tires NISSAN MURANO 2008 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: MURANO, Model: NISSAN MURANO 2008Pages: 444, PDF Size: 6.09 MB

Page 353 of 444

Black plate (351,1)

Model "Z51-D" EDITED: 2008/ 6/ 26

SCE0751

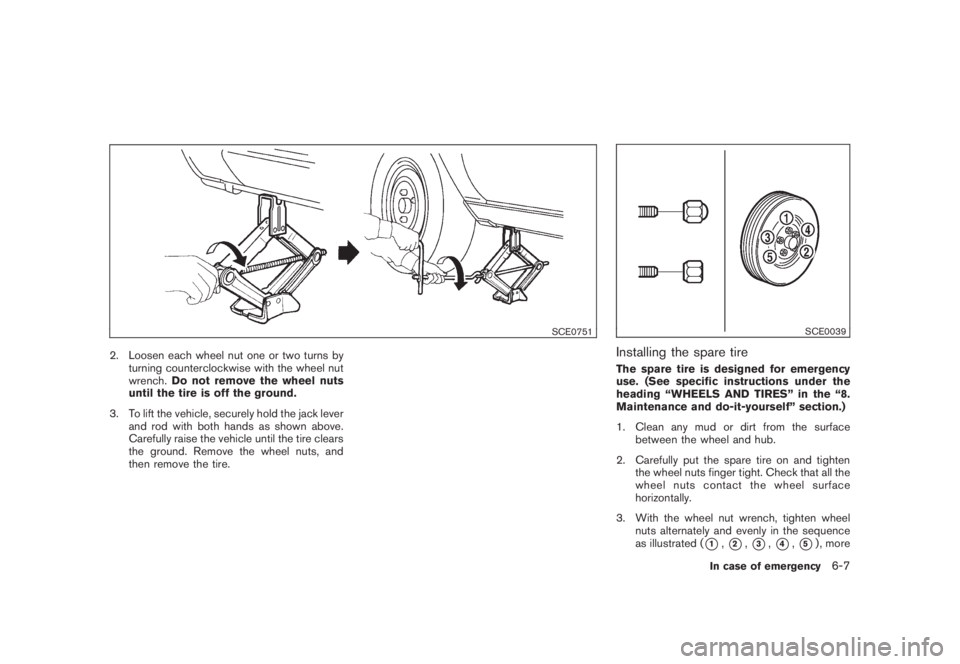

2. Loosen each wheel nut one or two turns by

turning counterclockwise with the wheel nut

wrench.Do not remove the wheel nuts

until the tire is off the ground.

3. To lift the vehicle, securely hold the jack lever

and rod with both hands as shown above.

Carefully raise the vehicle until the tire clears

the ground. Remove the wheel nuts, and

then remove the tire.

SCE0039

Installing the spare tireThe spare tire is designed for emergency

use. (See specific instructions under the

heading “WHEELS AND TIRES” in the “8.

Maintenance and do-it-yourself” section.)

1. Clean any mud or dirt from the surface

between the wheel and hub.

2. Carefully put the spare tire on and tighten

the wheel nuts finger tight. Check that all the

wheel nuts contact the wheel surface

horizontally.

3. With the wheel nut wrench, tighten wheel

nuts alternately and evenly in the sequence

as illustrated (

*1,*2,*3,*4,*5) , more

In case of emergency

6-7

Page 354 of 444

Black plate (352,1)

Model "Z51-D" EDITED: 2008/ 6/ 26

than 2 times, until they are tight.

4. Lower the vehicle slowly until the tire

touches the ground. Then, with the wheel

nut wrench, tighten the wheel nuts securely

in the sequence as illustrated. Lower the

vehicle completely.

WARNING

.Incorrect wheel nuts or improperly

tightened wheel nuts can cause the

wheel to become loose or come off.

This could cause an accident.

.Do not use oil or grease on the

wheel studs or nuts. This could

cause the nuts to become loose.

