tire pressure NISSAN MURANO 2011 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: MURANO, Model: NISSAN MURANO 2011Pages: 433, PDF Size: 3.7 MB

Page 337 of 433

Black plate (335,1)

Model "Z51-D" EDITED: 2010/ 7/ 23

as this may cause a malfunction of

the tire pressure sensors.

CHANGING A FLAT TIREIf you have a flat tire, follow the instructions

below.Stopping the vehicle1. Safely move the vehicle off the road andaway from traffic.

2. Turn on the hazard warning flashers.

3. Park on a level surface and apply the parking brake. Move the selector lever to the P

(Park) position.

4. Turn off the engine.

5. Raise the hood to warn other traffic, and to signal professional road assistance person-

nel that you need assistance.

6. Have all passengers get out of the vehicle and stand in a safe place, away from traffic

and clear of the vehicle.

WARNING

.Make sure the parking brake is

securely applied and the transmis-

sion is shifted into the P (Park)

position. .

Never change tires when the vehicle

is on a slope, ice or slippery areas.

This is hazardous.

. Never change tires if oncoming

traffic is close to your vehicle. Wait

for professional road assistance.

MCE0001A

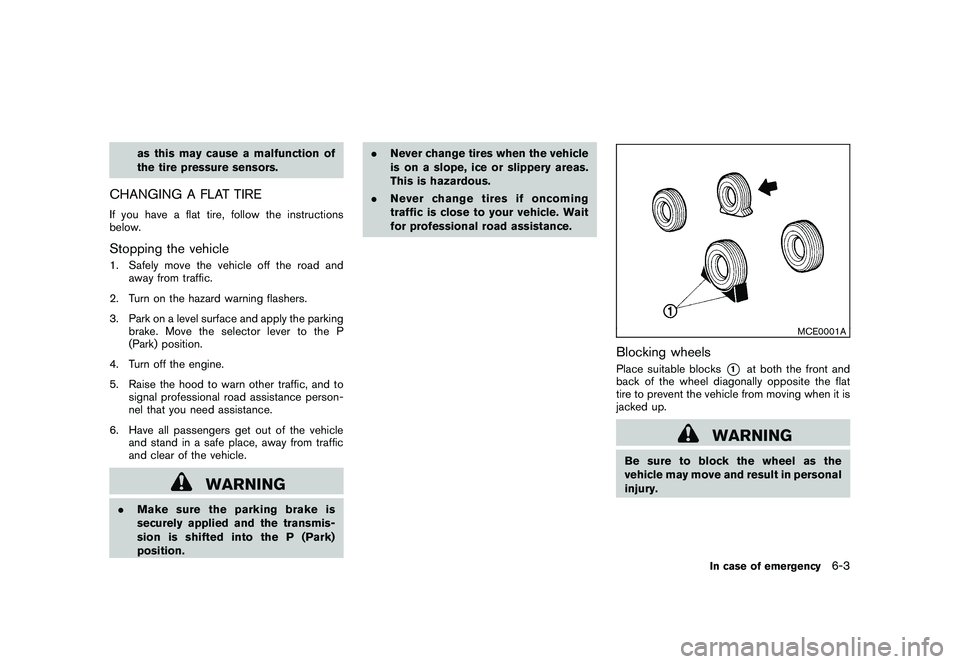

Blocking wheelsPlace suitable blocks

*1

at both the front and

back of the wheel diagonally opposite the flat

tire to prevent the vehicle from moving when it is

jacked up.

WARNING

Be sure to block the wheel as the

vehicle may move and result in personal

injury.

In case of emergency

6-3

Page 342 of 433

Black plate (340,1)

Model "Z51-D" EDITED: 2010/ 7/ 23

SCE0039

Installing the spare tireThe spare tire is designed for emergency

use. (See specific instructions under the

heading “WHEELS AND TIRES” in the “8.

Maintenance and do-it-yourself” section.)

