wheel size NISSAN LATIO 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 2704 of 3787

SERVICE DATA AND SPECIFICATIONS (SDS)FSU-19

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

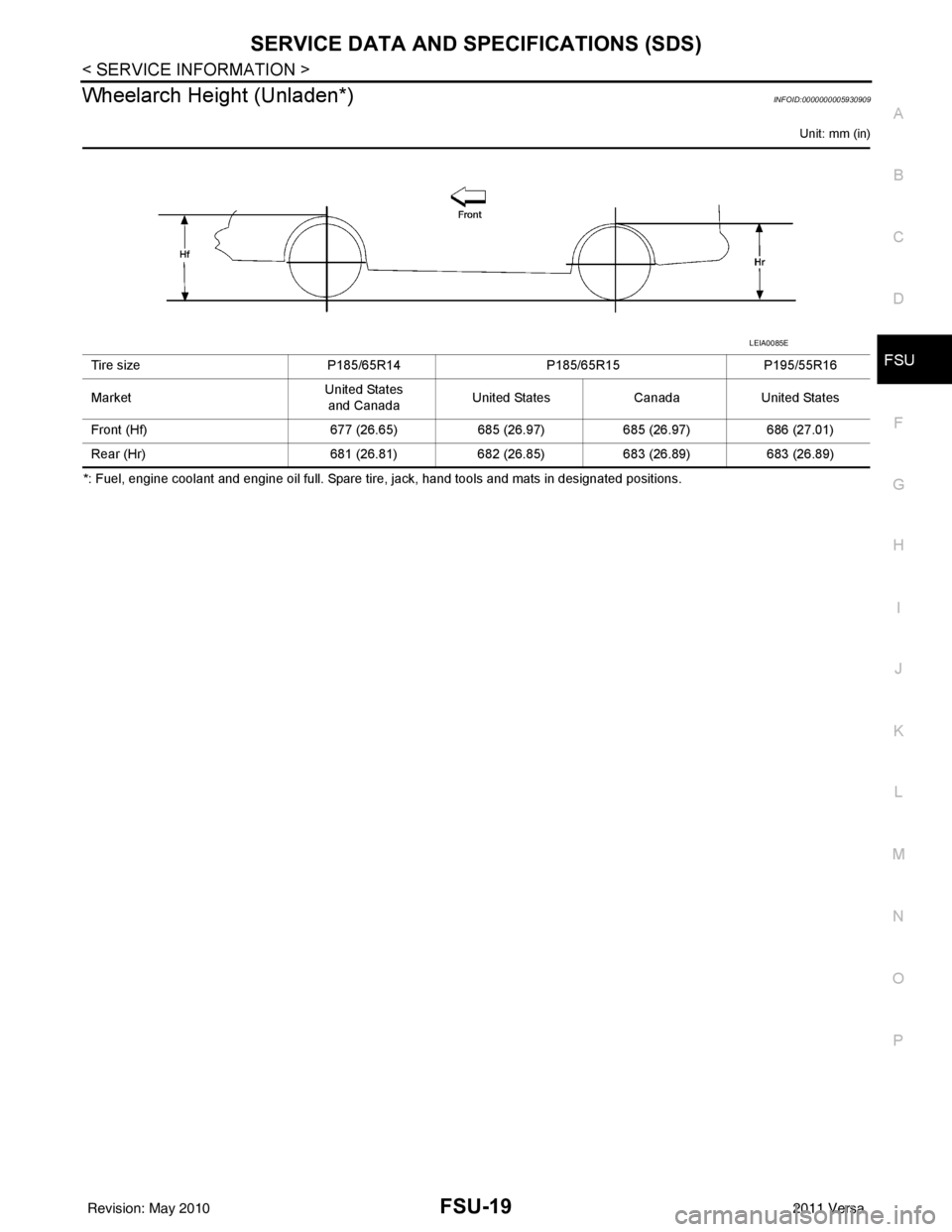

Wheelarch Height (Unladen*)INFOID:0000000005930909

Unit: mm (in)

