engine oil NISSAN MAXIMA 1998 A32 / 4.G Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: MAXIMA, Model: NISSAN MAXIMA 1998 A32 / 4.GPages: 231, PDF Size: 1.94 MB

Page 52 of 231

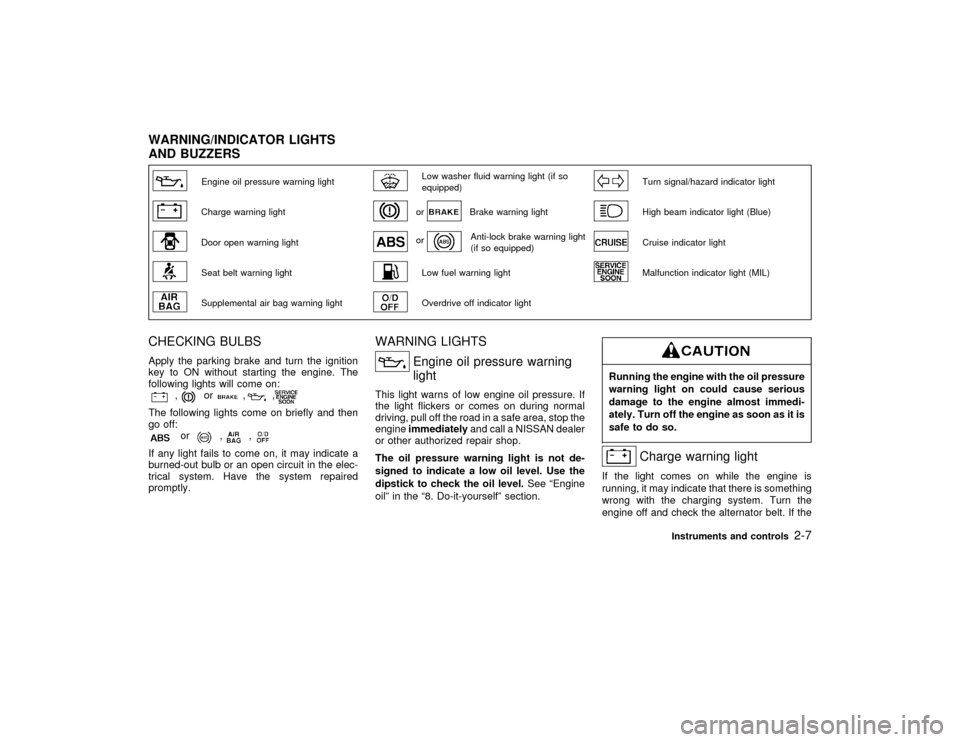

Engine oil pressure warning light

Low washer fluid warning light (if so

equipped)

Turn signal/hazard indicator light

Charge warning light

or

Brake warning light

High beam indicator light (Blue)

Door open warning light

or

Anti-lock brake warning light

(if so equipped)

Cruise indicator light

Seat belt warning light

Low fuel warning light

Malfunction indicator light (MIL)

Supplemental air bag warning light

Overdrive off indicator light

CHECKING BULBSApply the parking brake and turn the ignition

key to ON without starting the engine. The

following lights will come on:

,

or

,

,

The following lights come on briefly and then

go off:

or

,

,

If any light fails to come on, it may indicate a

burned-out bulb or an open circuit in the elec-

trical system. Have the system repaired

promptly.

WARNING LIGHTS

Engine oil pressure warning

light

This light warns of low engine oil pressure. If

the light flickers or comes on during normal

driving, pull off the road in a safe area, stop the

engineimmediatelyand call a NISSAN dealer

or other authorized repair shop.

The oil pressure warning light is not de-

signed to indicate a low oil level. Use the

dipstick to check the oil level.See ªEngine

oilº in the ª8. Do-it-yourselfº section.

Running the engine with the oil pressure

warning light on could cause serious

damage to the engine almost immedi-

ately. Turn off the engine as soon as it is

safe to do so.

