U1001 NISSAN LATIO 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 768 of 3745

NATS (NISSAN ANTI-THEFT SYSTEM)BL-259

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

This indication means that malfunction have been detected in NATS and engine control system.

>> GO TO 8

8.NATS TROUBLE DIAGNOSIS

Repair NATS according to self-diagnosis results refer to NATS (if necessary, perform “C/U INITIALZATIN” with

CONSULT-III.)

NOTE:

Do not erase “SELF-DIAGNOSI S” by using CONSULT-III.

>> GO TO 9

9.IDENTIFYING ENGINE CONTROL MALFUNCTION

Check engine “SELF-DIAGNOSIS” records with a general ized program card instead of the NATS program

card.

>> GO TO 10

10.ENGINE CONTROL SYSTEM TROUBLE DIAGNOSIS

Repair engine control system if engine related malfunction is detected.

With engine diagnostic codes present, refer to EC-468, "

DTCIndex" (HR16DE) or EC-503, "U0101-U1001"

(MR18DE).

Without engine diagnostic codes present, refer to EC-484, "

Symptom Table" (HR16DE) or EC-585, "Trouble

Diagnosis Introduction" (MR18DE).

NOTE:

If only “NATS MALFUNCTION” is display ed, erase the self-diagnosis results.

>> GO TO 11

11 .STARTING ENGINE

Check if the engine could be started by inserting the mechanical key into the ignition key cylinder and operate

ignition switch.

OK >> GO TO 12

NG >> GO TO 2

12.ERASE SELF-DIAGNOSIS

Erase both NATS and ENGINE "SELF-DI AGNOSIS" records by using CONSULT-III NATS program card.

>> GO TO 13

13.COMFIRMATION

Perform running test with CONSULT-II I in engine “SELF-DIAGNOSIS” mode.

“NO DTC” is displayed >> Inspection End.

Malfunction information is displayed >>GO TO 2

Trouble DiagnosisINFOID:0000000005396710

SYMPTOM MATRIX CHART 1

Revision: January 20102010 Versa

Page 1267 of 3745

EC-2

CAN COMMUNICATION ...................................59

System Description .................................................59

COOLING FAN CONTROL ...............................60

System Diagram .................................................. ...60

System Description .................................................60

Component Parts Location ...................................62

Component Description ..........................................66

EVAPORATIVE EMISSION SYSTEM ...............68

System Diagram .................................................. ...68

System Description .................................................68

Component Parts Location ...................................72

Component Description .........................................76

INTAKE VALVE TIMING CONTROL .................78

System Diagram .................................................. ...78

System Description .................................................78

Component Parts Location ...................................79

Component Description ..........................................83

ON BOARD DIAGNOSTIC (OBD) SYSTEM .....84

Diagnosis Description .......................................... ...84

CONSULT-III Function ...........................................98

Diagnosis Tool Function ......................................104

COMPONENT DIAGNOSIS .......................106

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE ............................................................ .

106

Description ........................................................... ..106

Component Function Check ..................................106

Diagnosis Procedure .............................................107

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT ........................................................