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions. Tire size

P185/65R14P185/65R15P195/55R16

Market United States

and Canada United States

CanadaUnited States

Front (Hf) 677 (26.65)685 (26.97)685 (26.97)686 (27.01)

Rear (Hr) 681 (26.81)682 (26.85)683 (26.89)683 (26.89)

LEIA0085E

Revision: May 2010 2011 Versa

Page 2750 of 3787

GI-46

< SERVICE INFORMATION >

IDENTIFICATION INFORMATION

CVT NUMBER

DimensionsINFOID:0000000005929741

Unit: mm (in)

Wheels & TiresINFOID:0000000005929742

HR16DE

MR18DE

LAIA0074E

Overall lengthHatchback: 4,295 (169.1) Sedan: 4470 (176.0)

Overall width 1,695 (66.7)

Overall height 1,540 (60.6)

Front tread 1,480 (58.3)

Rear tread 1,485 (58.5)

Wheelbase 2,600 (102.4)

Road wheel St ee l

Size 14 x 5.0 JJ

Offset mm (in)40 (1.57)

Tire size

Conventional P185/65R14

Spare T125/70D15

Road wheel St ee l

Size 15 x 5.5 JJ

Offset mm (in)40 (1.57)

Road wheel Aluminum

Size 15 x 5.5 JJ

Offset mm (in)40 (1.57)

Road wheel Aluminum

Size 16 X 6.0 J

Offset mm (in)40 (1.57)

Tire size

Conventional P185/65R15

P195/55R16

Spare T125/70D15

Revision: May 2010 2011 Versa

Page 3214 of 3787

CHASSIS AND BODY MAINTENANCEMA-43

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

Do not overfill.

4. Drive vehicle for approximately 5 minutes.

5. Re-check A/T fluid level at A/T fluid temperatures of 50° to 80 °C (122° to 176°F) using “HOT” range on A/

T fluid level gauge.

CAUTION:

• When wiping the A/T fluid level gauge, always use lint-free cloth.

• Firmly fix the A/T fluid level ga uge to the A/T fluid charging pipe using the stopper attached.

6. Check A/T fluid condition and make any necessary repairs. Refer to AT-51, "

Inspections Before Trouble

Diagnosis". If the A/T fluid contains frictional material (clutches, bands, etc.), or if the A/T is repaired, over-

hauled, or replaced, inspect and clean the A/T fluid cooler mounted in the radiator. Refer to AT-18, "

A/T

Fluid Cooler Cleaning".

7. Install the removed A/T fluid level gauge into the A/T fluid charging pipe. CAUTION:

Firmly fix the A/T fluid level gaug e to the A/T fluid charging pipe using the stopper attached.

A/T FLUID : Changing A/T FluidINFOID:0000000005931176

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid by removing the drain plug. Re install the drain plug to the specified torque.

CAUTION:

Do not reuse drain plug gasket.

4. Refill the transaxle with new specified A/T fluid through the A/T fluid charging pipe. Always refill the tran- saxle with the same volume of A/T fluid that was drained out.

5. Run engine at idle speed for 5 minutes.

6. Check A/T fluid level and condition. Refer to MA-42, "

A/T FLUID : Checking A/T Fluid".

WHEELS

WHEELS : AdjustmentINFOID:0000000006413331

BALANCING WHEELS (ADHESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the r oad wheel using releasing agent, remove double-faced

adhesive tape from the road wheel.

CAUTION:

• Be careful not scratch the road wheel during removal.

• After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road

wheel.

Wheel Balance Adjustment

• If a balancer machine has an adhesive weight mode setting, select the adhesive weight mode setting and skip Step 2. below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2.

to calculate the correct size adhesive weight.