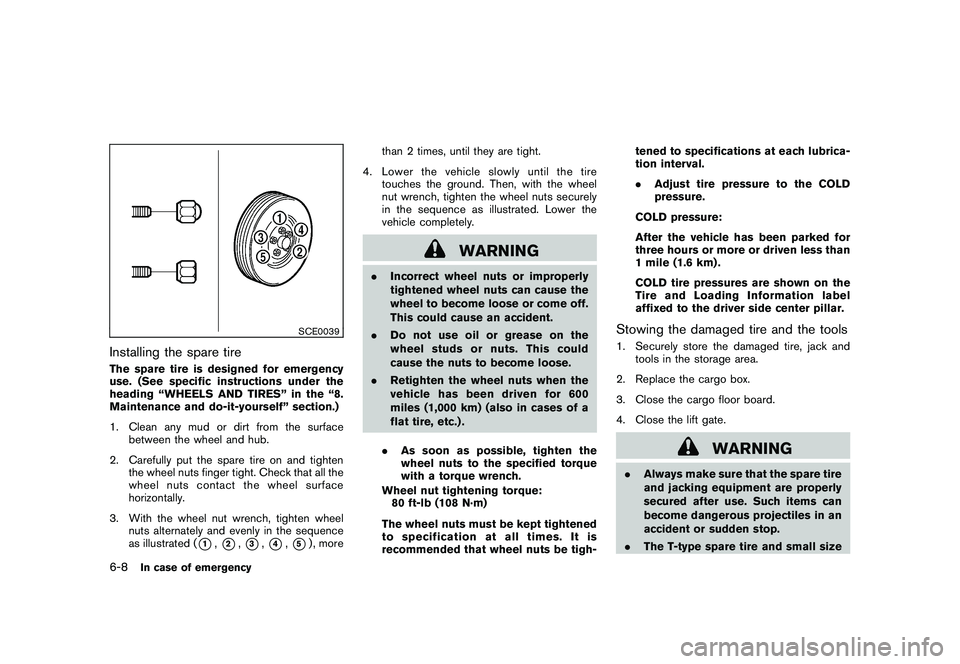

1. Clean any mud or dirt from the surfacebetween the wheel and hub.

2. Carefully put the spare tire on and tighten the wheel nuts finger tight. Check that all the

wheel nuts contact the wheel surface

horizontally.

3. With the wheel nut wrench, tighten wheel nuts alternately and evenly in the sequence

as illustrated (

*1,*2,*3,*4,*5) , more than 2 times, until they are tight.

4. Lower the vehicle slowly until the tire touches the ground. Then, with the wheel

nut wrench, tighten the wheel nuts securely

in the sequence as illustrated. Lower the

vehicle completely.

WARNING

.Incorrect wheel nuts or improperly

tightened wheel nuts can cause the

wheel to become loose or come off.

This could cause an accident.

. Do not use oil or grease on the

wheel studs or nuts. This could

cause the nuts to become loose.

. Retighten the wheel nuts when the

vehicle has been driven for 600

miles (1,000 km) (also in cases of a

flat tire, etc.) .

. As soon as possible, tighten the

wheel nuts to the specified torque

with a torque wrench.

Wheel nut tightening torque: 80 ft-lb (108 N·m)

The wheel nuts must be kept tightened

to specification at all times. It is

recommended that wheel nuts be tigh- tened to specifications at each lubrica-

tion interval.

.

Adjust tire pressure to the COLD

pressure.

COLD pressure:

After the vehicle has been parked for

three hours or more or driven less than

1 mile (1.6 km) .

COLD tire pressures are shown on the

Tire and Loading Information label

affixed to the driver side center pillar.

Stowing the damaged tire and the tools1. Securely store the damaged tire, jack and tools in the storage area.

2. Replace the cargo box.

3. Close the cargo floor board.

4. Close the lift gate.

WARNING

. Always make sure that the spare tire

and jacking equipment are properly

secured after use. Such items can

become dangerous projectiles in an

accident or sudden stop.

. The T-type spare tire and small size

6-8

In case of emergency

Page 357 of 433

Black plate (25,1)

8 Maintenance and do-it-yourself

Model "Z51-D" EDITED: 2010/ 7/ 23

Maintenance requirement..................................... 8-2

Scheduled maintenance ................................... 8-2

General maintenance ...................................... 8-2

Where to go for service ................................... 8-2

General maintenance .......................................... 8-2

Explanation of maintenance items ....................... 8-2

Maintenance precautions ..................................... 8-5

Engine compartment check locations ...................... 8-6

VQ35DE engine ............................................ 8-6

Engine cooling system ......................................... 8-7

Checking engine coolant level ........................... 8-7

Changing engine coolant ................................. 8-8

Engine oil ......................................................... 8-8

Checking engine oil level ................................. 8-8

Changing engine oil and filter ............................ 8-8

Continuously Variable Transmission (CVT) fluid ........ 8-11

Power steering fluid .......................................... 8-11

Brake fluid ...................................................... 8-12

Window washer fluid ........................................ 8-12

Battery .......................................................... 8-13

Jump starting .............................................. 8-14

Variable voltage control system (if so equipped) ...... 8-15

Drive belt ....................................................... 8-15 Spark plugs

