wiring diagram NISSAN LATIO 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 121 of 3787

AT-104

< SERVICE INFORMATION >

P0720 OUTPUT SPEED SENSOR

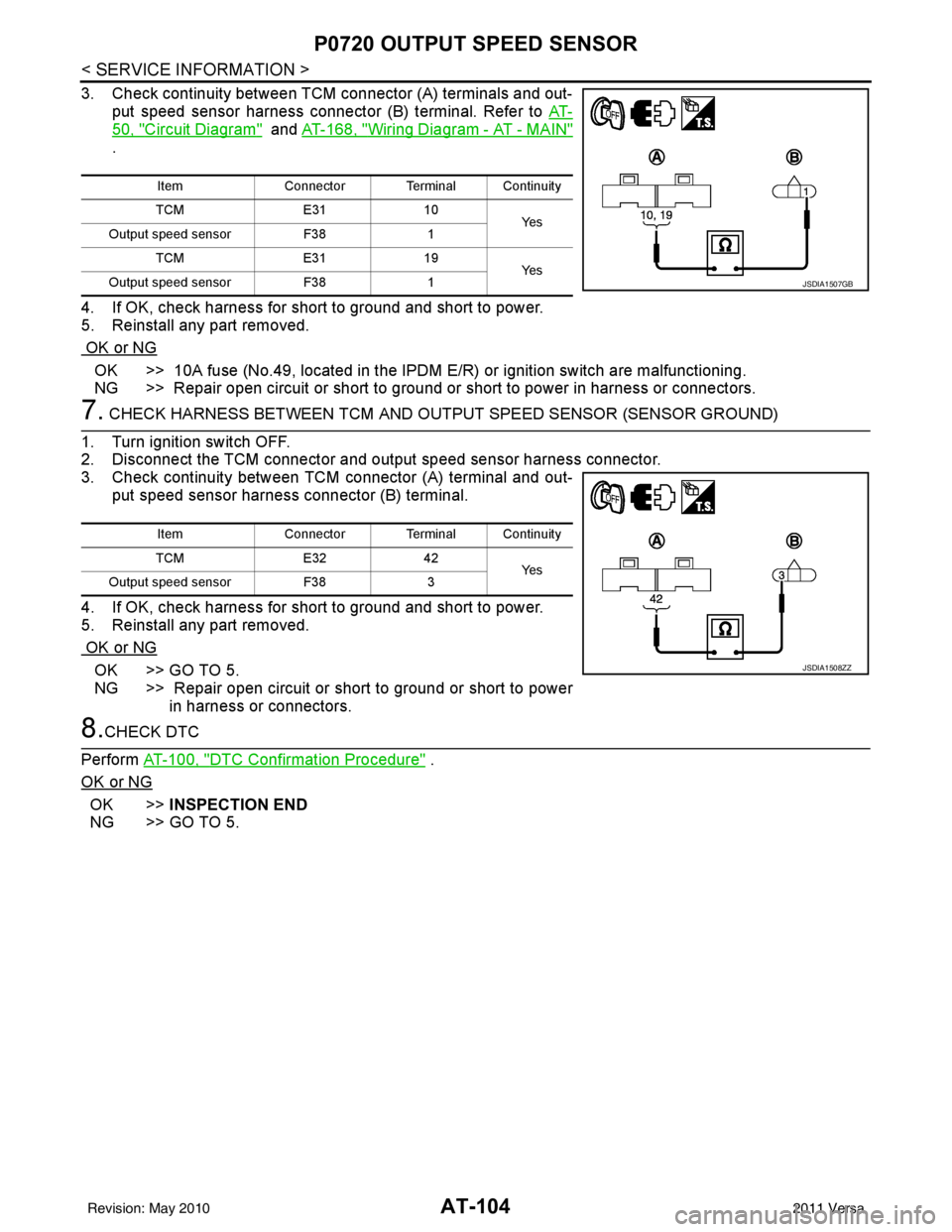

3. Check continuity between TCM connector (A) terminals and out-put speed sensor harness connector (B) terminal. Refer to AT-

50, "Circuit Diagram" and AT-168, "Wiring Diagram - AT - MAIN"

.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> 10A fuse (No.49, located in the IPDM E/R) or ignition switch are malfunctioning.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

7. CHECK HARNESS BETWEEN TCM AND OUTPUT SPEED SENSOR (SENSOR GROUND)

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and output speed sensor harness connector.

3. Check continuity between TCM connector (A) terminal and out-

put speed sensor harness connector (B) terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK DTC

Perform AT-100, "

DTC Confirmation Procedure" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 5.