1. Set road wheel on balancer machine using the cent er hole as a guide. Start the balancer machine.

2. For tire balance machines that only have a clip-on (ri m flange) weight mode setting, follow this step to cal-

culate the correct size adhesive weight to use. When inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of, or at the designated angle in relation to the road wheel.

Drain plug: Refer to

AT-237, "

Component".

Fluid grade and capacity: Refer to MA-14

.

Revision: May 2010 2011 Versa

Page 3566 of 3787

SERVICE DATA AND SPECIFICATIONS (SDS)RSU-13

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

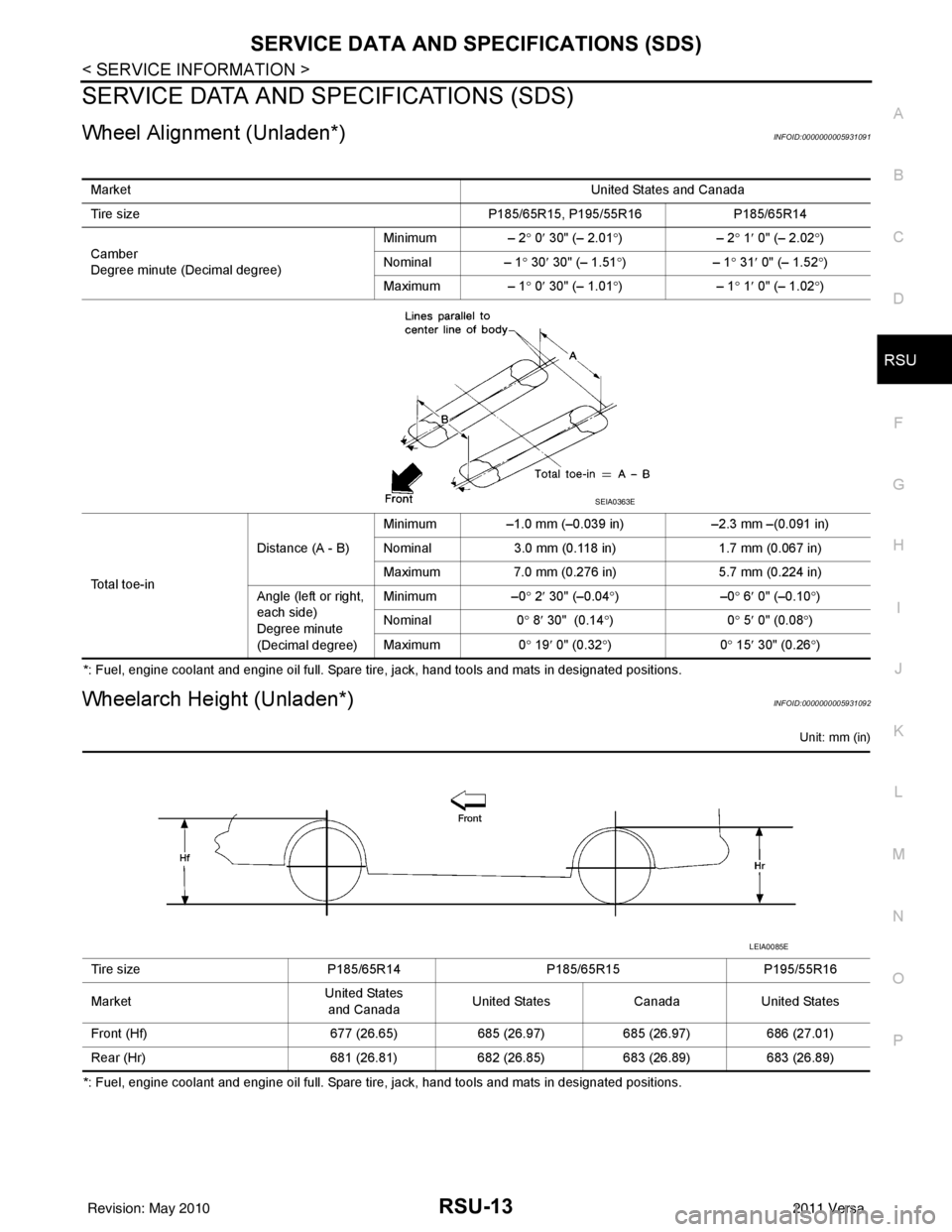

Wheel Alignment (Unladen*)INFOID:0000000005931091

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Wheelarch Height (Unladen*)INFOID:0000000005931092

