wheel NISSAN MAXIMA 2006 A34 / 6.G Towing Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: MAXIMA, Model: NISSAN MAXIMA 2006 A34 / 6.GPages: 28, PDF Size: 2.12 MB

Page 4 of 28

2006 Nissan Towing Guide 3 If you are buying a travel or boat trailer, be sure that your Nissan vehicle has the towing

capacity to pull it. See the SPECIFICATIONS section of this guide, or refer to your owner’s

manual for detailed information regarding the towing capacity of your specific vehicle. Your

owner’s manual should ALWAYS be referenced before making any towing decisions.

Naturally, you’ll want to buy the highest-quality equipment you can find for maximum

towing safety. And if you plan to tow often, consider convenience. Quick-disconnect trailer

light connectors and ratchet-type tie-downs, for example, make the job go faster and easier,

and are usually worth the small extra investment.

WHAT’S

RIGHT FOR YOU

TYPES OF EQUIPMENT

Towing requires a variety of equipment, and, depending upon the application, there can be

several types or styles of each piece of equipment. Working with your Nissan dealer or a

professional supplier of towing equipment, it should be relatively simple to determine the

proper type of equipment for your specific vehicle given the intended application. This

section explains the most common pieces of towing equipment available.

HITCHES

Whichever type of hitch you use, it should be firmly bolted to your vehicle, and should be of

the appropriate weight class for the equipment you intend to tow. In addition, keep the

following in mind:

�Š Do not modify the vehicle’s braking or exhaust systems or its body structure/frame when

installing the hitch.

�Š Be sure that the hitch does not interfere in any way with the vehicle’s energy-absorbing

bumper.

�Š Regularly check to see that all hitch-mounting bolts are securely fastened.

�Š Where practical, remove the hitch when not in use. Your Nissan dealer can assist you in

hitch removal and reinstallation. When removed, seal the bolt holes to prevent road

spray, fumes, water, and dirt from entering the vehicle.

�Š For receiver-type hitches using a ball mount, the ball mount should be removed when

not towing.

�Š If you install a hitch yourself, remember that it must be securely attached to the frame or

underbody, according to the manufacturer’s instructions. Never attach a hitch or

towing device to the vehicle axle housing. This may damage the housing, wheel

bearings, wheels, or tires.

Page 6 of 28

2006 Nissan Towing Guide 5 Clamp-On Bumper Hitch – As the name

suggests, this type of temporary hitch

clamps onto the bumper assembly.

Nissan does not recommend the use of

this type hitch for a number of reasons.

It may interfere with performance of the

energy-absorbing bumper. And because

the bumper was not designed to carry

this type of load, it could damage the

bumper and bodywork, and may possibly result in trailer separation during towing.

Therefore, tow only with a permanent hitch.

