horn NISSAN LEAF 2023 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2023, Model line: LEAF, Model: NISSAN LEAF 2023Pages: 612, PDF Size: 7.42 MB

Page 266 of 612

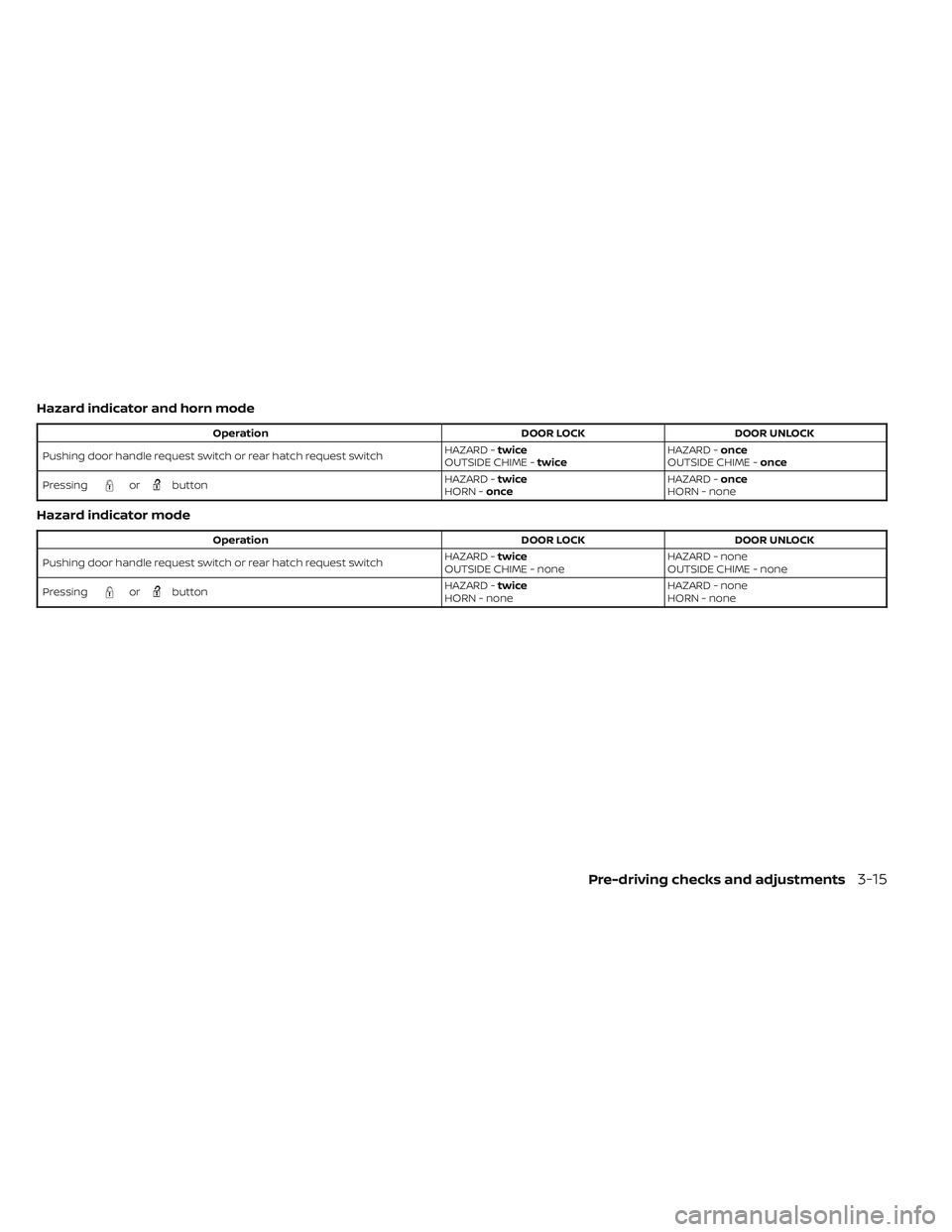

Hazard indicator and horn mode

OperationDOOR LOCKDOOR UNLOCK

Pushing door handle request switch or rear hatch request switch HAZARD -

twice

OUTSIDE CHIME - twice HAZARD -

once

OUTSIDE CHIME - once

Pressing

orbutton HAZARD -

twice

HORN - once HAZARD -

once

HORN - none

Hazard indicator mode

Operation DOOR LOCKDOOR UNLOCK

Pushing door handle request switch or rear hatch request switch HAZARD -

twice

OUTSIDE CHIME - none HAZARD - none

OUTSIDE CHIME - none

Pressing

orbutton HAZARD -

twice

HORN - none HAZARD - none

HORN - none

Pre-driving checks and adjustments3-15

Page 267 of 612

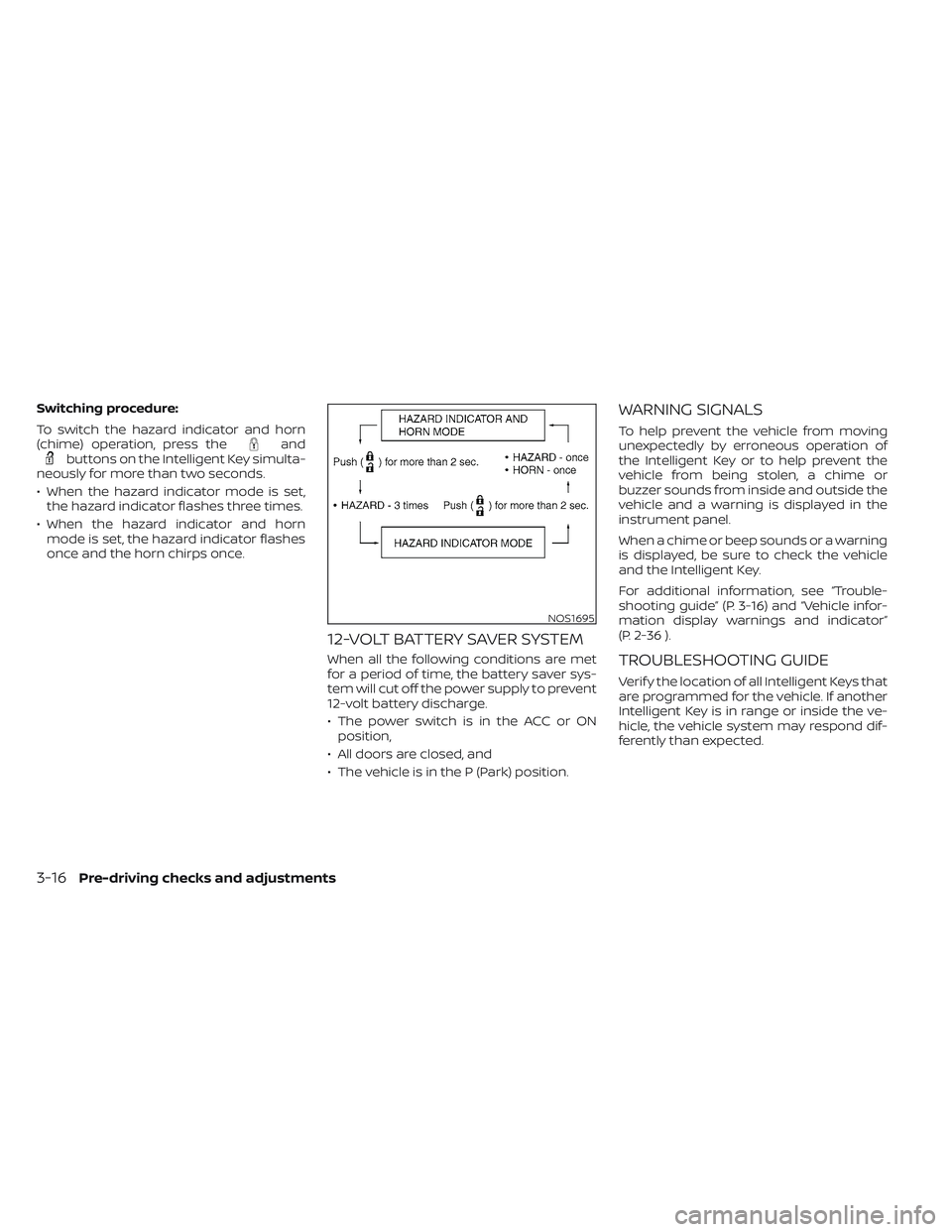

Switching procedure:

To switch the hazard indicator and horn

(chime) operation, press the

andbuttons on the Intelligent Key simulta-

neously for more than two seconds.

• When the hazard indicator mode is set, the hazard indicator flashes three times.

• When the hazard indicator and horn mode is set, the hazard indicator flashes

once and the horn chirps once.

12-VOLT BATTERY SAVER SYSTEM

When all the following conditions are met

for a period of time, the battery saver sys-

tem will cut off the power supply to prevent

12-volt battery discharge.

• The power switch is in the ACC or ONposition,

• All doors are closed, and

• The vehicle is in the P (Park) position.

WARNING SIGNALS

To help prevent the vehicle from moving

unexpectedly by erroneous operation of

the Intelligent Key or to help prevent the

vehicle from being stolen, a chime or

buzzer sounds from inside and outside the

vehicle and a warning is displayed in the

instrument panel.

When a chime or beep sounds or a warning

is displayed, be sure to check the vehicle

and the Intelligent Key.

For additional information, see “Trouble-

shooting guide” (P. 3-16) and “Vehicle infor-

mation display warnings and indicator”

(P. 2-36 ).

TROUBLESHOOTING GUIDE

Verif y the location of all Intelligent Keys that

are programmed for the vehicle. If another

Intelligent Key is in range or inside the ve-

hicle, the vehicle system may respond dif-

ferently than expected.