114

Description ........................................................... ..114

Diagnosis Procedure .............................................114

POWER SUPPLY AND GROUND CIRCUIT ...115

Wiring Diagram .................................................... ..115

Diagnosis Procedure .............................................115

Ground Inspection .................................................119

U0101 CAN COMM CIRCUIT ..........................120

Description ........................................................... ..120

DTC Logic ..............................................................120

Wiring Diagram ......................................................121

Diagnosis Procedure .............................................121

U0140 CAN COMM CIRCUIT ..........................122

Description ........................................................... ..122

DTC Logic ..............................................................122

Wiring Diagram ......................................................123

Diagnosis Procedure .............................................123

U1001 CAN COMM CIRCUIT ..........................124

Description ........................................................... ..124

DTC Logic ..............................................................124

Wiring Diagram ......................................................125

Diagnosis Procedure .............................................125

P0011 IVT CONTROL ......................................126

DTC Logic ............................................................ .126

Diagnosis Procedure .............................................127

Component Inspection ..........................................128

P0031, P0032 A/F SENSOR 1 HEATER ..........130

Description ........................................................... .130

DTC Logic .............................................................130

Wiring Diagram .....................................................131

Diagnosis Procedure .............................................131

Component Inspection ..........................................133

P0037, P0038 HO2S2 HEATER .......................134

Description ........................................................... .134

DTC Logic .............................................................134

Wiring Diagram .....................................................135

Diagnosis Procedure .............................................135

Component Inspection ..........................................137

P0075 IVT CONTROL SOLENOID VALVE ......138

Description ........................................................... .138

DTC Logic .............................................................138

Wiring Diagram .....................................................139

Diagnosis Procedure .............................................139

Component Inspection ..........................................140

P0101 MAF SENSOR .......................................142

Description ........................................................... .142

DTC Logic .............................................................142

Component Function Check .................................143

Wiring Diagram .....................................................145

Diagnosis Procedure .............................................145

Component Inspection ..........................................147

P0102, P0103 MAF SENSOR ..........................150

Description ........................................................... .150

DTC Logic .............................................................150

Wiring Diagram .....................................................151

Diagnosis Procedure .............................................151

Component Inspection ..........................................153

P0112, P0113 IAT SENSOR ............................156

Description ............................................................156

DTC Logic .............................................................156

Wiring Diagram .....................................................157

Diagnosis Procedure .............................................157

Component Inspection ..........................................158

P0116 ECT SENSOR .......................................159

Description ............................................................159

DTC Logic .............................................................159

Diagnosis Procedure .............................................160

Component Inspection ..........................................160

P0117, P0118 ECT SENSOR ...........................161

Description ............................................................161

DTC Logic .............................................................161

Wiring Diagram .....................................................162

Diagnosis Procedure .............................................162

Component Inspection ..........................................163

Revision: January 20102010 Versa

Page 1272 of 3745

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

FUEL PRESSURE .......................................... ..496

Inspection ............................................................ ..496

EVAP LEAK CHECK ........................................498

Inspection ............................................................ ..498

ON-VEHICLE REPAIR ...............................500

EVAP CANISTER .............................................500

Exploded View .................................................... ..500

Removal and Installation .......................................500

Inspection ............................................................ ..501

SERVICE DATA AND SPECIFICATIONS

(SDS) ......... ................................. ................

502

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

502

Idle Speed ........................................................... ..502

Ignition Timing .......................................................502

Calculated Load Value ..........................................502

Mass Air Flow Sensor ...........................................502

MR18DE

SERVICE INFORMATION .. .......................

503

INDEX FOR DTC ............................................ ..503

U0101-U1001 ...................................................... ..503

P0011-P0075 ........................................................503

P0101-P0128 ........................................................503

P0130-P0183 ........................................................504

P0222-P0420 ........................................................504

P0441-P0463 ........................................................505

P0500-P0643 ........................................................505

P0705-P0734 ........................................................506

P0740-P0840 ........................................................506

P0850-P1574 ........................................................507

P1610-P1615 ........................................................507

P1715-P1805 ........................................................507

P2100-P2A00 ........................................................508

PRECAUTIONS ................................................509

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

509

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

509

Precaution for Procedure without Cowl Top Cover ..510

On Board Diagnosis (OBD) System of Engine and

A/T, CVT ...............................................................

510

Precaution .............................................................510

PREPARATION ................................................514

Special Service Tool ........................................... ..514

Commercial Service Tool ......................................514

ENGINE CONTROL SYSTEM ..........................516

Schematic ........................................................... ..516

Multiport Fuel Injection (MFI) System ...................516

Electronic Ignition (EI) System ..............................519

Fuel Cut Control (at No Load and High Engine

Speed) ................................................................. ..

519

AIR CONDITIONING CUT CONTROL ............521

Input/Output Signal Chart ......................................521

System Description ................................................521

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ............................................................

522

System Description ................................................522

Component Description .........................................523

CAN COMMUNICATION .................................524

System Description ................................................524

EVAPORATIVE EMISSION SYSTEM .............525

Description .............................................................525

Component Inspection ...........................................527

Exploded View .......................................................529

Removal and Installation .......................................529

How to Detect Fuel Vapor Leakage .......................530

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ....................................................

532

System Description ................................................532

Diagnosis Procedure .............................................532

Component Inspection ...........................................535

POSITIVE CRANKCASE VENTILATION .......538

Description .............................................................538

Component Inspection ...........................................538

NVIS (NISSAN VEHICLE IMMOBILIZER SYS-

TEM-NATS) .....................................................

540

Description .............................................................540

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..541

Introduction ............................................................541

Two Trip Detection Logic .......................................541

Emission-related Diagnostic Information ...............542

Malfunction Indicator Lamp (MIL) ..........................565

OBD System Operation Chart ...............................568

BASIC SERVICE PROCEDURE .....................574

Basic Inspection ....................................................574

Idle Speed and Ignition Timing Check ...................578

Procedure After Replacing ECM ...........................579

VIN Registration ....................................................580

Accelerator Pedal Released Position Learning .....580

Throttle Valve Closed Position Learning ...............580

Idle Air Volume Learning .......................................580

Fuel Pressure Check .............................................582

TROUBLE DIAGNOSIS ..................................585

Trouble Diagnosis Introduction ..............................585

DTC Inspection Priority Chart ................................590

Fail-Safe Chart ......................................................590

Symptom Matrix Chart ...........................................592

Engine Control Component Parts Location ...........596

Vacuum Hose Drawing ..........................................602

Circuit Diagram ......................................................603

Revision: January 20102010 Versa

Page 1273 of 3745

EC-8

ECM Harness Connector Terminal Layout ............605

ECM Terminal and Reference Value ................... ..605

CONSULT-III Function (ENGINE) .........................612

Generic Scan Tool (GST) Function .......................618

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

620

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE .............................................................

