Oil NISSAN MAXIMA 1999 A32 / 4.G User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: MAXIMA, Model: NISSAN MAXIMA 1999 A32 / 4.GPages: 233, PDF Size: 1.96 MB

Page 169 of 233

Be careful not to burn yourself, as the

engine oil may be hot.4. Wipe the engine oil filter mounting surface

with a clean rag.

Be sure to remove any old rubber gasket

remaining on the mounting surface of the

engine.

5. Coat the rubber gasket on the new filter

with clean engine oil.

6. Screw in the oil filter until a slight resistance

is felt, then tighten additionally more than

2/3 turn.

Oil filter tightening torque:

10.85 to 15.19 ft-lb

(14.7 to 20.6 N×m)

7. Start the engine and check for leakage

around the oil filter. Correct as required.

8. Turn the engine off and wait several min-

utes. Check the oil level. Add engine oil if

necessary.

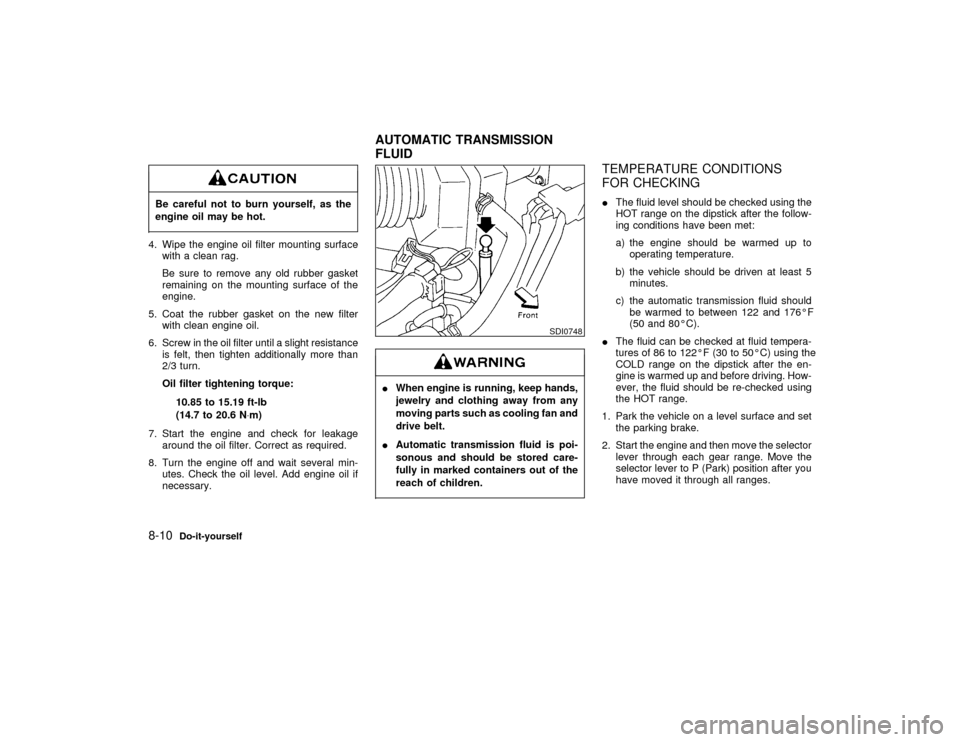

IWhen engine is running, keep hands,

jewelry and clothing away from any

moving parts such as cooling fan and

drive belt.

IAutomatic transmission fluid is poi-

sonous and should be stored care-

fully in marked containers out of the

reach of children.

TEMPERATURE CONDITIONS

FOR CHECKINGIThe fluid level should be checked using the

HOT range on the dipstick after the follow-

ing conditions have been met:

a) the engine should be warmed up to

operating temperature.

b) the vehicle should be driven at least 5

minutes.

c) the automatic transmission fluid should

be warmed to between 122 and 176ÉF

(50 and 80ÉC).

IThe fluid can be checked at fluid tempera-

tures of 86 to 122ÉF (30 to 50ÉC) using the

COLD range on the dipstick after the en-

gine is warmed up and before driving. How-

ever, the fluid should be re-checked using

the HOT range.

