ABS NISSAN LATIO 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 385 of 3787

AT-368

< SERVICE INFORMATION >

ASSEMBLY

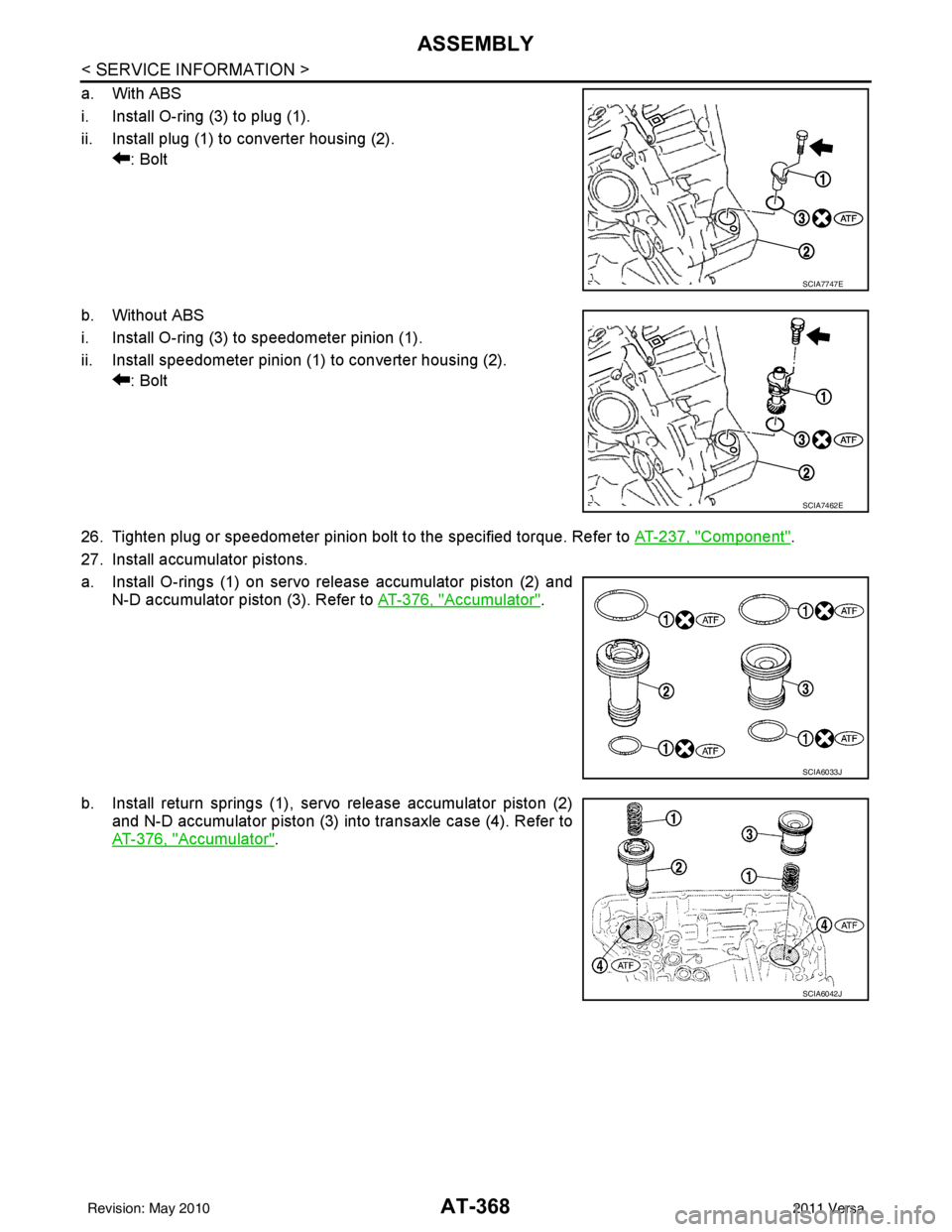

a. With ABS

i. Install O-ring (3) to plug (1).

ii. Install plug (1) to converter housing (2).: Bolt

b. Without ABS

i. Install O-ring (3) to speedometer pinion (1).

ii. Install speedometer pinion (1) to converter housing (2). : Bolt

26. Tighten plug or speedometer pinion bolt to the specified torque. Refer to AT-237, "

Component".

27. Install accumulator pistons.

a. Install O-rings (1) on servo release accumulator piston (2) and N-D accumulator piston (3). Refer to AT-376, "

Accumulator".

b. Install return springs (1), servo release accumulator piston (2) and N-D accumulator piston (3) into transaxle case (4). Refer to

AT-376, "

Accumulator".