624

Description ........................................................... ..624

Testing Condition ...................................................624

Inspection Procedure .............................................624

Diagnosis Procedure .............................................624

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT ........................................................

632

Description ........................................................... ..632

Diagnosis Procedure .............................................632

POWER SUPPLY AND GROUND CIRCUIT ...633

Wiring Diagram .................................................... ..633

Diagnosis Procedure .............................................634

Ground Inspection .................................................638

DTC U0101 CAN COMMUNICATION LINE ....639

Description ........................................................... ..639

On Board Diagnosis Logic .....................................639

DTC Confirmation Procedure ................................639

Wiring Diagram ......................................................640

Diagnosis Procedure .............................................640

DTC U0140 CAN COMMUNICATION LINE ....641

Description ........................................................... ..641

On Board Diagnosis Logic .....................................641

DTC Confirmation Procedure ................................641

Wiring Diagram ......................................................642

Diagnosis Procedure .............................................642

DTC U1001 CAN COMMUNICATION LINE ....643

Description ........................................................... ..643

On Board Diagnosis Logic .....................................643

DTC Confirmation Procedure ................................643

Wiring Diagram ......................................................644

Diagnosis Procedure .............................................644

DTC P0011 IVT CONTROL .............................645

Description ........................................................... ..645

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

645

On Board Diagnosis Logic .....................................646

DTC Confirmation Procedure ................................646

Diagnosis Procedure .............................................647

Component Inspection ...........................................648

Removal and Installation .......................................648

DTC P0031, P0032 A/F SENSOR 1 HEATER .649

Description ........................................................... ..649

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

649

On Board Diagnosis Logic .....................................649

DTC Confirmation Procedure ................................649

Wiring Diagram .................................................... .650

Diagnosis Procedure .............................................651

Component Inspection ..........................................652

Removal and Installation .......................................653

DTC P0037, P0038 HO2S2 HEATER ............ ..654

Description ........................................................... .654

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

654

On Board Diagnosis Logic ....................................654

DTC Confirmation Procedure ................................654

Wiring Diagram .....................................................655

Diagnosis Procedure .............................................656

Component Inspection ..........................................658

Removal and Installation .......................................658

DTC P0075 IVT CONTROL SOLENOID

VALVE ............................................................ ..

659

Component Description ....................................... .659

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

659

On Board Diagnosis Logic ....................................659

DTC Confirmation Procedure ................................659

Wiring Diagram .....................................................660

Diagnosis Procedure .............................................661

Component Inspection ..........................................662

Removal and Installation .......................................663

DTC P0101 MAF SENSOR ............................ ..664

Component Description ....................................... .664

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

664

On Board Diagnosis Logic ....................................664

DTC Confirmation Procedure ................................664

Overall Function Check .........................................665

Wiring Diagram .....................................................667

Diagnosis Procedure .............................................668

Component Inspection ..........................................670

Removal and Installation .......................................671

DTC P0102, P0103 MAF SENSOR ................ ..672

Component Description ....................................... .672

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

672

On Board Diagnosis Logic ....................................672

DTC Confirmation Procedure ................................672

Wiring Diagram .....................................................674

Diagnosis Procedure .............................................675

Component Inspection ..........................................677

Removal and Installation .......................................678

DTC P0112, P0113 IAT SENSOR .................. ..679

Component Description ....................................... .679

On Board Diagnosis Logic ....................................679

DTC Confirmation Procedure ................................679

Wiring Diagram .....................................................680

Diagnosis Procedure .............................................680

Component Inspection ..........................................682

Removal and Installation .......................................682

Revision: January 20102010 Versa

Page 1389 of 3745

![NISSAN LATIO 2010 Service Repair Manual EC-124

< COMPONENT DIAGNOSIS >[HR16DE]

U1001 CAN COMM CIRCUIT

U1001 CAN COMM CIRCUIT

DescriptionINFOID:0000000005398296

CAN (Controller Area Network) is a serial communication line for real time appli NISSAN LATIO 2010 Service Repair Manual EC-124

< COMPONENT DIAGNOSIS >[HR16DE]

U1001 CAN COMM CIRCUIT

U1001 CAN COMM CIRCUIT

DescriptionINFOID:0000000005398296

CAN (Controller Area Network) is a serial communication line for real time appli](/img/5/57358/w960_57358-1388.png)