Charge warning light

If the light comes on while the engine is

running, it may indicate that there is something

wrong with the charging system. Turn the

engine off and check the alternator belt. If the

WARNING/INDICATOR LIGHTS

AND BUZZERS

Instruments and controls

2-7

Z

01.1.31/A32-D

X

Page 121 of 231

KEY POSITIONSThe switch includes an anti-theft steering lock

device.

LOCK (Normal parking position) (0)

The ignition key can only be removed when

the switch is in this position.

OFF (1)

The engine can be turned off without locking

the steering wheel.

ACC (Accessories) (2)

This position activates electrical accessories

such as the radio when the engine is not

running.

ON (Normal operating position) (3)

This position turns on the ignition system and

the electrical accessories.

START (4)

This position activates the starter motor, start-

ing the engine.IMake sure the area around the vehicle is

clear.

IMaintenance items listed here should be

checked periodically, e.g., each time you

check engine oil.

ICheck that all windows and lights are clean.

IVisually inspect tires for their appearance

and condition. Also check tires for proper

inflation.

ILock all doors.

IPosition seat and adjust head restraints.

IAdjust inside and outside mirrors.

IFasten seat belts and ask all passengers to

do likewise.

ICheck the operation of warning lights when

key is turned to the ON (3) position.1. Apply the parking brake.

2.Automatic transmission:

Move the selector lever to P (Park) or N

(Neutral). (P preferred.)

The selector lever cannot be moved out of

P (Park) position and into any of the other

gear positions if the key is removed from

the switch.

The starter is designed not to operate if the

selector lever is in one of the driving posi-

tions.

Manual transmission:

Move the shift lever to N (Neutral) position,

and depress the clutch pedal to the floor

while cranking the engine.

The starter is designed not to operate un-

less the clutch pedal is depressed.

3. Crank the enginewith your foot off the

accelerator pedalby turning the ignition

key to START. Release the key when the

engine starts. If the engine starts, but fails

to run, repeat the above procedure.

IIf the engine is very hard to start in

extremely cold or hot weather, de-

press the accelerator pedal and hold it

to help start the engine.

BEFORE STARTING THE ENGINE STARTING THE ENGINE

5-6

Starting and driving

Z

01.1.31/A32-D

X

Page 142 of 231

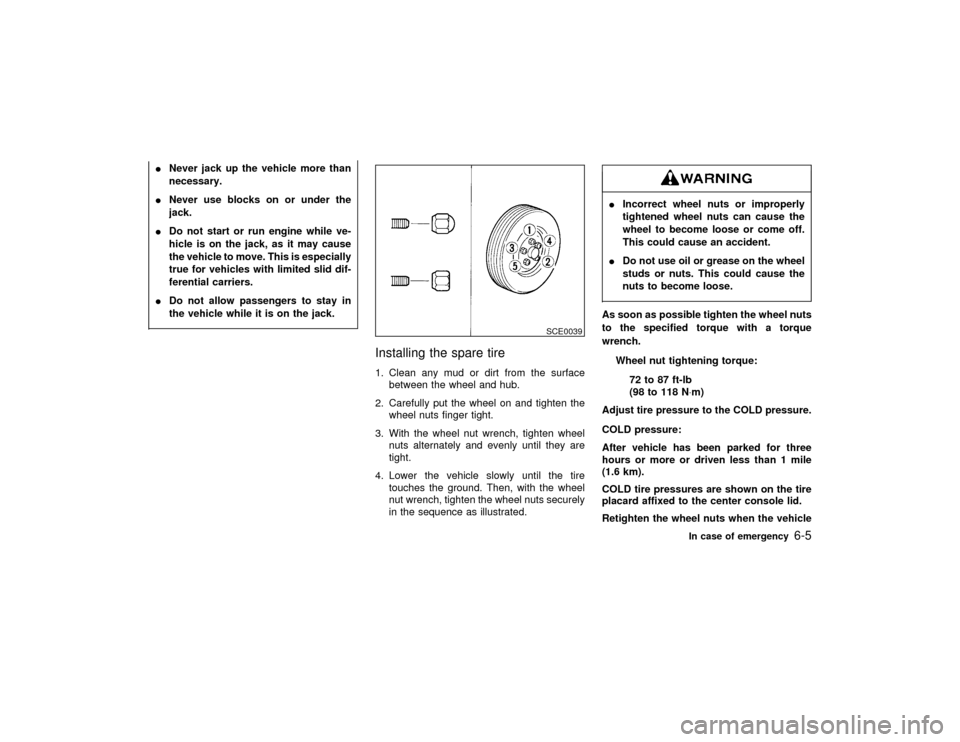

INever jack up the vehicle more than

necessary.