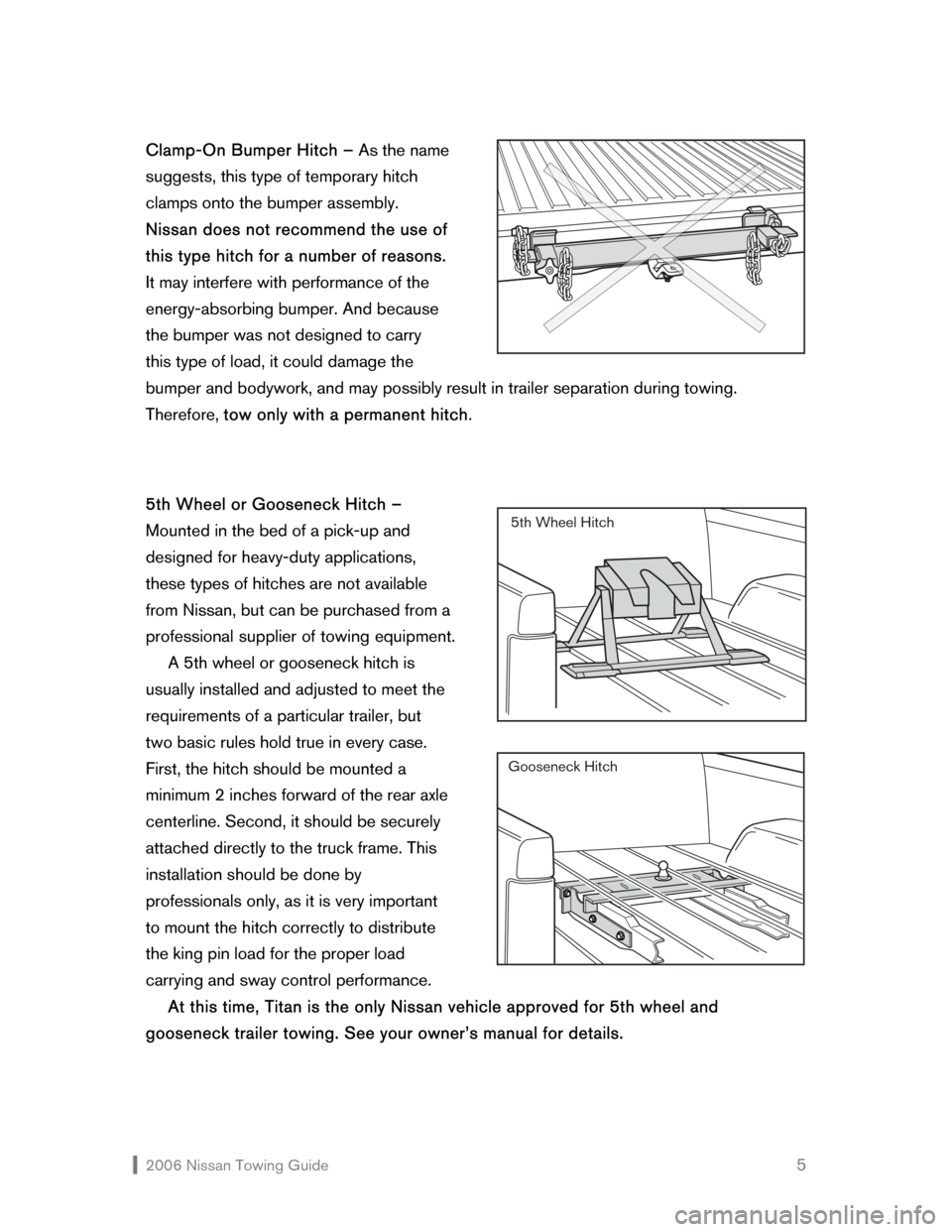

5th Wheel or Gooseneck Hitch –

Mounted in the bed of a pick-up and

designed for heavy-duty applications,

these types of hitches are not available

from Nissan, but can be purchased from a

professional supplier of towing equipment.

A 5th wheel or gooseneck hitch is

usually installed and adjusted to meet the

requirements of a particular trailer, but

two basic rules hold true in every case.

First, the hitch should be mounted a

minimum 2 inches forward of the rear axle

centerline. Second, it should be securely

attached directly to the truck frame. This

installation should be done by

professionals only, as it is very important

to mount the hitch correctly to distribute

the king pin load for the proper load

carrying and sway control performance.

At this time, Titan is the only Nissan vehicle approved for 5th wheel and

gooseneck trailer towing. See your owner’s manual for details.