.Retighten the wheel nuts when the

vehicle has been driven for 600

miles (1,000 km) (also in cases of a

flat tire, etc.) .

.As soon as possible, tighten the

wheel nuts to the specified torque

with a torque wrench.

Wheel nut tightening torque:

80 ft-lb (108 N·m)

The wheel nuts must be kept tightened

to specification at all times. It is

recommended that wheel nuts be tigh-tened to specifications at each lubrica-

tion interval.

.Adjust tire pressure to the COLD

pressure.

COLD pressure:

After the vehicle has been parked for

three hours or more or driven less than

1 mile (1.6 km) .

COLD tire pressures are shown on the

Tire and Loading Information label

affixed to the driver side center pillar.

Stowing the damaged tire and the tools1. Securely store the damaged tire, jack and

tools in the storage area.

2. Replace the cargo box.

3. Close the cargo floor board.

4. Close the lift gate.

WARNING

.Always make sure that the spare tire

and jacking equipment are properly

secured after use. Such items can

become dangerous projectiles in an

accident or sudden stop.

.The T-type spare tire and small sizespare tire are designed for emer-

gency use. See specific instructions

under the heading “WHEELS AND

TIRES” in the “8. Maintenance and

do-it-yourself” section.

6-8

In case of emergency

Page 361 of 444

Black plate (359,1)

Model "Z51-D" EDITED: 2008/ 6/ 26

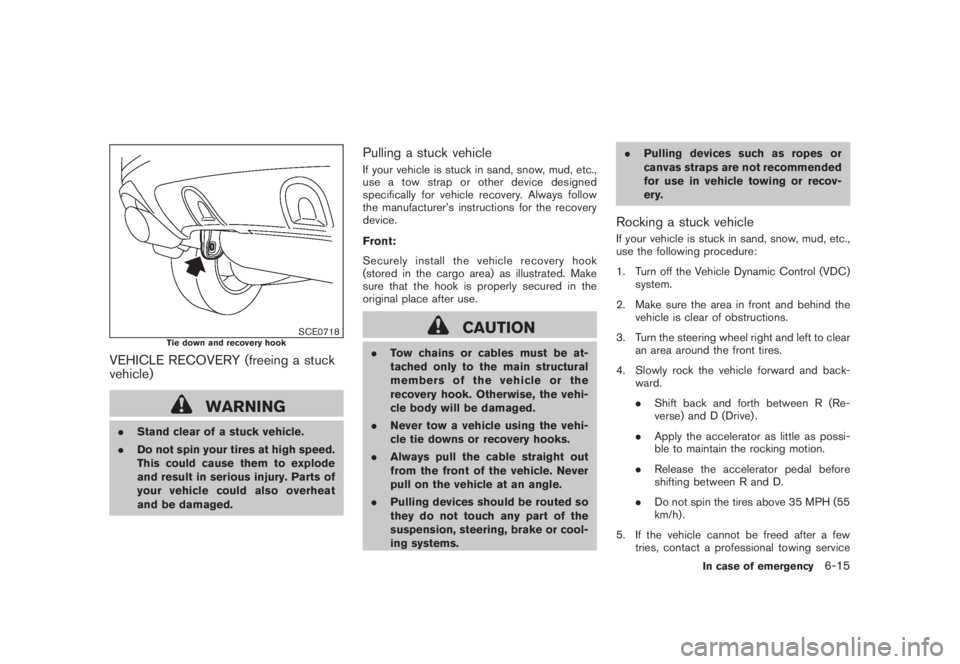

SCE0718

Tie down and recovery hook

VEHICLE RECOVERY (freeing a stuck

vehicle)

WARNING

.Stand clear of a stuck vehicle.

.Do not spin your tires at high speed.

This could cause them to explode

and result in serious injury. Parts of

your vehicle could also overheat

and be damaged.

Pulling a stuck vehicleIf your vehicle is stuck in sand, snow, mud, etc.,

use a tow strap or other device designed

specifically for vehicle recovery. Always follow

the manufacturer’s instructions for the recovery

device.