SCIA7747E

SCIA7462E

SCIA6033J

SCIA6042J

Revision: May 2010 2011 Versa

Page 783 of 3787

BODY REPAIRBL-273

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

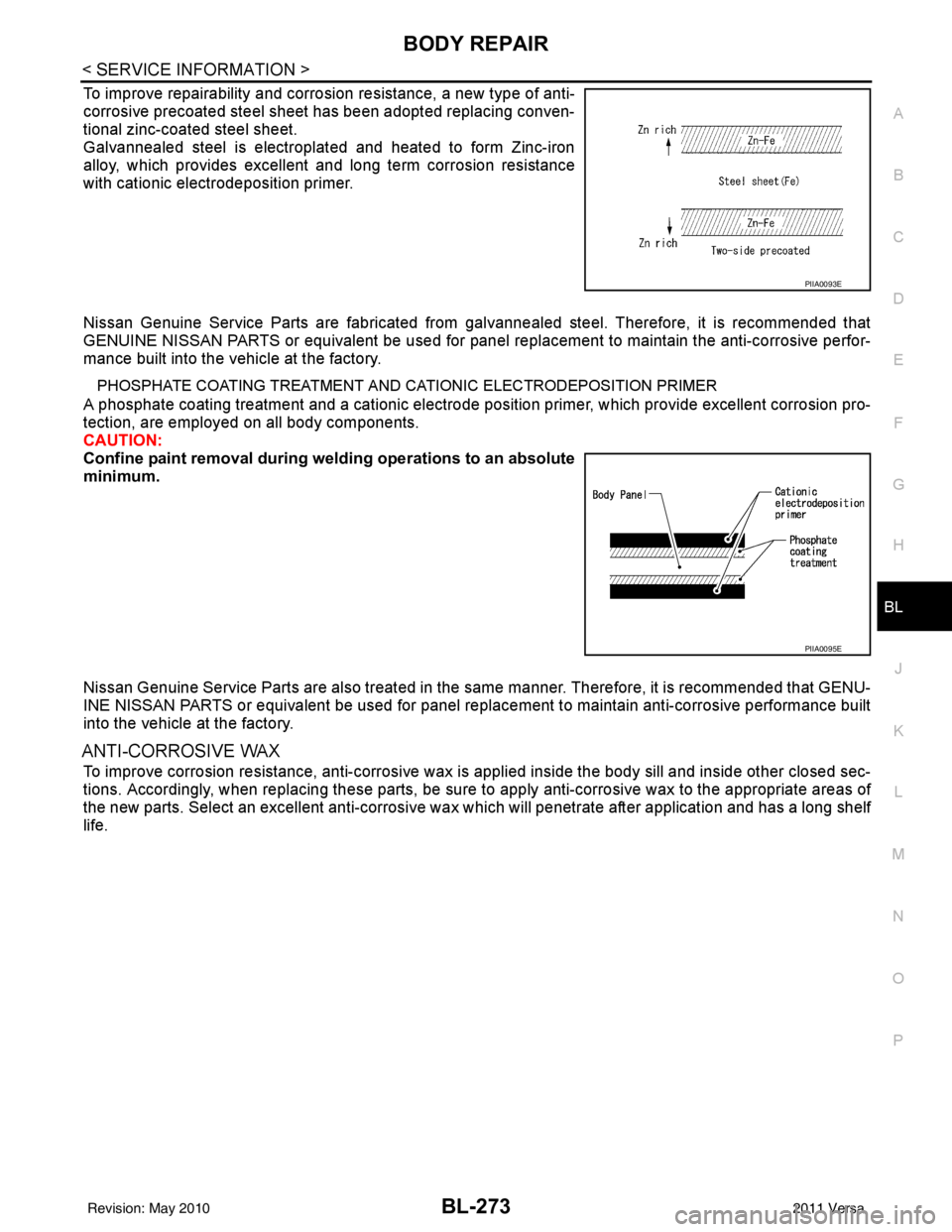

To improve repairability and corrosion resistance, a new type of anti-

corrosive precoated steel sheet has been adopted replacing conven-

tional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron

alloy, which provides excellent and long term corrosion resistance

with cationic electrodeposition primer.

Nissan Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that

GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive perfor-

mance built into the vehicle at the factory.

PHOSPHATE COATING TREATMENT AND CA TIONIC ELECTRODEPOSITION PRIMER

A phosphate coating treatment and a cationic electrode posit ion primer, which provide excellent corrosion pro-

tection, are employed on all body components.

CAUTION:

Confine paint removal during weld ing operations to an absolute

minimum.

Nissan Genuine Service Parts are also treated in the same manner. Therefore, it is recommended that GENU-

INE NISSAN PARTS or equivalent be used for panel repl acement to maintain anti-corrosive performance built

into the vehicle at the factory.

ANTI-CORROSIVE WAX

To improve corrosion resistance, anti-corrosive wax is applied inside the body sill and inside other closed sec-

tions. Accordingly, when replacing these parts, be sure to apply anti-corrosive wax to the appropriate areas of

the new parts. Select an excellent anti-corrosive wax which will penetrate after application and has a long shelf

life.