Item Connector Terminal Continuity

TCM E3110

Ye s

Output speed sensor F381

TCM E3119

Ye s

Output speed sensor F381

JSDIA1507GB

Item Connector Terminal Continuity

TCM E3242

Ye s

Output speed sensor F383

JSDIA1508ZZ

Revision: May 2010 2011 Versa

Page 123 of 3787

AT-106

< SERVICE INFORMATION >

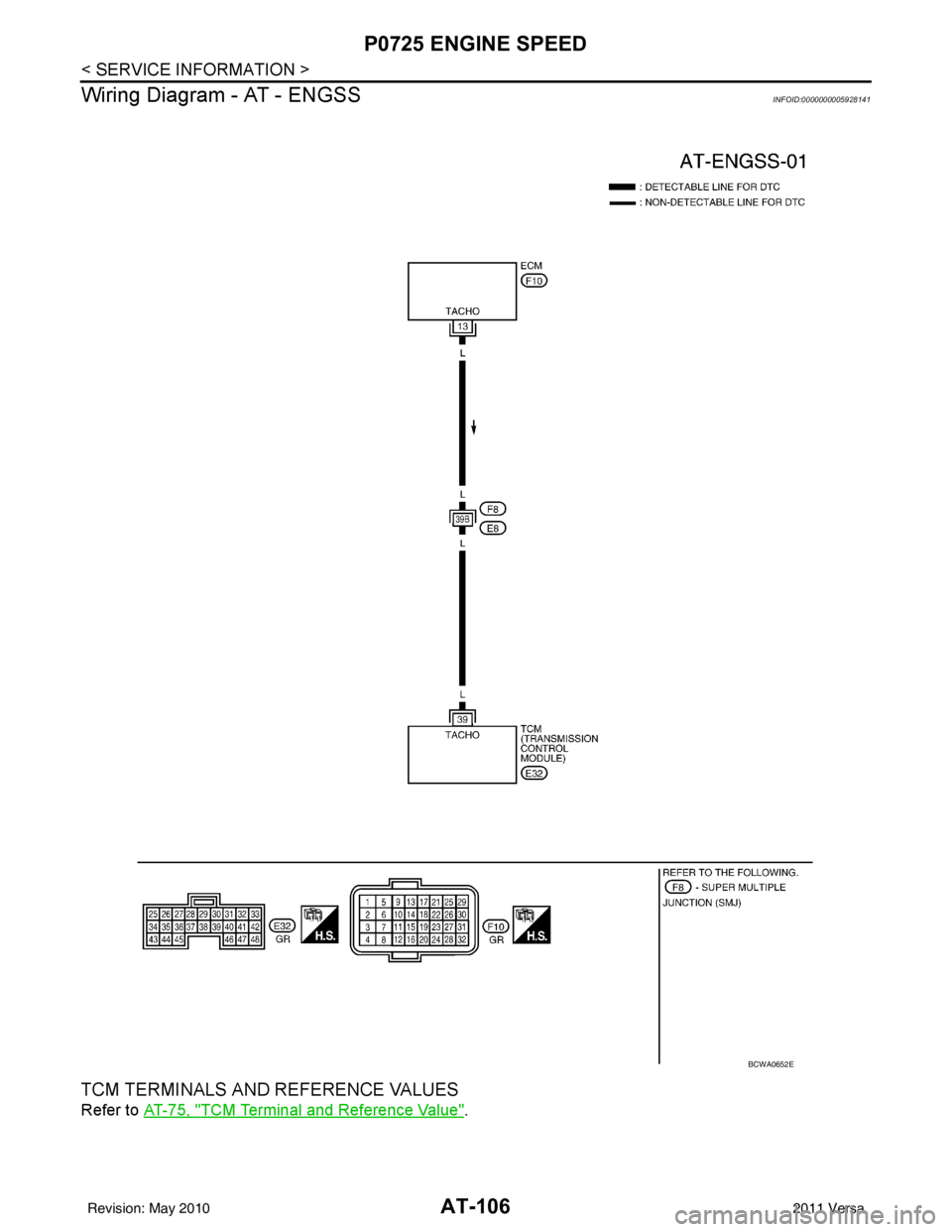

P0725 ENGINE SPEED

Wiring Diagram - AT - ENGSS

INFOID:0000000005928141

TCM TERMINALS AND REFERENCE VALUES

Refer to AT-75, "TCM Terminal and Reference Value".

BCWA0652E

Revision: May 2010 2011 Versa

Page 127 of 3787

AT-110

< SERVICE INFORMATION >

P0731 1GR INCORRECT RATIO

5. Accelerate vehicle to 20 to 25 km/h (12 to 16 MPH) under the following conditions and release the accel-erator pedal completely.

THROTTLE POSI: Less than 1.0/8 (at all times during step 4)

SLCT LVR POSI: “D” position

- Make sure that “GEAR” shows “2” after releasing pedal.

6. Depress accelerator pedal to WOT (more than 7.0/8 of “THROTTLE POSI”) quickly from a speed of 20 to

25 km/h (12 to 16 MPH) until “TESTING” changes to “STOP VEHICLE” or “COMPLETED”. (It will take

approximately 3 seconds.)

If the check result NG appears on CONSULT-III screen, go to AT-110, "

Diagnosis Procedure".

If “STOP VEHICLE” appears on CONSULT- III screen, go to the following step.

- Make sure that “GEAR” shows “1” wh en depressing accelerator pedal to WOT.

- If “TESTING” does not appear on CONSULT-III fo r a long time, select “SELF-DIAG RESULTS” for

“TRANSMISSION”. In case a DTC other than “P0731 1GR INCORRECT RATIO” is shown, refer to

AT-77, "

CONSULT-III Funct ion (TRANSMISSION)".

7. Stop vehicle.

8. Follow the instruction displayed. (Check for normal shifting referring to the table below.)

9. Make sure that “OK” is displayed. (If “NG” is displayed, refer to “Diagnostic Procedure”.)

Refer to AT-110, "

Diagnosis Procedure".

Refer to AT-64, "

Vehicle Speed at Which Gear Shifting Occurs".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005928147