5th Wheel Hitch

Gooseneck Hitch

Page 7 of 28

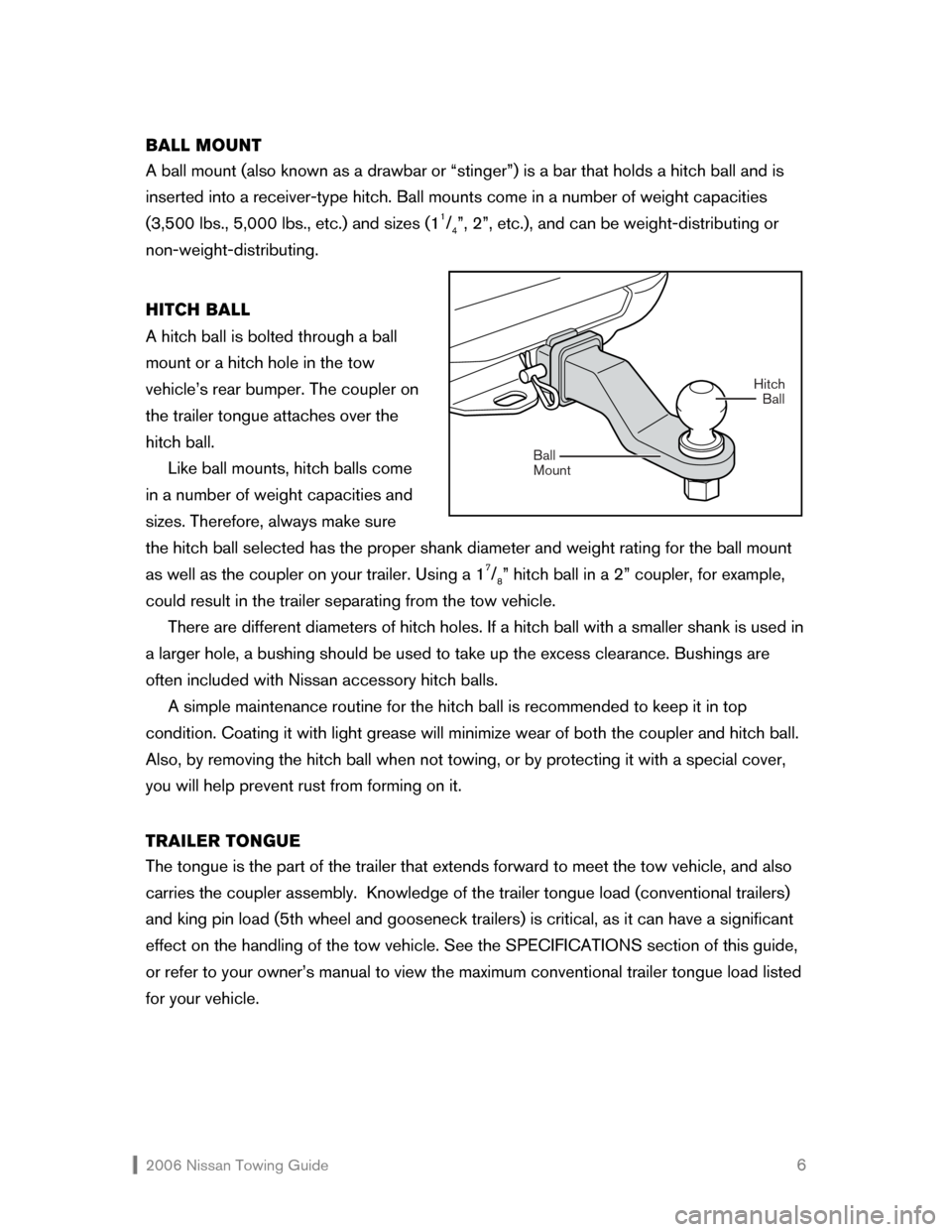

2006 Nissan Towing Guide 6 BALL MOUNT

A ball mount (also known as a drawbar or “stinger”) is a bar that holds a hitch ball and is

inserted into a receiver-type hitch. Ball mounts come in a number of weight capacities

(3,500 lbs., 5,000 lbs., etc.) and sizes (1

1/4”, 2”, etc.), and can be weight-distributing or

non-weight-distributing.

HITCH BALL

A hitch ball is bolted through a ball

mount or a hitch hole in the tow

vehicle’s rear bumper. The coupler on

the trailer tongue attaches over the

hitch ball.

Like ball mounts, hitch balls come

in a number of weight capacities and

sizes. Therefore, always make sure

the hitch ball selected has the proper shank diameter and weight rating for the ball mount

as well as the coupler on your trailer. Using a 1

7/8” hitch ball in a 2” coupler, for example,

could result in the trailer separating from the tow vehicle.

There are different diameters of hitch holes. If a hitch ball with a smaller shank is used in

a larger hole, a bushing should be used to take up the excess clearance. Bushings are

often included with Nissan accessory hitch balls.

A simple maintenance routine for the hitch ball is recommended to keep it in top

condition. Coating it with light grease will minimize wear of both the coupler and hitch ball.

Also, by removing the hitch ball when not towing, or by protecting it with a special cover,

you will help prevent rust from forming on it.

TRAILER TONGUE

The tongue is the part of the trailer that extends forward to meet the tow vehicle, and also

carries the coupler assembly. Knowledge of the trailer tongue load (conventional trailers)

and king pin load (5th wheel and gooseneck trailers) is critical, as it can have a significant

effect on the handling of the tow vehicle. See the SPECIFICATIONS section of this guide,

or refer to your owner’s manual to view the maximum conventional trailer tongue load listed

for your vehicle.

Hitch

Mount BallBall

Page 10 of 28

2006 Nissan Towing Guide 9 BRAKES

As with hitches, there are several types of braking systems available. Most states require a

separate braking system on trailers with a loaded weight above a specific amount, so

check to ensure you comply with all regulations.

NOTE – Never connect a hydraulic trailer brake system directly to the vehicle

hydraulic brake system.

Surge Brakes – The surge brake is mounted on the trailer tongue with a hydraulic line

running to each trailer wheel. Surge brakes are activated by the trailer pushing against the

hitch when the tow vehicle is braking. Hydraulic surge brakes are common on rental trailers

and some boat trailers. In this type of system, there is no hydraulic or electric connection

for brake operation between the tow vehicle and the trailer.

Electric Trailer Brakes – Electric braking systems are activated by an electronic signal

sent from a trailer brake controller (special brake-sensing module).

If electric trailer brakes are used, Nissan recommends all-electronic actuation because

with this system it will not be necessary to tap into the tow vehicle’s hydraulic system.

For your convenience, Armada, Frontier, Pathfinder, Titan, and Xterra vehicles are pre-

wired to accommodate most popular electric trailer brake controllers. A wiring harness* is

either included with your vehicle or available from your Nissan dealer. This harness

provides electric trailer brake controller input and output connections to the vehicle wiring.

See a professional supplier of towing equipment for electric trailer brake controller

availability.