INever use blocks on or under the

jack.

IDo not start or run engine while ve-

hicle is on the jack, as it may cause

the vehicle to move. This is especially

true for vehicles with limited slid dif-

ferential carriers.

IDo not allow passengers to stay in

the vehicle while it is on the jack.

Installing the spare tire1. Clean any mud or dirt from the surface

between the wheel and hub.

2. Carefully put the wheel on and tighten the

wheel nuts finger tight.

3. With the wheel nut wrench, tighten wheel

nuts alternately and evenly until they are

tight.

4. Lower the vehicle slowly until the tire

touches the ground. Then, with the wheel

nut wrench, tighten the wheel nuts securely

in the sequence as illustrated.

IIncorrect wheel nuts or improperly

tightened wheel nuts can cause the

wheel to become loose or come off.

This could cause an accident.

IDo not use oil or grease on the wheel

studs or nuts. This could cause the

nuts to become loose.As soon as possible tighten the wheel nuts

to the specified torque with a torque

wrench.

Wheel nut tightening torque:

72 to 87 ft-lb

(98 to 118 N×m)

Adjust tire pressure to the COLD pressure.

COLD pressure:

After vehicle has been parked for three

hours or more or driven less than 1 mile

(1.6 km).

COLD tire pressures are shown on the tire

placard affixed to the center console lid.

Retighten the wheel nuts when the vehicle

SCE0039

In case of emergency

6-5

Z

01.1.31/A32-D

X

Page 156 of 231

8 Do-it-yourselfMaintenance precautions .......................................... 8-2

Engine compartment check locations ....................... 8-4

Engine cooling system .............................................. 8-5

Engine oil .................................................................. 8-8

Automatic transaxle fluid ......................................... 8-10

Power steering fluid ................................................ 8-12

Brake and clutch fluid ............................................. 8-12

Window washer fluid ............................................... 8-13

Battery ..................................................................... 8-14

Drive belts ............................................................... 8-15

Spark plugs ............................................................. 8-16

Air cleaner ............................................................... 8-18

Windshield wiper blades ......................................... 8-18

Parking brake and brake pedal ............................... 8-20

Clutch pedal ............................................................ 8-21

Fuses....................................................................... 8-21

Lights ....................................................................... 8-24

Tires and wheels ..................................................... 8-31

Z

01.1.31/A32-D

X

Page 157 of 231

When performing any inspection or mainte-

nance work on your vehicle, always take care

to prevent serious accidental injury to yourself

or damage to the vehicle. The following are

general precautions which should be closely

observed.IPark the vehicle on a level surface,

apply the parking brake securely and

block the wheels to prevent the ve-

hicle from moving. For a manual

transmission, move the shift lever to

N (Neutral) position. For an automatic

transmission, move the selector lever

to P (Park) position.

IBe sure the ignition key is OFF or

LOCK when performing any parts re-

placement or repairs.

IYour vehicle is equipped with an au-

tomatic engine cooling fan. It may

come on at any time without warning,

even if the ignition key is in the OFF

position and the engine is not run-

ning. To avoid injury, always discon-

nect the negative battery cable before

working near the fan.IIf you must work with the engine

running, keep your hands, clothing,

hair and tools away from moving

fans, belts and any other moving

parts.

IIt is advisable to remove necktie and

any jewelry, such as rings, watches,

etc. before working on your vehicle.

IAlways wear eye protection when-

ever you work on your vehicle.

IIf you must run the engine in an

enclosed space such as a garage, be

sure there is proper ventilation for

exhaust gases.

INever get under the vehicle while it is

supported only by a jack. If it is nec-

essary to work under the vehicle,

support it with safety stands.