Unit: mm (in)

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions. Market

United States and Canada

Tire size P185/65R15, P195/55R16 P185/65R14

Camber

Degree minute (Decimal degree) Minimum – 2°

0′ 30" (– 2.01 °)– 2 ° 1 ′ 0" (– 2.02 °)

Nominal – 1 ° 30 ′ 30" (– 1.51 °)– 1° 31 ′ 0" (– 1.52 °)

Maximum – 1° 0′ 30" (– 1.01 °)– 1° 1 ′ 0" (– 1.02 °)

To t a l t o e - i n Distance (A - B)

Minimum

–1.0 mm (–0.039 in) –2.3 mm –(0.091 in)

Nominal 3.0 mm (0.118 in) 1.7 mm (0.067 in)

Maximum 7.0 mm (0.276 in) 5.7 mm (0.224 in)

Angle (left or right,

each side)

Degree minute

(Decimal degree) Minimum

–0° 2 ′ 30" (–0.04 °)– 0° 6 ′ 0" (–0.10 °)

Nominal 0° 8 ′ 30" (0.14 °)0 ° 5 ′ 0" (0.08 °)

Maximum 0° 19 ′ 0" (0.32 °)0 ° 15 ′ 30" (0.26 °)

SEIA0363E

Tire size P185/65R14P185/65R15P195/55R16

Market United States

and Canada United States

CanadaUnited States

Front (Hf) 677 (26.65)685 (26.97)685 (26.97)686 (27.01)

Rear (Hr) 681 (26.81)682 (26.85)683 (26.89)683 (26.89)

LEIA0085E

Revision: May 2010 2011 Versa

Page 3718 of 3787

![NISSAN LATIO 2011 Service User Guide PRECAUTIONSSTC-31

< PRECAUTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cab NISSAN LATIO 2011 Service User Guide PRECAUTIONSSTC-31

< PRECAUTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cab](/img/5/57357/w960_57357-3717.png)

PRECAUTIONSSTC-31

< PRECAUTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Service Notice or Precaution for EPS SystemINFOID:0000000005931271

CAUTION:

Check or confirm the following item wh en performing the trouble diagnosis.

• Check any possible causes by interviewing the symptom and it’s condition from the customer if any

malfunction, such as EPS warn ing lamp turns ON, occurs.

• Check if air pressure and size of tires are proper, the specified part is used for the steering wheel,

and control unit is genuine part.

• Check if the connection of steer ing column assembly and steering gear assembly is proper (there is

not looseness of mounting bolts, damage of rods, boots or sealants, and leakage of grease, etc).

• Check if the wheel alignment is adjusted properly.

• Check if there is any damage or modification to su spension or body resulting in increased weight or

altered ground clearance.

• Check if installation conditions of each link and suspension are proper.

• Check if the battery voltage is proper

• Check connection conditions of each connector are proper.

• Before connecting or disconnect ing the EPS control unit har-

ness connector, turn ignition switch “OFF” and disconnect

battery ground cable. Because battery voltage is applied to

EPS control unit even if igniti on switch is turned “OFF”.

• When connecting or disconnect ing pin connectors into or

from EPS control unit, take care not to damage pin terminals

(bend or break).

When connecting pin connectors, make sure that there are no

bends or breaks on EPS control unit pin terminal.

• Before replacing EPS control unit, perform EPS control unit input/output signal inspectio n and make sure whether EPS

control unit functions properly or not. Refer to STC-20, "

Ref-

erence Value".