NOTE – Improper or poor quality trailer harness wiring may affect your vehicle’s electrical

system. Use only a Nissan approved wiring harness, or consult your dealer or a

professional supplier of towing equipment for compatible equipment.

GENUINE NISSAN PARTS AND ACCESSORIES

Whether you’ll be towing occasionally or on a regular basis, Nissan offers a full range of

Genuine Nissan Parts and Accessories to help you tow with confidence.

Every accessory is thoroughly tested and inspected for fit and workmanship. Therefore,

you can be certain that every item is designed to be compatible with the standard features

of your vehicle and designed to assist you with your towing needs.

Contact your Nissan dealer for more information on accessories or towing-related parts

for your Nissan vehicle.

*See the SPECIFICATIONS section of this guide for wiring harness information specific to your

vehicle.

Page 13 of 28

2006 Nissan Towing Guide 12

GROSS AXLE WEIGHT (GAW)

The Gross Axle Weight (GAW) is the maximum weight each axle (front and rear) is

designed to safely carry.

To determine the GAW, load the vehicle as you would for towing and attach the loaded

trailer. At a public scale, with the loaded trailer attached, place only the tow vehicle front

wheels on the scale to determine the actual front axle GAW. To obtain the rear axle GAW,

place all four tow vehicle wheels on the scale. From that figure, subtract the front GAW

and you’ve got the rear GAW amount.

The GAW you come up with must not exceed the Gross Axle Weight Rating

(GAWR) for your vehicle. On Nissan vehicles, the GAWR for both axles is listed on the

F.M.V.S.S. certification label.

GROSS COMBINED WEIGHT (GCW)

The Gross Combined Weight (GCW) is the total weight of the tow vehicle with all

passengers, cargo, and fuel, plus the total weight of the trailer and all its cargo.

To determine the GCW, simply weigh your vehicle when fully loaded and ready to tow,

and add in the weight of the loaded trailer.

The GCW you come up with must not exceed the Gross Combined Weight Rating

(GCWR) for your vehicle. See the SPECIFICATIONS section of this guide, or refer to

your owner’s manual to view the GCWR listed for your vehicle.