1. Park the vehicle on a level surface and set

the parking brake.

2. Start the engine and then move the selector

lever through each gear range. Move the

selector lever to P (Park) position after you

have moved it through all ranges.

SDI0748

AUTOMATIC TRANSMISSION

FLUID

8-10

Do-it-yourself

Z

01.1.22/A32-D/V5.0

X

Page 174 of 233

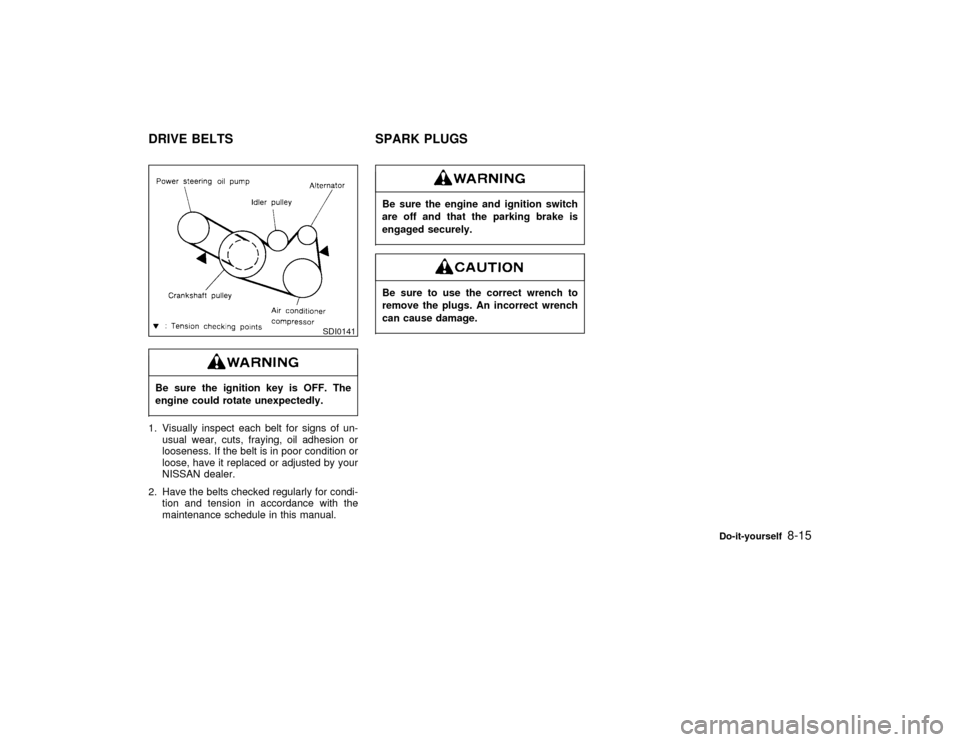

Be sure the ignition key is OFF. The

engine could rotate unexpectedly.1. Visually inspect each belt for signs of un-

usual wear, cuts, fraying, oil adhesion or

looseness. If the belt is in poor condition or

loose, have it replaced or adjusted by your

NISSAN dealer.

2. Have the belts checked regularly for condi-

tion and tension in accordance with the

maintenance schedule in this manual.

Be sure the engine and ignition switch

are off and that the parking brake is

engaged securely.Be sure to use the correct wrench to

remove the plugs. An incorrect wrench

can cause damage.

