suspension NISSAN LATIO 2011 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 3501 of 3787

STEERING WHEELPS-7

< SERVICE INFORMATION >

C

DE

F

H I

J

K L

M A

B

PS

N

O P

• Check front wheel turning angle after toe-in inspection. Place front wheels on turning radius gauges and rear wheels on stands.

Check the maximum inner and outer wheel turning angles for LH

and RH road wheels.

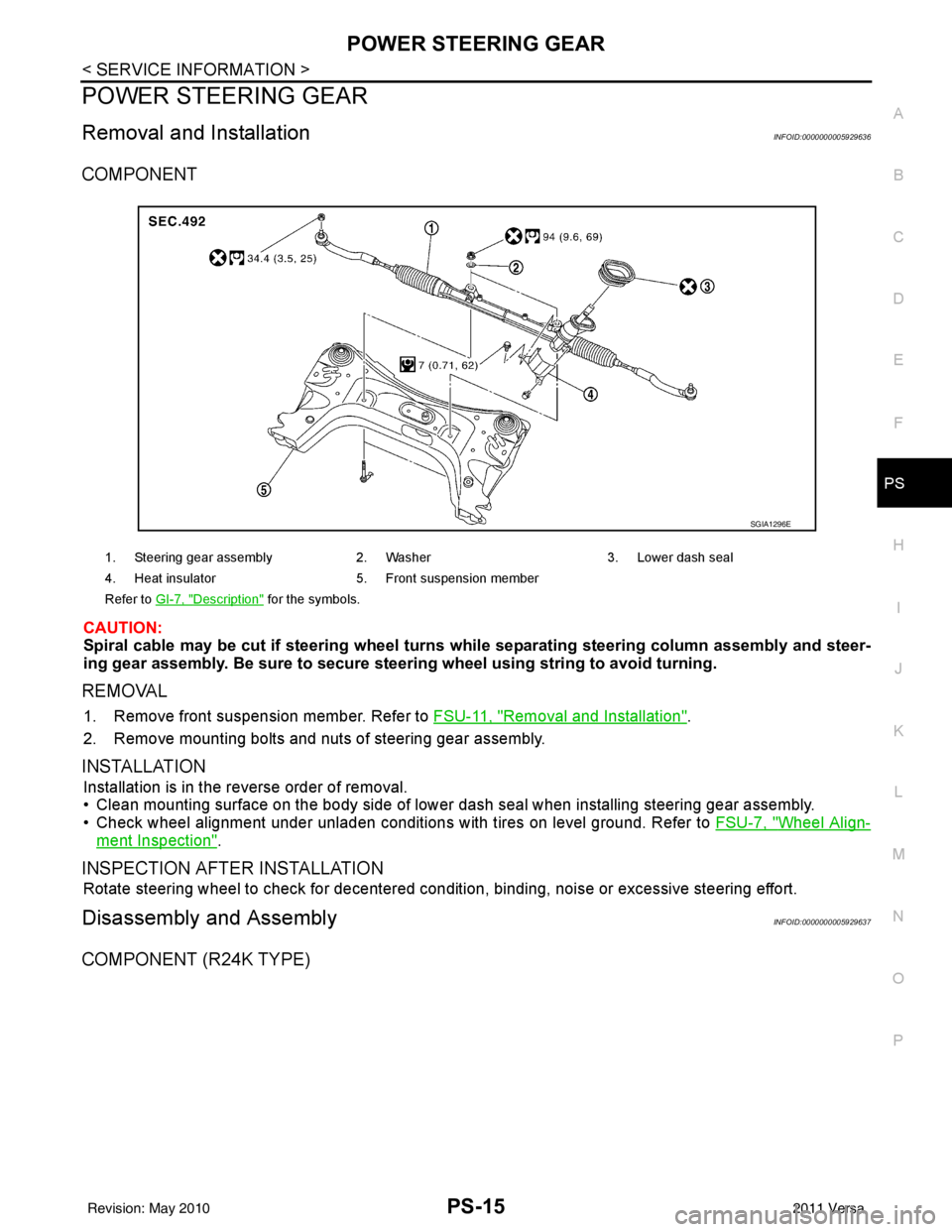

• With the engine at idle, turn steering wheel from full left stop to full right stop and measure the turning angles.