NOS1695

3-16Pre-driving checks and adjustments

Page 268 of 612

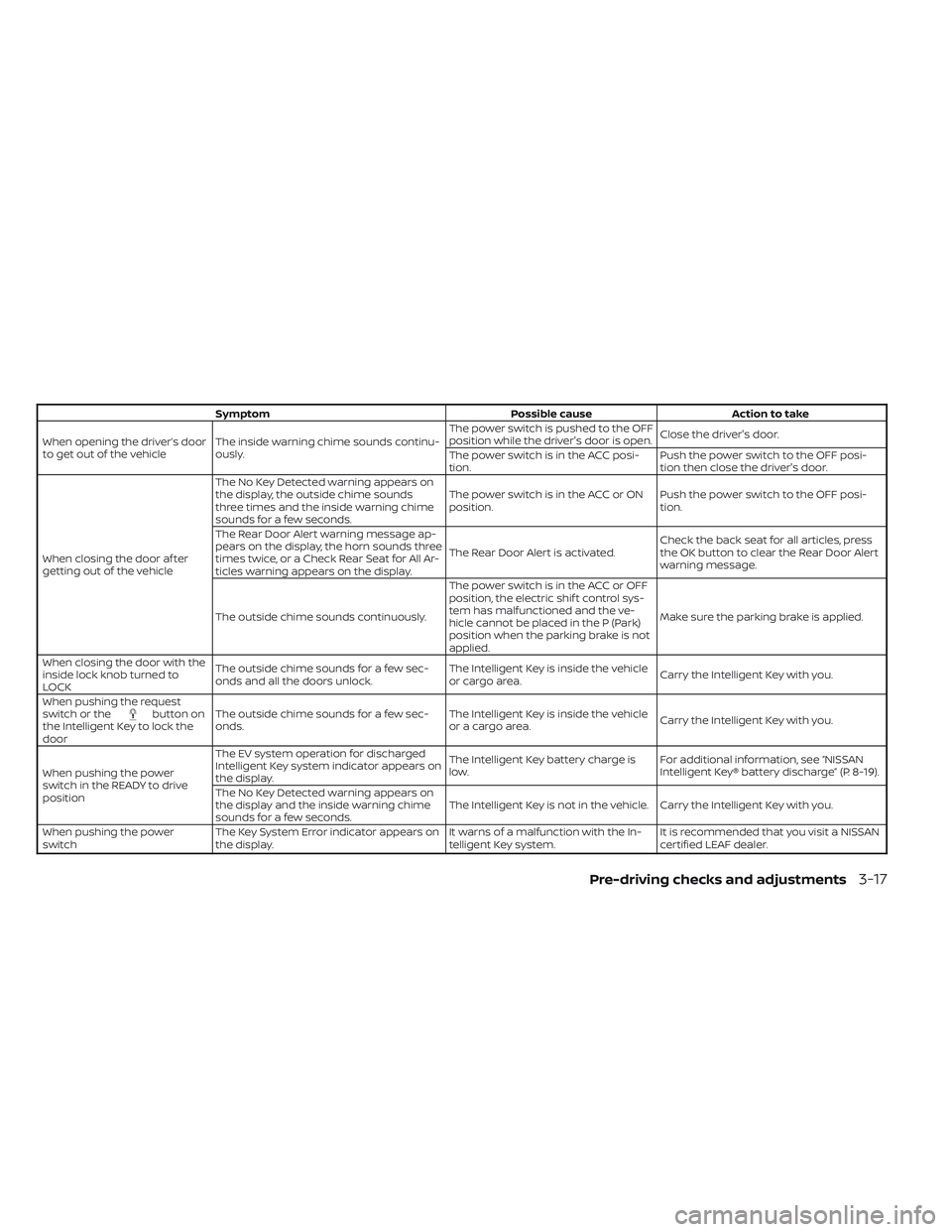

SymptomPossible causeAction to take

When opening the driver’s door

to get out of the vehicle The inside warning chime sounds continu-

ously. The power switch is pushed to the OFF

position while the driver's door is open.

Close the driver's door.

The power switch is in the ACC posi-

tion. Push the power switch to the OFF posi-

tion then close the driver's door.

When closing the door af ter

getting out of the vehicle The No Key Detected warning appears on

the display, the outside chime sounds

three times and the inside warning chime

sounds for a few seconds.

The power switch is in the ACC or ON

position.

Push the power switch to the OFF posi-

tion.

The Rear Door Alert warning message ap-

pears on the display, the horn sounds three

times twice, or a Check Rear Seat for All Ar-

ticles warning appears on the display. The Rear Door Alert is activated.

Check the back seat for all articles, press

the OK button to clear the Rear Door Alert

warning message.

The outside chime sounds continuously. The power switch is in the ACC or OFF

position, the electric shif t control sys-

tem has malfunctioned and the ve-

hicle cannot be placed in the P (Park)

position when the parking brake is not

applied.Make sure the parking brake is applied.

When closing the door with the

inside lock knob turned to

LOCK The outside chime sounds for a few sec-

onds and all the doors unlock.

The Intelligent Key is inside the vehicle

or cargo area.

Carry the Intelligent Key with you.

When pushing the request

switch or the

button on

the Intelligent Key to lock the

door The outside chime sounds for a few sec-

onds.

The Intelligent Key is inside the vehicle

or a cargo area.

Carry the Intelligent Key with you.

When pushing the power

switch in the READY to drive

position The EV system operation for discharged

Intelligent Key system indicator appears on

the display.

The Intelligent Key battery charge is

low.

For additional information, see “NISSAN

Intelligent Key® battery discharge” (P. 8-19).

The No Key Detected warning appears on

the display and the inside warning chime

sounds for a few seconds. The Intelligent Key is not in the vehicle. Carry the Intelligent Key with you.

When pushing the power

switch The Key System Error indicator appears on

the display. It warns of a malfunction with the In-

telligent Key system.It is recommended that you visit a NISSAN

certified LEAF dealer.

Pre-driving checks and adjustments3-17

Page 330 of 612

TPMS with Easy-Fill Tire Alert

When tire pressure is low, the low tire pres-

sure warning light illuminates.

This vehicle provides visual and audible

signals to help you inflate the tires to the

recommended COLD tire pressure.

Vehicle set-up:

1. Park the vehicle in a safe and level place.

2. Apply the parking brake and push the P(Park) position switch on the shif t lever.

3. Place the power switch in the ON posi- tion. Do not place in the READY to drive

mode.

Operation:

1. Add air to the tire.

2. Af ter a few seconds, the hazard indica- tors will start flashing.

3. When the designated pressure is reached, the horn beeps once and the

hazard indicators stop flashing.

4. Perform the above steps for each tire. • If the tire is over-inflated more thanapproximately 4 psi (30 kPa), the horn

beeps and the hazard indicators flash

three times. To correct the pressure,

push the core of the valve stem on the tire briefly to release pressure. When

the pressure reaches the designated

pressure, the horn beeps once.

• If the hazard indicator does not flash within approximately 15 seconds af ter

starting to inflate the tire, it indicates

that the Easy-Fill Tire Alert is not

operating.

• The TPMS will not activate the Easy-Fill Tire Alert under the following

conditions:– If there is interference from an exter- nal device or transmitter.

– The air pressure from the inflation device is not sufficient to inflate the

tire, such as those using a power

socket.

– If electrical equipment is being used in or near the vehicle.

– There is a malfunction in the TPMS.

– There is a malfunction in the horn or hazard indicators.

– If the Easy-Fill Tire Alert does not op- erate due to TPMS interference,

move the vehicle about 3 f t (1 m)

backward or forward and try again.

If the Easy-Fill Tire Alert is not working, use a

tire pressure gauge.

AVOIDING COLLISION AND

ROLLOVER

WARNING

Failure to operate this vehicle in a safe

and prudent manner may result in loss

of control or an accident.