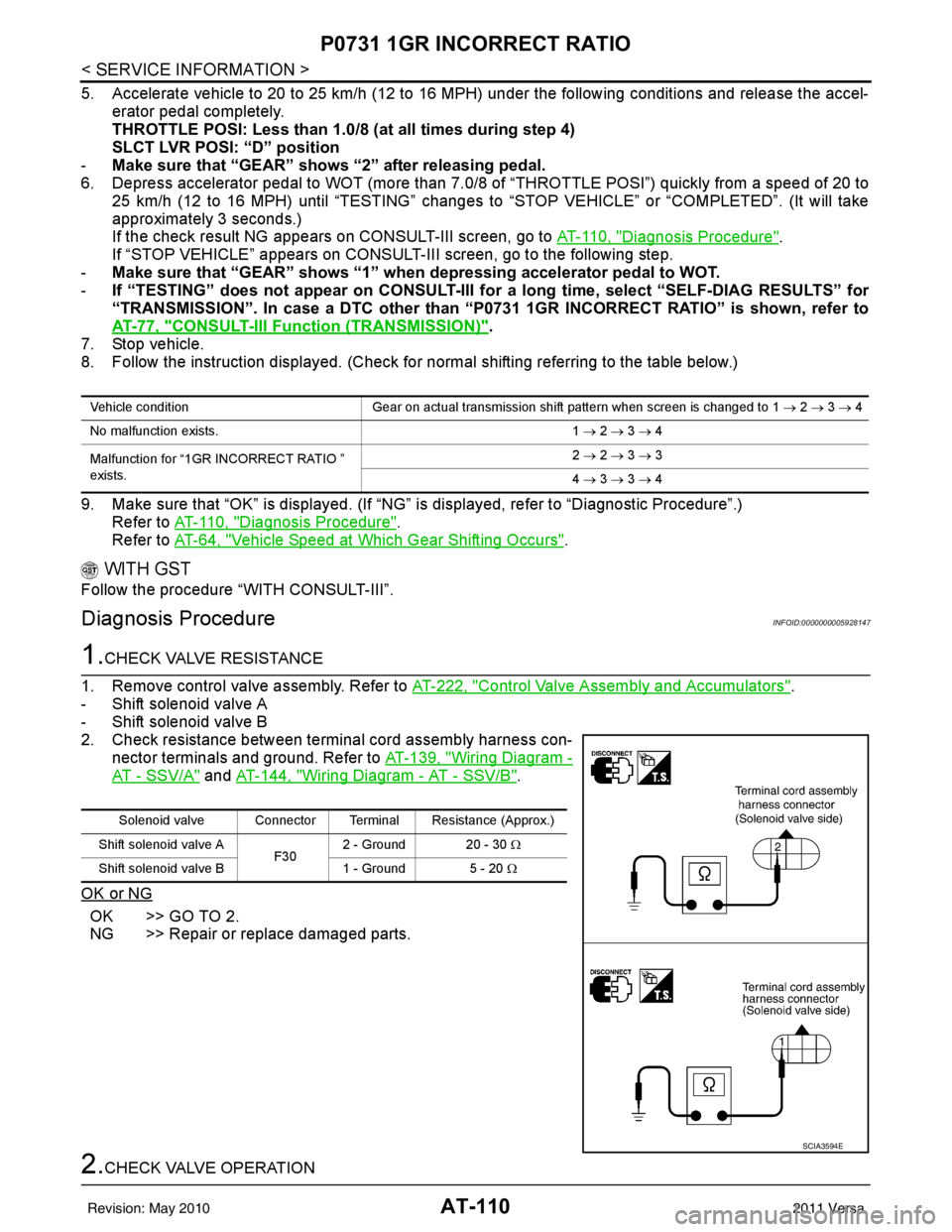

1.CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con- nector terminals and ground. Refer to AT-139, "

Wiring Diagram -

AT - SSV/A" and AT-144, "Wiring Diagram - AT - SSV/B".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2.CHECK VALVE OPERATION

Vehicle condition Gear on actual transmission shift pattern when screen is changed to 1 → 2 → 3 → 4

No malfunction exists. 1 → 2 → 3 → 4

Malfunction for “1GR INCORRECT RATIO ”

exists. 2

→ 2 → 3 → 3

4 → 3 → 3 → 4

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve A F302 - Ground 20 - 30

Ω

Shift solenoid valve B 1 - Ground 5 - 20 Ω

SCIA3594E

Revision: May 2010 2011 Versa

Page 128 of 3787

P0731 1GR INCORRECT RATIOAT-111

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

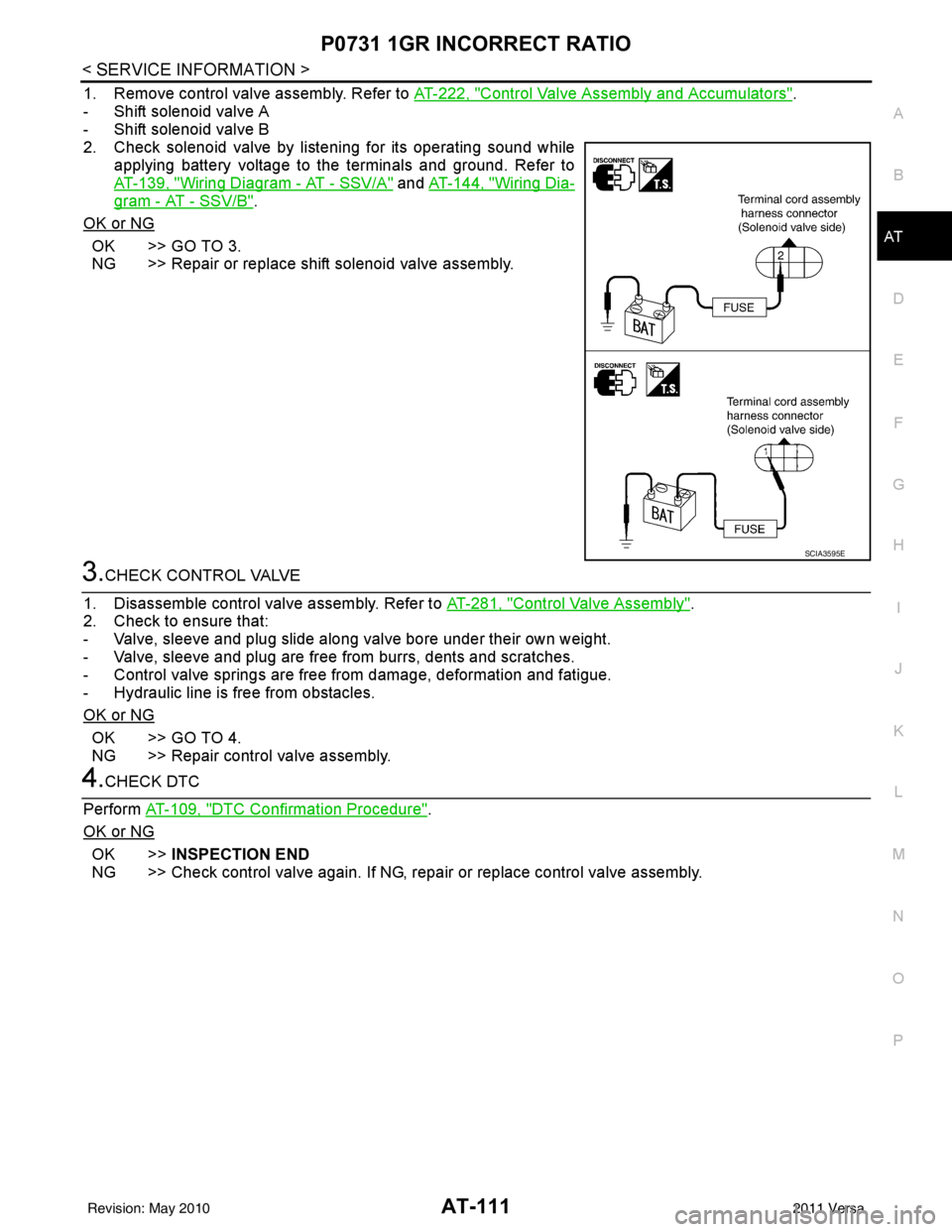

1. Remove control valve assembly. Refer to AT-222, "Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

2. Check solenoid valve by listening for its operating sound while applying battery voltage to the terminals and ground. Refer to

AT-139, "

Wiring Diagram - AT - SSV/A" and AT-144, "Wiring Dia-

gram - AT - SSV/B".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace shift solenoid valve assembly.