SDI0141

DRIVE BELTS SPARK PLUGS

Do-it-yourself

8-15

Z

01.1.22/A32-D/V5.0

X

Page 175 of 233

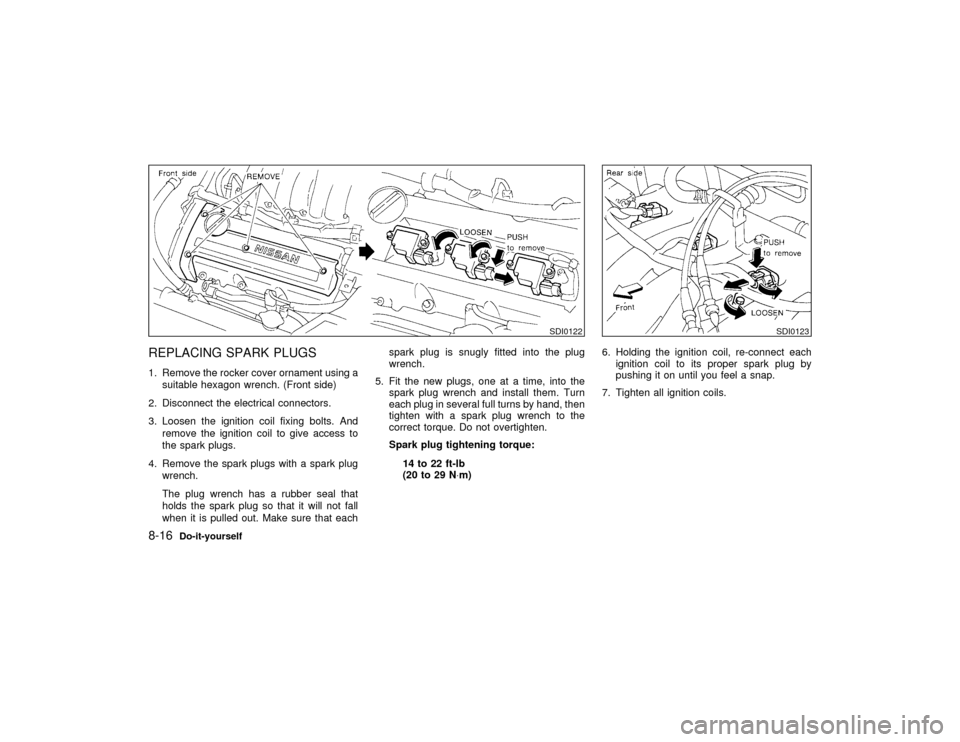

REPLACING SPARK PLUGS1. Remove the rocker cover ornament using a

suitable hexagon wrench. (Front side)

2. Disconnect the electrical connectors.

3. Loosen the ignition coil fixing bolts. And

remove the ignition coil to give access to

the spark plugs.

4. Remove the spark plugs with a spark plug

wrench.

The plug wrench has a rubber seal that

holds the spark plug so that it will not fall

when it is pulled out. Make sure that eachspark plug is snugly fitted into the plug

wrench.

5. Fit the new plugs, one at a time, into the

spark plug wrench and install them. Turn

each plug in several full turns by hand, then

tighten with a spark plug wrench to the

correct torque. Do not overtighten.

Spark plug tightening torque:

14 to 22 ft-lb

(20 to 29 N×m)6. Holding the ignition coil, re-connect each

ignition coil to its proper spark plug by

pushing it on until you feel a snap.

7. Tighten all ignition coils.

SDI0122

SDI0123

8-16

Do-it-yourself

Z

01.1.22/A32-D/V5.0

X

Page 199 of 233

and that the locks (if equipped) hold securely

in all latched positions.

Seat belts:Check that all parts of the seat belt

system (for example, buckles, anchors, adjust-

ers and retractors) operate properly and

smoothly, and are installed securely. Check

the belt webbing for cuts, fraying, wear or

damage.

Accelerator pedal:Check the pedal for

smooth operation and make sure the pedal

does not catch or require uneven effort. Keep

the floor mats away from the pedal.

Clutch pedal*:Make sure the pedal operates

smoothly and check that it has the proper free

play.

Brakes:Check that the brakes do not pull the

vehicle to one side when applied.

Brake pedal and booster*:Check the pedal

for smooth operation and make sure it has the

proper distance under it when depressed fully.

Check the brake booster function. Be sure to

keep floor mats away from the pedal.

Parking brake*:Check that the lever has the

proper travel and make sure that the vehicle is

held securely on a fairly steep hill when onlythe parking brake is applied.

Automatic transmission P (Park) position

mechanism:Check that the brake pedal must

be depressed for the selector lever to be

moved from the P (Park) position. On a fairly

steep hill check that the vehicle is held se-

curely with the selector lever in the P (Park)

position without applying any brakes.

Under the hood and the vehicleThe maintenance items listed here should be

checked periodically (for example, each time

you check the engine oil or refuel).