EC-124

< COMPONENT DIAGNOSIS >[HR16DE]

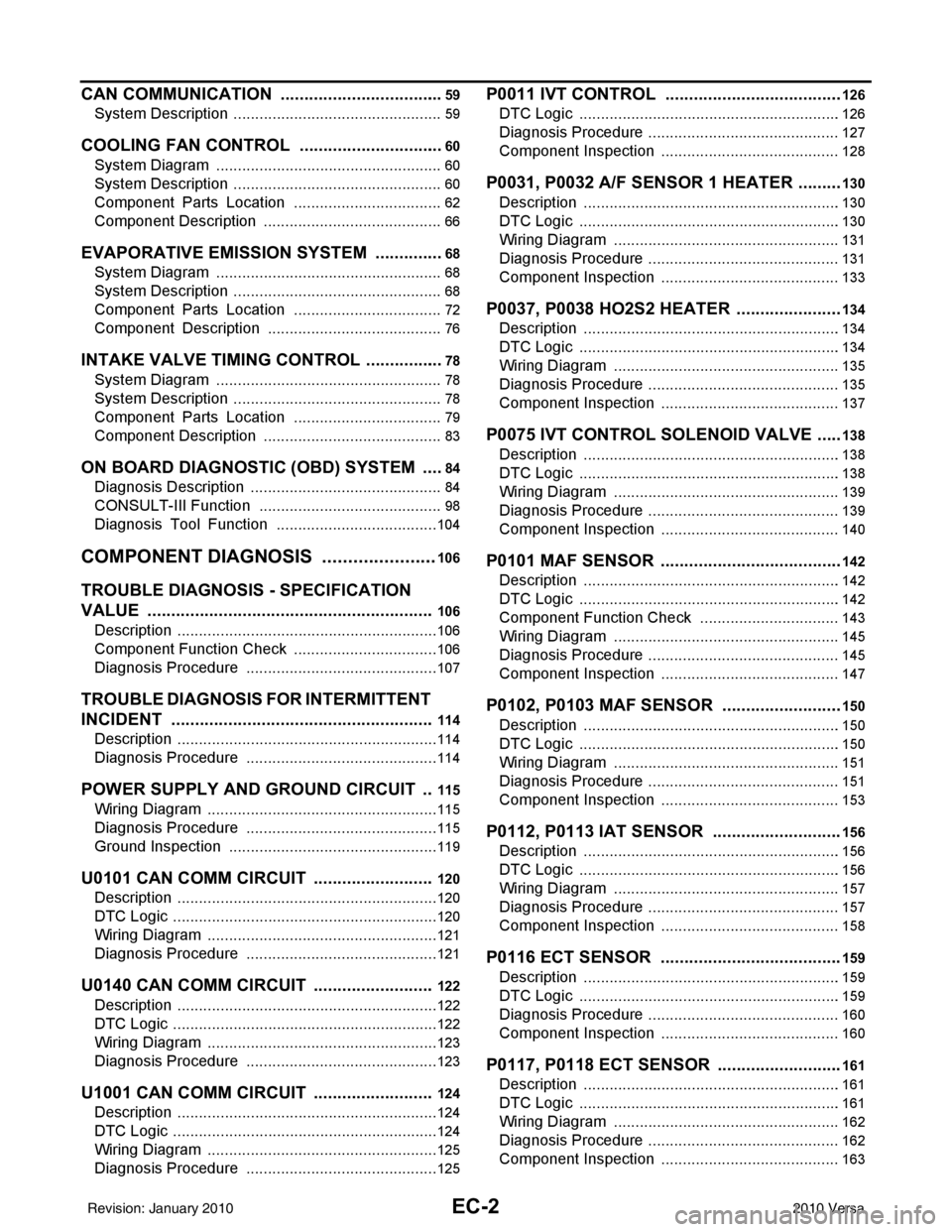

U1001 CAN COMM CIRCUIT

U1001 CAN COMM CIRCUIT

DescriptionINFOID:0000000005398296

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s

peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

DTC LogicINFOID:0000000005398297

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 3 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> EC-125, "Diagnosis Procedure".

NO >> INSPECTION END

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

U1001 CAN communication line When ECM is not transmitting or receiving CAN

communication signal other than OBD (emission

related diagnosis) for 2 seconds or more. • Harness or connectors

(CAN communication line is open or

shorted)

Revision: January 20102010 Versa

Page 1390 of 3745

![NISSAN LATIO 2010 Service Repair Manual U1001 CAN COMM CIRCUITEC-125

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Wiring DiagramINFOID:0000000005398298

Diagnosis ProcedureINFOID:0000000005398299

Go to

LAN-17, "Trouble D NISSAN LATIO 2010 Service Repair Manual U1001 CAN COMM CIRCUITEC-125

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Wiring DiagramINFOID:0000000005398298

Diagnosis ProcedureINFOID:0000000005398299

Go to

LAN-17, "Trouble D](/img/5/57358/w960_57358-1389.png)

U1001 CAN COMM CIRCUITEC-125

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Wiring DiagramINFOID:0000000005398298

Diagnosis ProcedureINFOID:0000000005398299

Go to

LAN-17, "Trouble Diagnosis Flow Chart".