3.CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-281, "

Control Valve Assembly".

2. Check to ensure that:

- Valve, sleeve and plug slide along valve bore under their own weight.

- Valve, sleeve and plug are free from burrs, dents and scratches.

- Control valve springs are free from damage, deformation and fatigue.

- Hydraulic line is free from obstacles.

OK or NG

OK >> GO TO 4.

NG >> Repair control valve assembly.

4.CHECK DTC

Perform AT-109, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> Check control valve again. If NG, repa ir or replace control valve assembly.

SCIA3595E

Revision: May 2010 2011 Versa

Page 130 of 3787

P0732 2GR INCORRECT RATIOAT-113

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

- Make sure that “GEAR” shows “3” or “4” after releasing pedal.

6. Depress accelerator pedal to WOT (more than 7.0/8 of “THROTTLE POSI”) quickly from a speed of 45 to 50 km/h (28 to 31 MPH) until “TESTING” changes to “STOP VEHICLE” or “COMPLETE”. (It will take

approximately 3 seconds.)

If the check result NG appears on CONSULT-III screen, go to AT-113, "

Diagnosis Procedure".

If “STOP VEHICLE” appears on CONSULT-III screen, go to following step.

- Make sure that “GEAR” shows “2” when depressing accelerator pedal to WOT.

- If “TESTING” does not appear on CONSULT-III fo r a long time, select “SELF-DIAG RESULTS” for

“TRANSMISSION”. In case a DTC other than “P0732 2GR INCORRECT RATIO” is shown, refer to

AT-77, "

CONSULT-III Function (TRANSMISSION)".

7. Stop vehicle.

8. Follow the instruction displayed. (Check for normal shifting referring to the table below.)

9. Make sure that “OK” is disp layed. (If “NG” is displayed, refer to “Diagnostic Procedure”.)

Refer to AT-113, "

Diagnosis Procedure".

Refer to AT-64, "

Vehicle Speed at Which Gear Shifting Occurs".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005928152

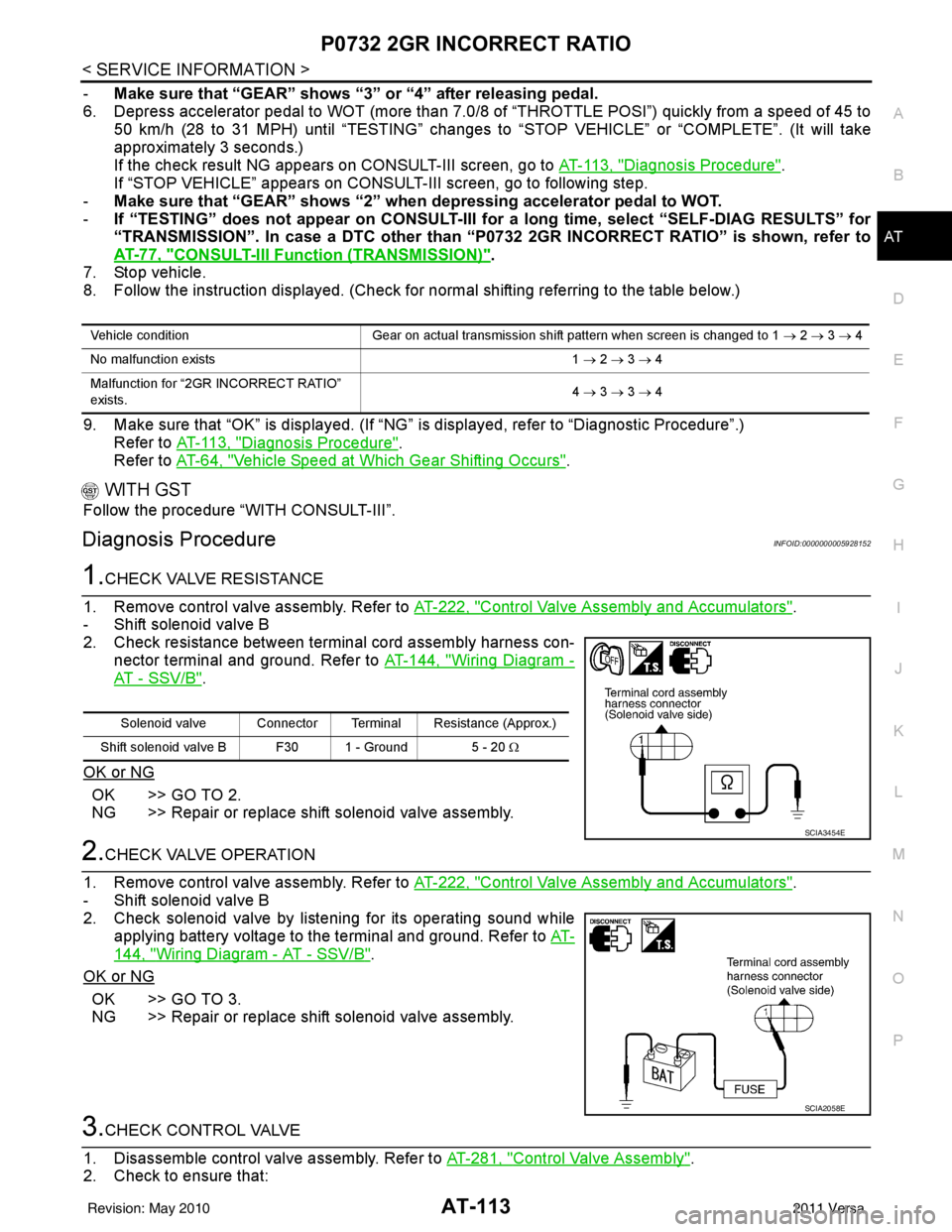

1.CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con- nector terminal and ground. Refer to AT-144, "

Wiring Diagram -

AT - SSV/B".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace shift solenoid valve assembly.

2.CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve B

2. Check solenoid valve by listening for its operating sound while applying battery voltage to the terminal and ground. Refer to AT-

144, "Wiring Diagram - AT - SSV/B".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace shift solenoid valve assembly.