Be alert and drive defensively at all times.

Obey all traffic regulations. Avoid excessive

speed, high speed cornering, or sudden

steering maneuvers because these driving

practices could cause you to lose control of

your vehicle.

As with any vehicle, loss of control could

result in a collision with other vehicles or

objects or cause the vehicle to roll over,

particularly if the loss of control causes

the vehicle to slide sideways.

Be attentive at all times, and avoid driving

when tired. Never drive when under the in-

fluence of alcohol or drugs (including pre-

scription or over-the-counter drugs which

may cause drowsiness). Always wear your

seat belt as outlined in “Seat belts” (P. 7-6),

and also instruct your passengers to do so.

Seat belts help reduce the risk of injury in

collisions and rollovers.

Starting and driving5-7

Page 568 of 612

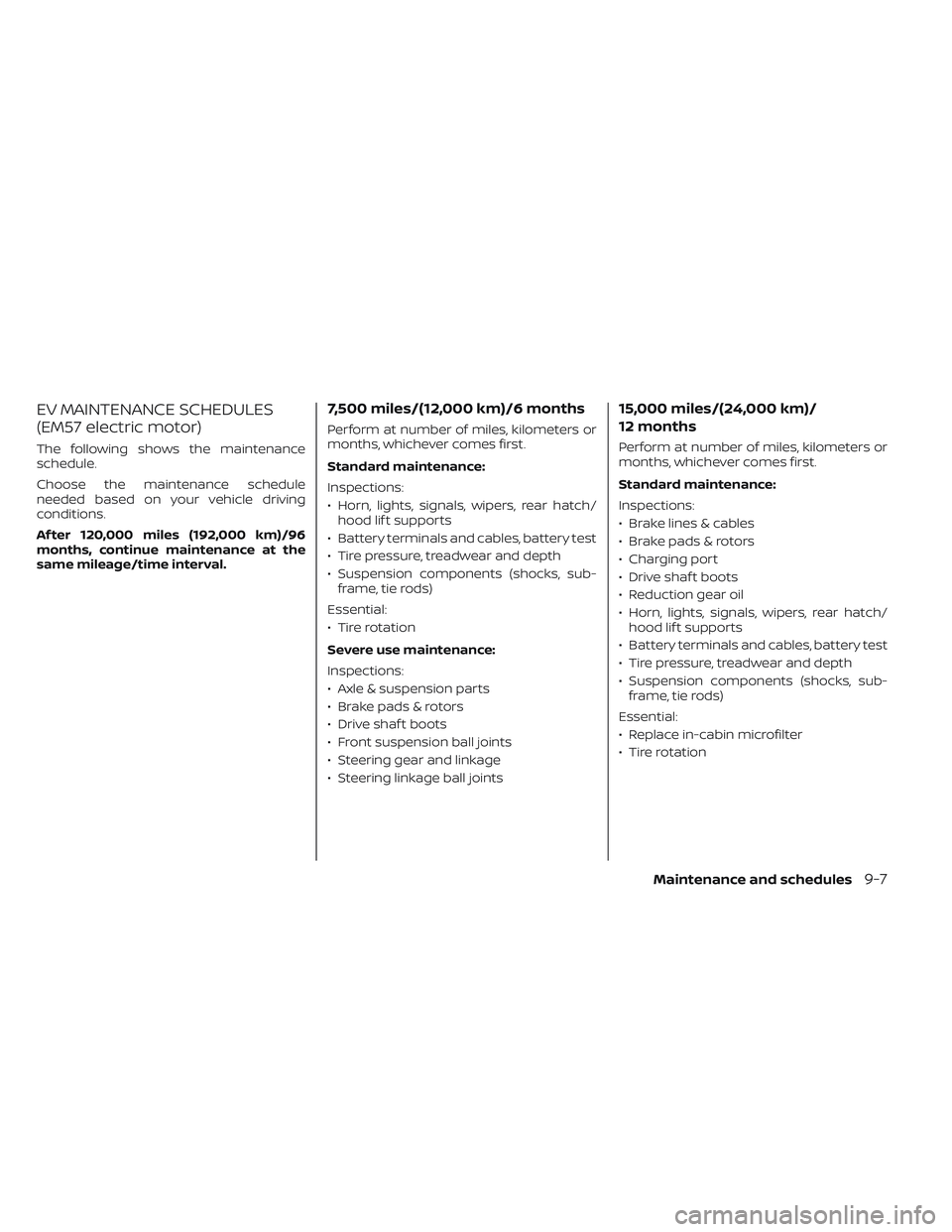

EV MAINTENANCE SCHEDULES

(EM57 electric motor)

The following shows the maintenance

schedule.

Choose the maintenance schedule

needed based on your vehicle driving

conditions.

Af ter 120,000 miles (192,000 km)/96

months, continue maintenance at the

same mileage/time interval.

7,500 miles/(12,000 km)/6 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Horn, lights, signals, wipers, rear hatch/hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

Essential:

• Tire rotation

Severe use maintenance:

Inspections:

• Axle & suspension parts

• Brake pads & rotors

• Drive shaf t boots

• Front suspension ball joints

• Steering gear and linkage

• Steering linkage ball joints

15,000 miles/(24,000 km)/

12 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Brake lines & cables

• Brake pads & rotors

• Charging port

• Drive shaf t boots

• Reduction gear oil

• Horn, lights, signals, wipers, rear hatch/ hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

Essential:

• Replace in-cabin microfilter

• Tire rotation

Maintenance and schedules9-7

Page 569 of 612

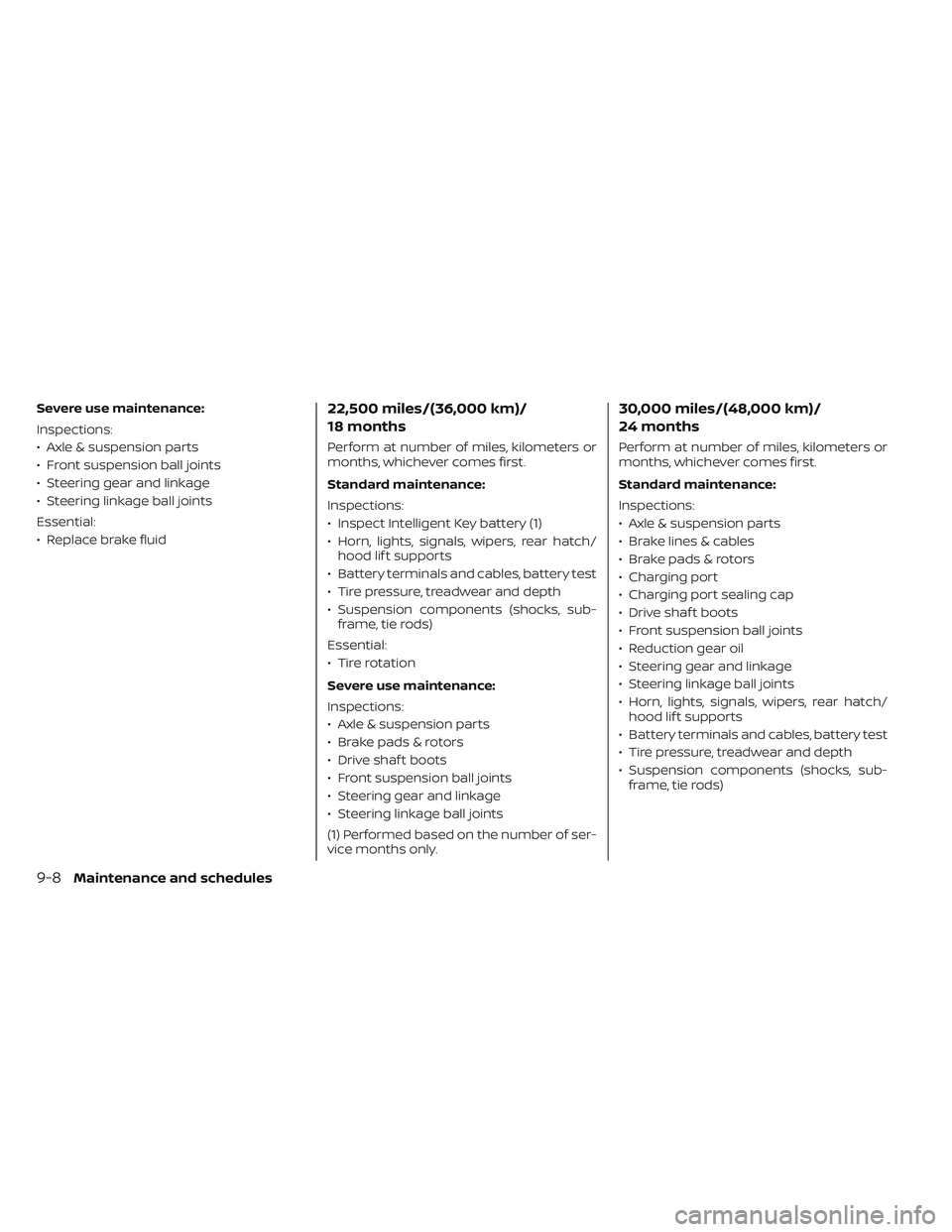

Severe use maintenance:

Inspections:

• Axle & suspension parts

• Front suspension ball joints

• Steering gear and linkage

• Steering linkage ball joints

Essential:

• Replace brake fluid22,500 miles/(36,000 km)/

18 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Inspect Intelligent Key battery (1)

• Horn, lights, signals, wipers, rear hatch/hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

Essential:

• Tire rotation

Severe use maintenance:

Inspections:

• Axle & suspension parts

• Brake pads & rotors

• Drive shaf t boots

• Front suspension ball joints

• Steering gear and linkage

• Steering linkage ball joints

(1) Performed based on the number of ser-

vice months only.

30,000 miles/(48,000 km)/

24 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Axle & suspension parts

• Brake lines & cables

• Brake pads & rotors

• Charging port

• Charging port sealing cap

• Drive shaf t boots

• Front suspension ball joints

• Reduction gear oil

• Steering gear and linkage

• Steering linkage ball joints

• Horn, lights, signals, wipers, rear hatch/ hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