Front:

Securely install the vehicle recovery hook

(stored in the cargo area) as illustrated. Make

sure that the hook is properly secured in the

original place after use.

CAUTION

.Tow chains or cables must be at-

tached only to the main structural

members of the vehicle or the

recovery hook. Otherwise, the vehi-

cle body will be damaged.

.Never tow a vehicle using the vehi-

cle tie downs or recovery hooks.

.Always pull the cable straight out

from the front of the vehicle. Never

pull on the vehicle at an angle.

.Pulling devices should be routed so

they do not touch any part of the

suspension, steering, brake or cool-

ing systems..Pulling devices such as ropes or

canvas straps are not recommended

for use in vehicle towing or recov-

ery.

Rocking a stuck vehicleIf your vehicle is stuck in sand, snow, mud, etc.,

use the following procedure:

1. Turn off the Vehicle Dynamic Control (VDC)

system.

2. Make sure the area in front and behind the

vehicle is clear of obstructions.

3. Turn the steering wheel right and left to clear

an area around the front tires.

4. Slowly rock the vehicle forward and back-

ward.

.Shift back and forth between R (Re-

verse) and D (Drive) .

.Apply the accelerator as little as possi-

ble to maintain the rocking motion.

.Release the accelerator pedal before

shifting between R and D.

.Do not spin the tires above 35 MPH (55

km/h) .

5. If the vehicle cannot be freed after a few

tries, contact a professional towing service

In case of emergency

6-15

Page 365 of 444

Black plate (363,1)

Model "Z51-D" EDITED: 2008/ 6/ 26

REMOVING SPOTSRemove tar and oil spots, industrial dust,

insects, and tree sap as quickly as possible

from the paint surface to avoid lasting damage

or staining. Special cleaning products are

available at a NISSAN dealer or any automotive

accessory stores.UNDERBODYIn areas where road salt is used in winter, the

underbody must be cleaned regularly. This will

prevent dirt and salt from building up and

causing the acceleration of corrosion on the

underbody and suspension. Before the winter

period and again in the spring, the underseal

must be checked and, if necessary, re-treated.GLASSUse glass cleaner to remove smoke and dust

film from the glass surfaces. It is normal for glass

to become coated with a film after the vehicle is

parked in the hot sun. Glass cleaner and a soft

cloth will easily remove this film.

CAUTION

When cleaning the inside of the win-

dows, do not use sharp-edged tools,

abrasive cleaners or chlorine-based

disinfectant cleaners. They could da-mage the electrical conductors, radio

antenna elements or rear window

defroster elements.

ALUMINUM ALLOY WHEELSWash regularly with a sponge dampened in a

mild soap solution, especially during winter

months in areas where road salt is used. Salt

could discolor the wheels if not removed.

CAUTION

Follow the directions below to avoid

staining or discoloring the wheels:

.Do not use a cleaner that uses

strong acid or alkali contents to

clean the wheels.

.Do not apply wheel cleaners to the

wheels when they are hot. The

wheel temperature should be the

same as ambient temperature.

.Rinse the wheel to completely re-

move the cleaner within 15 minutes

after the cleaner is applied.CHROME PARTSClean chrome parts regularly with a non-

abrasive chrome polish to maintain the finish.

TIRE DRESSINGNISSAN does not recommend the use of tire

dressings. Tire manufacturers apply a coating to

the tires to help reduce discoloration of the

rubber. If a tire dressing is applied to the tires, it

may react with the coating and form a com-

pound. This compound may come off the tire

while driving and stain the vehicle paint.

If you choose to use a tire dressing, take the

following precautions:

.Use a water-based tire dressing. The coat-

ing on the tire dissolves more easily with an

oil-based tire dressing.

.Apply a light coat of tire dressing to help

prevent it from entering the tire tread/

grooves (where it would be difficult to

remove) .

.Wipe off excess tire dressing using a dry

towel. Make sure the tire dressing is

completely removed from the tire tread/

grooves.

.Allow the tire dressing to dry as recom-

mended by tire dressing manufacturer.