PIIA0093E

PIIA0095E

Revision: May 2010 2011 Versa

Page 812 of 3787

BL-302

< SERVICE INFORMATION >

BODY REPAIR

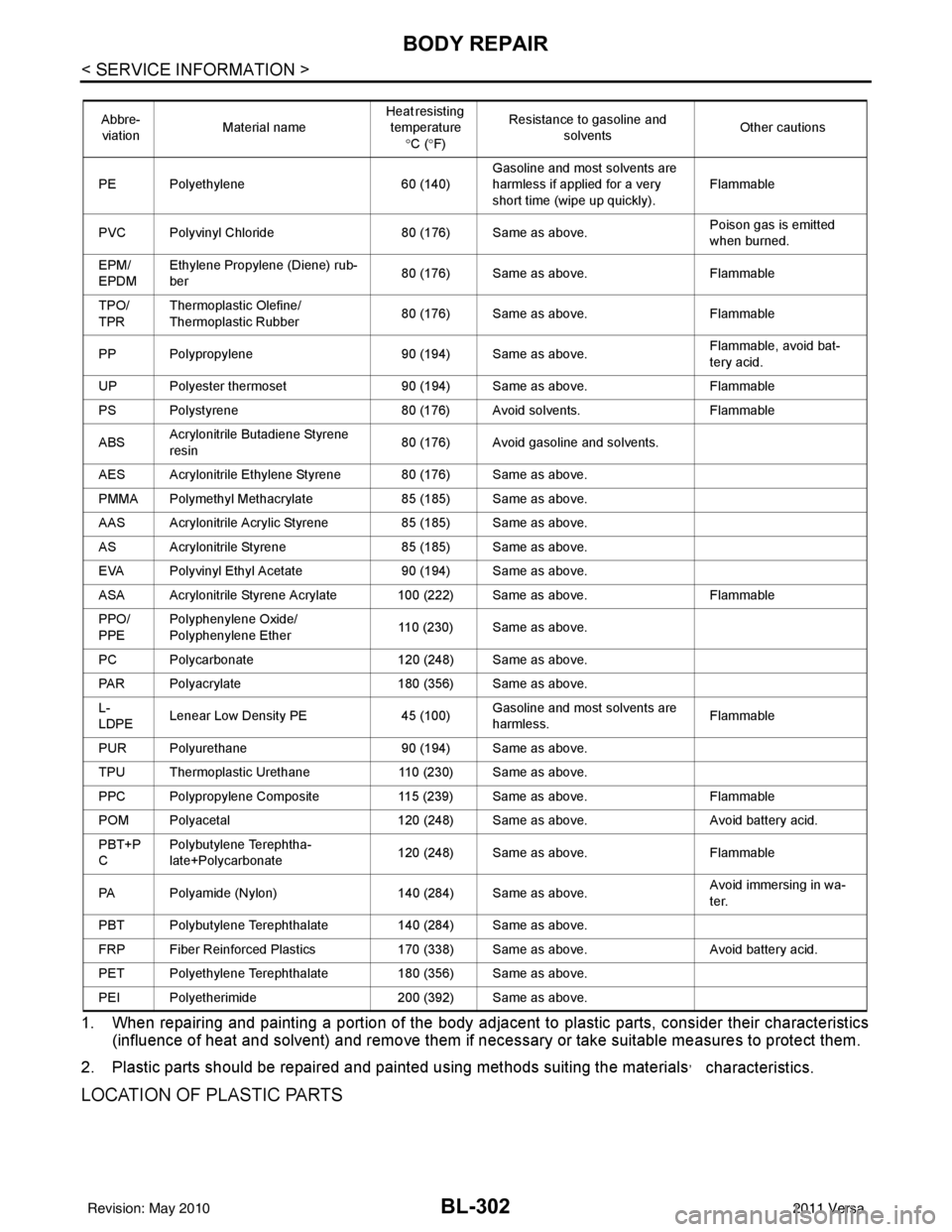

1. When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics

(influence of heat and solvent) and remove them if neces sary or take suitable measures to protect them.

2. Plastic parts should be repaired and painted using methods suiting the materials

, characteristics.

LOCATION OF PLASTIC PARTS

Abbre- viation Material name Heat resisting

temperature °C ( °F) Resistance to gasoline and

solvents Other cautions

PE Polyethylene 60 (140)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly). Flammable

PVC Polyvinyl Chloride 80 (176) Same as above. Poison gas is emitted

when burned.

EPM/

EPDM Ethylene Propylene (Diene) rub-

ber

80 (176) Same as above.

Flammable

TPO/

TPR Thermoplastic Olefine/

Thermoplastic Rubber

80 (176) Same as above.

Flammable

PP Polypropylene 90 (194) Same as above. Flammable, avoid bat-

tery acid.

UP Polyester thermoset 90 (194) Same as above. Flammable

PS Polystyrene 80 (176) Avoid solvents. Flammable

ABS Acrylonitrile Butadiene Styrene

resin

80 (176) Avoid gasoline and solvents.

AES Acrylonitrile Ethylene Styrene 80 (176) Same as above.

PMMA Polymethyl Methacrylate 85 (185) Same as above.

AAS Acrylonitrile Acrylic Styrene 85 (185) Same as above.

AS Acrylonitrile Styrene 85 (185) Same as above.

EVA Polyvinyl Ethyl Acetate 90 (194) Same as above.

ASA Acrylonitrile Styrene Acrylate 100 (222) Same as above. Flammable

PPO/

PPE Polyphenylene Oxide/

Polyphenylene Ether

110 (230) Same as above.

PC Polycarbonate 120 (248) Same as above.

PAR Polyacrylate 180 (356) Same as above.

L-

LDPE Lenear Low Density PE

45 (100)Gasoline and most solvents are

harmless. Flammable

PUR Polyurethane 90 (194) Same as above.

TPU Thermoplastic Urethane 110 (230) Same as above.

PPC Polypropylene Composite 115 (239) Same as above. Flammable

POM Polyacetal 120 (248) Same as above. Avoid battery acid.

PBT+P

C Polybutylene Terephtha-

late+Polycarbonate

120 (248) Same as above.

Flammable

PA Polyamide (Nylon) 140 (284) Same as above. Avoid immersing in wa-

ter.

PBT Polybutylene Terephthalate 140 (284) Same as above.

FRP Fiber Reinforced Plastics 170 (338) Same as above. Avoid battery acid.

PET Polyethylene Terephthalate 180 (356) Same as above.

PEI Polyetherimide 200 (392) Same as above.