BBWA2626E

Revision: January 20102010 Versa

Page 1732 of 3745

![NISSAN LATIO 2010 Service Repair Manual ECM

EC-467

< ECU DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC Inspection Priority ChartINFOID:0000000005398638

If some DTCs are displayed at the same time, perform inspections one by one b NISSAN LATIO 2010 Service Repair Manual ECM

EC-467

< ECU DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC Inspection Priority ChartINFOID:0000000005398638

If some DTCs are displayed at the same time, perform inspections one by one b](/img/5/57358/w960_57358-1731.png)

ECM

EC-467

< ECU DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

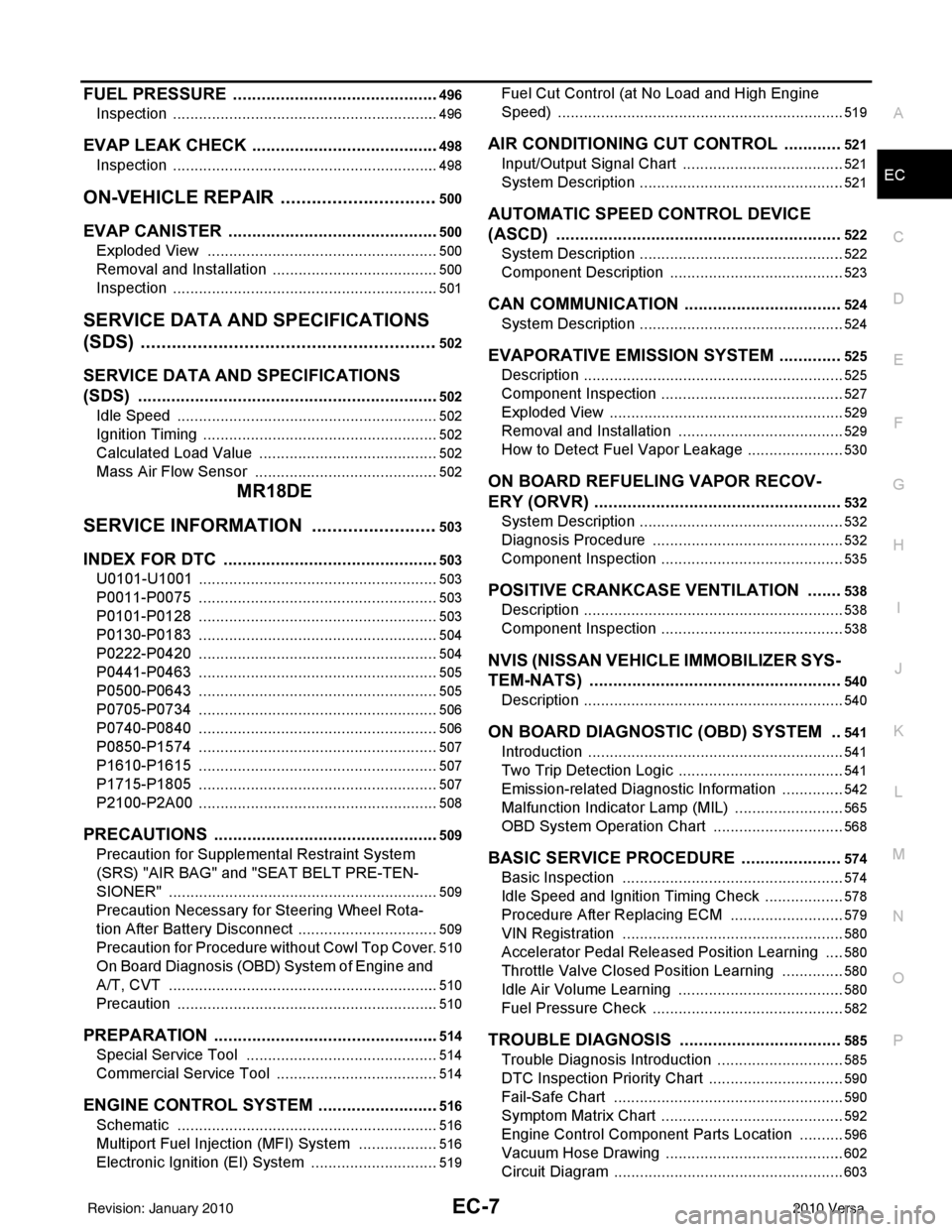

DTC Inspection Priority ChartINFOID:0000000005398638

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

P2119 Electric thro

ttle control ac-

tuator (When electric throttle control actuator does not function properly due to the return spring

malfunction:)

ECM controls the electric throttle actuator by regulating the throttle opening around the

idle position. The engine speed will not rise more than 2,000 rpm.