Appearance and care

7-3

Page 369 of 444

Black plate (25,1)

8 Maintenance and do-it-yourself

Model "Z51-D" EDITED: 2008/ 6/ 23

Maintenance requirement..................................... 8-2

Scheduled maintenance................................... 8-2

General maintenance...................................... 8-2

Where to go for service................................... 8-2

General maintenance.......................................... 8-2

Explanation of maintenance items....................... 8-2

Maintenance precautions..................................... 8-5

Engine compartment check locations...................... 8-6

VQ35DE engine............................................ 8-6

Engine cooling system......................................... 8-7

Checking engine coolant level........................... 8-7

Changing engine coolant................................. 8-8

Engine oil......................................................... 8-8

Checking engine oil level................................. 8-8

Changing engine oil and filter............................ 8-8

Continuously Variable Transmission (CVT) fluid........ 8-11

Power steering fluid.......................................... 8-11

Brake fluid...................................................... 8-12

Window washer fluid........................................ 8-12

Battery.......................................................... 8-13

Jump starting.............................................. 8-14

Variable voltage control system (if so equipped)...... 8-15

Drive belts...................................................... 8-15Spark plugs.................................................... 8-16

Replacing spark plugs................................... 8-16

Air cleaner...................................................... 8-16

Windshield wiper blades.................................... 8-17

Cleaning.................................................... 8-17

Replacing................................................... 8-18

Rear window wiper blade................................... 8-19

Brakes........................................................... 8-19

Self-adjusting brakes.................................... 8-19

Brake pad wear indicators.............................. 8-19

Fuses............................................................ 8-20

Engine compartment..................................... 8-20

Passenger compartment................................ 8-21

Battery replacement.......................................... 8-21

Lights............................................................ 8-24

Headlights.................................................. 8-25

Exterior and interior lights............................... 8-27

Wheels and tires.............................................. 8-30

Tire pressure............................................... 8-30

Tire labeling................................................ 8-33

Types of tires.............................................. 8-35

Tire chains.................................................. 8-36

Changing wheels and tires............................. 8-37

Page 371 of 444

Black plate (369,1)

Model "Z51-D" EDITED: 2008/ 6/ 26

Lights*:Clean the headlights on a regular basis.

Make sure that the headlights, stop lights, tail

lights, turn signal lights, and other lights are all

operating properly and installed securely. Also

check headlight aim.

Road wheel nuts (lug nuts)*:When checking

the tires, make sure no wheel nuts are missing,

and check for any loose wheel nuts. Tighten if

necessary.

Tire rotation*:Tires should be rotated every

7,500 miles (12,000 km).

Tires*:Check the pressure with a gauge often

and always prior to long distance trips. If

necessary, adjust the pressure in all tires,

including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive

wear.

Tire Pressure Monitoring System (TPMS)

transmitter components:Replace the TPMS

transmitter grommet seal, valve core and cap

when the tires are replaced due to wear or age.

Wheel alignment and balance:If the vehicle

should pull to either side while driving on a

straight and level road, or if you detect uneven or

abnormal tire wear, there may be a need for

wheel alignment.

If the steering wheel or seat vibrates at normal

highway speeds, wheel balancing may be

needed.For additional information regarding tires, refer

to “Important Tire Safety Information” (US) or

“Tire Safety Information” (Canada) in the War-

ranty Information Booklet.

Windshield:Clean the windshield on a regular

basis. Check the windshield at least every six

months for cracks or other damage. Have a

damaged windshield repaired by a qualified

repair facility.

Windshield wiper blades*:Check for cracks

or wear if they do not wipe properly.

Inside the vehicleThe maintenance items listed here should be

checked on a regular basis, such as when

performing scheduled maintenance, cleaning

the vehicle, etc.

Accelerator pedal:Check the pedal for

smooth operation and make sure the pedal

does not catch or require uneven effort. Keep

the floor mat away from the pedal.