SEF289H

SEF291H

SDIA1848E

Revision: May 2010 2011 Versa

Page 3723 of 3787

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGWT-5

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

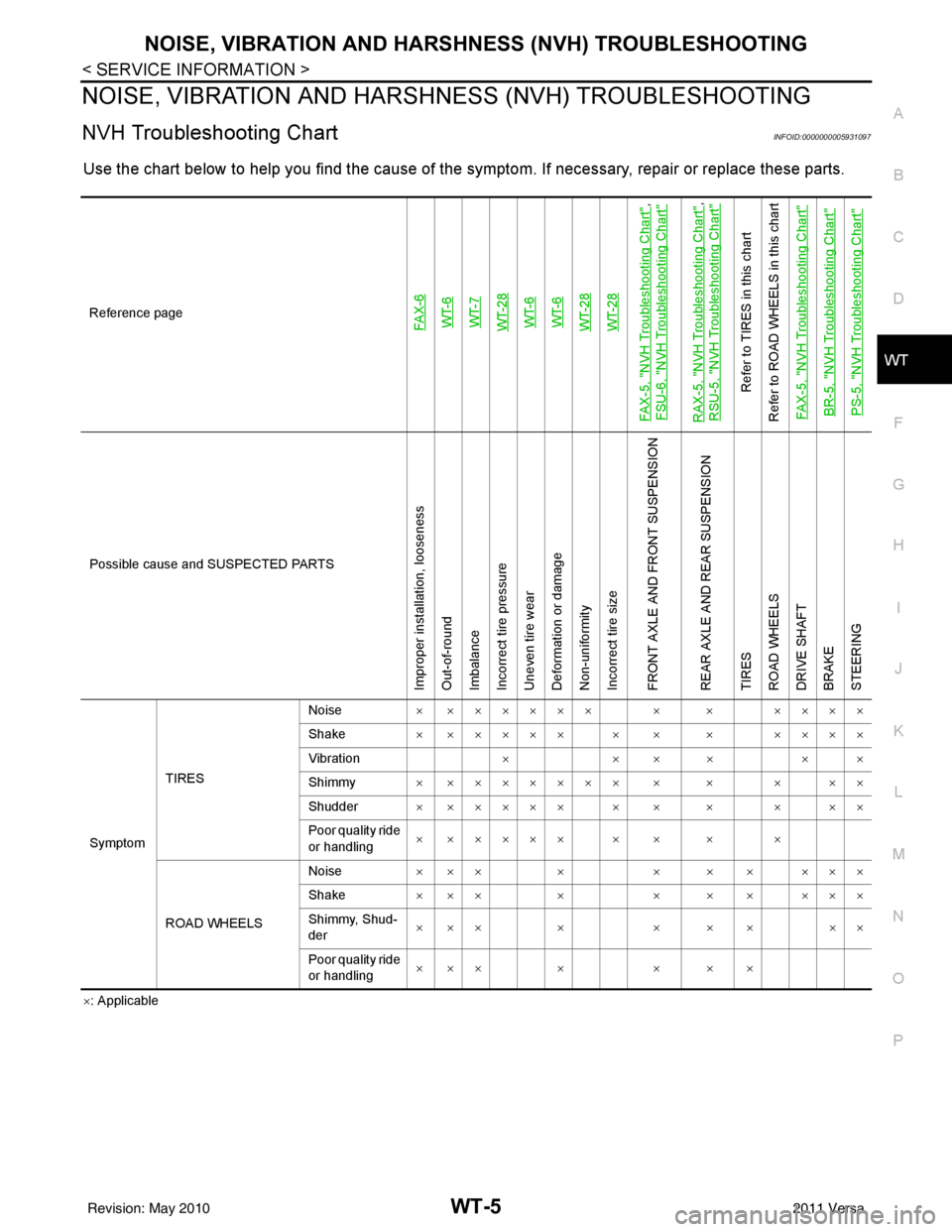

NVH Troubleshooting ChartINFOID:0000000005931097

Use the chart below to help you find t he cause of the symptom. If necessary, repair or replace these parts.