Revision: May 2010 2011 Versa

Page 850 of 3787

PRECAUTIONSBR-3

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

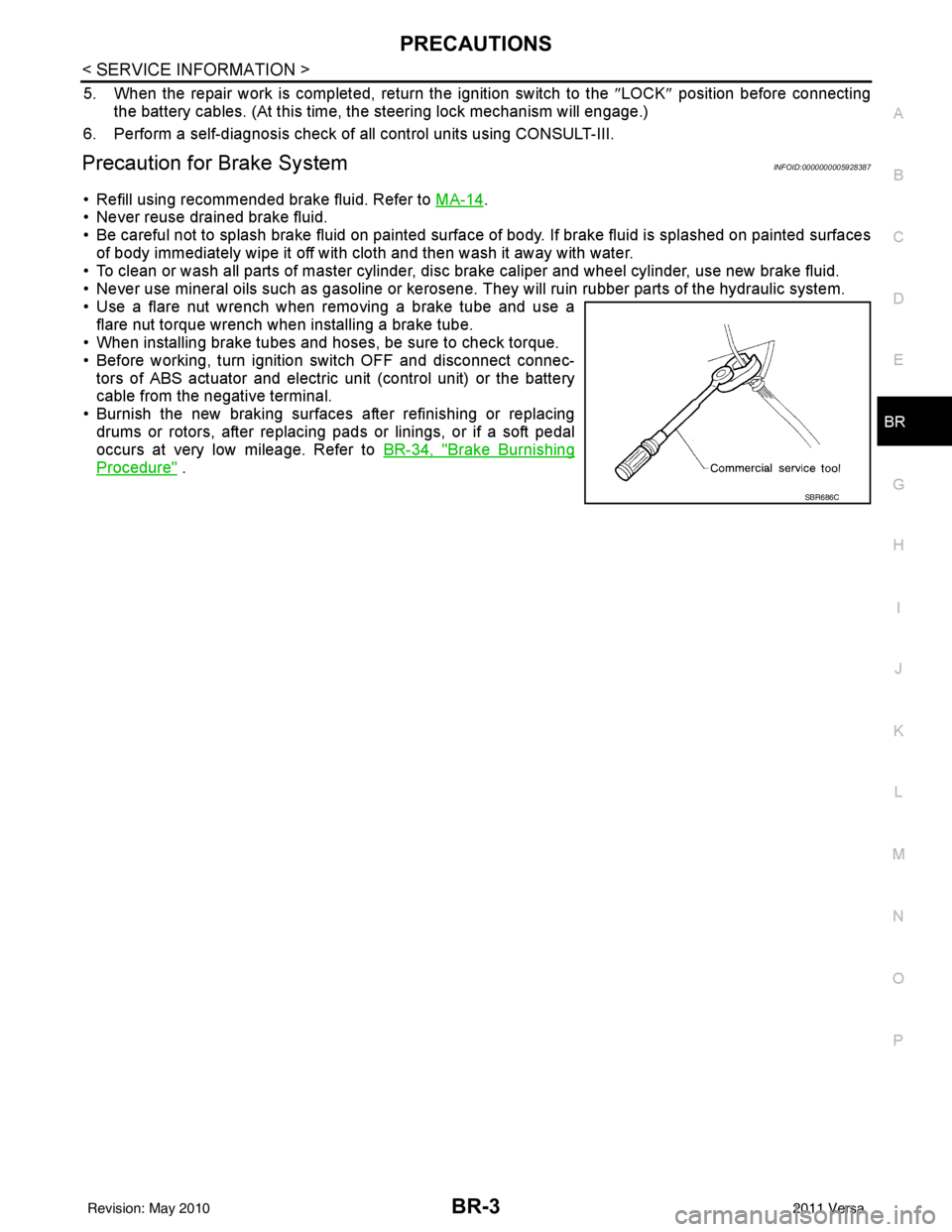

Precaution for Brake SystemINFOID:0000000005928387

• Refill using recommended brake fluid. Refer to MA-14.

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted surface of body. If brake fluid is splashed on painted surfaces of body immediately wipe it off with cloth and then wash it away with water.

• To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use new brake fluid.

• Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

• Use a flare nut wrench when removing a brake tube and use a flare nut torque wrench when installing a brake tube.

• When installing brake tubes and hoses, be sure to check torque.

• Before working, turn igniti on switch OFF and disconnect connec-

tors of ABS actuator and electric unit (control unit) or the battery

cable from the negative terminal.

• Burnish the new braking surfaces after refinishing or replacing drums or rotors, after replacing p ads or linings, or if a soft pedal

occurs at very low mileage. Refer to BR-34, "

Brake Burnishing

Procedure" .

