checking oil NISSAN LATIO 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 242 of 3787

ON-VEHICLE SERVICEAT-225

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

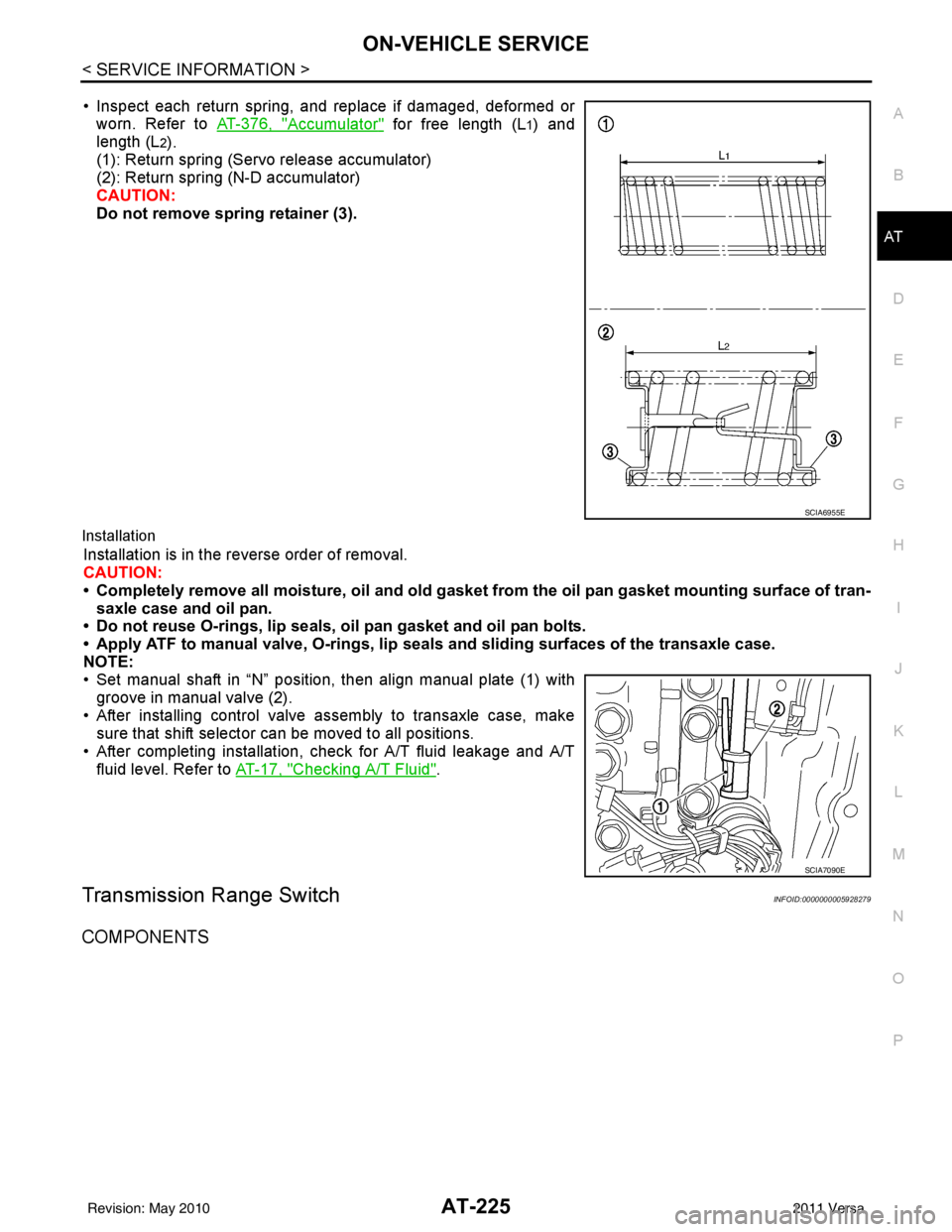

• Inspect each return spring, and replace if damaged, deformed or worn. Refer to AT-376, "

Accumulator" for free length (L1) and

length (L

2).