.................................................... 8-16

Replacing spark plugs ................................... 8-16

Air cleaner ...................................................... 8-16

Windshield wiper blades .................................... 8-17

Cleaning .................................................... 8-17

Replacing ................................................... 8-18

Rear window wiper blade ................................... 8-19

Brakes ........................................................... 8-19

Self-adjusting brakes .................................... 8-19

Brake pad wear warning ................................ 8-19

Fuses ............................................................ 8-20

Engine compartment ..................................... 8-20

Passenger compartment ................................ 8-21

Intelligent Key battery replacement ....................... 8-22

Lights ............................................................ 8-24

Headlights .................................................. 8-25

Exterior and interior lights ............................... 8-27

Wheels and tires .............................................. 8-30

Tire pressure ............................................... 8-30

Tire labeling ................................................ 8-33

Types of tires .............................................. 8-35

Tire chains .................................................. 8-36

Changing wheels and tires ............................. 8-36

Page 359 of 433

Black plate (361,1)

Model "Z51-D" EDITED: 2010/ 7/ 23

Lights*:Clean the headlights on a regular basis.

Make sure that the headlights, stop lights, tail

lights, turn signal lights, and other lights are all

operating properly and installed securely. Also

check headlight aim.

Road wheel nuts (lug nuts)*: When checking

the tires, make sure no wheel nuts are missing,

and check for any loose wheel nuts. Tighten if

necessary.

Tire rotation*: Tires should be rotated every

7,500 miles (12,000 km).

Tires*: Check the pressure with a gauge often

and always prior to long distance trips. If

necessary, adjust the pressure in all tires,

including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive

wear.

Tire Pressure Monitoring System (TPMS)

transmitter components: Replace the TPMS

transmitter grommet seal, valve core and cap

when the tires are replaced due to wear or age.

Wheel alignment and balance: If the vehicle

should pull to either side while driving on a

straight and level road, or if you detect uneven or

abnormal tire wear, there may be a need for

wheel alignment.

If the steering wheel or seat vibrates at normal

highway speeds, wheel balancing may be

needed. For additional information regarding tires, refer

to “Important Tire Safety Information” (US) or

“Tire Safety Information” (Canada) in the War-

ranty Information Booklet.

Windshield:

Clean the windshield on a regular

basis. Check the windshield at least every six

months for cracks or other damage. Have a

damaged windshield repaired by a qualified

repair facility.

Windshield wiper blades*: Check for cracks

or wear if they do not wipe properly.

Inside the vehicleThe maintenance items listed here should be

checked on a regular basis, such as when

performing scheduled maintenance, cleaning

the vehicle, etc.

Accelerator pedal: Check the pedal for

smooth operation and make sure the pedal

does not catch or require uneven effort. Keep

the floor mat away from the pedal.

Brake pedal: Check the pedal for smooth

operation. If the brake pedal suddenly goes

down further than normal, the pedal feels

spongy or the vehicle seems to take longer to

stop, see a NISSAN dealer immediately. Keep

the floor mat away from the pedal.

Brakes: Check that the brakes do not pull the

vehicle to one side when applied. Continuously Variable Transmission (CVT)

P (Park) position mechanism:

On a fairly

steep hill, check that the vehicle is held securely

with the selector lever in the P (Park) position

without applying any brakes.

Parking brake: Check the parking brake

operation regularly. The vehicle should be

securely held on a fairly steep hill with only the

parking brake applied. If the parking brake needs

adjustment, see a NISSAN dealer.

Seat belts: Check that all parts of the seat belt

system (for example, buckles, anchors, adjusters

and retractors) operate properly and smoothly,

and are installed securely. Check the belt

webbing for cuts, fraying, wear or damage.

Seats: Check seat position controls such as

seat adjusters, seatback recliner, etc. to ensure

they operate smoothly and that all latches lock

securely in every position. Check that the head

restraints/headrests move up and down

smoothly and that the locks (if so equipped)

hold securely in all latched positions.