SBR686C

Revision: May 2010 2011 Versa

Page 856 of 3787

BRAKE FLUIDBR-9

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE FLUID

On Board InspectionINFOID:0000000005928393

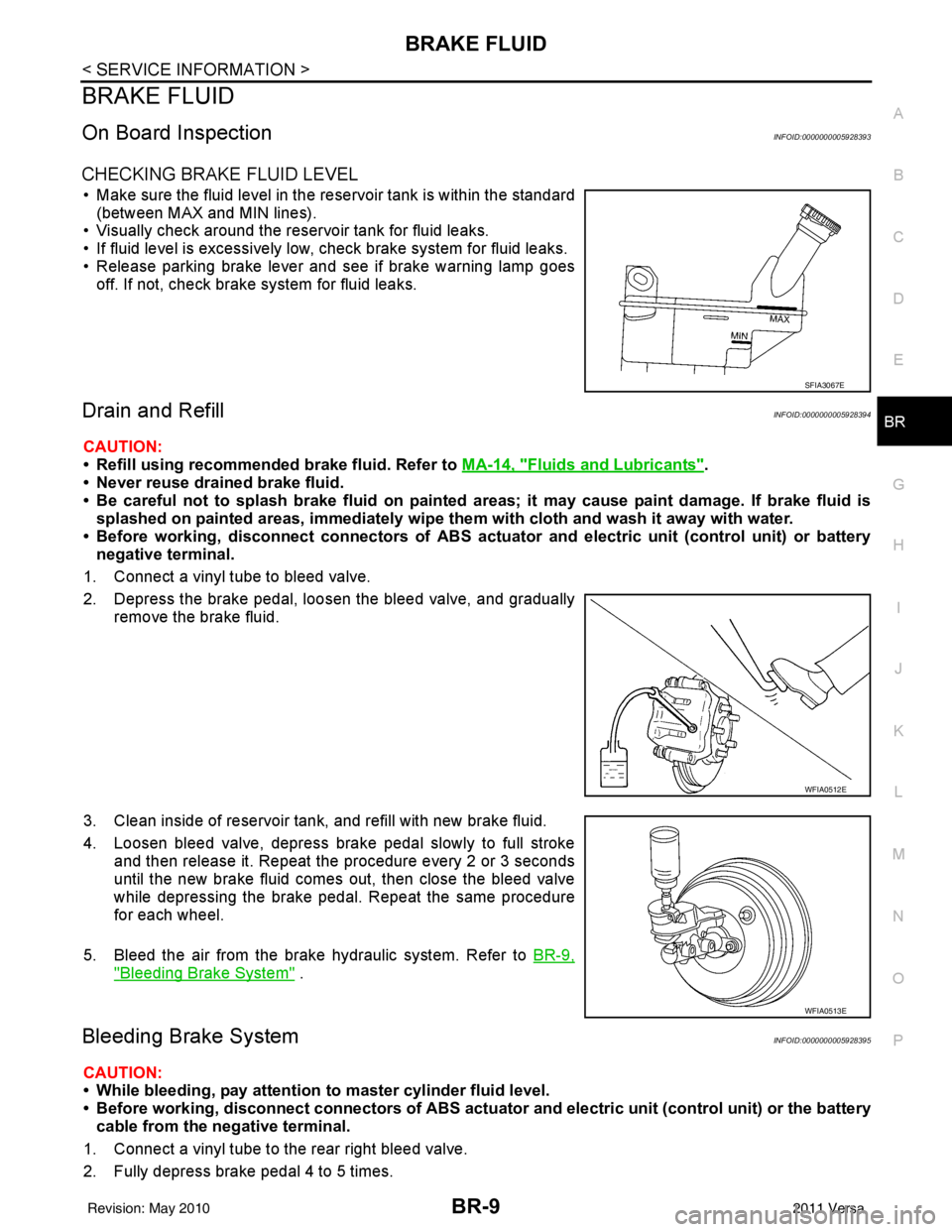

CHECKING BRAKE FLUID LEVEL

• Make sure the fluid level in the reservoir tank is within the standard (between MAX and MIN lines).

• Visually check around the reservoir tank for fluid leaks.

• If fluid level is excessively low, check brake system for fluid leaks.

• Release parking brake lever and see if brake warning lamp goes off. If not, check brake system for fluid leaks.

Drain and RefillINFOID:0000000005928394

CAUTION:

• Refill using recommended brake fluid. Refer to MA-14, "

Fluids and Lubricants".

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe th em with cloth and wash it away with water.

• Before working, disconnect connect ors of ABS actuator and electric unit (control unit) or battery

negative terminal.

1. Connect a vinyl tube to bleed valve.

2. Depress the brake pedal, loosen the bleed valve, and gradually remove the brake fluid.

3. Clean inside of reservoir tank, and refill with new brake fluid.

4. Loosen bleed valve, depress brake pedal slowly to full stroke and then release it. Repeat the procedure every 2 or 3 seconds

until the new brake fluid comes out, then close the bleed valve

while depressing the brake pedal . Repeat the same procedure

for each wheel.

5. Bleed the air from the brake hydraulic system. Refer to BR-9,

"Bleeding Brake System" .

Bleeding Brake SystemINFOID:0000000005928395

CAUTION:

• While bleeding, pay attention to master cylinder fluid level.

• Before working, disconnect connectors of ABS actuator and electri c unit (control unit) or the battery

cable from the negative terminal.