(1): Return spring (Servo release accumulator)

(2): Return spring (N-D accumulator)

CAUTION:

Do not remove spring retainer (3).

Installation

Installation is in the reverse order of removal.

CAUTION:

• Completely remove all moisture, oil and old gasket from the oil pan gasket mounting surface of tran-

saxle case and oil pan.

• Do not reuse O-rings, lip seals, oil pan gasket and oil pan bolts.

• Apply ATF to manual valve, O-rings, lip seals and sliding surfaces of the transaxle case.

NOTE:

• Set manual shaft in “N” position, then align manual plate (1) with groove in manual valve (2).

• After installing control valve assembly to transaxle case, make sure that shift selector can be moved to all positions.

• After completing installation, check for A/T fluid leakage and A/T fluid level. Refer to AT-17, "

Checking A/T Fluid".

Transmission Range SwitchINFOID:0000000005928279

COMPONENTS

SCIA6955E

SCIA7090E

Revision: May 2010 2011 Versa

Page 248 of 3787

ON-VEHICLE SERVICEAT-231

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

• After installing differential side oil seal, check A/T fluid leakage and A/T fluid level. Refer to AT-17, "Checking

A/T Fluid".

Revision: May 2010 2011 Versa

Page 1014 of 3787

![NISSAN LATIO 2011 Service User Guide CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000005930779

• Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the e NISSAN LATIO 2011 Service User Guide CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000005930779

• Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the e](/img/5/57357/w960_57357-1013.png)

CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000005930779

• Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

• Pull negative-pressure valve to open it, and make sure that it is completely closed when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that the valve operates properly in the opening and closing conditions.

• Check radiator cap relief pressure using suitable tool and Tool.

- When connecting the radiator cap to the tester, apply water or coolant to the cap seal surface.

- Replace the radiator cap if ther e is an abnormality in the negative-

pressure valve, or if the open-valve pr essure is outside of the standard values.

• Replace radiator cap if there it does not comply to specifications to the above three checks.

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

Checking RadiatorINFOID:0000000005930780

Check radiator for mud or clogging. If necessary, clean radiator as follows.

• Be careful not to bend or damage radiator fins.

• When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

PBIC2816E

SMA967B

Tool number : EG17650301 (J-33984-A)

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm

2, 11

– 14 psi)

Limit: 59 kPa (0.59 bar, 0.6 kg/cm

2, 9 psi)

WBIA0570E

Revision: May 2010 2011 Versa

Page 1023 of 3787

![NISSAN LATIO 2011 Service User Guide THERMOSTATCO-23

< ON-VEHICLE REPAIR > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

• Install thermostat (2) into the cylinder block (1) with jiggle valve (A)

facing upwards.

Water Inlet.

After installa NISSAN LATIO 2011 Service User Guide THERMOSTATCO-23

< ON-VEHICLE REPAIR > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

• Install thermostat (2) into the cylinder block (1) with jiggle valve (A)

facing upwards.

Water Inlet.

After installa](/img/5/57357/w960_57357-1022.png)

THERMOSTATCO-23

< ON-VEHICLE REPAIR > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

• Install thermostat (2) into the cylinder block (1) with jiggle valve (A)

facing upwards.

Water Inlet.

After installation, fix water inlet clip (A) on the oil level gauge guide

(1) positioned (B) as shown.

InspectionINFOID:0000000005930792

INSPECTION AFTER REMOVAL

WARNING:

Use a protector to prevent a burn during the work.

Thermostat

• Place a thread (A) so that it is caught in the valves of thermostat(1). Immerse fully in a container (B) filled with water. Heat while

stirring.

• The valve opening temperature is the temperature at which the valve opens and falls from the thread.

• Continue heating. Check the full-open valve lift amount.

• After checking the full-open valve lift amount, lower the water tem- perature and check the valve closing temperature.

• If out of the standard, replace thermostat.

INSPECTION AFTER INSTALLATION

• Check that the reservoir tank cap is tightened.

• Check for leaks of engine coolant using suitable tools. Refer to CO-11, "

Inspection".

• Start and warm up the engine. Visually make sure that there is no leaks of engine coolant.