(When throttle valve opening angle in fail-safe mode is not in specified range:)

ECM controls the electric throttle control actuator by regulating the throttle opening to 20

degrees or less.

(When ECM detects the throttle valve is stuck open:)

While the vehicle is driving, it slows down gradually by fuel cut. After the vehicle stops, the

engine stalls.

The engine can restart in N or P (A/T), Neutral (M/T) position, and engine speed will not

exceed 1,000 rpm or more.

P2122

P2123

P2127

P2128

P2138 Accelerator pedal position

sensor

The ECM controls the electric throttle control actuator in regulating the throttle opening in

order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

DTC No. Detected items

Engine operating condition in fail-safe mode

PriorityDetected items (DTC)

1 • U0101 U0140 U1001 CAN communication line • P0101 P0102 P0103 Mass air flow sensor

• P0112 P0113 P0127 Intake air temperature sensor

• P0116 P0117 P0118 P0125 Engine coolant temperature sensor

• P0122 P0123 P0222 P0223 P1225 P1226 P2135 Throttle position sensor

• P0128 Thermostat function

• P0181 P0182 P0183 Fuel tank temperature sensor

• P0327 P0328 Knock sensor

• P0335 Crankshaft position sensor (POS)

• P0340 Camshaft position sensor (PHASE)

• P0460 P0461 P0462 P0463 Fuel level sensor

• P0500 Vehicle speed sensor

• P0605 P0607 ECM

• P0643 Sensor power supply

• P0705 Transmission range switch

• P0850 Park/neutral position (PNP) switch

• P1610 - P1615 NATS

• P2122 P2123 P2127 P2128 P2138 Accelerator pedal position sensor

Revision: January 20102010 Versa

Page 1733 of 3745

![NISSAN LATIO 2010 Service Repair Manual EC-468

< ECU DIAGNOSIS >[HR16DE]

ECM

DTC Index

INFOID:0000000005398639

× :Applicable —: Not applicable

2 • P0031 P0032 Air fuel ratio (A/F) sensor 1 heater

• P0037 P0038 Heated oxygen sensor 2 NISSAN LATIO 2010 Service Repair Manual EC-468

< ECU DIAGNOSIS >[HR16DE]

ECM

DTC Index

INFOID:0000000005398639

× :Applicable —: Not applicable

2 • P0031 P0032 Air fuel ratio (A/F) sensor 1 heater

• P0037 P0038 Heated oxygen sensor 2](/img/5/57358/w960_57358-1732.png)

EC-468

< ECU DIAGNOSIS >[HR16DE]

ECM

DTC Index

INFOID:0000000005398639

× :Applicable —: Not applicable

2 • P0031 P0032 Air fuel ratio (A/F) sensor 1 heater

• P0037 P0038 Heated oxygen sensor 2 heater

• P0075 Intake valve timing control solenoid valve

• P0130 P0131 P0132 P0133 P2A00 Air fuel ratio (A/F) sensor 1

• P0137 P0138 P0139 Heated oxygen sensor 2

• P0441 EVAP control system purge flow monitoring

• P0443 P0444 P0445 EVAP canister purge volume control solenoid valve

• P0447 P0448 EVAP canister vent control valve

• P0451 P0452 P0453 EVAP control system pressure sensor

• P0603 ECM power supply

• P0710 P0720 P0725 P0731 P0732 P0733 P0734 P0740 P0744 P0745 P0750 P0755 P1705 P1760 A/T related sensors,

solenoid valves and switches

• P1217 Engine over temperature (OVERHEAT)

• P1805 Brake switch

• P2100 P2103 Throttle control motor relay

• P2101 Electric throttle control function

• P2118 Throttle control motor

3 • P0011 Intake valve timing control • P0171 P0172 Fuel injection system function

• P0300 - P0304 Misfire

• P0420 Three way catalyst function

• P0442 P0456 EV AP control system (SMALL LEAK, VERY SMALL LEAK)

• P0455 EVAP control system (GROSS LEAK)

• P0506 P0507 Idle speed control system

• P1148 Closed loop control

• P1421 Cold start control

• P1715 Input speed sensor

• P2119 Electric throttle control actuator

Priority

Detected items (DTC)