Windshield washer fluid*:Check that there

is adequate fluid in the tank.

Engine coolant level*:Check the coolant

level when the engine is cold.

Radiator and hoses:Check the front of the

radiator and clean off any dirt, insects, leaves,

etc., that may have accumulated. Make sure

the hoses have no cracks, deformation, dete-

rioration or loose connections.

Brake and clutch fluid levels*:Make sure

that the brake and clutch fluid levels are be-

tween the MAX and MIN lines on the reservoir.

Battery*:Check the fluid level in each cell. Itshould be between the MAX and MIN lines.

Engine drive belts*:Make sure that no belt is

frayed, worn, cracked or oily.

Engine oil level*:Check the level on the

dipstick after parking the vehicle on a level

spot and turning off the engine. Be sure to wait

a few minutes to allow the oil to drain back into

the sump.

Power steering fluid level* and lines:Check

the level in the reservoir tank with the engine

off. Check the lines for proper attachment,

leaks, cracks, etc.

Automatic transmission fluid level*:Check

the level on the dipstick after putting the selec-

tor lever in P (Park) position with the engine

idling.

Exhaust system:Make sure there are no

loose supports, cracks or holes. If the sound of

the exhaust seems unusual or there is a smell

of exhaust fumes, immediately locate the

trouble and correct it. (See ªPrecautions when

starting and drivingº in the ª5. Starting and

drivingº section for exhaust gas (carbon mon-

oxide).)

Underbody:The underbody is frequently ex-

9-4

Maintenance

Z

01.1.22/A32-D/V5.0

X

Page 200 of 233

posed to corrosive substances such as those

used on icy roads or to control dust. It is very

important to remove these substances, other-

wise rust will form on the floor pan, frame, fuel

lines and around the exhaust system. At the

end of winter, the underbody should be thor-

oughly flushed with plain water, being careful

to clean those areas where mud and dirt may

accumulate. For additional information, see

ªCleaning exteriorº in the ª7. Appearance and

careº section.