1. Connect a vinyl tube to the rear right bleed valve.

2. Fully depress brake pedal 4 to 5 times.

SFIA3067E

WFIA0512E

WFIA0513E

Revision: May 2010 2011 Versa

Page 858 of 3787

BRAKE TUBE AND HOSEBR-11

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE TUBE AND HOSE

Hydraulic CircuitINFOID:0000000005928396

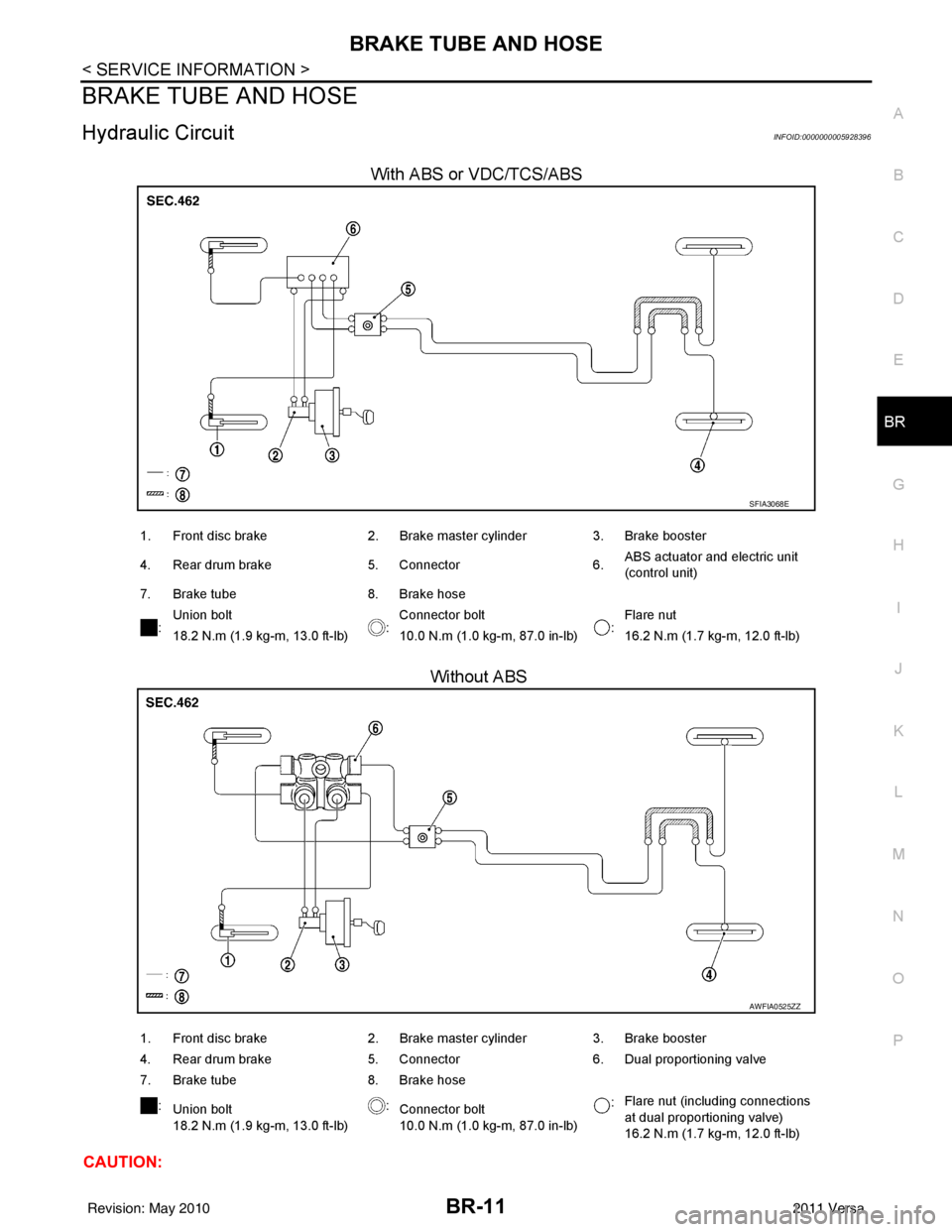

With ABS or VDC/TCS/ABS

Without ABS

CAUTION:

SFIA3068E

1. Front disc brake 2. Brake master cylinder3. Brake booster

4. Rear drum brake 5. Connector6.ABS actuator and electric unit

(control unit)

7. Brake tube 8. Brake hose

: Union bolt

:Connector bolt

:Flare nut

18.2 N.m (1.9 kg-m, 13.0 ft-lb) 10.0 N.m (1.0 kg-m, 87.0 in-lb) 16.2 N.m (1.7 kg-m, 12.0 ft-lb)

AWFIA0525ZZ

1. Front disc brake 2. Brake master cylinder3. Brake booster

4. Rear drum brake 5. Connector6. Dual proportioning valve

7. Brake tube 8. Brake hose

: Union bolt

18.2 N.m (1.9 kg-m, 13.0 ft-lb) :

Connector bolt

10.0 N.m (1.0 kg-m, 87.0 in-lb) :

Flare nut (including connections

at dual proportioning valve)

16.2 N.m (1.7 kg-m, 12.0 ft-lb)

Revision: May 2010

2011 Versa

Page 887 of 3787

BR-40

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005928420

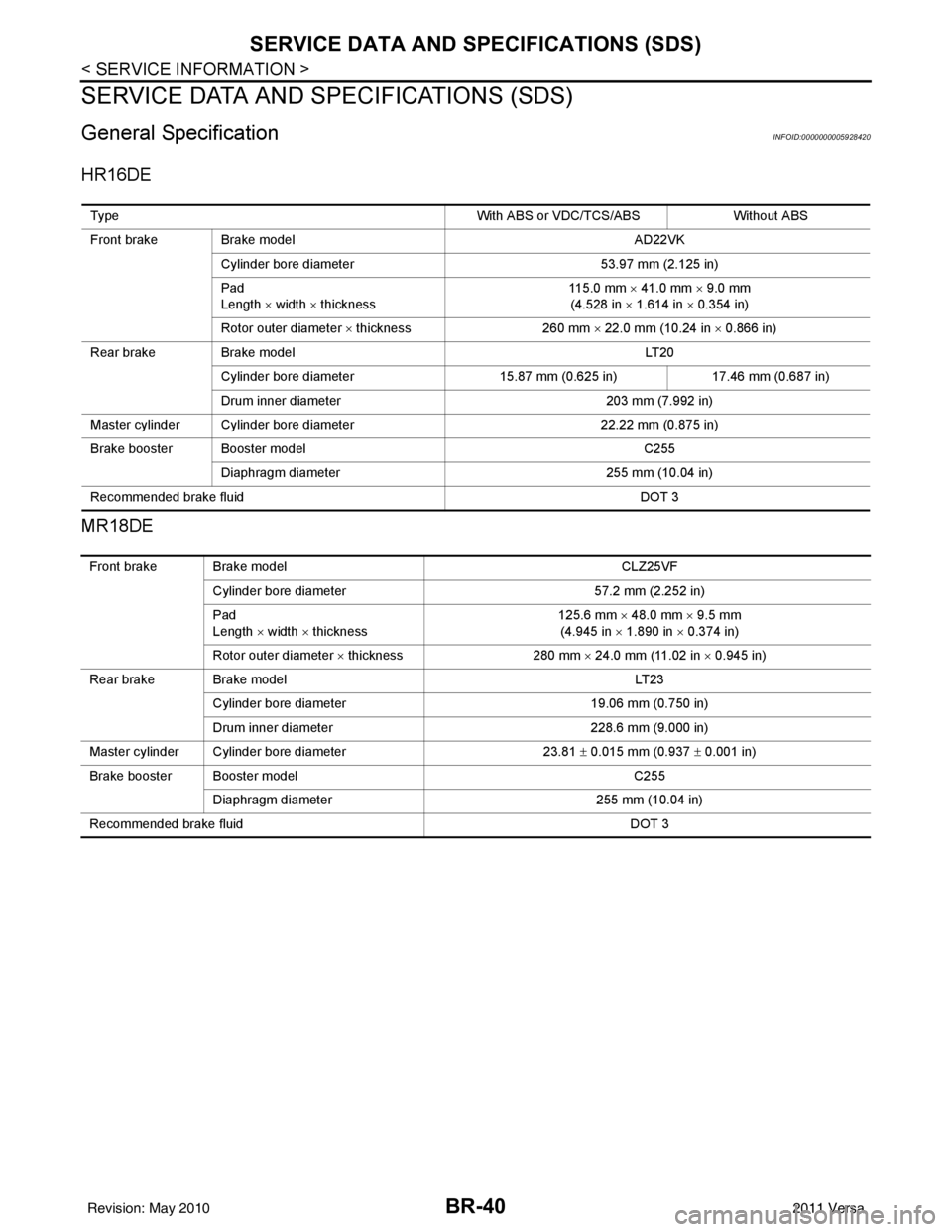

HR16DE

MR18DE

TypeWith ABS or VDC/TCS/ABSWithout ABS

Front brake Brake model AD22VK

Cylinder bore diameter 53.97 mm (2.125 in)