IKeep smoking materials, flame and

sparks away from fuel and the bat-

tery.

IOn gasoline engine models with the

Multiport Fuel Injection (MFI) System,

the fuel filter or fuel lines should be

serviced by a NISSAN dealer becausethe fuel lines are under high pressure

even when the engine is off.

IDo not work under the hood while the

engine is hot. Turn off the engine and

wait until it cools down.

INever connect or disconnect either

the battery or any transistorized com-

ponent connector while the ignition

key is on.

INever leave the engine or the auto-

matic transmission related compo-

nent harness connector discon-

nected while the ignition key is on.

IAvoid direct contact with used engine

oil. Improperly disposed motor oil

and/or other vehicle fluids can hurt

the environment. Always conform to

local regulations for disposal of ve-

hicle fluid.This ª8. Do-it-yourselfº section gives instruc-

tions regarding only those items which are

relatively easy for an owner to perform.

MAINTENANCE PRECAUTIONS8-2

Do-it-yourself

Z

01.1.31/A32-D

X

Page 163 of 231

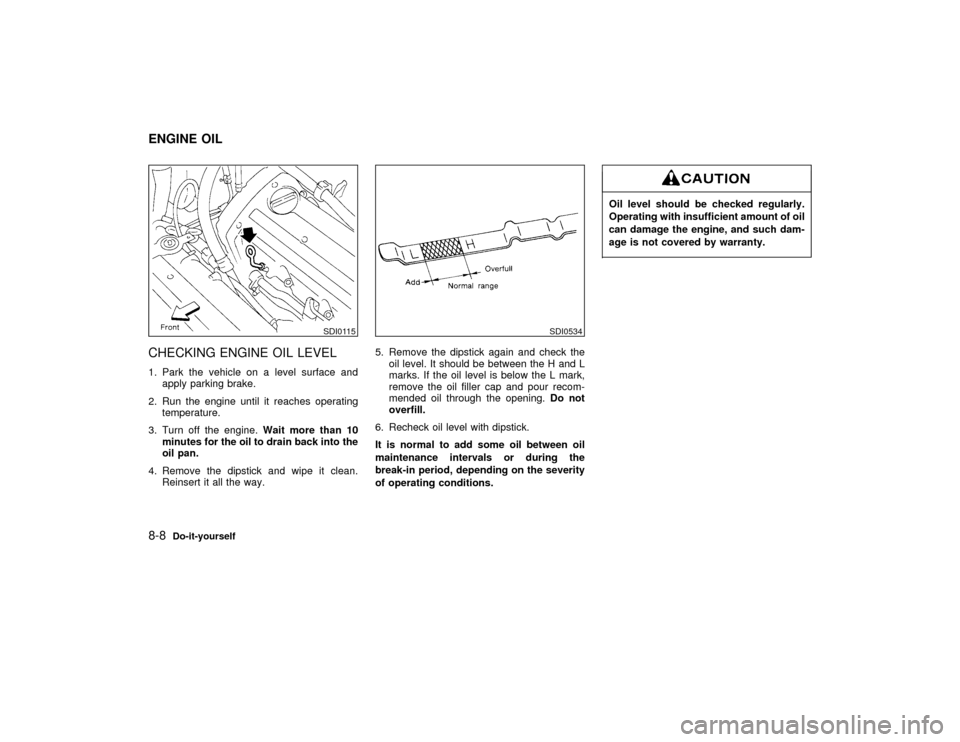

CHECKING ENGINE OIL LEVEL1. Park the vehicle on a level surface and

apply parking brake.

2. Run the engine until it reaches operating

temperature.

3. Turn off the engine.Wait more than 10

minutes for the oil to drain back into the

oil pan.

4. Remove the dipstick and wipe it clean.

Reinsert it all the way.5. Remove the dipstick again and check the

oil level. It should be between the H and L

marks. If the oil level is below the L mark,

remove the oil filler cap and pour recom-

mended oil through the opening.Do not

overfill.

6. Recheck oil level with dipstick.

It is normal to add some oil between oil

maintenance intervals or during the

break-in period, depending on the severity

of operating conditions.