Fluid leaks:Check under the vehicle for fuel,

oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping

from the air conditioner after use is normal. If

you should notice any leaks or if gasoline

fumes are evident, check for the cause and

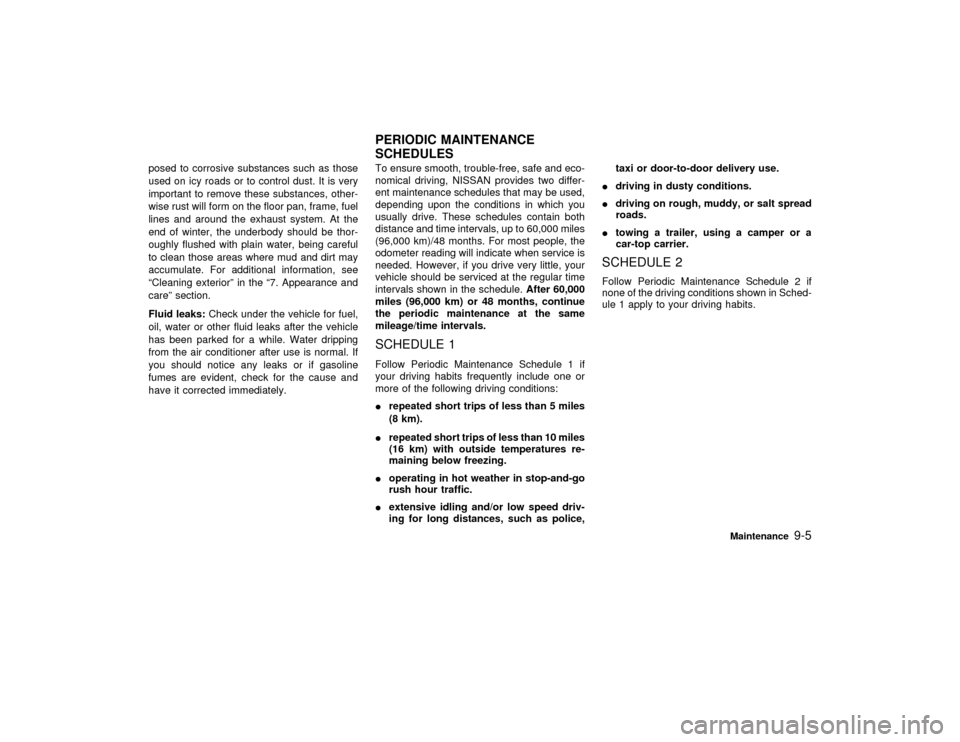

have it corrected immediately.To ensure smooth, trouble-free, safe and eco-

nomical driving, NISSAN provides two differ-

ent maintenance schedules that may be used,

depending upon the conditions in which you

usually drive. These schedules contain both

distance and time intervals, up to 60,000 miles

(96,000 km)/48 months. For most people, the

odometer reading will indicate when service is

needed. However, if you drive very little, your

vehicle should be serviced at the regular time

intervals shown in the schedule.After 60,000

miles (96,000 km) or 48 months, continue

the periodic maintenance at the same

mileage/time intervals.

SCHEDULE 1Follow Periodic Maintenance Schedule 1 if

your driving habits frequently include one or

more of the following driving conditions:

Irepeated short trips of less than 5 miles

(8 km).

Irepeated short trips of less than 10 miles

(16 km) with outside temperatures re-

maining below freezing.

Ioperating in hot weather in stop-and-go

rush hour traffic.

Iextensive idling and/or low speed driv-

ing for long distances, such as police,taxi or door-to-door delivery use.

Idriving in dusty conditions.

Idriving on rough, muddy, or salt spread

roads.

Itowing a trailer, using a camper or a

car-top carrier.

SCHEDULE 2Follow Periodic Maintenance Schedule 2 if

none of the driving conditions shown in Sched-

ule 1 apply to your driving habits.

PERIODIC MAINTENANCE

SCHEDULES

Maintenance

9-5

Z

01.1.22/A32-D/V5.0

X

Page 201 of 233

![NISSAN MAXIMA 1999 A32 / 4.G User Guide Schedule 1Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers or NISSAN MAXIMA 1999 A32 / 4.G User Guide Schedule 1Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers or](/img/5/633/w960_633-200.png)

Schedule 1Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers or months, which-

ever comes first.Miles x 1,000 3.75 7.5 11.25 15 18.75 22.5 26.25 30 33.75 37.5 41.25 45 48.75 52.5 56.25 60

(km x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72) (78) (84) (90) (96)

Months 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48Emission control system maintenanceDrive belts See NOTE (1)I*

Air cleaner filter See NOTE (2) [R] [R]

EVAP vapor linesI* I*

Fuel linesI* I*

Fuel filter See NOTE (3)*

Engine coolant See NOTE (4)R*

Engine oilRRRRRRRRRRRRRRRR

Engine oil filter (Use part No. 15208-31U00 or equivalent)RRRRRRRRRRRRRRRR

Spark plugs (Use PLATINUM-TIPPED type)[R]

Intake & exhaust valve clearance See NOTE (5)NOTE: (1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) If vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high, the filters might become clogged. In such an event, replace them immediately.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) If valve noise increases, inspect valve clearance.

(6) Maintenance items and intervals with ª*º are recommended by NISSAN for reliable vehicle operation. The owner need not