Page 14 of 28

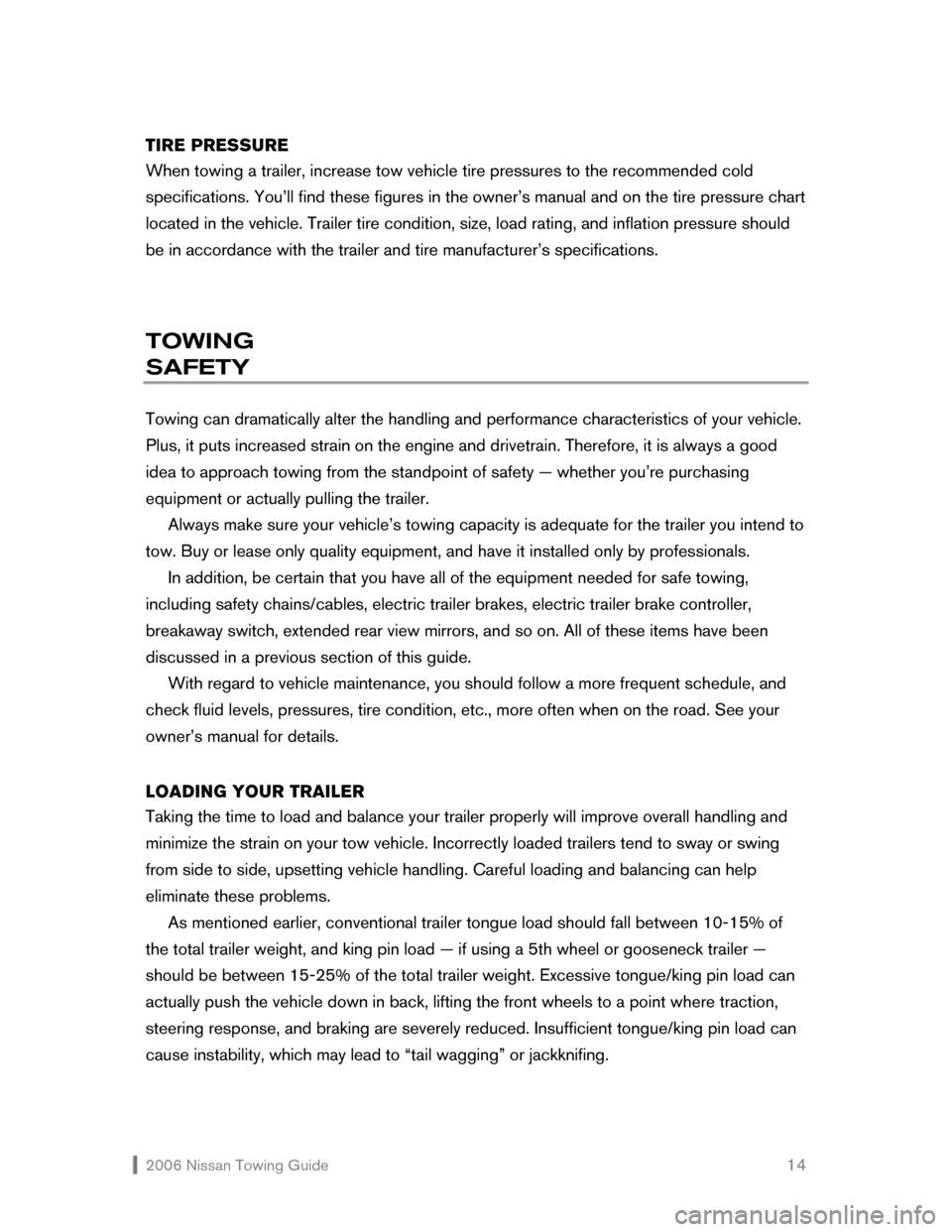

2006 Nissan Towing Guide 13 TRAILER TONGUE/KING PIN LOAD

The amount of weight pressing down on the tow vehicle hitch is called trailer tongue load

(conventional trailer) or king pin load (5th wheel or gooseneck trailers). To measure trailer

tongue/king pin load, place the tongue of the trailer on a scale when the trailer is not

attached to the vehicle. A separate vehicle jack — not the trailer jack — should be used, as

the location of the trailer jack

is rearward of the trailer

tongue and will not give you

an accurate measurement of

the true tongue/king pin load.

Make sure the vehicle jack is

placed directly under the

trailer tongue coupler, and the

tongue is set at the

height/level of the tow vehicle

hitch.

For proper handling, keep conventional trailer tongue load between 10-15% of the

actual trailer weight, within the limits of the maximum trailer tongue load allowable. For

example, to determine the proper trailer tongue load for a 1,500-lb. trailer, multiply the

weight of 1,500 lbs. by 10% to arrive at a figure of 150 lbs.

5th wheel and gooseneck trailer king pin load should be kept between 15-25% of the

actual trailer weight.

See the SPECIFICATIONS section of this guide, or refer to your vehicle owner’s manual

to view the maximum conventional trailer tongue load listed for your vehicle.

NOTE – Conventional trailer tongue load must be more than 10% but not over 15% of the

total trailer weight. King pin load must be more than 15% but not over 25% of the total

trailer weight. The vehicle weight ratings (GVWR, GAWR, GCWR, etc.) must not be

exceeded, regardless of trailer or hitch type.