• Measure rack stroke if angles are outside the specified value.

• Disassemble steering gear assembly to check the cause that rack stroke is outside of the standard.

• Steering angles are not adjustable. Check steering gear assembly, steering column assembly and front suspension components for

wear or damage if any of the turning angles are different from the

specified value. Replace any of them, if any non-standard condi-

tion exists.

Removal and InstallationINFOID:0000000006416715

COMPONENT

FAA0016D

Inner wheel (Angle: A) Minimum 35 ° 00 ′ (35.0 °)

Nominal 38° 00′ (38.0 °)

Maximum 39 ° 00 ′ (39.0 °)

Outer wheel (Angle: B) 33° 00 ′ (33.0 °)

SGIA0055E

Rack stroke (L) : 65.0 mm (2.559 in)

WGIA0181E

Revision: May 2010 2011 Versa

Page 3509 of 3787

POWER STEERING GEARPS-15

< SERVICE INFORMATION >

C

DE

F

H I

J

K L

M A

B

PS

N

O P

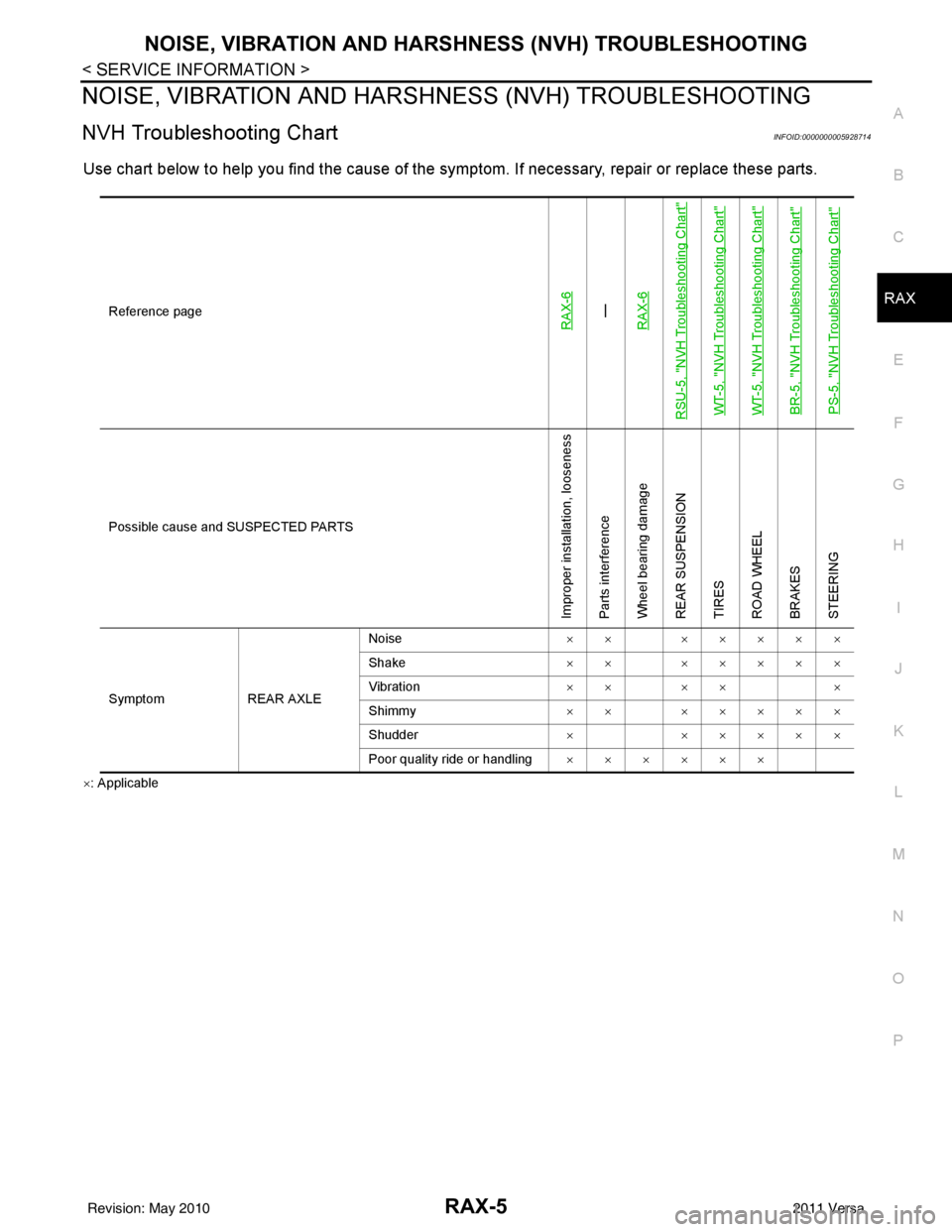

POWER STEERING GEAR

Removal and InstallationINFOID:0000000005929636

COMPONENT

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steering wheel using stri ng to avoid turning.

REMOVAL

1. Remove front suspension member. Refer to FSU-11, "Removal and Installation".

2. Remove mounting bolts and nuts of steering gear assembly.

INSTALLATION

Installation is in the reverse order of removal.

• Clean mounting surface on the body side of lower dash seal when installing steering gear assembly.

• Check wheel alignment under unladen conditions with tires on level ground. Refer to FSU-7, "

Wheel Align-

ment Inspection".

INSPECTION AFTER INSTALLATION

Rotate steering wheel to check for decentered condition, binding, noise or excessive steering effort.

Disassembly and AssemblyINFOID:0000000005929637

COMPONENT (R24K TYPE)

1. Steering gear assembly2. Washer 3. Lower dash seal

4. Heat insulator 5. Front suspension member

Refer to GI-7, "

Description" for the symbols.