3.CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-281, "

Control Valve Assembly".

2. Check to ensure that:

Vehicle condition Gear on actual transmission shift pattern when screen is changed to 1 → 2 → 3 → 4

No malfunction exists 1 → 2 → 3 → 4

Malfunction for “2GR INCORRECT RATIO”

exists. 4

→ 3 → 3 → 4

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve B F30 1 - Ground 5 - 20 Ω

SCIA3454E

SCIA2058E

Revision: May 2010 2011 Versa

Page 133 of 3787

AT-116

< SERVICE INFORMATION >

P0733 3GR INCORRECT RATIO

-Make sure that “GEAR” shows “4” after releasing pedal.

6. Depress accelerator pedal steadily with 3.5/8 - 4.5/8 of “THROTTLE POSI” from a speed of 60 to 75 km/h (37 to 47 MPH) until “TESTING” changes to “STOP VEHICLE” or “COMPLETED”. (It will take approxi-

mately 3 seconds.)

If the check result NG appears on CONSULT-III screen, go to AT-116, "

Diagnosis Procedure".

If “STOP VEHICLE” appears on CONSUL T-III screen, go to following step.

- Make sure that “GEAR” shows “3” when depressing accelerator pedal with 3.5/8 - 4.5/8 of

“THROTTLE POSI”.

- If “TESTING” does not appear on CONSULT-III fo r a long time, select “SELF-DIAG RESULTS” for

“TRANSMISSION”. In case a DTC other than “P0733 3GR INCORRECT RATIO” is shown, refer to

AT-77, "

CONSULT-III Funct ion (TRANSMISSION)".

7. Stop vehicle.

8. Follow the instruction displayed. (Check for normal shifting referring to the table below.)

9. Make sure that “OK” is displayed. (If “NG” is displayed, refer to “Diagnostic Procedure”.)

Refer to AT-116, "

Diagnosis Procedure".

Refer to AT-64, "

Vehicle Speed at Which Gear Shifting Occurs".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005928157

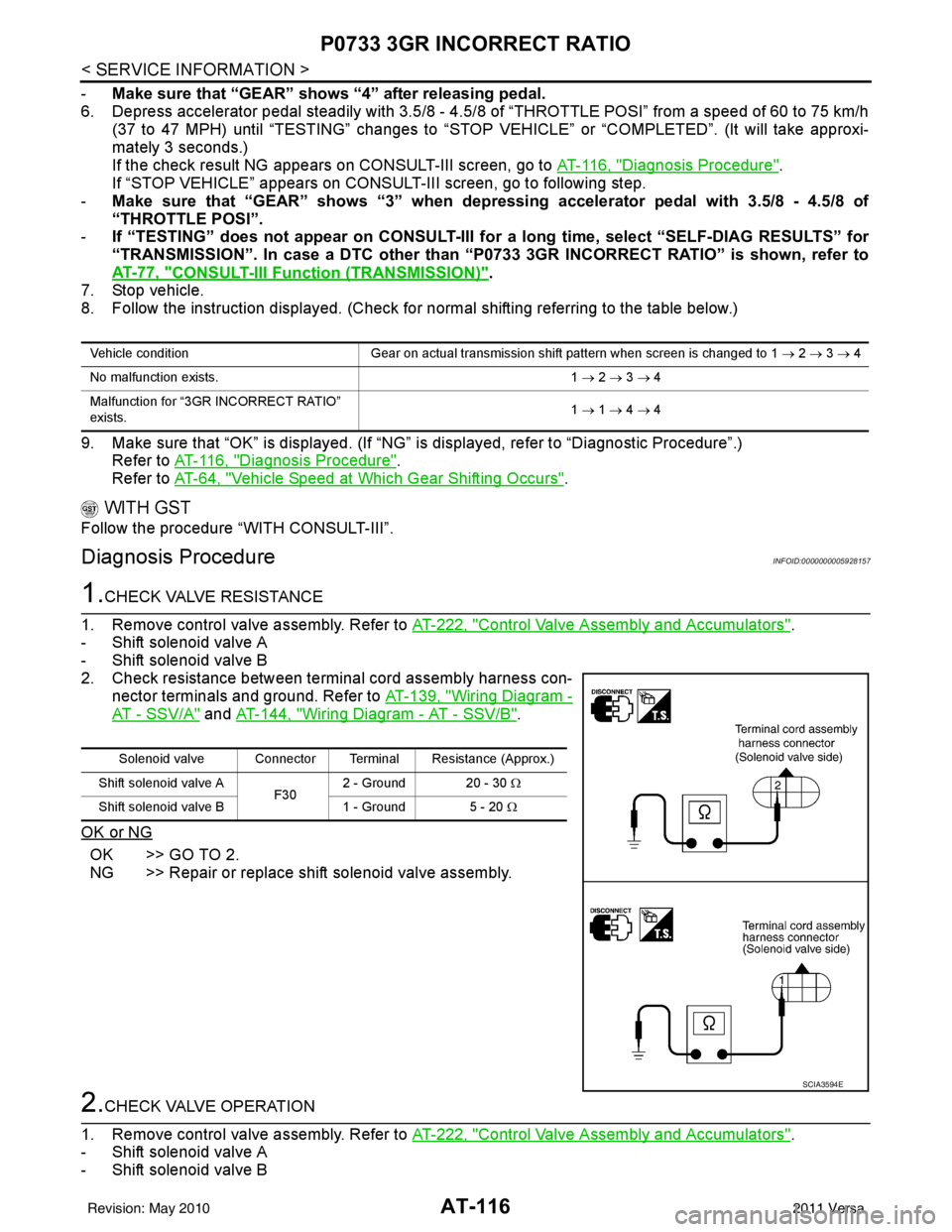

1.CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con- nector terminals and ground. Refer to AT-139, "

Wiring Diagram -

AT - SSV/A" and AT-144, "Wiring Diagram - AT - SSV/B".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace shift solenoid valve assembly.