Oil level should be checked regularly.

Operating with insufficient amount of oil

can damage the engine, and such dam-

age is not covered by warranty.

SDI0115

SDI0534

ENGINE OIL8-8

Do-it-yourself

Z

01.1.31/A32-D

X

Page 164 of 231

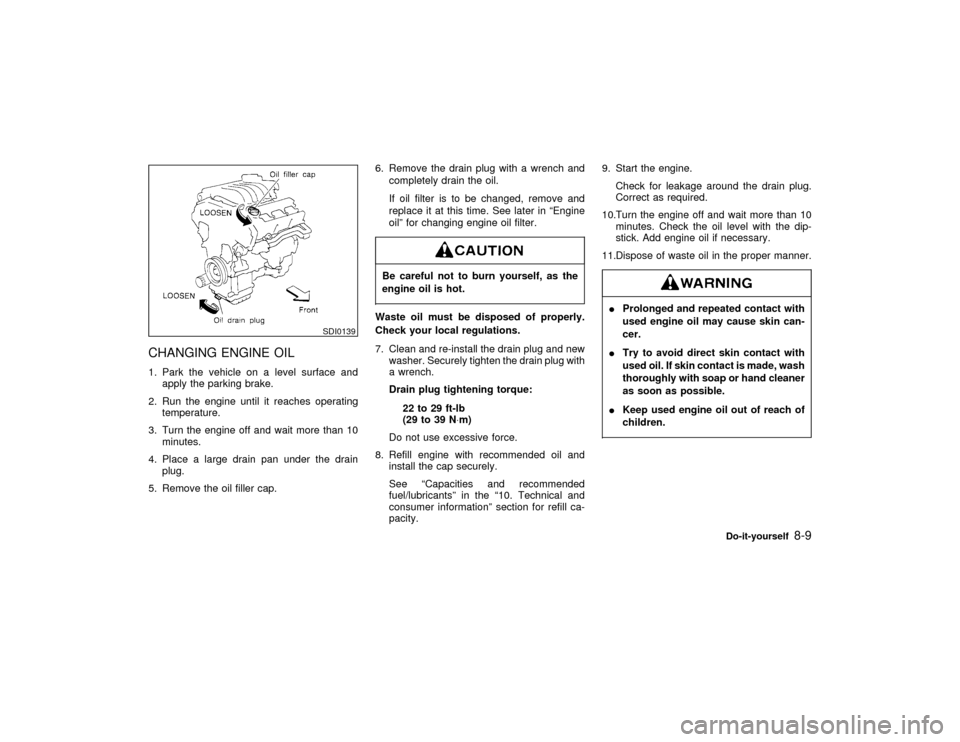

CHANGING ENGINE OIL1. Park the vehicle on a level surface and

apply the parking brake.

2. Run the engine until it reaches operating

temperature.

3. Turn the engine off and wait more than 10

minutes.

4. Place a large drain pan under the drain

plug.

5. Remove the oil filler cap.6. Remove the drain plug with a wrench and

completely drain the oil.

If oil filter is to be changed, remove and

replace it at this time. See later in ªEngine

oilº for changing engine oil filter.

Be careful not to burn yourself, as the

engine oil is hot.Waste oil must be disposed of properly.

Check your local regulations.

7. Clean and re-install the drain plug and new

washer. Securely tighten the drain plug with

a wrench.

Drain plug tightening torque:

22 to 29 ft-lb

(29 to 39 N×m)

Do not use excessive force.

8. Refill engine with recommended oil and

install the cap securely.

See ªCapacities and recommended

fuel/lubricantsº in the ª10. Technical and

consumer informationº section for refill ca-

pacity.9. Start the engine.

Check for leakage around the drain plug.

Correct as required.

10.Turn the engine off and wait more than 10

minutes. Check the oil level with the dip-

stick. Add engine oil if necessary.

11.Dispose of waste oil in the proper manner.

IProlonged and repeated contact with

used engine oil may cause skin can-

cer.

ITry to avoid direct skin contact with

used oil. If skin contact is made, wash

thoroughly with soap or hand cleaner

as soon as possible.