DTC*1

Items

(CONSULT-III screen terms) SRT

code Trip MIL Permanent

DTC

group*

4

Reference page

CONSULT-III

GST*

2ECM*3

U0101 0101*5LOST COMM (TCM) — 1×BEC-120

U0140

0140*5LOST COMM (BCM) — 1×BEC-122

U1001

1001*5CAN COMM CIRCUIT — 2——EC-120

P0000 0000 NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED. ——

Flashing*8——

P0011 0011 INT/V TIM CONT-B1 ×2 ×BEC-126

P0031 0031 A/F SEN1 HTR (B1) — 2×BEC-130

P0032 0032 A/F SEN1 HTR (B1) — 2×BEC-130

P0037 0037 HO2S2 HTR (B1) — 2×BEC-134

P0038 0038 HO2S2 HTR (B1) — 2×BEC-134

P0075 0075 INT/V TIM V/CIR-B1 — 2×BEC-138

P0101 0101 MAF SEN/CIRCUIT-B1 — 2×BEC-142

P0102 0102 MAF SEN/CIRCUIT-B1 — 1×BEC-150

P0103 0103 MAF SEN/CIRCUIT-B1 — 1×BEC-150

P0112 0112 IAT SEN/CIRCUIT-B1 — 2×BEC-156

P0113 0113 IAT SEN/CIRCUIT-B1 — 2×BEC-156

P0116 0116 ECT SEN/CIRC — 2×BEC-159

P0117 0117 ECT SEN/CIRC — 1×BEC-161

Revision: January 20102010 Versa

Page 1768 of 3745

![NISSAN LATIO 2010 Service Repair Manual INDEX FOR DTCEC-503

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SERVICE INFORMATION

INDEX FOR DTC

U0101-U1001INFOID:0000000005532361

*1: 1st trip DTC No. is

the same as DTC No.

* NISSAN LATIO 2010 Service Repair Manual INDEX FOR DTCEC-503

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SERVICE INFORMATION

INDEX FOR DTC

U0101-U1001INFOID:0000000005532361

*1: 1st trip DTC No. is

the same as DTC No.

*](/img/5/57358/w960_57358-1767.png)