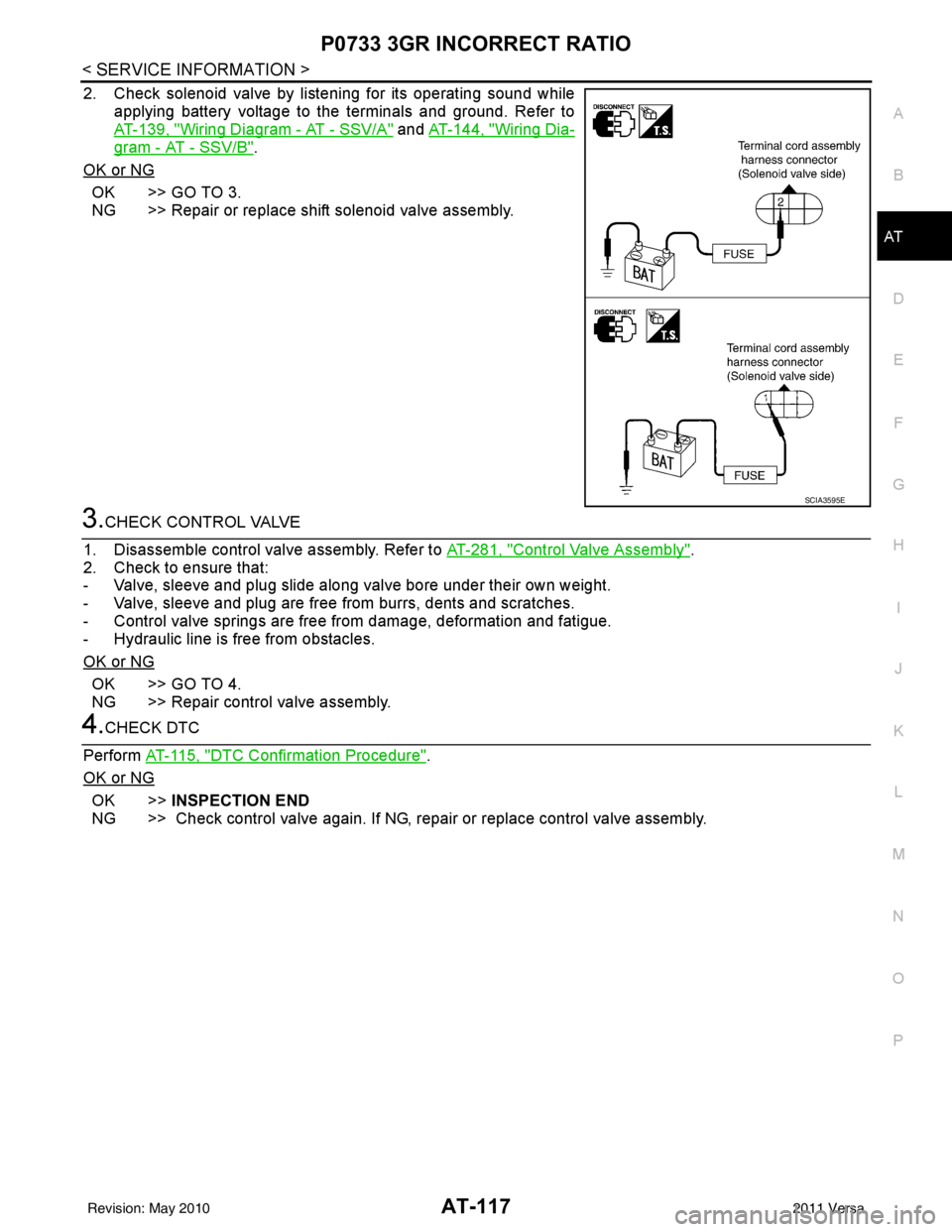

2.CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

Vehicle condition Gear on actual transmission shift pattern when screen is changed to 1 → 2 → 3 → 4

No malfunction exists. 1 → 2 → 3 → 4

Malfunction for “3GR INCORRECT RATIO”

exists. 1

→ 1 → 4 → 4

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve A F302 - Ground 20 - 30

Ω

Shift solenoid valve B 1 - Ground 5 - 20 Ω

SCIA3594E

Revision: May 2010 2011 Versa

Page 134 of 3787

P0733 3GR INCORRECT RATIOAT-117

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

2. Check solenoid valve by listening for its operating sound while applying battery voltage to the terminals and ground. Refer to

AT-139, "

Wiring Diagram - AT - SSV/A" and AT-144, "Wiring Dia-

gram - AT - SSV/B".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace shift solenoid valve assembly.

3.CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-281, "

Control Valve Assembly".

2. Check to ensure that:

- Valve, sleeve and plug slide along valve bore under their own weight.

- Valve, sleeve and plug are free from burrs, dents and scratches.

- Control valve springs are free from damage, deformation and fatigue.

- Hydraulic line is free from obstacles.

OK or NG

OK >> GO TO 4.

NG >> Repair control valve assembly.

4.CHECK DTC

Perform AT-115, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> Check control valve again. If NG, repair or replace control valve assembly.