Steering wheel: Check for changes in the

steering conditions, such as excessive free play,

hard steering or strange noises.

Warning lights and chimes: Make sure that

all warning lights and chimes are operating

properly.

Maintenance and do-it-yourself

8-3

Page 386 of 433

Black plate (388,1)

Model "Z51-D" EDITED: 2010/ 7/ 23

If you have a flat tire, see “FLAT TIRE” in

the “6. In case of emergency” section.TIRE PRESSURE

Tire Pressure Monitoring System (TPMS)This vehicle is equipped with the Tire Pressure

Monitoring System (TPMS) . It monitors tire

pressure of all tires except the spare. When

the low tire pressure warning light is lit and the

CHECK TIRE PRESSURE warning appears on

the dot matrix liquid crystal display, one or more

of your tires is significantly under-inflated.

The TPMS will activate only when the vehicle is

driven at speeds above 16 MPH (25 km/h) .

Also, this system may not detect a sudden drop

in tire pressure (for example a flat tire while

driving) .

For more details, see “Low tire pressure warning

light” in the “2. Instruments and controls”

section, “TIRE PRESSURE MONITORING SYS-

TEM (TPMS)” in the “5. Starting and driving”

section and “TIRE PRESSURE MONITORING

SYSTEM (TPMS)” in the “6. In case of

emergency” section.Tire inflation pressureCheck the pressure of the tires (including

the spare) often and always prior to long

distance trips. The recommended tire

pressure specifications are shown on theTire and Loading Information label under

the “Cold Tire Pressure” heading. The Tire

and Loading Information label is affixed to

the driver side center pillar. Tire pressures

should be checked regularly because:

.

Most tires naturally lose air over time.

.

Tires can lose air suddenly when driven

over potholes or other objects or if the

vehicle strikes a curb while parking.

The tire pressures should be checked

when the tires are cold. The tires are

considered COLD after the vehicle has

been parked for 3 or more hours, or driven

less than 1 mile (1.6 km) at moderate

speeds.

Incorrect tire pressure, including un-

der inflation, may adversely affect tire

life and vehicle handling.

WARNING

.

Improperly inflated tires can fail

suddenly and cause an accident.

.

The Gross Vehicle Weight rating

(GVWR) is located on the F.M.V.

S.S./C.M.V.S.S. certification la-

bel. The vehicle weight capacity is indicated on the Tire and

Loading Information label. Do

not load your vehicle beyond

this capacity. Overloading your

vehicle may result in reduced

tire life, unsafe operating condi-

tions due to premature tire fail-

ure, or unfavorable handling

characteristics and could also

lead to a serious accident. Load-

ing beyond the specified capa-

city may also result in failure of

other vehicle components.

.

Before taking a long trip, or

whenever you heavily load your

vehicle, use a tire pressure

gauge to ensure that the tire

pressures are at the specified

level.

.

For additional information re-

garding tires, refer to “Important

Tire Safety Information” (US) or

“Tire Safety Information” (Cana-

da) in the Warranty Information

Booklet.

WHEELS AND TIRES8-30

Maintenance and do-it-yourself

Page 387 of 433

Black plate (389,1)

