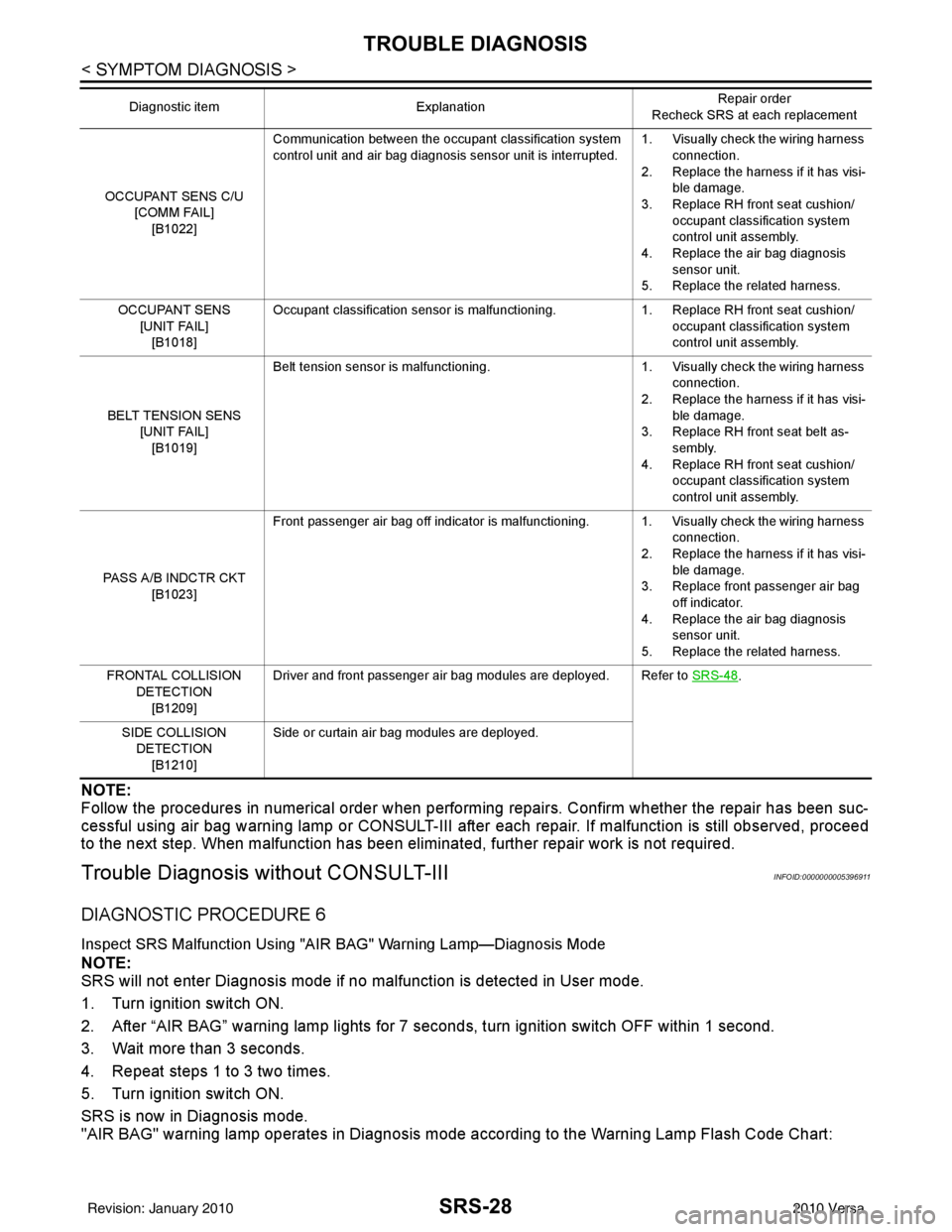

NOTE:

Follow the procedures in numerical order when performing repairs. Confirm whether the repair has been suc-

cessful using air bag warning lamp or CONSULT-III after each repair. If malfunction is still observed, proceed

to the next step. When malfunction has been elimi nated, further repair work is not required.