Pad

Length × width × thickness 115.0 mm ×

41.0 mm × 9.0 mm

(4.528 in × 1.614 in × 0.354 in)

Rotor outer diameter × thickness 260 mm × 22.0 mm (10.24 in × 0.866 in)

Rear brake Brake model LT20

Cylinder bore diameter 15.87 mm (0.625 in)17.46 mm (0.687 in)

Drum inner diameter 203 mm (7.992 in)

Master cylinder Cylinder bore diameter 22.22 mm (0.875 in)

Brake booster Booster model C255

Diaphragm diameter 255 mm (10.04 in)

Recommended brake fluid DOT 3

Front brake Brake modelCLZ25VF

Cylinder bore diameter 57.2 mm (2.252 in)

Pad

Length × width × thickness 125.6 mm

× 48.0 mm × 9.5 mm

(4.945 in × 1.890 in × 0.374 in)

Rotor outer diameter × thickness 280 mm × 24.0 mm (11.02 in × 0.945 in)

Rear brake Brake model LT23

Cylinder bore diameter 19.06 mm (0.750 in)

Drum inner diameter 228.6 mm (9.000 in)

Master cylinder Cylinder bore diameter 23.81 ± 0.015 mm (0.937 ± 0.001 in)

Brake booster Booster model C255

Diaphragm diameter 255 mm (10.04 in)

Recommended brake fluid DOT 3

Revision: May 2010 2011 Versa

Page 890 of 3787

BRC-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BRC

A

B

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

ABS

SERVICE INFORMATION .. ..........................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Brake System ....................................3

Precaution for Brake Control .....................................4

Precaution for CAN System ................................ ......4

PREPARATION ...................................................5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SYSTEM DESCRIPTION .....................................6

System Component ............................................. ......6

ABS Function ............................................................6

EBD Function ............................................................6

Fail-Safe Function .....................................................6

Hydraulic Circuit Diagram .........................................7

CAN COMMUNICATION ................................ .....8

System Description ............................................. ......8

TROUBLE DIAGNOSIS ......................................9

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ........................................................

9

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

12

Schematic ...............................................................13

Wiring Diagram - ABS - ...........................................14

Basic Inspection .................................................. ....17

Warning Lamp and Indicator Timing .......................18

Control Unit Input/Output Signal Standard ..............18

CONSULT-III Function (ABS) .................................19

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS ..................................................

25

Wheel Sensor System .............................................25

ABS Control Unit Inspection ....................................26

Solenoid Valve System Inspection ...................... ....26

Actuator Motor, Motor Relay, and Circuit Inspec-

tion ....................................................................... ....

27

ABS Control Unit Power and Ground Systems In-

spection ...................................................................

28

CAN Communication System Inspection .................29

TROUBLE DIAGNOSES FOR SYMPTOMS .....30

ABS Works Frequently ............................................30

Unexpected Pedal Action ........................................30

Long Stopping Distance ..........................................31

ABS Does Not Work ................................................31

Pedal Vibration or ABS Operation Noise .................31

WHEEL SENSORS ...........................................33

Removal and Installation ..................................... ....33

SENSOR ROTOR ..............................................35

Removal and Installation .........................................35

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) ..................................................................

36

Removal and Installation .........................................36

VDC/TCS/ABS

SERVICE INFORMATION .. .........................

38

PRECAUTIONS .................................................38

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

38

Precautions Necessary for Steering Wheel Rota-

tion after Battery Disconnect ...................................