9-8Maintenance and schedules

Page 570 of 612

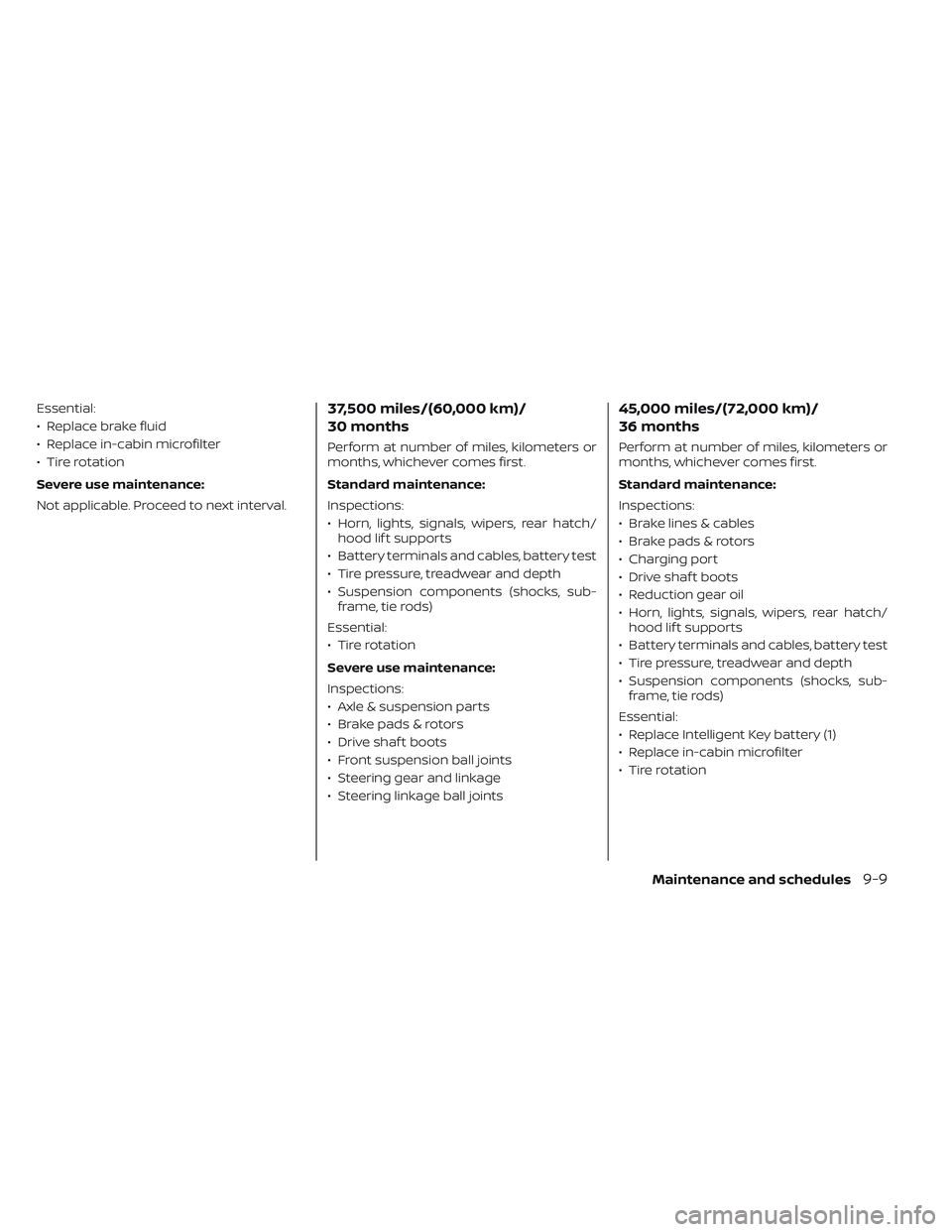

Essential:

• Replace brake fluid

• Replace in-cabin microfilter

• Tire rotation

Severe use maintenance:

Not applicable. Proceed to next interval.37,500 miles/(60,000 km)/

30 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Horn, lights, signals, wipers, rear hatch/hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

Essential:

• Tire rotation

Severe use maintenance:

Inspections:

• Axle & suspension parts

• Brake pads & rotors

• Drive shaf t boots

• Front suspension ball joints

• Steering gear and linkage

• Steering linkage ball joints

45,000 miles/(72,000 km)/

36 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Brake lines & cables

• Brake pads & rotors

• Charging port

• Drive shaf t boots

• Reduction gear oil

• Horn, lights, signals, wipers, rear hatch/ hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

Essential:

• Replace Intelligent Key battery (1)