SCIA3595E

Revision: May 2010 2011 Versa

Page 137 of 3787

AT-120

< SERVICE INFORMATION >

P0734 4GR INCORRECT RATIO

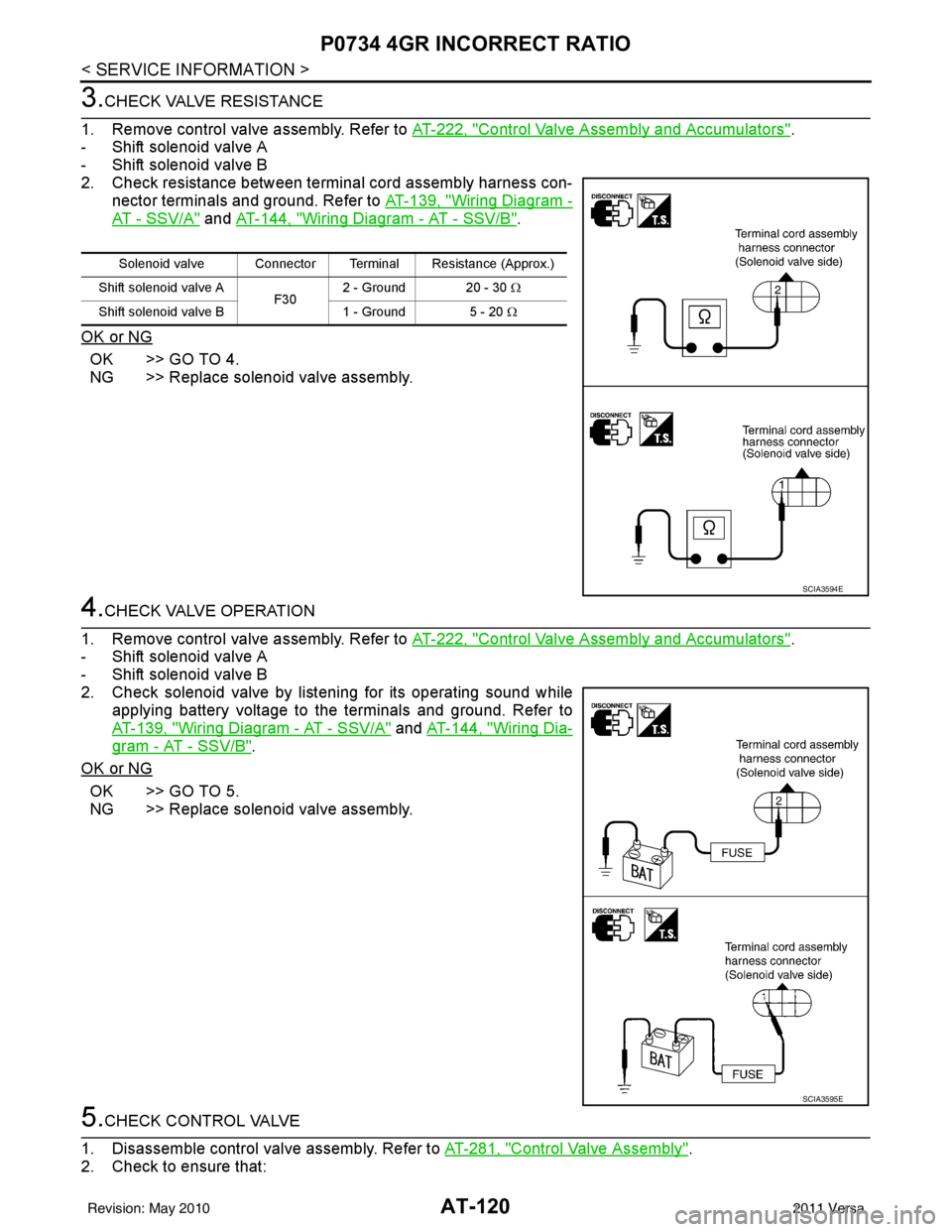

3.CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con- nector terminals and ground. Refer to AT-139, "

Wiring Diagram -

AT - SSV/A" and AT-144, "Wiring Diagram - AT - SSV/B".

OK or NG

OK >> GO TO 4.

NG >> Replace solenoid valve assembly.

4.CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

2. Check solenoid valve by listening for its operating sound while applying battery voltage to the terminals and ground. Refer to

AT-139, "

Wiring Diagram - AT - SSV/A" and AT-144, "Wiring Dia-

gram - AT - SSV/B".

OK or NG

OK >> GO TO 5.

NG >> Replace solenoid valve assembly.

5.CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-281, "

Control Valve Assembly".

2. Check to ensure that:

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve A F302 - Ground 20 - 30

Ω

Shift solenoid valve B 1 - Ground 5 - 20 Ω

SCIA3594E

SCIA3595E

Revision: May 2010 2011 Versa

Page 138 of 3787

P0734 4GR INCORRECT RATIOAT-121

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

- Valve, sleeve and plug slide along valve bore under their own weight.

- Valve, sleeve and plug are free from burrs, dents and scratches.

- Control valve springs are free from damage, deformation and fatigue.

- Hydraulic line is free from obstacles.

OK or NG

OK >> GO TO 6.

NG >> Repair control valve.