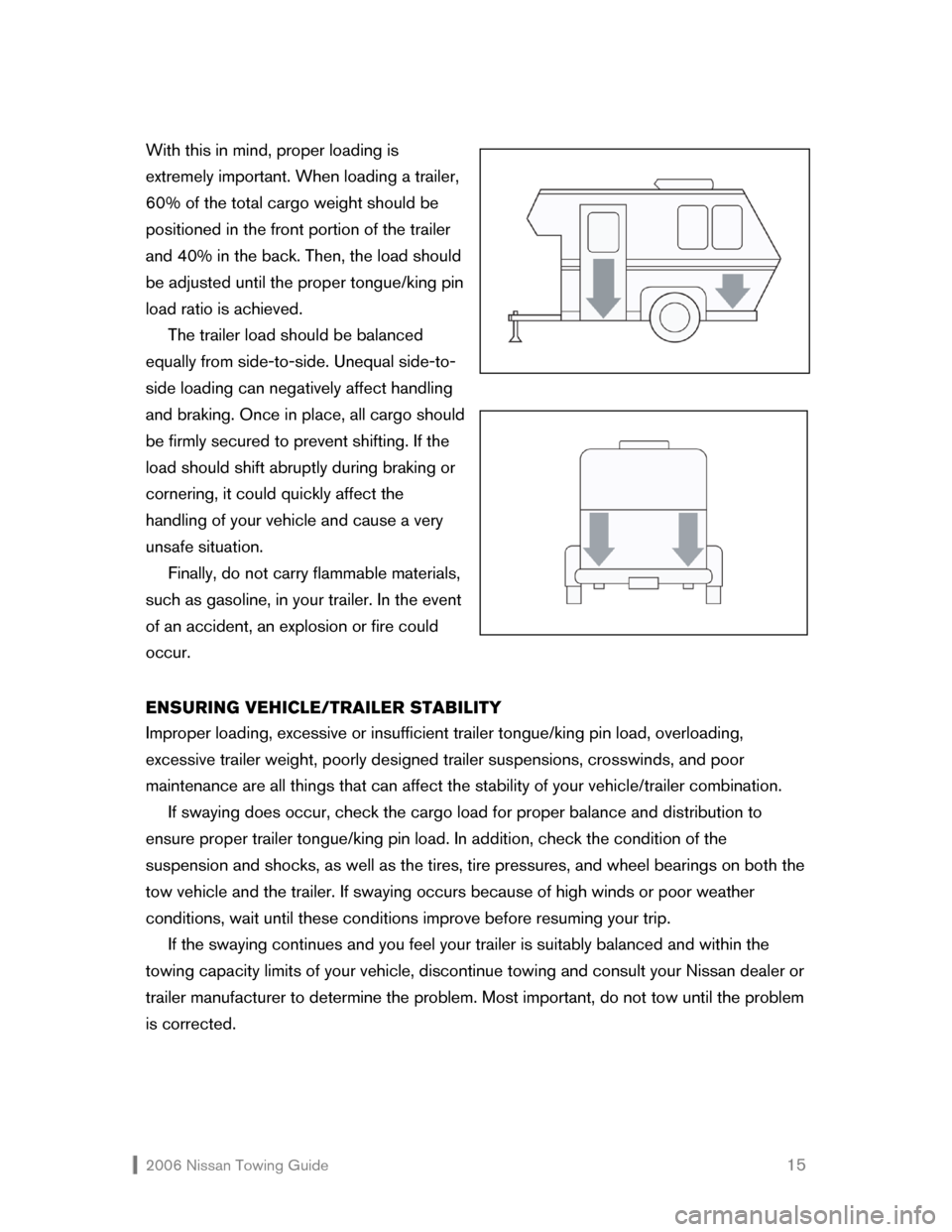

HITCH HEIGHT/TRAILER HEIGHT

It is important that your trailer floor and

tongue ride as level as possible. This will help

prevent over-angling, bottoming-out, and

improper load transfer. Therefore, the hitch or

trailer tongue should be adjusted during the

initial vehicle/trailer fit-up to ensure a level

ride. Ball mounts are available in different

configurations to change the hitch ball height.

Page 15 of 28

2006 Nissan Towing Guide 14 TIRE PRESSURE

When towing a trailer, increase tow vehicle tire pressures to the recommended cold

specifications. You’ll find these figures in the owner’s manual and on the tire pressure chart

located in the vehicle. Trailer tire condition, size, load rating, and inflation pressure should

be in accordance with the trailer and tire manufacturer’s specifications.

TOWING

SAFETY

Towing can dramatically alter the handling and performance characteristics of your vehicle.

Plus, it puts increased strain on the engine and drivetrain. Therefore, it is always a good

idea to approach towing from the standpoint of safety — whether you’re purchasing

equipment or actually pulling the trailer.

Always make sure your vehicle’s towing capacity is adequate for the trailer you intend to

tow. Buy or lease only quality equipment, and have it installed only by professionals.

In addition, be certain that you have all of the equipment needed for safe towing,

including safety chains/cables, electric trailer brakes, electric trailer brake controller,

breakaway switch, extended rear view mirrors, and so on. All of these items have been

discussed in a previous section of this guide.

With regard to vehicle maintenance, you should follow a more frequent schedule, and

check fluid levels, pressures, tire condition, etc., more often when on the road. See your

owner’s manual for details.

LOADING YOUR TRAILER

Taking the time to load and balance your trailer properly will improve overall handling and

minimize the strain on your tow vehicle. Incorrectly loaded trailers tend to sway or swing

from side to side, upsetting vehicle handling. Careful loading and balancing can help

eliminate these problems.

As mentioned earlier, conventional trailer tongue load should fall between 10-15% of

the total trailer weight, and king pin load — if using a 5th wheel or gooseneck trailer —

should be between 15-25% of the total trailer weight. Excessive tongue/king pin load can

actually push the vehicle down in back, lifting the front wheels to a point where traction,

steering response, and braking are severely reduced. Insufficient tongue/king pin load can

cause instability, which may lead to “tail wagging” or jackknifing.

Page 16 of 28

2006 Nissan Towing Guide 15 With this in mind, proper loading is

extremely important. When loading a trailer,

60% of the total cargo weight should be

positioned in the front portion of the trailer

and 40% in the back. Then, the load should

be adjusted until the proper tongue/king pin

load ratio is achieved.

The trailer load should be balanced

equally from side-to-side. Unequal side-to-

side loading can negatively affect handling

and braking. Once in place, all cargo should

be firmly secured to prevent shifting. If the

load should shift abruptly during braking or

cornering, it could quickly affect the

handling of your vehicle and cause a very

unsafe situation.

Finally, do not carry flammable materials,

such as gasoline, in your trailer. In the event

of an accident, an explosion or fire could

occur.

ENSURING VEHICLE/TRAILER STABILITY

Improper loading, excessive or insufficient trailer tongue/king pin load, overloading,

excessive trailer weight, poorly designed trailer suspensions, crosswinds, and poor

maintenance are all things that can affect the stability of your vehicle/trailer combination.