SGIA1296E

Revision: May 2010 2011 Versa

Page 3520 of 3787

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGRAX-5

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

RAX

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005928714

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: Applicable Reference page

RAX-6—

RAX-6

RSU-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Parts interference

Wheel bearing damage

REAR SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

Symptom REAR AXLENoise

×× ×××××

Shake ×× ×××××

Vibration ×× ×× ×

Shimmy ×× ×××××

Shudder ××××××

Poor quality ride or handling ××××××

Revision: May 2010 2011 Versa

Page 3521 of 3787

RAX-6

< SERVICE INFORMATION >

WHEEL HUB

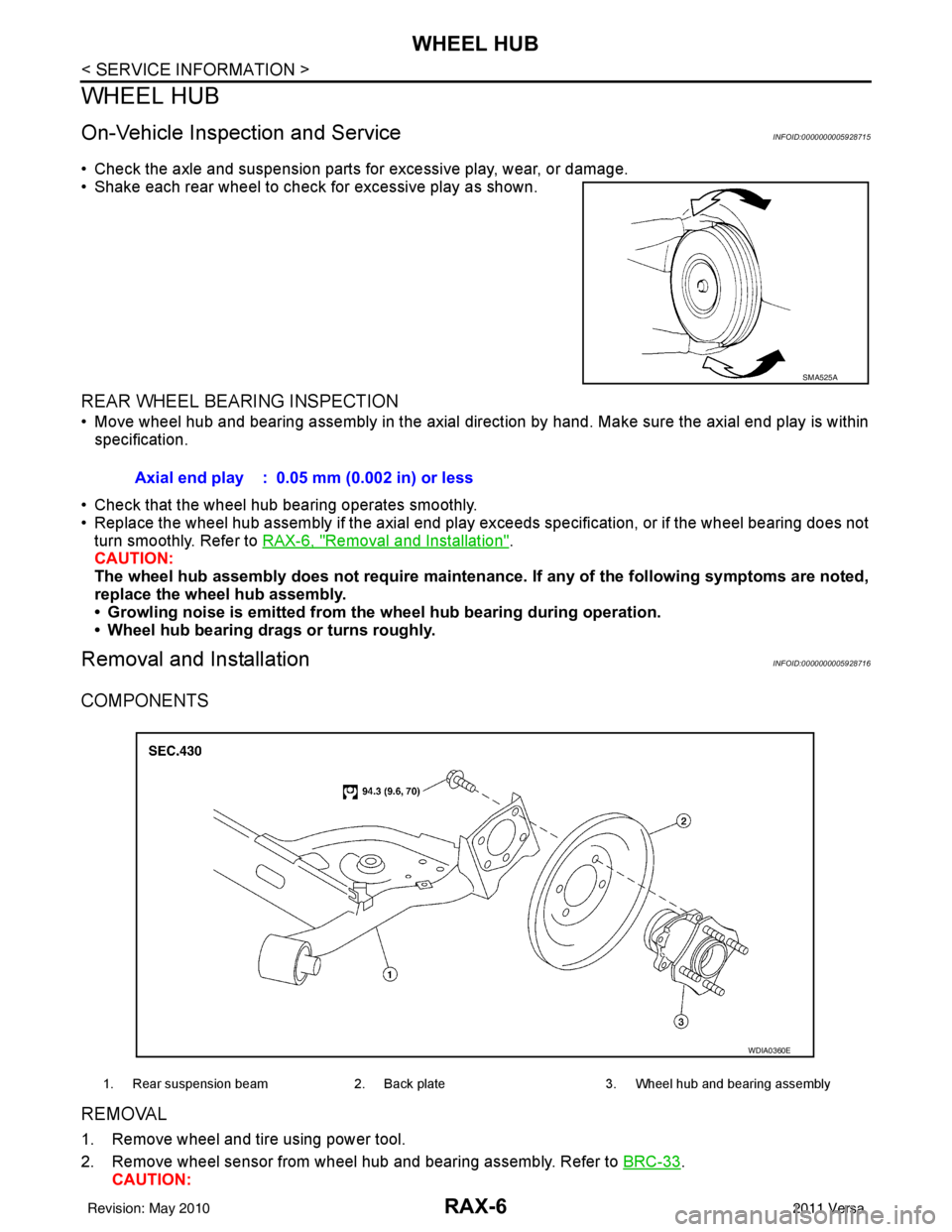

WHEEL HUB

On-Vehicle Inspection and ServiceINFOID:0000000005928715

• Check the axle and suspension parts for excessive play, wear, or damage.

• Shake each rear wheel to check for excessive play as shown.

REAR WHEEL BEARING INSPECTION

• Move wheel hub and bearing assembly in the axial direction by hand. Make sure the axial end play is within

specification.

• Check that the wheel hub bearing operates smoothly.

• Replace the wheel hub assembly if the axial end play exceeds specification, or if the wheel bearing does not turn smoothly. Refer to RAX-6, "

Removal and Installation".

CAUTION:

The wheel hub assembly does not requ ire maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

• Growling noise is emitted from the wheel hub bearing during operation.

• Wheel hub bearing drags or turns roughly.

Removal and InstallationINFOID:0000000005928716

COMPONENTS

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly. Refer to BRC-33

.