• Replace in-cabin microfilter

• Tire rotation

Maintenance and schedules9-9

Page 571 of 612

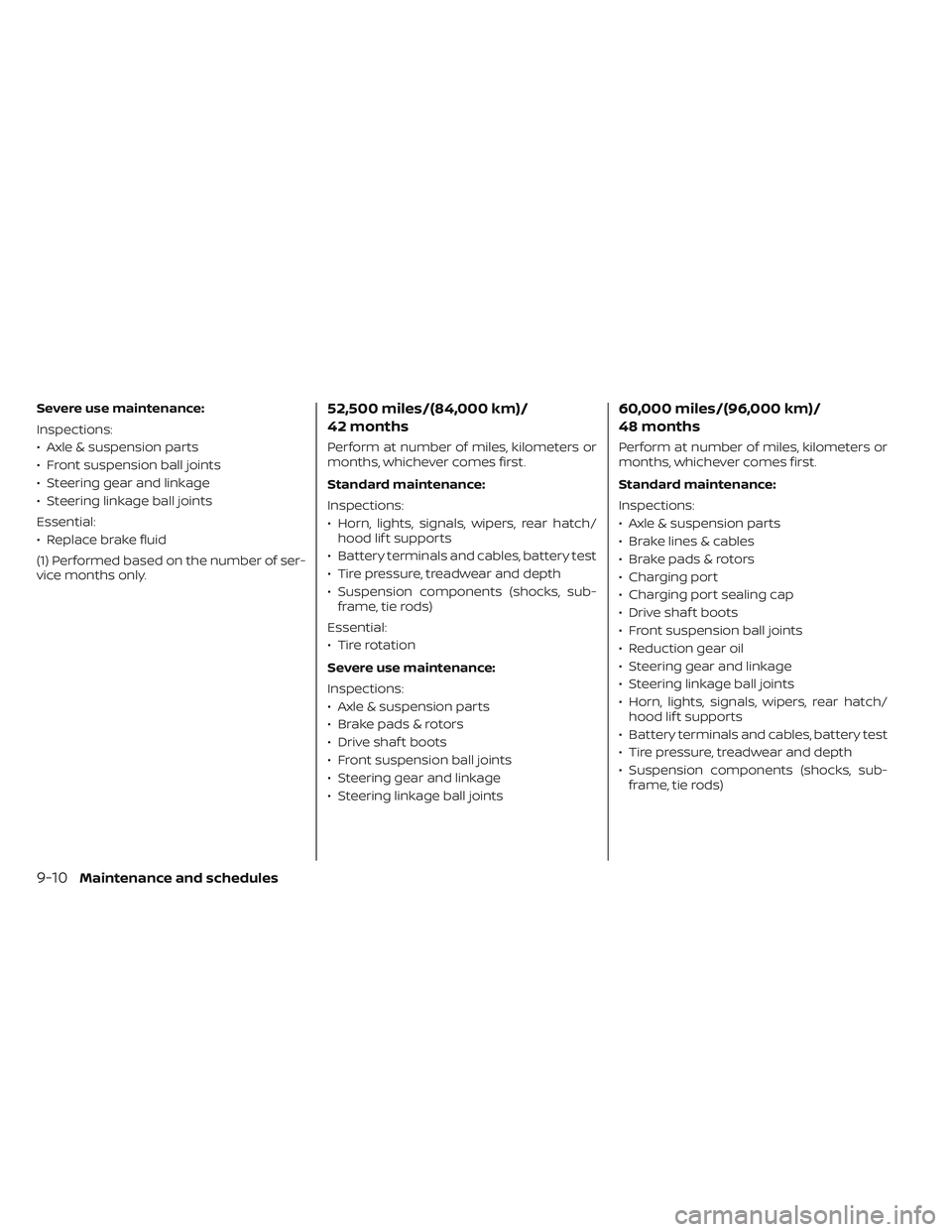

Severe use maintenance:

Inspections:

• Axle & suspension parts

• Front suspension ball joints

• Steering gear and linkage

• Steering linkage ball joints

Essential:

• Replace brake fluid

(1) Performed based on the number of ser-

vice months only.52,500 miles/(84,000 km)/

42 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Horn, lights, signals, wipers, rear hatch/hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

Essential:

• Tire rotation

Severe use maintenance:

Inspections:

• Axle & suspension parts

• Brake pads & rotors

• Drive shaf t boots

• Front suspension ball joints

• Steering gear and linkage

• Steering linkage ball joints

60,000 miles/(96,000 km)/

48 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Axle & suspension parts

• Brake lines & cables

• Brake pads & rotors

• Charging port

• Charging port sealing cap

• Drive shaf t boots

• Front suspension ball joints

• Reduction gear oil

• Steering gear and linkage

• Steering linkage ball joints

• Horn, lights, signals, wipers, rear hatch/ hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

9-10Maintenance and schedules

Page 572 of 612

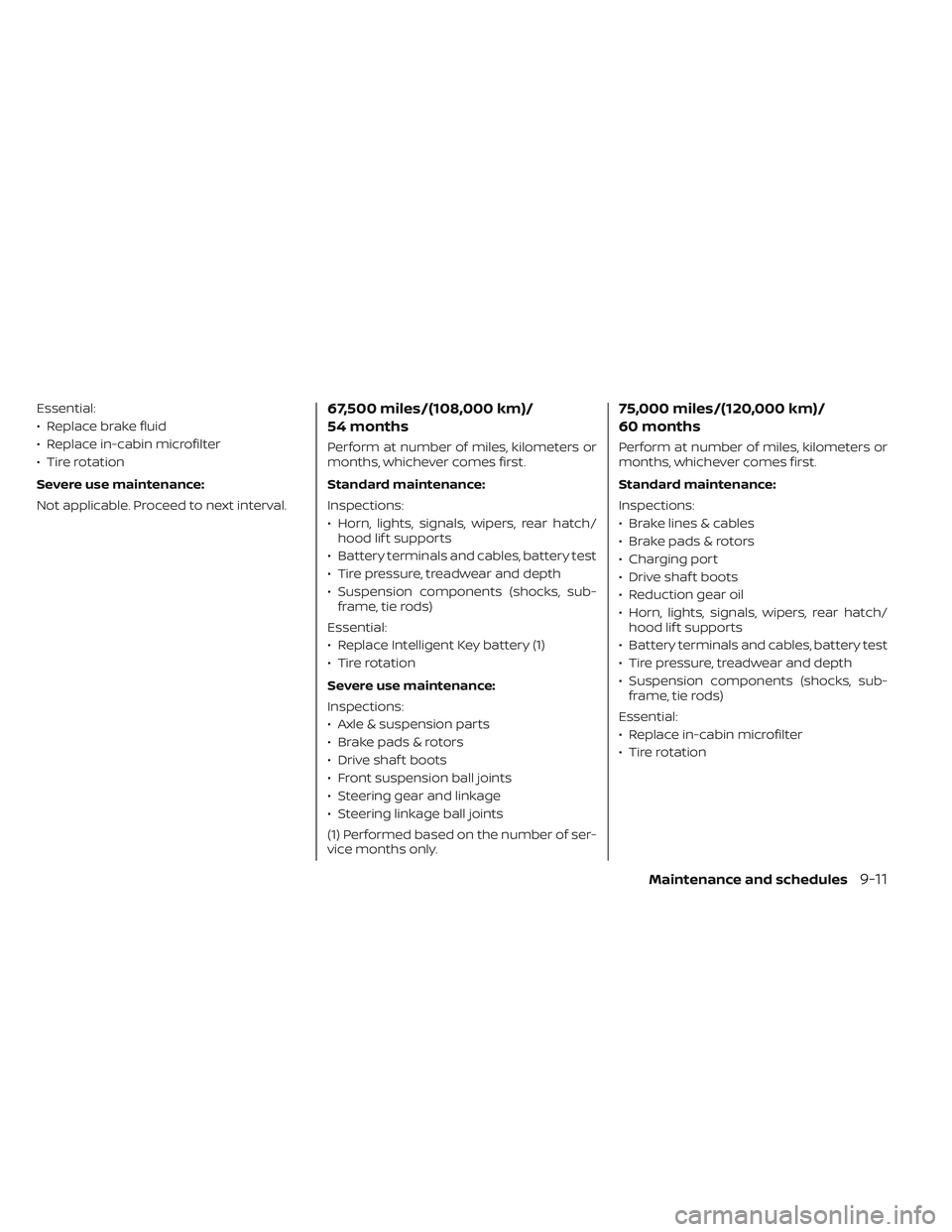

Essential:

• Replace brake fluid

• Replace in-cabin microfilter

• Tire rotation

Severe use maintenance:

Not applicable. Proceed to next interval.67,500 miles/(108,000 km)/

54 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Horn, lights, signals, wipers, rear hatch/hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

Essential:

• Replace Intelligent Key battery (1)

• Tire rotation

Severe use maintenance:

Inspections:

• Axle & suspension parts

• Brake pads & rotors

• Drive shaf t boots

• Front suspension ball joints

• Steering gear and linkage

• Steering linkage ball joints

(1) Performed based on the number of ser-

vice months only.