38

Precaution for Brake System ...................................39

Precaution for Brake Control ...................................39

Precaution for CAN System .....................................40

PREPARATION .................................................41

Special Service Tool ................................................41

Commercial Service Tool ........................................41

SYSTEM DESCRIPTION ..................................42

Revision: May 2010 2011 Versa

Page 891 of 3787

BRC-2

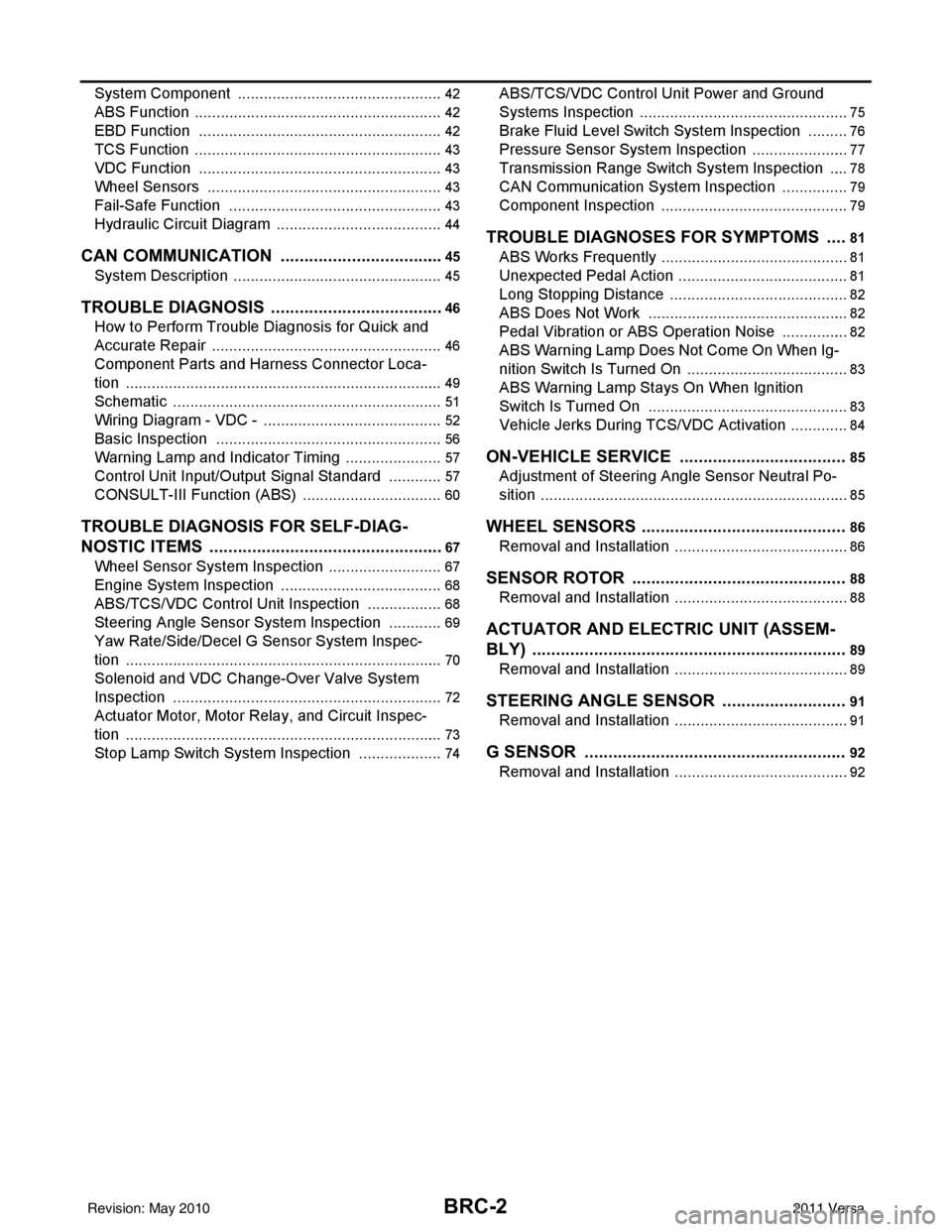

System Component ................................................42

ABS Function ....................................... ...................42

EBD Function ...................................................... ...42

TCS Function ..........................................................43

VDC Function .........................................................43

Wheel Sensors .......................................................43

Fail-Safe Function ..................................................43

Hydraulic Circuit Diagram .......................................44

CAN COMMUNICATION ...................................45

System Description .................................................45

TROUBLE DIAGNOSIS .....................................46

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ................................................... ...

46

Component Parts and Harness Connector Loca-

tion ..........................................................................

49

Schematic ...............................................................51

Wiring Diagram - VDC - ..........................................52

Basic Inspection .....................................................56

Warning Lamp and Indicator Timing .......................57

Control Unit Input/Output Signal Standard .............57

CONSULT-III Function (ABS) .................................60

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS ............................................... ...

67

Wheel Sensor System Inspection ...........................67

Engine System Inspection ................................... ...68

ABS/TCS/VDC Control Unit Inspection ..................68

Steering Angle Sensor System Inspection .......... ...69

Yaw Rate/Side/Decel G Sensor System Inspec-

tion ....................................................................... ...

70

Solenoid and VDC Change-Over Valve System

Inspection ...............................................................

72

Actuator Motor, Motor Relay, and Circuit Inspec-

tion ....................................................................... ...

73

Stop Lamp Switch System Inspection ....................74

ABS/TCS/VDC Control Unit Power and Ground

Systems Inspection .............................................. ...

75

Brake Fluid Level Switch System Inspection ..........76

Pressure Sensor System Inspection .......................77

Transmission Range Switch System Inspection .. ...78

CAN Communication System Inspection ................79

Component Inspection ............................................79

TROUBLE DIAGNOSES FOR SYMPTOMS .....81

ABS Works Frequently ............................................81

Unexpected Pedal Action ..................................... ...81

Long Stopping Distance ..........................................82

ABS Does Not Work ...............................................82

Pedal Vibration or ABS Op eration Noise ................82

ABS Warning Lamp Does Not Come On When Ig-

nition Switch Is Turned On ................................... ...

83

ABS Warning Lamp Stays On When Ignition

Switch Is Turned On ............................................ ...

83

Vehicle Jerks During TCS/VDC Activation ..............84

ON-VEHICLE SERVICE ....................................85

Adjustment of Steering Angle Sensor Neutral Po-

sition ..................................................................... ...

85

WHEEL SENSORS ............................................86

Removal and Installation .........................................86

SENSOR ROTOR ........................................... ...88

Removal and Installation .........................................88

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) ................................................................ ...

89

Removal and Installation .........................................89

STEERING ANGLE SENSOR ........................ ...91

Removal and Installation .........................................91

G SENSOR ........................................................92

Removal and Installation .........................................92

Revision: May 2010 2011 Versa

Page 892 of 3787

![NISSAN LATIO 2011 Service User Guide PRECAUTIONSBRC-3

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSI NISSAN LATIO 2011 Service User Guide PRECAUTIONSBRC-3

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSI](/img/5/57357/w960_57357-891.png)

PRECAUTIONSBRC-3

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928426

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution for Brake SystemINFOID:0000000005928427

CAUTION:

• Refer to MA-14

for recommended brake fluid.

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• To clean or wash all parts of master cylin der and disc brake caliper, use clean brake fluid.

• Never use mineral oils such as gasoline or kerosen e. They will ruin rubber parts of the hydraulic sys-

tem.

• Use flare nut wrench when removing and installing brake tube.

• If a brake fluid leak is found, the part must be disassembled

without fail. Then it has to be replaced with a new one if a

defect exists.

• Turn the ignition switch OFF and remove the connector of the

ABS actuator and electric unit (con trol unit) or the battery ter-

minal before performing the work.

• Always torque brake lines when installing.

• Burnish the brake contact surf aces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage. Refer to BR-34, "

Brake Burnishing Proce-

dure".

WARNING:

• Clean brake pads and shoes with a waste cl oth, then wipe with a dust collector.

SBR686C

Revision: May 2010 2011 Versa