CAUTION:

SMA525A

Axial end play : 0.05 mm (0.002 in) or less

1. Rear suspension beam 2. Back plate 3. Wheel hub and bearing assembly

WDIA0360E

Revision: May 2010 2011 Versa

Page 3554 of 3787

RSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION RSU

A

B

RSU

N

O PCONTENTS

REAR SUSPENSION

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Rear Suspension ......................... ......3

PREPARATION .............................................. .....4

Commercial Service Tool .................................... ......4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

5

NVH Troubleshooting Chart ................................ ......5

REAR SUSPENSION ASSEMBLY .....................6

On-Vehicle Inspection and Service ..................... .....6

Wheel AlignmentInspection ......................................6

Component ...............................................................8

SHOCK ABSORBER .........................................9

Removal and Installation ..........................................9

Disposal ...................................................................10

COIL SPRING ...................................................11

Removal and Installation .........................................11

REAR SUSPENSION BEAM ............................12

Removal and Installation ..................................... ....12

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

13

Wheel Alignment (Unladen*) ...................................13

Wheelarch Height (Unladen*) ..................................13

Revision: May 2010 2011 Versa

Page 3556 of 3787

PRECAUTIONSRSU-3

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Rear SuspensionINFOID:0000000005931081

• When installing the rubber bushings, the final tightening must be done under unladen condition and with the

tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

• Unladen condition means the fuel tank, engine coolant and lubricants are at the full specification. The spare

tire, jack, hand tools, and mats are in their designated positions.

• After installing suspension components, check the wheel alignment.

• Caulking nuts are not reusable. Always use new caulking nuts for installation. New caulking nuts are pre- oiled, do not apply any additional lubrication.