75,000 miles/(120,000 km)/

60 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Brake lines & cables

• Brake pads & rotors

• Charging port

• Drive shaf t boots

• Reduction gear oil

• Horn, lights, signals, wipers, rear hatch/ hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

Essential:

• Replace in-cabin microfilter

• Tire rotation

Maintenance and schedules9-11

Page 573 of 612

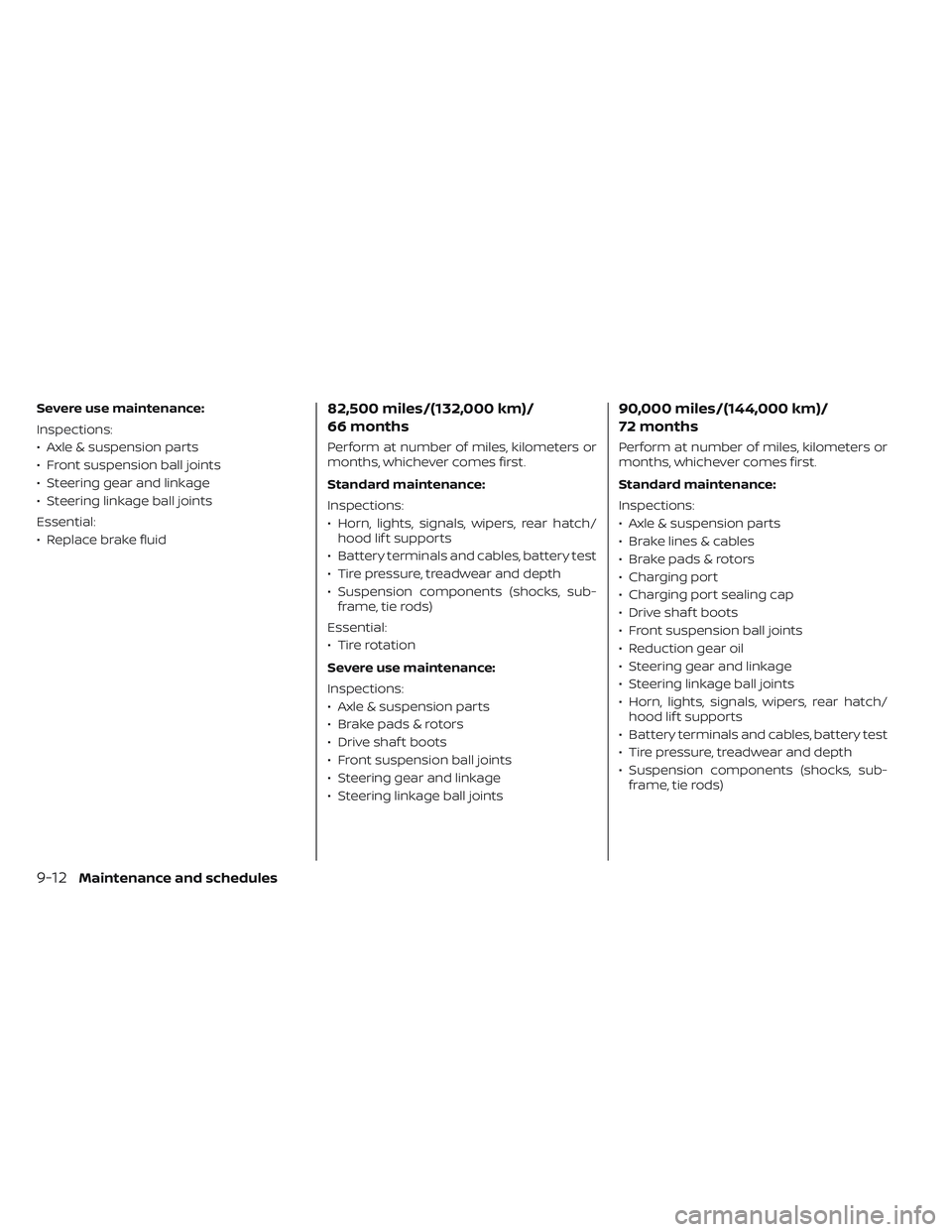

Severe use maintenance:

Inspections:

• Axle & suspension parts

• Front suspension ball joints

• Steering gear and linkage

• Steering linkage ball joints

Essential:

• Replace brake fluid82,500 miles/(132,000 km)/

66 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Horn, lights, signals, wipers, rear hatch/hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

Essential:

• Tire rotation

Severe use maintenance:

Inspections:

• Axle & suspension parts

• Brake pads & rotors

• Drive shaf t boots

• Front suspension ball joints

• Steering gear and linkage

• Steering linkage ball joints

90,000 miles/(144,000 km)/

72 months

Perform at number of miles, kilometers or

months, whichever comes first.

Standard maintenance:

Inspections:

• Axle & suspension parts

• Brake lines & cables

• Brake pads & rotors

• Charging port

• Charging port sealing cap

• Drive shaf t boots

• Front suspension ball joints

• Reduction gear oil

• Steering gear and linkage

• Steering linkage ball joints

• Horn, lights, signals, wipers, rear hatch/ hood lif t supports

• Battery terminals and cables, battery test

• Tire pressure, treadwear and depth

• Suspension components (shocks, sub- frame, tie rods)

9-12Maintenance and schedules