Trouble Diagnosis without CONSULT-IIIINFOID:0000000005396911

DIAGNOSTIC PROCEDURE 6

Inspect SRS Malfunction Using "AIR BAG" Warning Lamp—Diagnosis Mode

NOTE:

SRS will not enter Diagnosis mode if no malfunction is detected in User mode.

1. Turn ignition switch ON.

2. After “AIR BAG” warning lamp lights for 7 seconds, turn ignition switch OFF within 1 second.

3. Wait more than 3 seconds.

4. Repeat steps 1 to 3 two times.

5. Turn ignition switch ON.

SRS is now in Diagnosis mode.

"AIR BAG" warning lamp operates in Diagnosis mode according to the Warning Lamp Flash Code Chart:

OCCUPANT SENS C/U [COMM FAIL]

[B1022] Communication between the occupant classification system

control unit and air bag diagnosis sensor unit is interrupted.

1. Visually check the wiring harness

connection.

2. Replace the harness if it has visi- ble damage.

3. Replace RH front seat cushion/ occupant classification system

control unit assembly.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

OCCUPANT SENS [UNIT FAIL][B1018] Occupant classification sensor is malfunctioning.

1. Replace RH front seat cushion/

occupant classification system

control unit assembly.

BELT TENSION SENS [UNIT FAIL]

[B1019] Belt tension sensor is malfunctioning.

1. Visually check the wiring harness

connection.

2. Replace the harness if it has visi- ble damage.

3. Replace RH front seat belt as-

sembly.

4. Replace RH front seat cushion/ occupant classification system

control unit assembly.

PASS A/B INDCTR CKT [B1023] Front passenger air bag off indicator is malfunctioning. 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visi-

ble damage.

3. Replace front passenger air bag off indicator.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

FRONTAL COLLISION DETECTION[B1209] Driver and front passenger air bag modules are deployed. Refer to

SRS-48

.

SIDE COLLISION DETECTION

[B1210] Side or curtain air bag modules are deployed.