Revision: May 2010 2011 Versa

Page 3558 of 3787

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGRSU-5

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

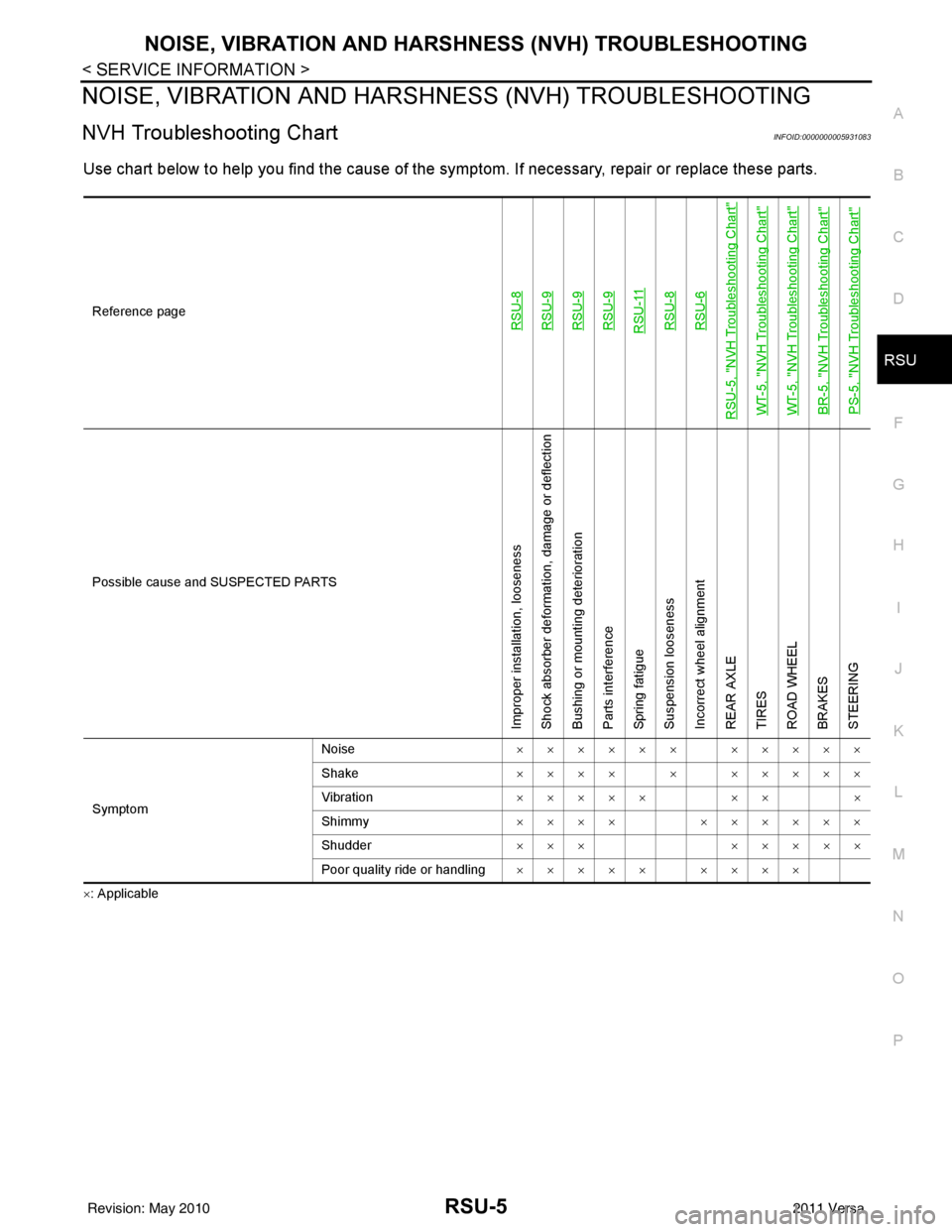

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005931083

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

RSU-8RSU-9RSU-9RSU-9RSU-11RSU-8RSU-6

RSU-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

REAR AXLE

TIRES

ROAD WHEEL

BRAKES

STEERING

Symptom

Noise

×××××× ×××××

Shake ×××× × ×××××

Vibration ××××× ×× ×

Shimmy ×××× ××××××

Shudder ××× ×××××

Poor quality ride or handling ××××× ××××

Revision: May 2010 2011 Versa

Page 3559 of 3787

RSU-6

< SERVICE INFORMATION >

REAR SUSPENSION ASSEMBLY

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000005931084

Make sure the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are within specifications.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace it if necessary.

Wheel AlignmentInspectionINFOID:0000000005931085

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-6

.

3. Wheel bearing axial end play. Refer to RAX-6, "

On-Vehicle Inspection and Service" .

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed. • This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be ca pable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific al ignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-13, "Wheel

Alignment (Unladen*)" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators may not be correct.

• This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com- pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

• Use the “Jacking Compensation” method. After inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

• See Instructions in the alignment machine you are using for more information.