PBIC3812E

PBIC3755E

Standard : Refer to CO-26, "Thermostat".

PBIC3314J

Revision: May 2010 2011 Versa

Page 1039 of 3787

![NISSAN LATIO 2011 Service User Guide RADIATORCO-39

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

RADIATOR

Checking Radiator CapINFOID:0000000005930808

• Check valve seat of radiator cap.

- Check if valve seat is swo NISSAN LATIO 2011 Service User Guide RADIATORCO-39

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

RADIATOR

Checking Radiator CapINFOID:0000000005930808

• Check valve seat of radiator cap.

- Check if valve seat is swo](/img/5/57357/w960_57357-1038.png)

RADIATORCO-39

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

RADIATOR

Checking Radiator CapINFOID:0000000005930808

• Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

• Pull negative-pressure valve to open it, and make sure that it is completely closed when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that the valve operates properly in the opening and closing conditions.

• Check radiator cap relief pressure using suitable tool and Tool.

- When connecting the radiator cap to the tester, apply water or coolant to the cap seal surface.

- Replace the radiator cap if there is an abnormality in the negative- pressure valve, or if the open-valve pressure is outside of the standard values.

• Replace radiator cap if there it does not comply to specifications to the above three checks.

CAUTION:

When installing radiator cap, thor oughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

Checking RadiatorINFOID:0000000005930809

Check radiator for mud or clogging. If necessary, clean radiator as follows.

• Be careful not to bend or damage radiator fins.

• When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

PBIC2816E

SMA967B

Tool number : EG17650301 (J-33984-A)

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm

2, 11

– 14 psi)

Limit: 59 kPa (0.59 bar, 0.6 kg/cm

2, 9 psi)

WBIA0570E

Revision: May 2010 2011 Versa

Page 1059 of 3787

CVT-4

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

135

Wiring Diagram - CVT - ODSW .............................136

Diagnosis Procedure .............................................136

Component Inspection ...........................................138

SHIFT POSITION INDICATOR CIRCUIT ........140

Description ........................................................... ..140

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

140

Diagnosis Procedure .............................................140

TROUBLE DIAGNOSIS FOR SYMPTOMS .....141

Wiring Diagram - CVT - NONDTC ....................... ..141

O/D OFF Indicator Lamp Does Not Come On .......143

Engine Cannot Be Started in "P" and "N" Position ..145

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

145

In "N" Position, Vehicle Moves ............................ ..146

Large Shock "N" → "R" Position .......................... ..146

Vehicle Does Not Creep Backward in "R" Position ..147

Vehicle Does Not Creep Forward in "D" or "L" Po-

sition ......................................................................

148

Vehicle Speed Does Not Change in "L" Position ...149

Vehicle Speed Does Not Change in overdrive-off

mode ......................................................................

150

Vehicle Speed Does Not Change in "D" Position ..151

Vehicle Does Not Decelerate by Engine Brake .....151

CVT SHIFT LOCK SYSTEM ........................... .153

Description ........................................................... ..153

Shift Lock System Electrical Parts Location ..........154

Wiring Diagram - CVT - SHIFT ..............................155

Diagnosis Procedure .............................................155

TCM ..................................................................159

Removal and Installation ..................................... ..159

SHIFT CONTROL SYSTEM ............................160

Removal and Installation ..................................... ..160

CVT Shift Selector Disassembly and Assembly ....163

Shift Selector Handle Removal and Installation ....163

Adjustment of CVT Position ................................. ..164

Checking of CVT Position ......................................164

KEY INTERLOCK CABLE ...............................166

Removal and Installation ..................................... ..166

PRIMARY SPEED SENSOR ...........................169

Exploded View ..................................................... ..169

Removal and Installation .......................................169

Inspection ............................................................. .169

SECONDARY SPEED SENSOR ......................170

Exploded View ..................................................... .170

Removal and Installation .......................................170

Inspection ............................................................. .170

AIR BREATHER HOSE ....................................171

Removal and Installation .......................................171

OIL PAN .......................................................... ..172

Exploded View ..................................................... .172

Removal and Installation .......................................172

Inspection ............................................................. .173

DIFFERENTIAL SIDE OIL SEAL .....................174

Removal and Installation .......................................174

CVT OIL WARMER SYSTEM ......................... ..175

WATER HOSE ........................................................ .175

WATER HOSE : Exploded View ...........................175

WATER HOSE : Removal and Installation ...........175

WATER HOSE : Inspection ..................................176

CVT FLUID COOLER HOSE .................................. .176

CVT FLUID COOLER HOSE : Exploded View .....177

CVT FLUID COOLER HOSE : Removal and In-

stallation ................................................................