Diagnostic item

Explanation Repair order

Recheck SRS at each replacement

Revision: January 20102010 Versa

Page 3630 of 3745

SPIRAL CABLESRS-37

< ON-VEHICLE REPAIR >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

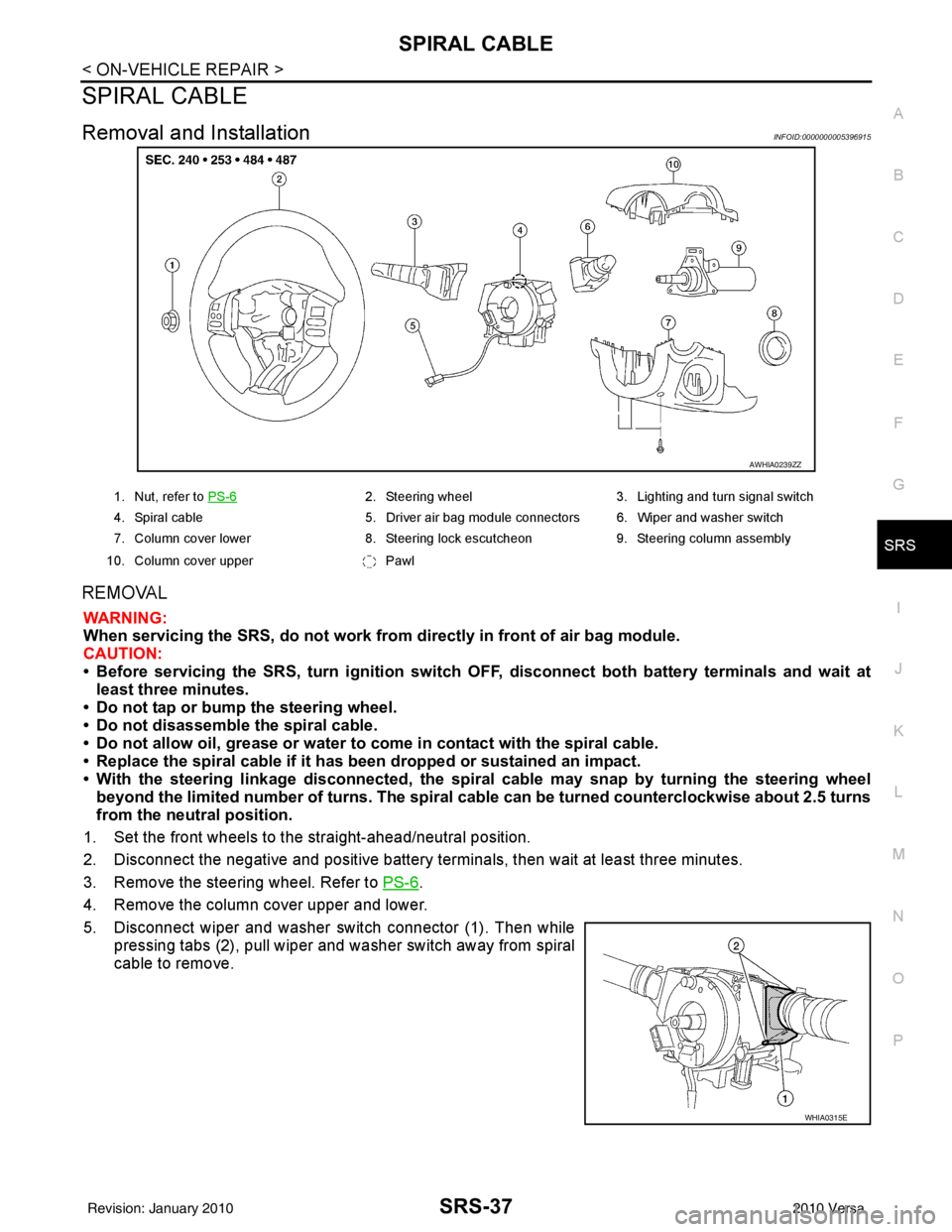

SPIRAL CABLE

Removal and InstallationINFOID:0000000005396915

REMOVAL

WARNING:

When servicing the SRS, do not work from directly in front of air bag module.

CAUTION:

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery terminals and wait at

least three minutes.

• Do not tap or bump the steering wheel.

• Do not disassemble the spiral cable.

• Do not allow oil, grease or water to co me in contact with the spiral cable.

• Replace the spiral cable if it has b een dropped or sustained an impact.

• With the steering linkage disconn ected, the spiral cable may snap by turning the steering wheel

beyond the limited number of turns. The spiral cable can be turned counterclockwise about 2.5 turns

from the neutral position.

1. Set the front wheels to the straight-ahead/neutral position.

2. Disconnect the negative and positive battery term inals, then wait at least three minutes.

3. Remove the steering wheel. Refer to PS-6

.

4. Remove the column cover upper and lower.

5. Disconnect wiper and washer switch connector (1). Then while pressing tabs (2), pull wiper and washer switch away from spiral

cable to remove.

AWHIA0239ZZ

1. Nut, refer to PS-62. Steering wheel 3. Lighting and turn signal switch

4. Spiral cable 5. Driver air bag module connectors 6. Wiper and washer switch

7. Column cover lower 8. Steering lock escutcheon 9. Steering column assembly

10. Column cover upper Pawl

WHIA0315E

Revision: January 20102010 Versa

Page 3647 of 3745

STC-1

STEERING

C

DE

F

H I

J

K L

M

SECTION STC

A

B

STC

N

O P

CONTENTS

STEERING CONTROL SYSTEM

EPS

BASIC INSPECTION ....... .............................

3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Work Flow ........................................................... ......3

SYSTEM DESCRIPTION ..............................5

EPS SYSTEM ... .............................................. .....5

System Diagram .................................................. ......5

System Description ...................................................5

Component Parts Location ........................................6

Component Description .............................................6

DIAGNOSIS SYSTEM (EPS CONTROL UNIT)

.....