CAMBER INSPECTION

Revision: May 2010 2011 Versa

Page 3560 of 3787

REAR SUSPENSION ASSEMBLYRSU-7

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

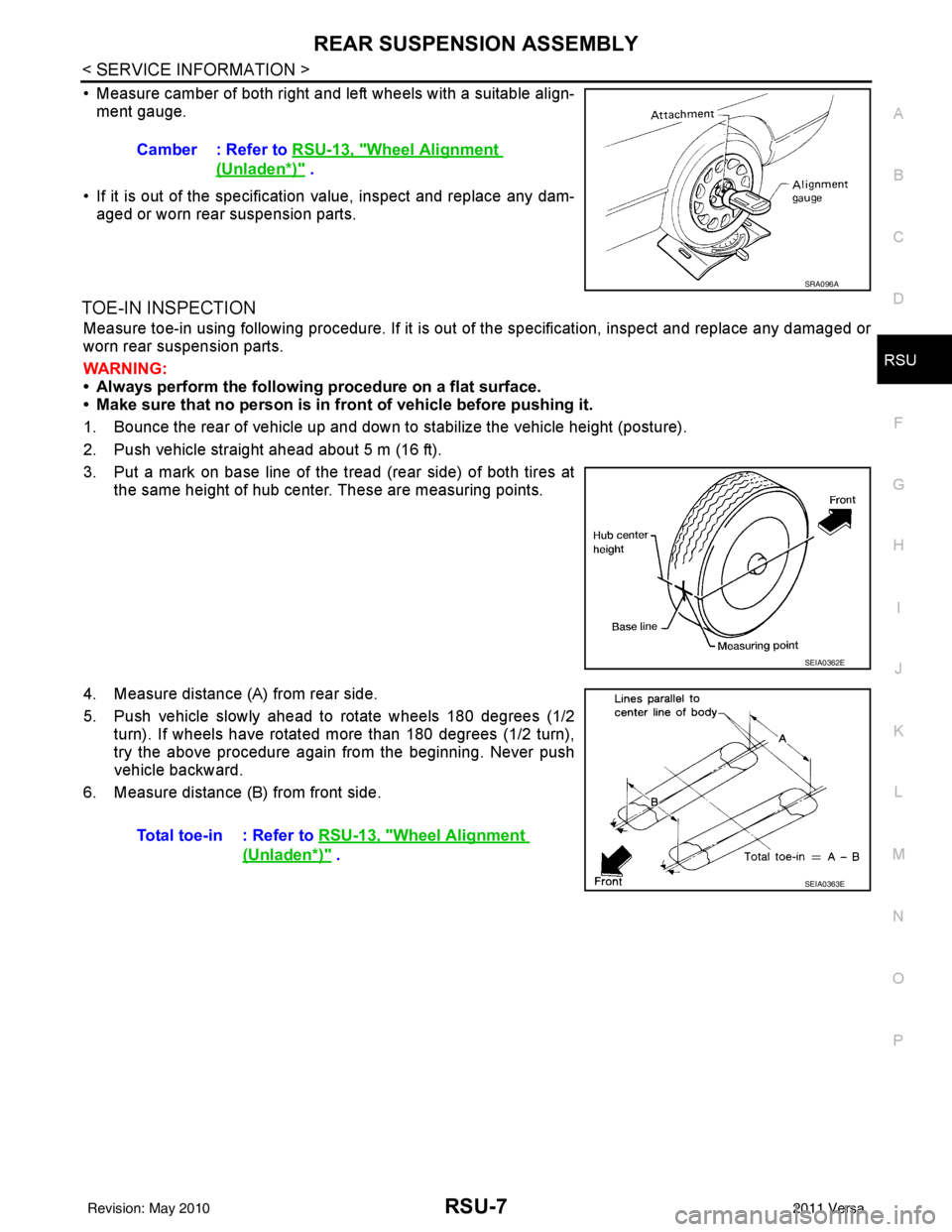

• Measure camber of both right and left wheels with a suitable align- ment gauge.

• If it is out of the specificati on value, inspect and replace any dam-

aged or worn rear suspension parts.

TOE-IN INSPECTION

Measure toe-in using following procedure. If it is out of the specification, inspect and replace any damaged or

worn rear suspension parts.

WARNING:

• Always perform the following procedure on a flat surface.

• Make sure that no person is in fron t of vehicle before pushing it.

1. Bounce the rear of vehicle up and down to stabilize the vehicle height (posture).

2. Push vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of both tires at the same height of hub center. These are measuring points.

4. Measure distance (A) from rear side.

5. Push vehicle slowly ahead to rotate wheels 180 degrees (1/2 turn). If wheels have rotated more than 180 degrees (1/2 turn),

try the above procedure again from the beginning. Never push

vehicle backward.

6. Measure distance (B) from front side. Camber : Refer to

RSU-13, "

Wheel Alignment

(Unladen*)" .

SRA096A

SEIA0362E

Total toe-in : Refer to RSU-13, "Wheel Alignment

(Unladen*)" .