perform such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance

items and intervals are required.9-6

Maintenance

Z

01.1.22/A32-D/V5.0

X

Page 202 of 233

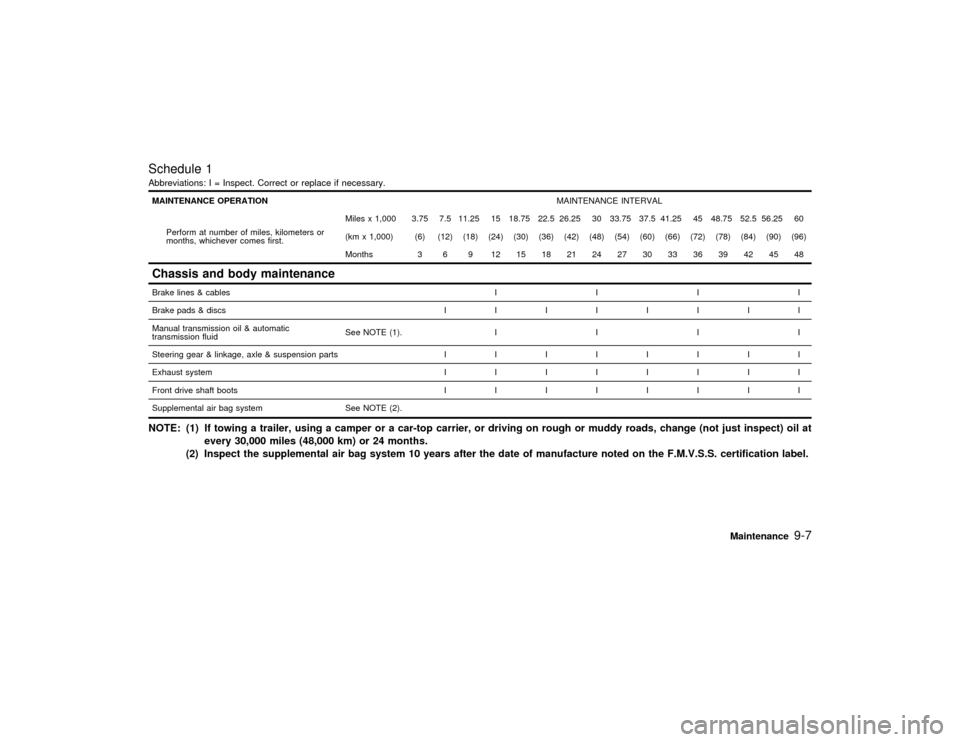

Schedule 1Abbreviations: I = Inspect. Correct or replace if necessary.MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers or

months, whichever comes first.Miles x 1,000 3.75 7.5 11.25 15 18.75 22.5 26.25 30 33.75 37.5 41.25 45 48.75 52.5 56.25 60

(km x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72) (78) (84) (90) (96)

Months 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48Chassis and body maintenanceBrake lines & cablesIIII

Brake pads & discsIIIIIIII

Manual transmission oil & automatic

transmission fluidSee NOTE (1).IIII

Steering gear & linkage, axle & suspension partsIIIIIIII

Exhaust systemIIIIIIII

Front drive shaft bootsIIIIIIII

Supplemental air bag system See NOTE (2).NOTE: (1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at

every 30,000 miles (48,000 km) or 24 months.

(2) Inspect the supplemental air bag system 10 years after the date of manufacture noted on the F.M.V.S.S. certification label.

Maintenance

9-7

Z

01.1.22/A32-D/V5.0

X

Page 203 of 233

![NISSAN MAXIMA 1999 A32 / 4.G User Guide Schedule 2Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers

or NISSAN MAXIMA 1999 A32 / 4.G User Guide Schedule 2Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers

or](/img/5/633/w960_633-202.png)

Schedule 2Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers

or months, whichever comes first.Miles x 1,000 7.5 15 22.5 30 37.5 45 52.5 60

(km x 1,000) (12) (24) (36) (48) (60) (72) (84) (96)

Months 6 12 18 24 30 36 42 48Emission control system maintenanceDrive belts See NOTE (1)I*

Air cleaner filter[R] [R]

EVAP vapor linesI* I*

Fuel linesI* I*

Fuel filter See NOTE (2)*

Engine coolant See NOTE (3)R*

Engine oilRRRRRRRR

Engine oil filter (Use part No. 15208-31U00 or equivalent)RRRRRRRR

Spark plugs (Use PLATINUM-TIPPED type)[R]

Intake & exhaust valve clearance See NOTE (4)NOTE: (1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) If vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high, the filters might become clogged. In such an event, replace them immediately.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) If valve noise increases, inspect valve clearance.