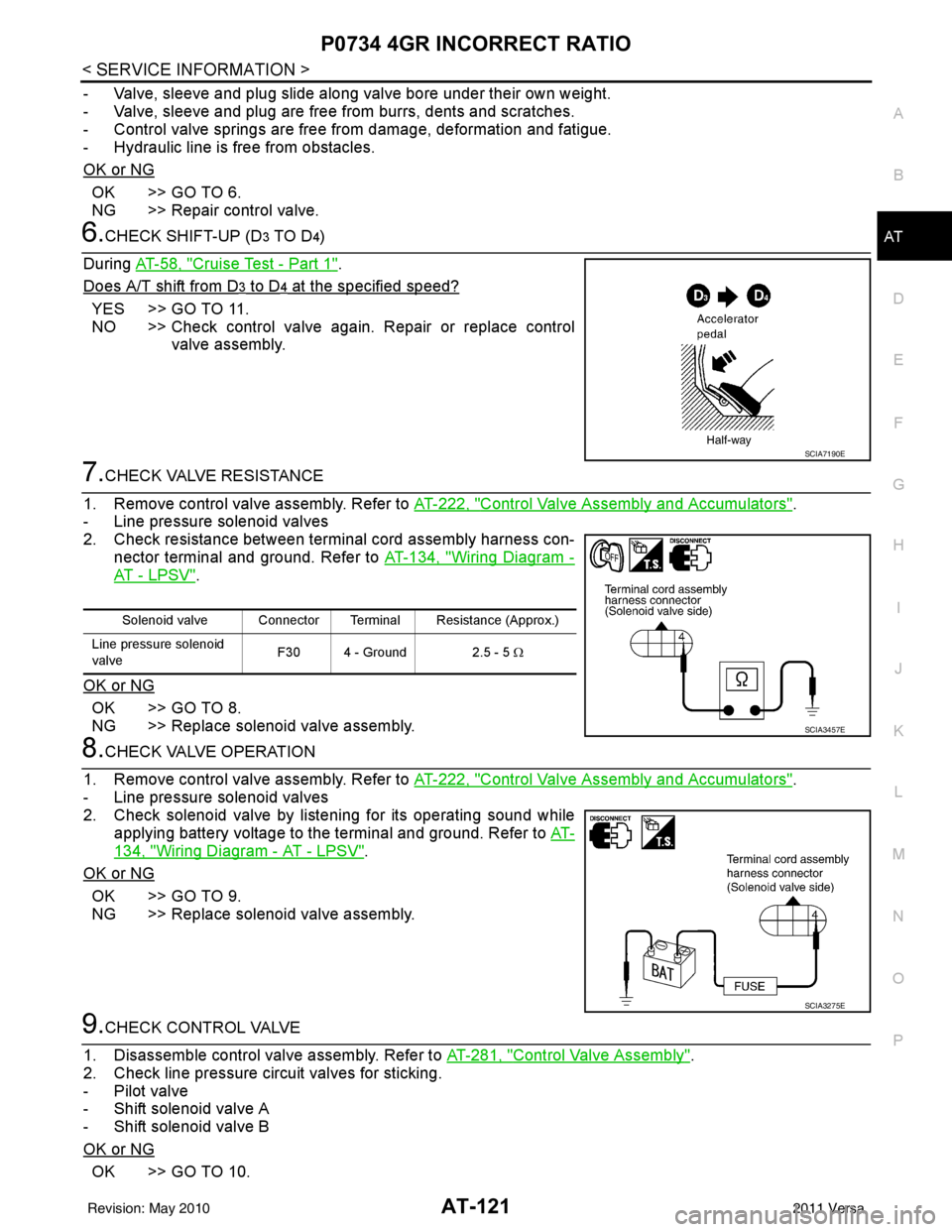

6.CHECK SHIFT-UP (D3 TO D4)

During AT-58, "

Cruise Test - Part 1".

Does A/T shift from D

3 to D4 at the specified speed?

YES >> GO TO 11.

NO >> Check control valve again. Repair or replace control valve assembly.

7.CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Line pressure solenoid valves

2. Check resistance between terminal cord assembly harness con- nector terminal and ground. Refer to AT-134, "

Wiring Diagram -

AT - L P S V".

OK or NG

OK >> GO TO 8.

NG >> Replace solenoid valve assembly.

8.CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Line pressure solenoid valves

2. Check solenoid valve by listening for its operating sound while applying battery voltage to the terminal and ground. Refer to AT-

134, "Wiring Diagram - AT - LPSV".

OK or NG

OK >> GO TO 9.

NG >> Replace solenoid valve assembly.

9.CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-281, "

Control Valve Assembly".

2. Check line pressure circuit valves for sticking.

- Pilot valve

- Shift solenoid valve A

- Shift solenoid valve B

OK or NG

OK >> GO TO 10.

SCIA7190E

Solenoid valve Connector Terminal Resistance (Approx.)

Line pressure solenoid

valve F30 4 - Ground 2.5 - 5

Ω

SCIA3457E

SCIA3275E

Revision: May 2010 2011 Versa

Page 141 of 3787

AT-124

< SERVICE INFORMATION >

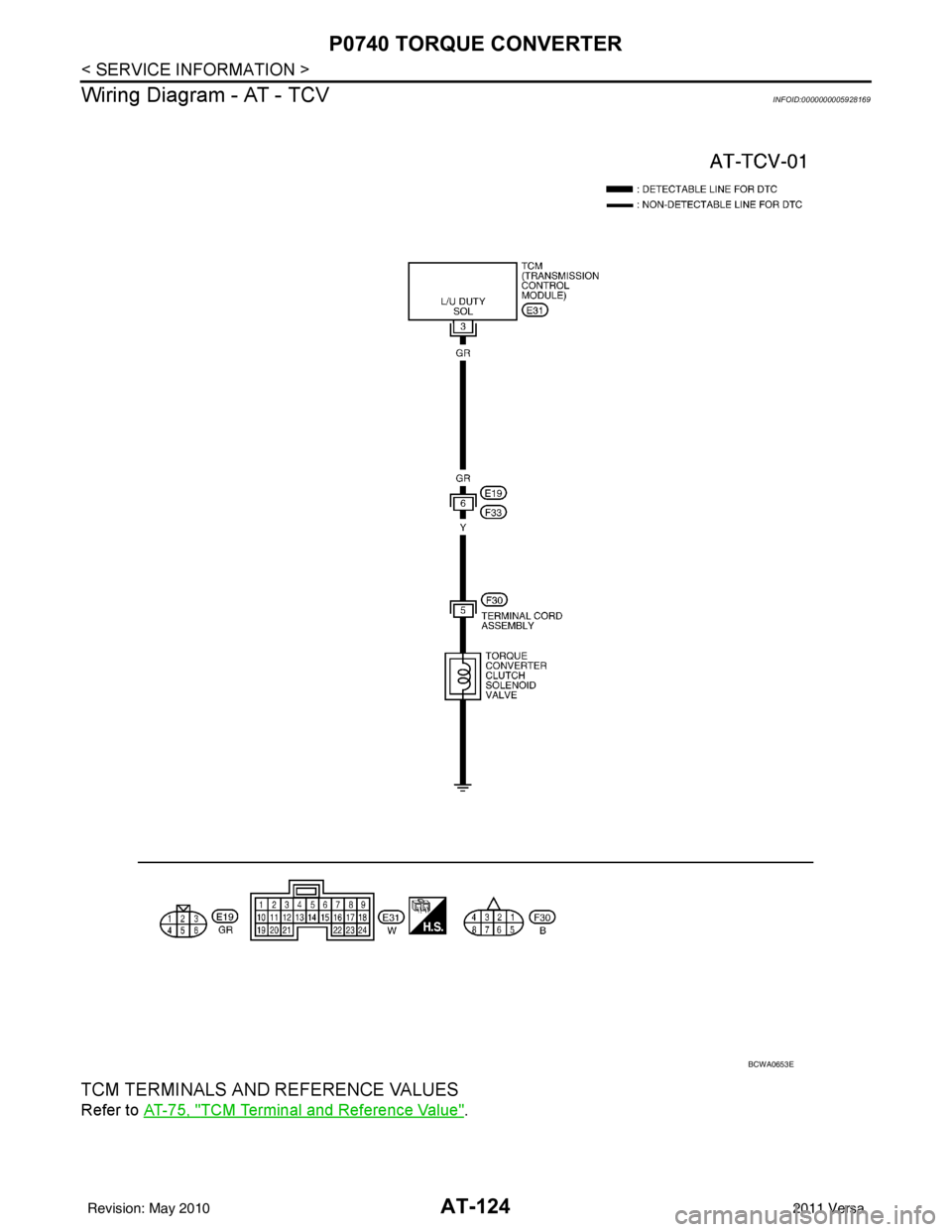

P0740 TORQUE CONVERTER

Wiring Diagram - AT - TCV

INFOID:0000000005928169

TCM TERMINALS AND REFERENCE VALUES

Refer to AT-75, "TCM Terminal and Reference Value".

BCWA0653E

Revision: May 2010 2011 Versa