SEIA0363E

Revision: May 2010 2011 Versa

Page 3561 of 3787

RSU-8

< SERVICE INFORMATION >

REAR SUSPENSION ASSEMBLY

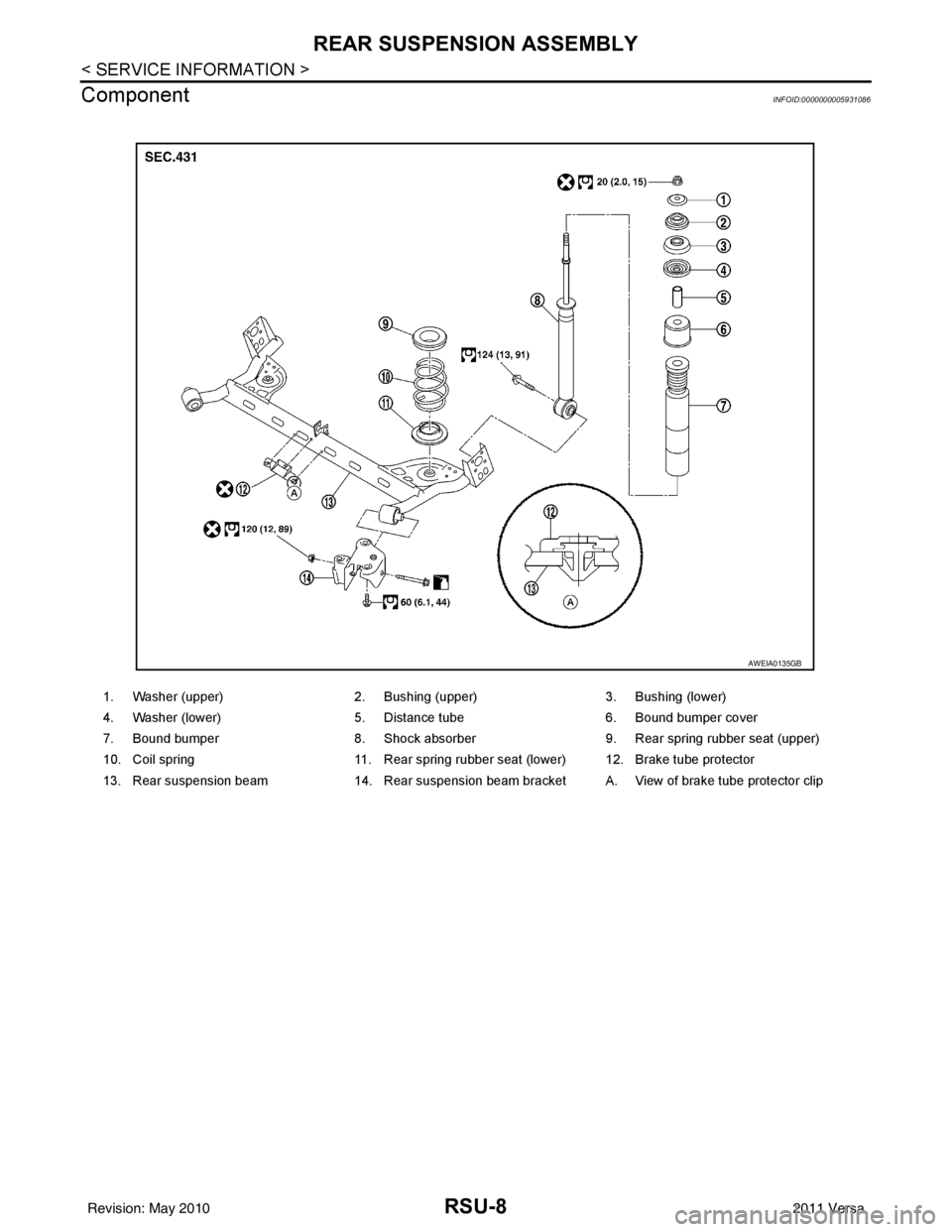

Component

INFOID:0000000005931086

1. Washer (upper) 2. Bushing (upper)3. Bushing (lower)

4. Washer (lower) 5. Distance tube6. Bound bumper cover

7. Bound bumper 8. Shock absorber 9. Rear spring rubber seat (upper)

10. Coil spring 11. Rear spring rubber seat (lower) 12. Brake tube protector

13. Rear suspension beam 14. Rear suspension beam bracket A. View of brake tube protector clip

AWEIA0135GB

Revision: May 2010 2011 Versa