(5) Maintenance items and intervals with ª*º are recommended by NISSAN for reliable vehicle operation. The owner need not

perform such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance

items and intervals are required.9-8

Maintenance

Z

01.1.22/A32-D/V5.0

X

Page 204 of 233

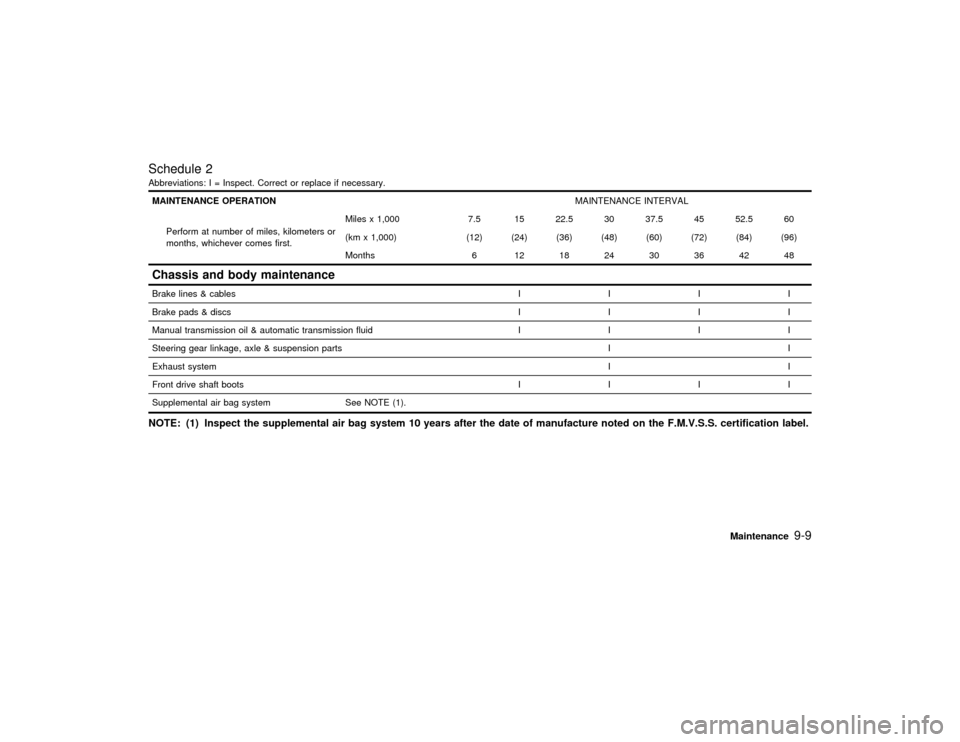

Schedule 2Abbreviations: I = Inspect. Correct or replace if necessary.MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers or

months, whichever comes first.Miles x 1,000 7.5 15 22.5 30 37.5 45 52.5 60

(km x 1,000) (12) (24) (36) (48) (60) (72) (84) (96)

Months 6 12 18 24 30 36 42 48Chassis and body maintenanceBrake lines & cablesIIII

Brake pads & discsIIII

Manual transmission oil & automatic transmission fluidIIII

Steering gear linkage, axle & suspension parts I I

Exhaust systemII

Front drive shaft bootsIIII

Supplemental air bag system See NOTE (1).NOTE: (1) Inspect the supplemental air bag system 10 years after the date of manufacture noted on the F.M.V.S.S. certification label.