×: Applicable

Reference page

FAX-6WT-6

WT-7

WT-28WT-6

WT-6

WT-28WT-28

FAX-5, "

NVH Troubleshooting Chart

",

FSU-6, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

",

RSU-5, "

NVH Troubleshooting Chart

"

Refer to TIRES in this chart

Refer to ROAD WHEELS in this chart

FAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEELS

DRIVE SHAFT

BRAKE

STEERING

Symptom TIRES Noise

× ×××××× × × ××××

Shake × ××××× × × × ××××

Vibration ××××××

Shimmy × ××××××× × × × ××

Shudder × ××××× × × × × ××

Poor quality ride

or handling × ××××× × × × ×

ROAD WHEELS Noise

× ×× × × × × ×××

Shake × ×× × × × × ×××

Shimmy, Shud-

der ××× × × × × ××

Poor quality ride

or handling ××× × × × ×

Revision: May 2010

2011 Versa

Page 3725 of 3787

ROAD WHEEL TIRE ASSEMBLYWT-7

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

ROAD WHEEL TIRE ASSEMBLY

AdjustmentINFOID:0000000005931099

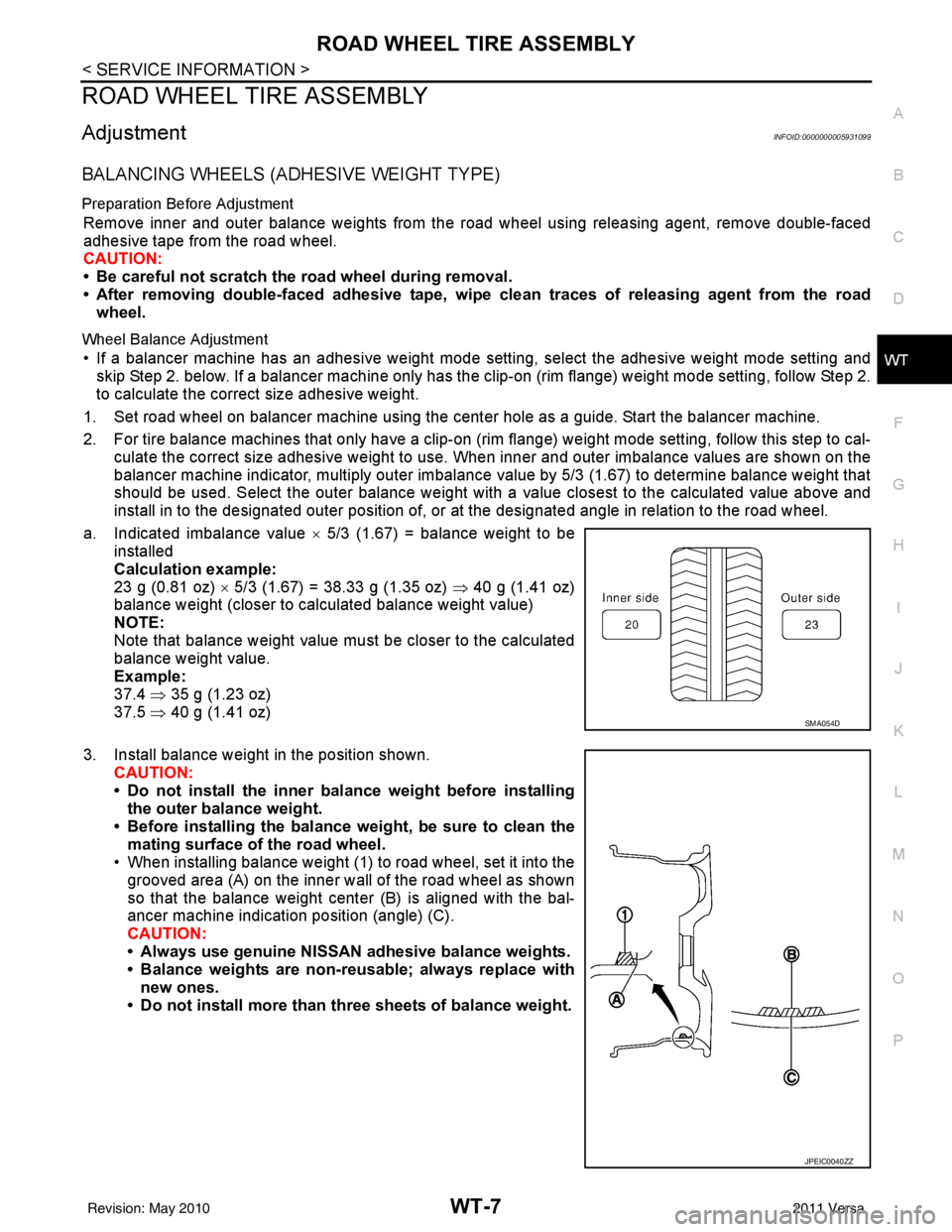

BALANCING WHEELS (ADH ESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the r oad wheel using releasing agent, remove double-faced

adhesive tape from the road wheel.

CAUTION:

• Be careful not scratch the road wheel during removal.

• After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road

wheel.

Wheel Balance Adjustment

• If a balancer machine has an adhesive weight mode setting, select the adhesive weight mode setting and skip Step 2. below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2.

to calculate the correct size adhesive weight.

1. Set road wheel on balancer machine using the cent er hole as a guide. Start the balancer machine.

2. For tire balance machines that only have a clip-on (ri m flange) weight mode setting, follow this step to cal-

culate the correct size adhesive weight to use. When inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of, or at the designated angle in relation to the road wheel.

a. Indicated imbalance value × 5/3 (1.67) = balance weight to be

installed

Calculation example:

23 g (0.81 oz) × 5/3 (1.67) = 38.33 g (1.35 oz) ⇒ 40 g (1.41 oz)

balance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 ⇒ 35 g (1.23 oz)

37.5 ⇒ 40 g (1.41 oz)

3. Install balance weight in the position shown. CAUTION:

• Do not install the inner bala nce weight before installing

the outer balance weight.

• Before installing the balance weight, be sure to clean the mating surface of the road wheel.

• When installing balance weight (1) to road wheel, set it into the

grooved area (A) on the inner wall of the road wheel as shown

so that the balance weight cent er (B) is aligned with the bal-

ancer machine indication position (angle) (C).

CAUTION:

• Always use genuine NISSAN adhesive balance weights.

• Balance weights are non-re usable; always replace with

new ones.

• Do not install more than th ree sheets of balance weight.