177

CVT FLUID COOLER HOSE : Inspection .............179

CVT OIL WARMER ................................................ .179

CVT OIL WARMER : Exploded View ....................179

CVT OIL WARMER : Removal and Installation ....179

CVT OIL WARMER : Inspection .......................... .179

TRANSAXLE ASSEMBLY ...............................180

Removal and Installation .......................................180

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

183

General Specification ........................................... .183

Vehicle Speed When Shifting Gears .....................183

Stall Speed ............................................................183

Line Pressure ........................................................183

Solenoid Valves ....................................................184

CVT Fluid Temperature Sensor ............................184

Primary Speed Sensor ..........................................184

Secondary Speed Sensor .................................... .184

Removal and Installation .......................................184

Revision: May 2010 2011 Versa

Page 1070 of 3787

![NISSAN LATIO 2011 Service User Guide CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 m NISSAN LATIO 2011 Service User Guide CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 m](/img/5/57357/w960_57357-1069.png)

CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 minutes.

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2. Drain CVT fluid from CVT fluid cooler hose [outlet side (1)] and refill with new specified NISSAN CVT fluid in the CVT fluid

charging pipe with the engine running at idle speed.

CAUTION:

Only use the specifi ed NISSAN CVT fluid.

3. Refill until new CVT fluid comes out from CVT fluid cooler hose [outlet side (1)]. NOTE:

About 30 to 50% extra fluid will be required for this procedure.

4. Check fluid level and condition. Refer to CVT-14, "

Checking CVT Fluid".

CAUTION:

Delete CVT fluid deterioration date with CONSULT-III after changing CVT fluid. Refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

CVT Fluid Cooler CleaningINFOID:0000000005928732

Whenever a CVT is repaired, overhauled, or replaced, the CVT fluid cooler mounted in the radiator must be

inspected and cleaned.

Metal debris and friction material, if present, can be trapped or become deposit in the CVT fluid cooler. This

debris can contaminate the newly serviced CVT or, in severe cases, can block or restrict the flow of CVT fluid.

In either case, malfunction of the newly serviced CVT may occur.

Debris, if present, may deposit as CVT fluid enters the cool er inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

CVT FLUID COOLER CLEANING PROCEDURE

1. Identify the CVT inlet and outlet fluid cooler hoses.

2. Position an oil pan under the inlet and outlet cooler hoses.

Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harness, cooler

pipes, etc.)

Milky white or cloudy Water in the fluid Replace the CVT fluid and check for places where water is getting in.

Large amount of

metal powder mixed

in fluid Unusual wear of

sliding parts within

CVTReplace the CVT fluid and check for

improper operation of the CVT.

ATA0022D

Fluid capacity and grade: Refer to

MA-14, "Fluids

and Lubricants".SCIA6088E

Revision: May 2010 2011 Versa

Page 1093 of 3787

![NISSAN LATIO 2011 Service User Guide CVT-38

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

• Inspect for fluid leakage and check the fluid level. Refer to

CVT-14, "Checking CVT Fluid" .

Fluid Condition Check

Inspect the fluid cond NISSAN LATIO 2011 Service User Guide CVT-38

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

• Inspect for fluid leakage and check the fluid level. Refer to

CVT-14, "Checking CVT Fluid" .

Fluid Condition Check

Inspect the fluid cond](/img/5/57357/w960_57357-1092.png)

CVT-38

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

• Inspect for fluid leakage and check the fluid level. Refer to

CVT-14, "Checking CVT Fluid" .

Fluid Condition Check

Inspect the fluid condition.