IKeep used engine oil out of reach of

children.

SDI0139

Do-it-yourself

8-9

Z

01.1.31/A32-D

X

Page 165 of 231

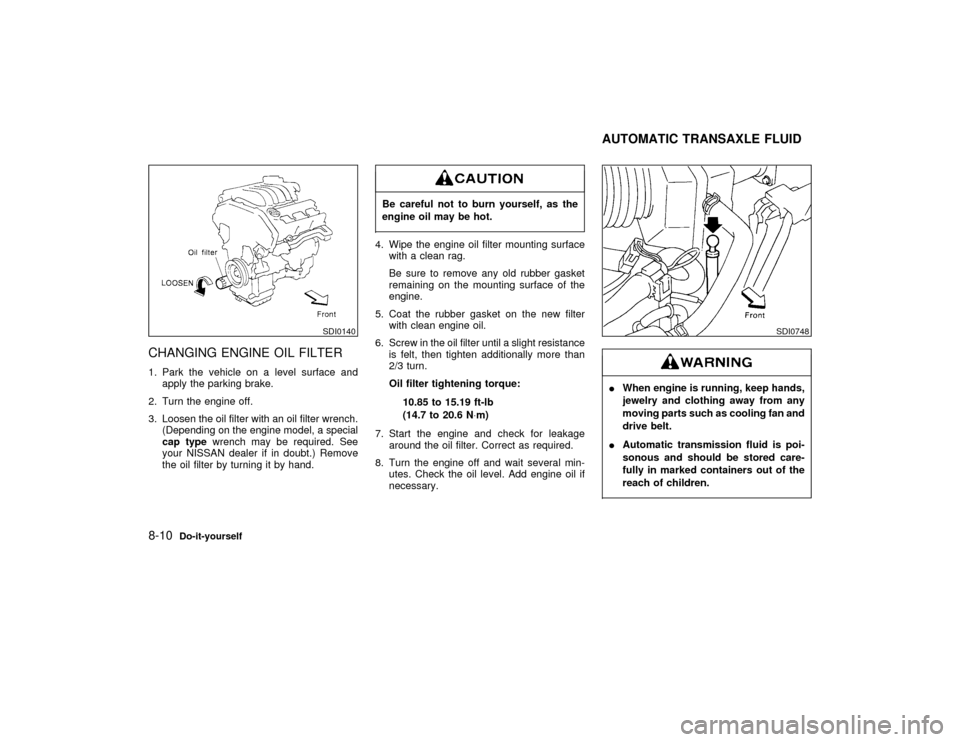

CHANGING ENGINE OIL FILTER1. Park the vehicle on a level surface and

apply the parking brake.

2. Turn the engine off.

3. Loosen the oil filter with an oil filter wrench.

(Depending on the engine model, a special

cap typewrench may be required. See

your NISSAN dealer if in doubt.) Remove

the oil filter by turning it by hand.

Be careful not to burn yourself, as the

engine oil may be hot.4. Wipe the engine oil filter mounting surface

with a clean rag.

Be sure to remove any old rubber gasket

remaining on the mounting surface of the

engine.

5. Coat the rubber gasket on the new filter

with clean engine oil.

6. Screw in the oil filter until a slight resistance

is felt, then tighten additionally more than

2/3 turn.

Oil filter tightening torque:

10.85 to 15.19 ft-lb

(14.7 to 20.6 N×m)

7. Start the engine and check for leakage

around the oil filter. Correct as required.

8. Turn the engine off and wait several min-

utes. Check the oil level. Add engine oil if

necessary.

IWhen engine is running, keep hands,

jewelry and clothing away from any

moving parts such as cooling fan and

drive belt.

IAutomatic transmission fluid is poi-

sonous and should be stored care-

fully in marked containers out of the

reach of children.