If swaying does occur, check the cargo load for proper balance and distribution to

ensure proper trailer tongue/king pin load. In addition, check the condition of the

suspension and shocks, as well as the tires, tire pressures, and wheel bearings on both the

tow vehicle and the trailer. If swaying occurs because of high winds or poor weather

conditions, wait until these conditions improve before resuming your trip.

If the swaying continues and you feel your trailer is suitably balanced and within the

towing capacity limits of your vehicle, discontinue towing and consult your Nissan dealer or

trailer manufacturer to determine the problem. Most important, do not tow until the problem

is corrected.

Page 19 of 28

2006 Nissan Towing Guide 18 CORNER MORE SLOWLY

Know your vehicle and trailer capabilities. Entering a sharp corner too quickly or abruptly

can “crack the whip,” whereby the trailer can actually pull the tow vehicle off the road.

Therefore, when approaching a relatively sharp corner, begin braking sooner than you

would when not towing. Do your braking in a straight line prior to the corner, and turn

smoothly into it. In addition, remember to make a wider turn than normal to ensure that the

trailer safely clears the inside of the turn.

When towing a 5th wheel or gooseneck trailer, do not make sharp turns while driving or

backing as the trailer may contact the vehicle and cause damage to both the trailer and

vehicle. A special extended 5th wheel pin box or sliding hitch may be required to provide

additional trailer-to-truck clearance for tight maneuvering.

BACK UP WITH CAUTION

Backing up with a trailer is a difficult maneuver; however, there is a “trick” that can simplify

the procedure considerably. Simply steer with one hand at the bottom of the steering

wheel. To turn the trailer to the left, first move the steering wheel to the left. To turn the

trailer to the right, move the wheel to the right. All movements of the wheel should be done

in small increments. Of course, backing up should be done only at very slow speeds. For

large trailers that obstruct your rearward vision, have someone outside the vehicle act as a

“spotter” to guide you along.

PARK SMART

A tow vehicle and trailer can be an unwieldy combination in a small area, so always try to

park where you will have a relatively easy time maneuvering. Once parked, always block the

wheels on both the tow vehicle and the trailer.

Parking on a slope is not recommended. If, however, you must park on a slope, and your

vehicle is equipped with an automatic transmission, there are some precautions you should

take:

�Š Have someone block the wheels once the tow vehicle and trailer are in position and

being held by the vehicle’s brake.

�Š Next, apply the parking brake, and only then move the gear lever into PARK. If you move

the lever into PARK before blocking the wheels and applying the parking brake,

transmission damage may occur.

HIGH-ALTITUDE PERFORMANCE

An engine will lose about 4% of its performance for every 1,000 feet above sea level that

you travel. If you will be towing in high altitudes, it’s a good idea to allow more time than

usual due to the engine’s reduced performance.