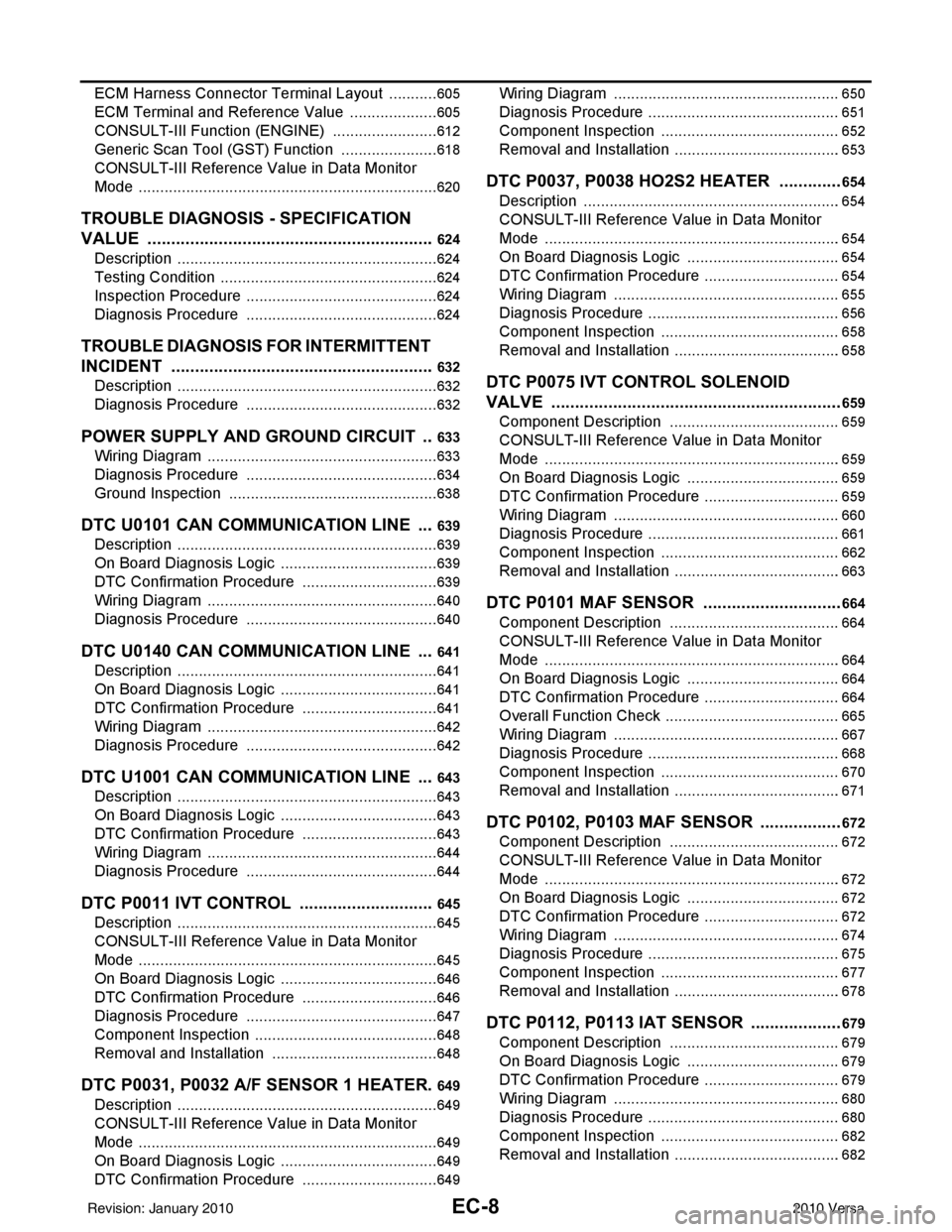

INDEX FOR DTCEC-503

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SERVICE INFORMATION

INDEX FOR DTC

U0101-U1001INFOID:0000000005532361

*1: 1st trip DTC No. is

the same as DTC No.

*2: This number is prescri bed by SAE J2012/ISO 15031-6.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

*4: The troubleshooting for this DTC needs CONSULT-III.

P0011-P0075INFOID:0000000005532362

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescri bed by SAE J2012/ISO 15031-6.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

P0101-P0128INFOID:0000000005532363

DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST*

2ECM*3

U0101 0101*4LOST COMM (TCM) EC-639

U0140

0140*4LOST COMM (BCM) EC-641

U1001

1001*4CAN COMM CIRCUIT EC-643

DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST*

2ECM*3

P0011 0011 INT/V TIM CONT-B1 EC-645

P00310031 A/F SEN1 HTR (B1) EC-649

P00320032 A/F SEN1 HTR (B1) EC-649

P00370037 HO2S2 HTR (B1) EC-654

P00380038 HO2S2 HTR (B1) EC-654

P00750075 INT/V TIM V/CIR-B1 EC-659

DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST*

2ECM*3

P0101 0101 MAF SEN/CIRCUIT-B1 EC-664

P01020102 MAF SEN/CIRCUIT-B1 EC-672

P01030103 MAF SEN/CIRCUIT-B1 EC-672

P01120112 IAT SEN/CIRCUIT-B1 EC-679

P01130113 IAT SEN/CIRCUIT-B1 EC-679

P01160116 ECT SEN/CIRC EC-683

P01170117 ECT SEN/CIRC EC-683

P01180118 ECT SEN/CIRC EC-683

P01220122 TP SEN 2/CIRC-B1 EC-691

P01230123 TP SEN 2/CIRC-B1 EC-691

P01250125 ECT SENSOR EC-696

Revision: January 20102010 Versa

Page 1805 of 3745

![NISSAN LATIO 2010 Service Repair Manual EC-540

< SERVICE INFORMATION >[MR18DE]

NVIS (NISSAN VEHICLE I

MMOBILIZER SYSTEM-NATS)

NVIS (NISSAN VEHICLE IMMOBILIZER SYSTEM-NATS)

DescriptionINFOID:0000000005532398

•If the security indicator illu NISSAN LATIO 2010 Service Repair Manual EC-540

< SERVICE INFORMATION >[MR18DE]

NVIS (NISSAN VEHICLE I

MMOBILIZER SYSTEM-NATS)

NVIS (NISSAN VEHICLE IMMOBILIZER SYSTEM-NATS)

DescriptionINFOID:0000000005532398

•If the security indicator illu](/img/5/57358/w960_57358-1804.png)

EC-540

< SERVICE INFORMATION >[MR18DE]

NVIS (NISSAN VEHICLE I

MMOBILIZER SYSTEM-NATS)

NVIS (NISSAN VEHICLE IMMOBILIZER SYSTEM-NATS)

DescriptionINFOID:0000000005532398

•If the security indicator illuminates with the igni tion switch ON or DTC P1610 - P1615 is displayed in

“SELF DIAGNOSTIC RESULT” mode, perform the trouble diagnosis for corresponding to the

detected DTC. Refer to EC-503, "

U0101-U1001".

• Check that no DTC is displayed in “SELF DIAGNOSIS RESULT” mode of “BCM” before erasing the

detected DTC in “ENGINE” mode with CONSULT-III.

• When replacing ECM, refer to EC-579, "

Procedure After Replacing ECM".

Revision: January 20102010 Versa