8

CONSULT-III Function ........................................ ......8

DTC/CIRCUIT DIAGNOSIS ..........................9

C1601 BATTERY POWER SUPPLY ..................9

Description .......................................................... ......9

DTC Logic .................................................................9

Diagnosis Procedure .................................................9

C1604 TORQUE SENSOR .................................11

Description ..............................................................11

DTC Logic ...............................................................11

Diagnosis Procedure ...............................................11

C1606 EPS MOTOR ...........................................13

Description .......................................................... ....13

DTC Logic ...............................................................13

Diagnosis Procedure ...............................................13

Component Inspection ............................................13

C1607, C1608 EPS CONTROL UNIT ................15

Description .......................................................... ....15

DTC Logic ...............................................................15

Diagnosis Procedure ...............................................15

C1609 VEHICLE SPEED SIGNAL .....................16

Description ........................................................... ....16

DTC Logic ................................................................16

Diagnosis Procedure ...............................................16

C1610 ENGINE STATUS SIGNAL ...................17

Description ...............................................................17

DTC Logic ................................................................17

Diagnosis Procedure ...............................................17

U1000 CAN COMM CIRCUIT ...........................18

Description ...............................................................18

DTC Logic ................................................................18

Diagnosis Procedure ...............................................18

EPS WARNING LAMP ......................................19

Description ...............................................................19

Component Function Check ....................................19

Diagnosis Procedure ...............................................19

ECU DIAGNOSIS INFORMATION ..............20

EPS CONTROL UNIT .......................................20

Reference Value .................................................. ....20

Wiring Diagram - ELECTRONICALLY CON-

TROLLED POWER STEERING SYSTEM - ............

22

Fail-Safe .............................................................. ....23

DTC Inspection Priority Chart ..................................24

DTC Index ...............................................................24

SYMPTOM DIAGNOSIS ..............................25

EPS WARNING LAMP DOES NOT TURN ON ...25

Description ........................................................... ....25

Diagnosis Procedure ...............................................25

EPS WARNING LAMP DOES NOT TURN

OFF ....................................................................

26

Description ...............................................................26

Diagnosis Procedure ...............................................26

STEERING WHEEL TURNING FORCE IS

HEAVY OR LIGHT ............................................

27

Revision: January 20102010 Versa

Page 3673 of 3745

![NISSAN LATIO 2010 Service Owners Guide STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHTSTC-27

< SYMPTOM DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

STEERING WHEEL TURNING FO RCE IS HEAVY OR LIGHT

DescriptionINFOID:0000000005600199

St NISSAN LATIO 2010 Service Owners Guide STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHTSTC-27

< SYMPTOM DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

STEERING WHEEL TURNING FO RCE IS HEAVY OR LIGHT

DescriptionINFOID:0000000005600199

St](/img/5/57358/w960_57358-3672.png)

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHTSTC-27

< SYMPTOM DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

STEERING WHEEL TURNING FO RCE IS HEAVY OR LIGHT

DescriptionINFOID:0000000005600199

Steering wheel turning force is heavy or light.

Diagnosis ProcedureINFOID:0000000005600200

1.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check that the EPS warning lamp turns ON when igni tion switch turns ON. Then, EPS warning lamp turns

OFF after the engine is started.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 2.

2.PERFORM SELF-DIAGNOSIS

With CONSULT-III

1. Turn the ignition switch OFF to ON.

2. Perform EPS control unit self-diagnosis.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-24, "DTC Index".

NO >> GO TO 3.

3.CHECK EPS CONTROL UNIT SIGNAL

With CONSULT-III

1. Start the engine. CAUTION:

Stop the vehicle.

2. Turn steering wheel from full left stop to full right stop.

3. Select “TORQUE SENSOR” of “DATA MONITOR” for EPS control unit.

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK EPS MOTOR

Perform the trouble diagnosis of EPS motor. Refer to STC-13, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace the specific malfunctioning part.

5.CHECK STEERING WH EEL TURNING FORCE

Check the steering wheel turning force. Refer to PS-6, "

On-Vehicle Inspection and Service".

Is the inspection result normal?

YES >> Inspection End

NO >> Check the steering wheel turning force for mechanical malfunction. Refer to PS-6, "

On-Vehicle

Inspection and Service".

Monitor item ConditionDisplay value

TORQUE SENSOR Steering wheel: Not steer-

ing (There is no steering

force)

Approx. 0 Nm

Steering wheel: Right turn Positive value (Nm)

Steering wheel: Left turn Negative value (Nm)

Revision: January 20102010 Versa