Brake pedal:Check the pedal for smooth

operation. If the brake pedal suddenly goes

down further than normal, the pedal feels

spongy or the vehicle seems to take longer to

stop, see a NISSAN dealer immediately. Keep

the floor mat away from the pedal.

Brakes:Check that the brakes do not pull the

vehicle to one side when applied.Continuously Variable Transmission (CVT)

P (Park) position mechanism:On a fairly

steep hill, check that the vehicle is held securely

with the selector lever in the P (Park) position

without applying any brakes.

Parking brake:Check the parking brake

operation regularly. The vehicle should be

securely held on a fairly steep hill with only the

parking brake applied. If the parking brake needs

adjustment, see a NISSAN dealer.

Seat belts:Check that all parts of the seat belt

system (for example, buckles, anchors, adjusters

and retractors) operate properly and smoothly,

and are installed securely. Check the belt

webbing for cuts, fraying, wear or damage.

Seats:Check seat position controls such as

seat adjusters, seatback recliner, etc. to ensure

they operate smoothly and that all latches lock

securely in every position. Check that the head

restraints move up and down smoothly and that

the locks (if so equipped) hold securely in all

latched positions.

Steering wheel:Check for changes in the

steering conditions, such as excessive free play,

hard steering or strange noises.

Warning lights and chimes:Make sure that

all warning lights and chimes are operating

properly.

Maintenance and do-it-yourself

8-3

Page 398 of 444

Black plate (396,1)

Model "Z51-D" EDITED: 2008/ 6/ 26

If you have a flat tire, see “FLAT TIRE” in

the “6. In case of emergency” section.TIRE PRESSURE

Tire Pressure Monitoring System (TPMS)This vehicle is equipped with the Tire Pressure

Monitoring System (TPMS) . It monitors tire

pressure of all tires except the spare. When

the low tire pressure warning light is lit, one or

more of your tires is significantly under-inflated.

The TPMS will activate only when the vehicle is

driven at speeds above 16 MPH (25 km/h) .

Also, this system may not detect a sudden drop

in tire pressure (for example a flat tire while

driving) .

For more details, see “Low tire pressure warning

light” in the “2. Instruments and controls”

section, “TIRE PRESSURE MONITORING SYS-

TEM (TPMS)” in the “5. Starting and driving”

section and “TIRE PRESSURE MONITORING

SYSTEM (TPMS)” in the “6. In case of

emergency” section.Tire inflation pressureCheck the pressure of the tires (including

the spare) often and always prior to long

distance trips. The recommended tire

pressure specifications are shown on the

Tire and Loading Information label under

the “Cold Tire Pressure” heading. The Tireand Loading Information label is affixed to

the driver side center pillar. Tire pressures

should be checked regularly because:

.

Most tires naturally lose air over time.

.

Tires can lose air suddenly when driven

over potholes or other objects or if the

vehicle strikes a curb while parking.

The tire pressures should be checked

when the tires are cold. The tires are

considered COLD after the vehicle has

been parked for 3 or more hours, or driven

less than 1 mile (1.6 km) at moderate

speeds.

Incorrect tire pressure, including un-

der inflation, may adversely affect tire

life and vehicle handling.

WARNING

.

Improperly inflated tires can fail

suddenly and cause an accident.

.

The Gross Vehicle Weight rating

(GVWR) is located on the F.M.V.

S.S./C.M.V.S.S. certification la-

bel. The vehicle weight capacity

is indicated on the Tire and

Loading Information label. Donot load your vehicle beyond

this capacity. Overloading your

vehicle may result in reduced

tire life, unsafe operating condi-

tions due to premature tire fail-

ure, or unfavorable handling

characteristics and could also

lead to a serious accident. Load-

ing beyond the specified capa-

city may also result in failure of

other vehicle components.

.

Before taking a long trip, or

whenever you heavily load your

vehicle, use a tire pressure

gauge to ensure that the tire

pressures are at the specified

level.

.