STALL TEST

Stall Test Procedure

1. Inspect the amount of engine oil. Replenish the engine oil if necessary.

2. Drive for about 10 minutes to warm up the vehicle so that the

CVT fluid temperature is 50 to 80 °C (122 to 176° F). Inspect the

amount of CVT fluid. Replenish if necessary.

3. Securely engage the parking brake so that the tires do not turn.

4. Install a tachometer where it can be seen by driver during test. •It is good practice to mark the point of specified engine

rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in “D” position.

Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harnesses, cool-

er pipes, etc.)

Milky white or

cloudy Water in the fluidReplace the CVT fluid and check for

places where water is getting in.

Large amount of

metal powder mixed

in Unusual wear of

sliding parts within

CVT

Replace the CVT fluid and check for

improper operation of the CVT.

SAT638A

SAT647B

SAT513G

SAT775B

Revision: May 2010

2011 Versa

Page 1228 of 3787

![NISSAN LATIO 2011 Service User Guide OIL PANCVT-173

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• Never reuse oil pan gasket and drain plug gasket.

• Completely remove all moisture, oil and old gasket, etc. f NISSAN LATIO 2011 Service User Guide OIL PANCVT-173

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• Never reuse oil pan gasket and drain plug gasket.

• Completely remove all moisture, oil and old gasket, etc. f](/img/5/57357/w960_57357-1227.png)

OIL PANCVT-173

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• Never reuse oil pan gasket and drain plug gasket.

• Completely remove all moisture, oil and old gasket, etc. from the oil pan gasket mounting surface of

transaxle case and oil pan.

InspectionINFOID:0000000006413340

INSPECTION AFTER REMOVAL

Check oil pan for foreign material.

• If a large amount of worn material is found, clutch plate may be worn.

• If iron powder is found, bearings, gears, or clutch plates may be worn.

• If aluminum powder is found, bushing may be worn, or ch ips or burrs of aluminum casting parts may enter.

Check points where wear is found in all cases.

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage and check CVT fluid level. Refer to CVT-14, "Checking CVT Fluid".

Revision: May 2010 2011 Versa

Page 1229 of 3787

![NISSAN LATIO 2011 Service User Guide CVT-174

< SERVICE INFORMATION >[RE0F08B]

DIFFERENTIAL SIDE OIL SEAL

DIFFERENTIAL SIDE OIL SEAL

Removal and InstallationINFOID:0000000005928975

COMPONENTS

REMOVAL

1. Remove drive shaft assembly. Refer NISSAN LATIO 2011 Service User Guide CVT-174

< SERVICE INFORMATION >[RE0F08B]

DIFFERENTIAL SIDE OIL SEAL

DIFFERENTIAL SIDE OIL SEAL

Removal and InstallationINFOID:0000000005928975

COMPONENTS

REMOVAL

1. Remove drive shaft assembly. Refer](/img/5/57357/w960_57357-1228.png)

CVT-174

< SERVICE INFORMATION >[RE0F08B]

DIFFERENTIAL SIDE OIL SEAL

DIFFERENTIAL SIDE OIL SEAL

Removal and InstallationINFOID:0000000005928975

COMPONENTS

REMOVAL

1. Remove drive shaft assembly. Refer to

FAX-9.

2. Remove differential side oil seal using a suitable tool. CAUTION:

Do not scratch transaxle case or converter housing.

INSTALLATION

1. Drive the new differential side oil seal into the transaxle caseside (B) and converter housing side (C) until it is flush using

Tool.

Unit: mm (in)

CAUTION:

• Do not reuse differential side oil seals.

• Apply specified NISSAN CVT fluid to side oil seals.

2. Install drive shaft assembly. Refer to FA X - 9

.

3. Check CVT fluid level and leakage. Refer to CVT-14, "

Checking CVT Fluid".

1. CVT2. Differential side oil seal : Apply CVT Fluid NS-2.

WCIA0610E

SCIA2412E

Tool number : — (J-47244)

: ST33400001 (J-47005)

Dimensions (A) 0±0.5 (0 ±0.020)

WCIA0611E

Revision: May 2010 2011 Versa