Page 22 of 28

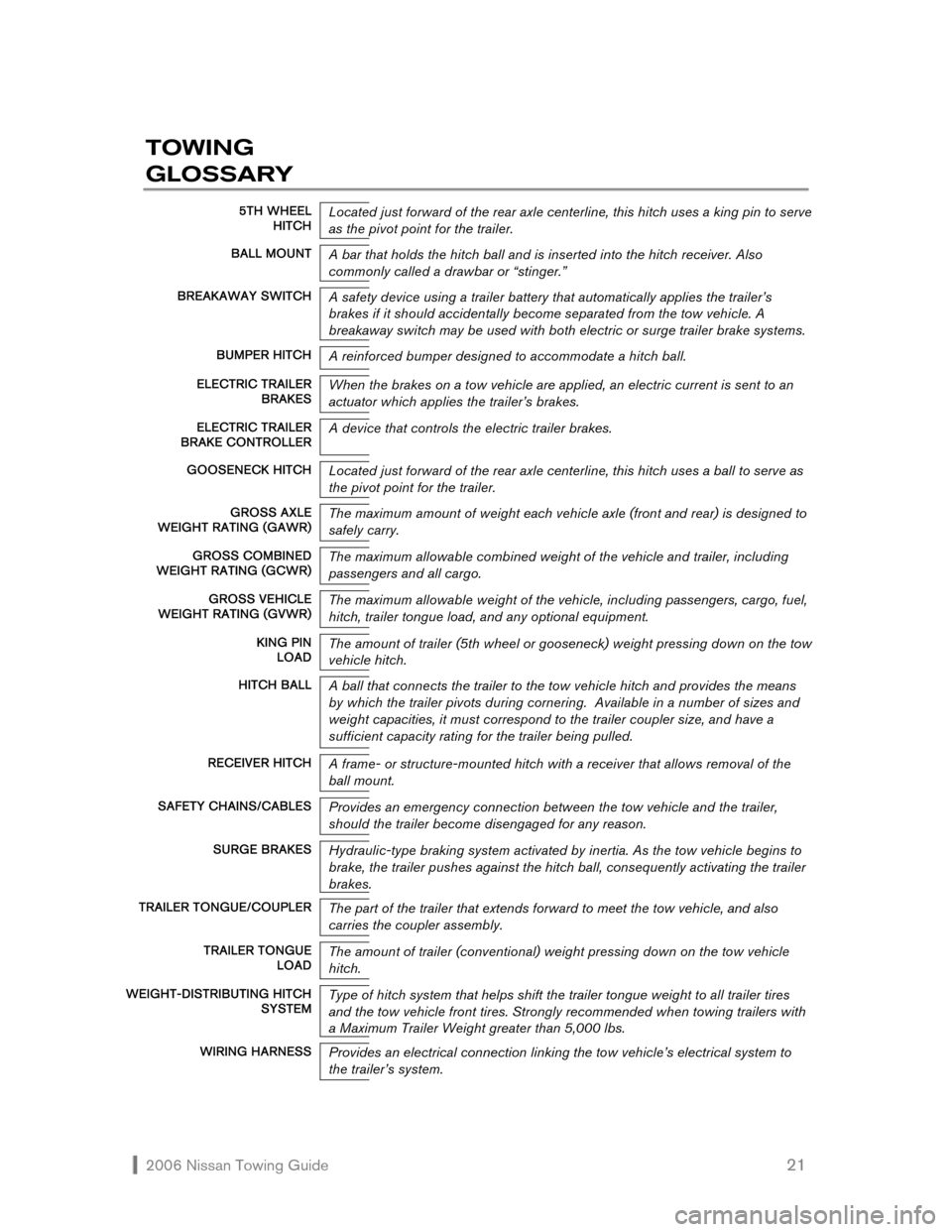

2006 Nissan Towing Guide 21

TOWING

GLOSSARY

5TH WHEEL

HITCH Located just forward of the rear axle centerline, this hitch uses a king pin to serve

as the pivot point for the trailer.

BALL MOUNT A bar that holds the hitch ball and is inserted into the hitch receiver. Also

commonly called a drawbar or “stinger.”

BREAKAWAY SWITCH A safety device using a trailer battery that automatically applies the trailer’s

brakes if it should accidentally become separated from the tow vehicle. A

breakaway switch may be used with both electric or surge trailer brake systems.

BUMPER HITCH A reinforced bumper designed to accommodate a hitch ball.

ELECTRIC TRAILER

BRAKES When the brakes on a tow vehicle are applied, an electric current is sent to an

actuator which applies the trailer’s brakes.

ELECTRIC TRAILER

BRAKE CONTROLLER A device that controls the electric trailer brakes.

GOOSENECK HITCH Located just forward of the rear axle centerline, this hitch uses a ball to serve as

the pivot point for the trailer.

GROSS AXLE

WEIGHT RATING (GAWR) The maximum amount of weight each vehicle axle (front and rear) is designed to

safely carry.

GROSS COMBINED

WEIGHT RATING (GCWR) The maximum allowable combined weight of the vehicle and trailer, including

passengers and all cargo.

GROSS VEHICLE

WEIGHT RATING (GVWR) The maximum allowable weight of the vehicle, including passengers, cargo, fuel,

hitch, trailer tongue load, and any optional equipment.

KING PIN

LOAD The amount of trailer (5th wheel or gooseneck) weight pressing down on the tow

vehicle hitch.

HITCH BALL

A ball that connects the trailer to the tow vehicle hitch and provides the means

by which the trailer pivots during cornering. Available in a number of sizes and

weight capacities, it must correspond to the trailer coupler size, and have a

sufficient capacity rating for the trailer being pulled.

RECEIVER HITCH A frame- or structure-mounted hitch with a receiver that allows removal of the

ball mount.

SAFETY CHAINS/CABLES Provides an emergency connection between the tow vehicle and the trailer,

should the trailer become disengaged for any reason.

SURGE BRAKES

Hydraulic-type braking system activated by inertia. As the tow vehicle begins to

brake, the trailer pushes against the hitch ball, consequently activating the trailer

brakes.

TRAILER TONGUE/COUPLER The part of the trailer that extends forward to meet the tow vehicle, and also

carries the coupler assembly.

TRAILER TONGUE

LOAD The amount of trailer (conventional) weight pressing down on the tow vehicle

hitch.

WEIGHT-DISTRIBUTING HITCH

SYSTEM Type of hitch system that helps shift the trailer tongue weight to all trailer tires

and the tow vehicle front tires. Strongly recommended when towing trailers with

a Maximum Trailer Weight greater than 5,000 lbs.

WIRING HARNESS

Provides an electrical connection linking the tow vehicle’s electrical system to

the trailer’s system.