Do not drive your vehicle over 85

MPH (137 km/h) unless it is

equipped with high speed rated

tires. Driving faster than 85 MPH

(137 km/h) may result in tire

failure, loss of control and pos-

sible injury.

.

For additional information re-

garding tires, refer to “Important

Tire Safety Information” (US) or

“Tire Safety Information” (Cana-

WHEELS AND TIRES8-30

Maintenance and do-it-yourself

Page 399 of 444

Black plate (397,1)

Model "Z51-D" EDITED: 2008/ 6/ 26

da) in the Warranty Information

Booklet.

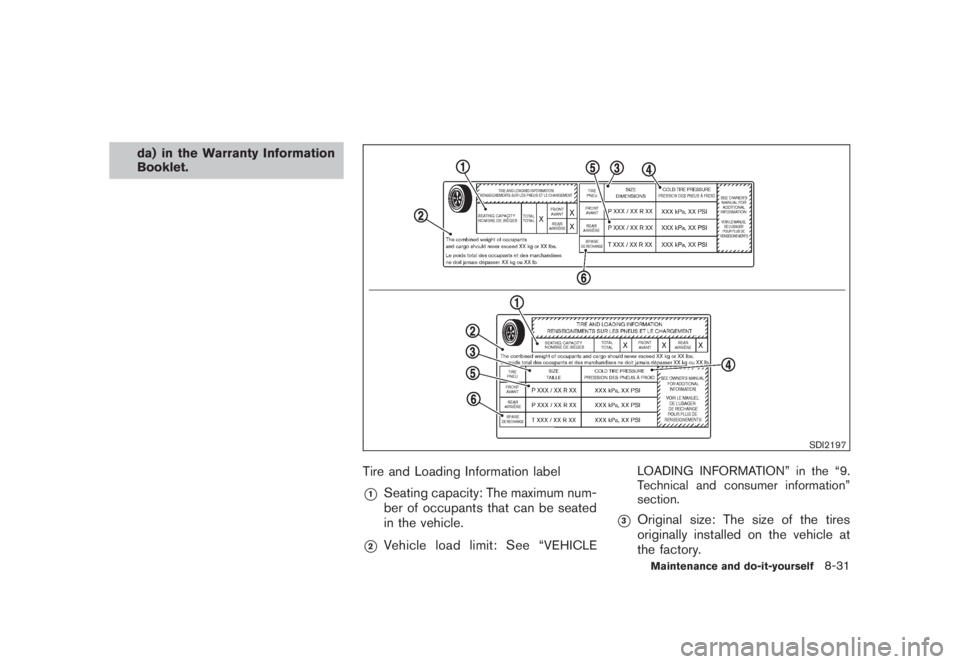

SDI2197

Tire and Loading Information label*1

Seating capacity: The maximum num-

ber of occupants that can be seated

in the vehicle.

*2

Vehicle load limit: See “

VEHICLELOADING INFORMATION” in the “9.

Technical and consumer information”

section.

*3

Original size: The size of the tires

originally installed on the vehicle at

the factory.Maintenance and do-it-yourself

8-31

Page 400 of 444

Black plate (398,1)

Model "Z51-D" EDITED: 2008/ 6/ 26

*4

Cold tire pressure: Inflate the tires to

this pressure when the tires are cold.

Tires are considered COLD after the

vehicle has been parked for 3 or

more hours, or driven less than 1 mile

(1.6 km) at moderate speeds. The

recommended cold tire inflation is set

by the manufacturer to provide the

best balance of tire wear, vehicle

handling, driveability, tire noise, etc.,

up to the vehicle’s GVWR.

*5

Tire size — see “

TIRE LABELING”

later in this section.

*6

Spare tire size or compact spare tire

size (if so equipped)

SDI1949

Checking the tire pressure1.

Remove the valve stem cap from the

tire.

2.

Press the pressure gauge squarely onto

the valve stem. Do not press too hard or

force the valve stem sideways, or air will

escape. If the hissing sound of air

escaping from the tire is heard while

checking the pressure, reposition the

gauge to eliminate this leakage.

3.