Maintenance

9-9

Z

01.1.22/A32-D/V5.0

X

Page 205 of 233

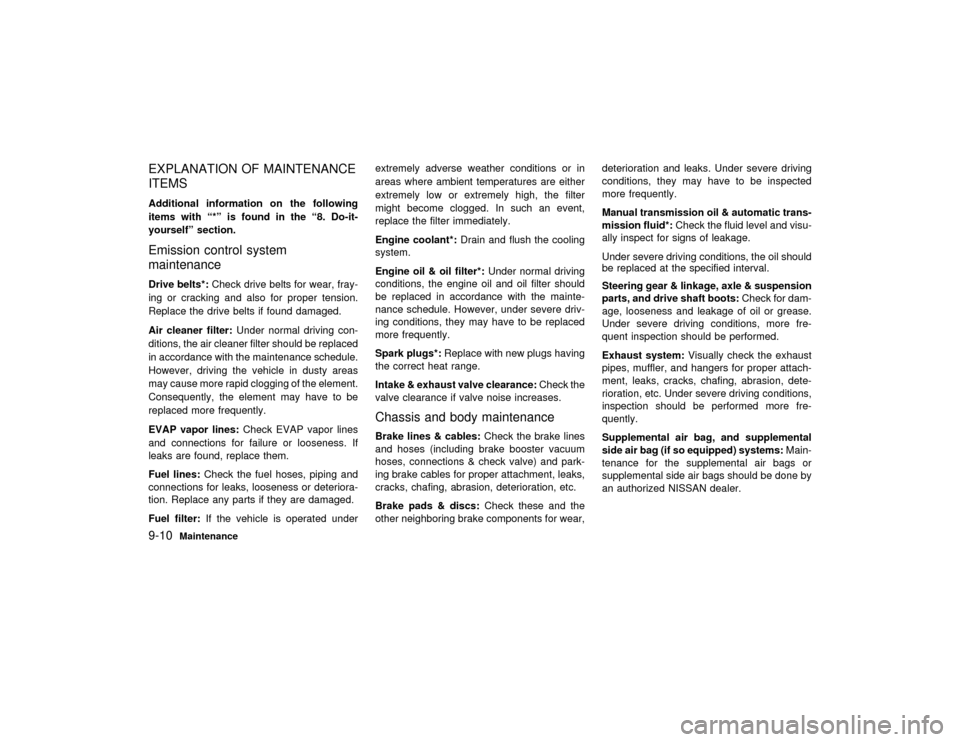

EXPLANATION OF MAINTENANCE

ITEMSAdditional information on the following

items with ª*º is found in the ª8. Do-it-

yourselfº section.Emission control system

maintenanceDrive belts*:Check drive belts for wear, fray-

ing or cracking and also for proper tension.

Replace the drive belts if found damaged.

Air cleaner filter:Under normal driving con-

ditions, the air cleaner filter should be replaced

in accordance with the maintenance schedule.

However, driving the vehicle in dusty areas

may cause more rapid clogging of the element.

Consequently, the element may have to be

replaced more frequently.

EVAP vapor lines:Check EVAP vapor lines

and connections for failure or looseness. If

leaks are found, replace them.

Fuel lines:Check the fuel hoses, piping and

connections for leaks, looseness or deteriora-

tion. Replace any parts if they are damaged.

Fuel filter:If the vehicle is operated underextremely adverse weather conditions or in

areas where ambient temperatures are either

extremely low or extremely high, the filter

might become clogged. In such an event,

replace the filter immediately.

Engine coolant*:Drain and flush the cooling

system.

Engine oil & oil filter*:Under normal driving

conditions, the engine oil and oil filter should

be replaced in accordance with the mainte-

nance schedule. However, under severe driv-

ing conditions, they may have to be replaced

more frequently.

Spark plugs*:Replace with new plugs having

the correct heat range.

Intake & exhaust valve clearance:Check the

valve clearance if valve noise increases.

Chassis and body maintenanceBrake lines & cables:Check the brake lines

and hoses (including brake booster vacuum

hoses, connections & check valve) and park-

ing brake cables for proper attachment, leaks,

cracks, chafing, abrasion, deterioration, etc.

Brake pads & discs:Check these and the

other neighboring brake components for wear,deterioration and leaks. Under severe driving

conditions, they may have to be inspected

more frequently.

Manual transmission oil & automatic trans-

mission fluid*:Check the fluid level and visu-

ally inspect for signs of leakage.

Under severe driving conditions, the oil should

be replaced at the specified interval.

Steering gear & linkage, axle & suspension

parts, and drive shaft boots:Check for dam-

age, looseness and leakage of oil or grease.

Under severe driving conditions, more fre-

quent inspection should be performed.

Exhaust system:Visually check the exhaust

pipes, muffler, and hangers for proper attach-

ment, leaks, cracks, chafing, abrasion, dete-

rioration, etc. Under severe driving conditions,

inspection should be performed more fre-

quently.

Supplemental air bag, and supplemental

side air bag (if so equipped) systems:Main-

tenance for the supplemental air bags or

supplemental side air bags should be done by

an authorized NISSAN dealer.

9-10

Maintenance

Z

01.1.22/A32-D/V5.0

X