SDI0140

SDI0748

AUTOMATIC TRANSAXLE FLUID

8-10

Do-it-yourself

Z

01.1.31/A32-D

X

Page 170 of 231

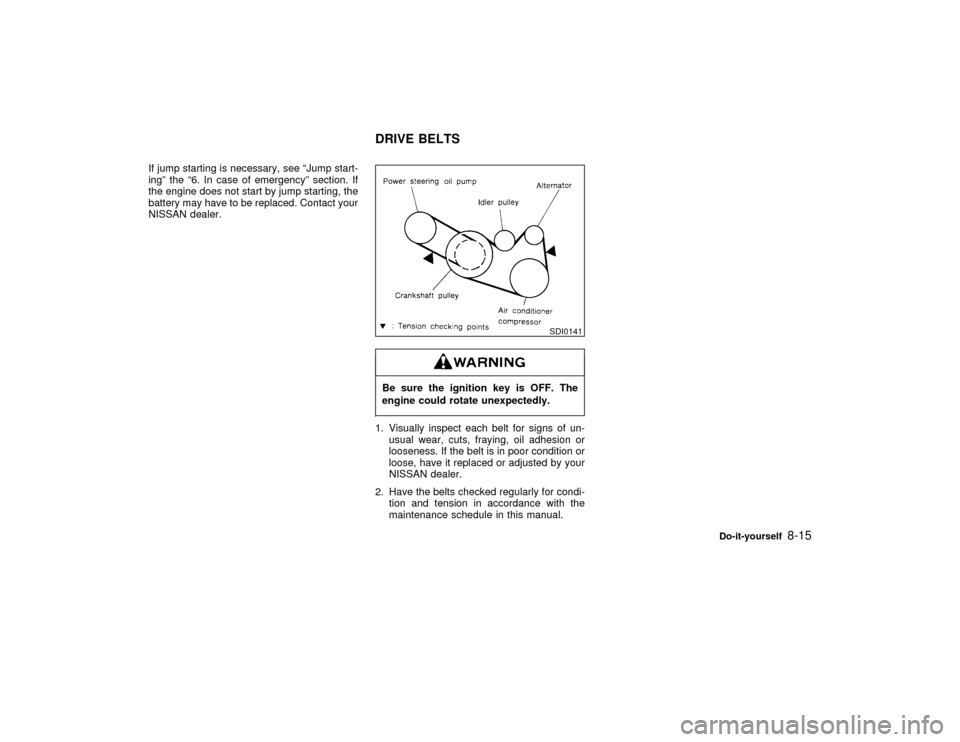

If jump starting is necessary, see ªJump start-

ingº the ª6. In case of emergencyº section. If

the engine does not start by jump starting, the

battery may have to be replaced. Contact your

NISSAN dealer.

Be sure the ignition key is OFF. The

engine could rotate unexpectedly.1. Visually inspect each belt for signs of un-

usual wear, cuts, fraying, oil adhesion or

looseness. If the belt is in poor condition or

loose, have it replaced or adjusted by your

NISSAN dealer.

2. Have the belts checked regularly for condi-

tion and tension in accordance with the

maintenance schedule in this manual.

SDI0141

DRIVE BELTS

Do-it-yourself

8-15

Z

01.1.31/A32-D

X

Page 171 of 231

Be sure the engine and ignition switch

are off and that the parking brake is

engaged securely.Be sure to use the correct wrench to

remove the plugs. An incorrect wrench

can cause damage.

REPLACING SPARK PLUGS1. Remove the rocker cover ornament using a

suitable hexagon wrench. (Front side)

2. Disconnect the electrical connectors.

3. Loosen the ignition coil fixing bolts. And

remove the ignition coil to give access to

the spark plugs.

4. Remove the spark plugs with a spark plug

wrench.

The plug wrench has a rubber seal that

holds the spark plug so that it will not fall

when it is pulled out. Make sure that eachspark plug is snugly fitted into the plug

wrench.

5. Fit the new plugs, one at a time, into the

spark plug wrench and install them. Turn

each plug in several full turns by hand, then

tighten with a spark plug wrench to the

correct torque. Do not overtighten.

Spark plug tightening torque:

14 to 22 ft-lb

(20 to 29 N×m)

SDI0122

SPARK PLUGS8-16

Do-it-yourself

Z

01.1.31/A32-D

X