Remove the gauge.

4.

Read the tire pressure on the gauge

stem and compare it to the specifica-tion shown on the Tire and Loading

Information label.

5.

Add air to the tire as needed. If too

much air is added, press the core of the

valve stem briefly with the tip of the

gauge stem to release pressure. Re-

check the pressure and add or release

air as needed.

6.

Install the valve stem cap.

7.

Check the pressure of all other tires,

including the spare.

8-32

Maintenance and do-it-yourself

Page 401 of 444

Black plate (399,1)

Model "Z51-D" EDITED: 2008/ 6/ 26

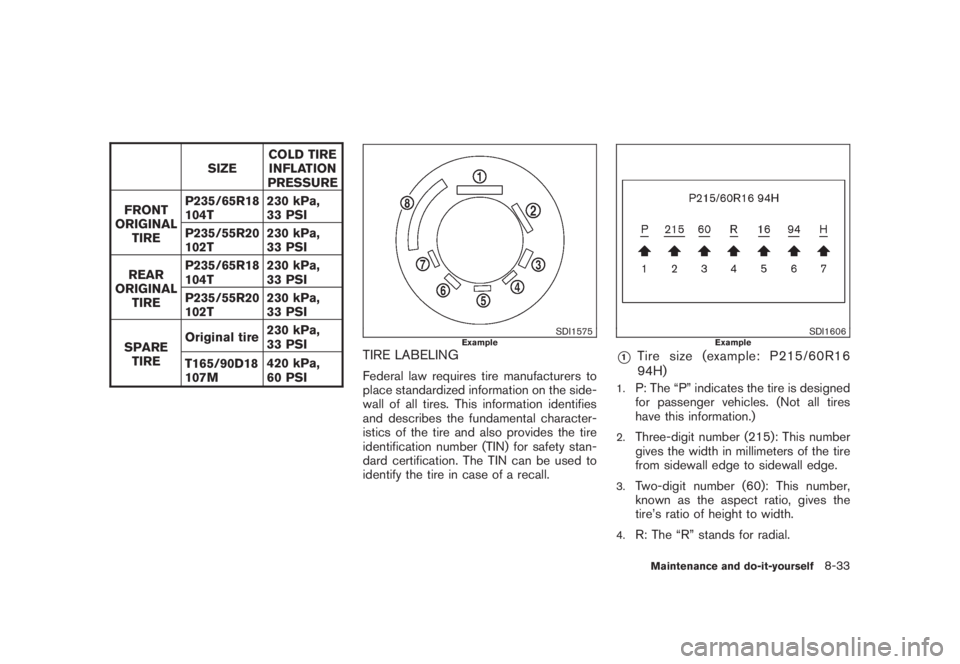

SIZECOLD TIRE

INFLATION

PRESSURE

FRONT

ORIGINAL

TIREP235/65R18

104T230 kPa,

33 PSI

P235/55R20

102T230 kPa,

33 PSI

REAR

ORIGINAL

TIREP235/65R18

104T230 kPa,

33 PSI

P235/55R20

102T230 kPa,

33 PSI

SPARE

TIREOriginal tire230 kPa,

33 PSI

T165/90D18

107M420 kPa,

60 PSI

SDI1575

Example

TIRE LABELINGFederal law requires tire manufacturers to

place standardized information on the side-

wall of all tires. This information identifies

and describes the fundamental character-

istics of the tire and also provides the tire

identification number (TIN) for safety stan-

dard certification. The TIN can be used to

identify the tire in case of a recall.

SDI1606

Example

*1

Tire size (example: P215/60R16

94H)

1.

P: The “P” indicates the tire is designed

for passenger vehicles. (Not all tires

have this information.)

2.

Three-digit number (215): This number

gives the width in millimeters of the tire

from sidewall edge to sidewall edge.

3.

Two-digit number (60): This number,

known as the aspect ratio, gives the

tire’s ratio of height to width.

4.

R: The “R” stands for radial.

Maintenance and do-it-yourself

8-33