SMA054D

JPEIC0040ZZ

Revision: May 2010 2011 Versa

Page 3746 of 3787

WT-28

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

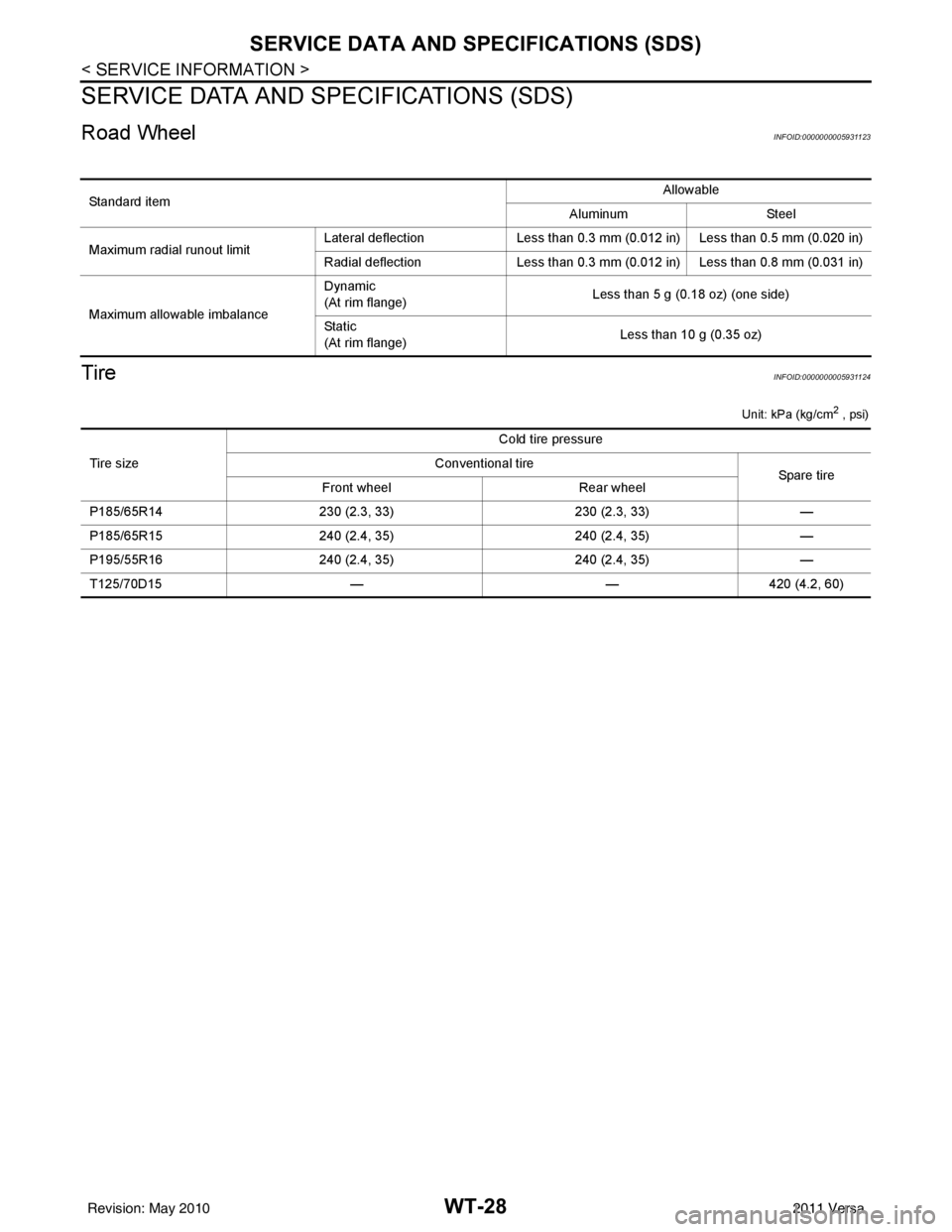

Road WheelINFOID:0000000005931123

TireINFOID:0000000005931124

Unit: kPa (kg/cm2 , psi)

Standard itemAllowable

Aluminum Steel

Maximum radial runout limit Lateral deflection

Less than 0.3 mm (0.012 in) Less than 0.5 mm (0.020 in)

Radial deflection Less than 0.3 mm (0.012 in) Less than 0.8 mm (0.031 in)

Maximum allowable imbalance Dynamic

(At rim flange)

Less than 5 g (0.18 oz) (one side)

Stati c

(At rim flange) Less than 10 g (0.35 oz)

Tire size Cold tire pressure

Conventional tire Spare ti re

Front wheel Rear wheel

P185/65R14 230 (2.3, 33) 230 (2.3, 33)—

P185/65R15 240 (2.4, 35) 240 (2.4, 35)—

P195/55R16 240 (2.4, 35) 240 (2.4, 35)—

T125/70D15 ——420 (4.2, 60)

Revision: May 2010 2011 Versa