Model "Z51-D" EDITED: 2010/ 7/ 23

SDI2197

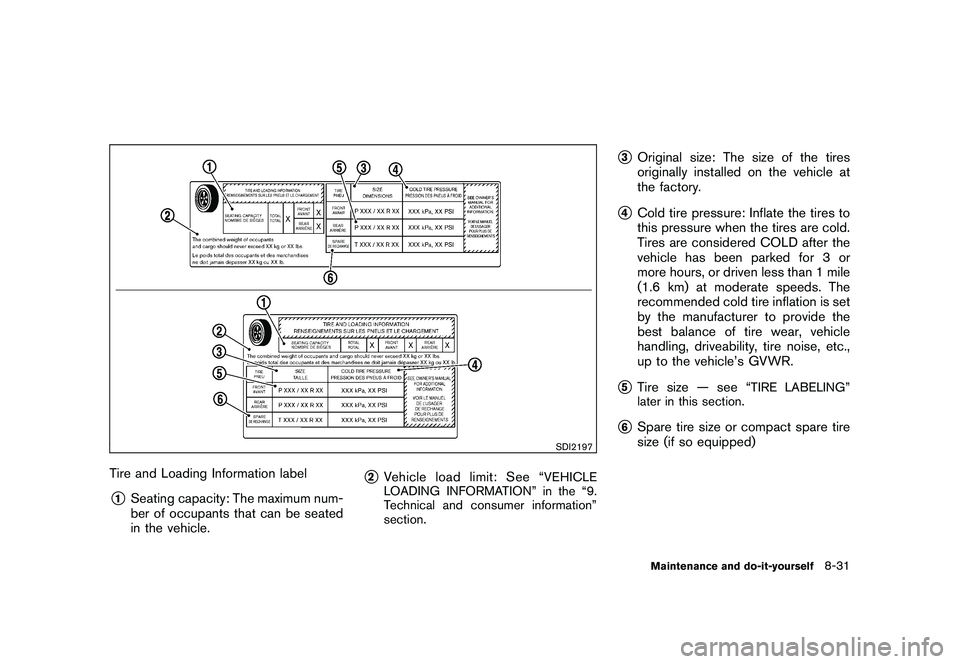

Tire and Loading Information label*1

Seating capacity: The maximum num-

ber of occupants that can be seated

in the vehicle.

*2

Vehicle load limit: See “

VEHICLE

LOADING INFORMATION” in the “9.

Technical and consumer information”

section.

*3

Original size: The size of the tires

originally installed on the vehicle at

the factory.

*4

Cold tire pressure: Inflate the tires to

this pressure when the tires are cold.

Tires are considered COLD after the

vehicle has been parked for 3 or

more hours, or driven less than 1 mile

(1.6 km) at moderate speeds. The

recommended cold tire inflation is set

by the manufacturer to provide the

best balance of tire wear, vehicle

handling, driveability, tire noise, etc.,

up to the vehicle’s GVWR.

*5

Tire size — see “

TIRE LABELING”

later in this section.

*6

Spare tire size or compact spare tire

size (if so equipped)Maintenance and do-it-yourself

8-31

Page 388 of 433

Black plate (390,1)

Model "Z51-D" EDITED: 2010/ 7/ 23

SDI1949

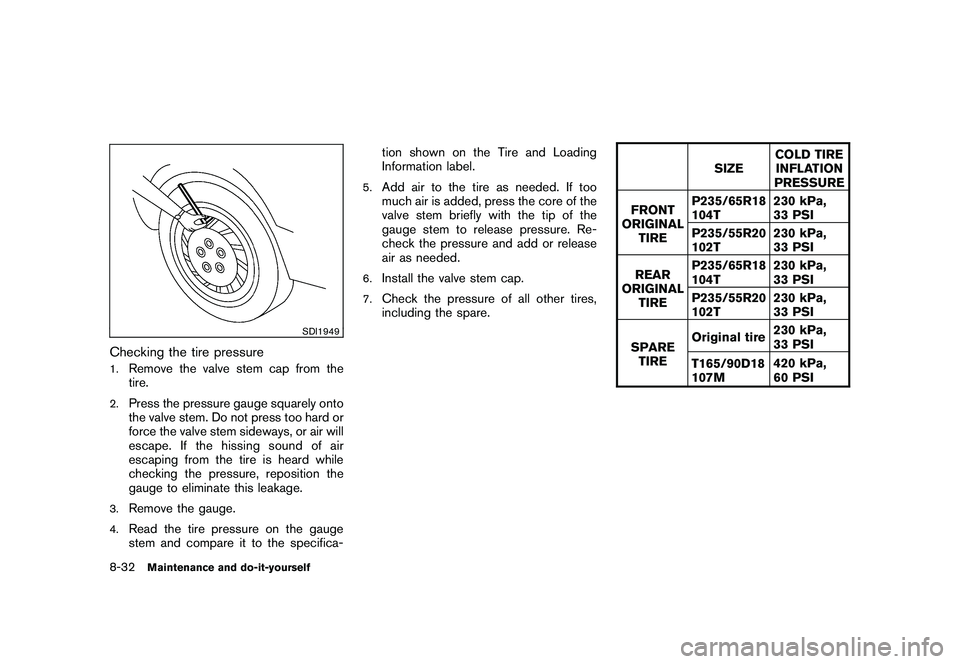

Checking the tire pressure1.

Remove the valve stem cap from the

tire.

2.

Press the pressure gauge squarely onto

the valve stem. Do not press too hard or

force the valve stem sideways, or air will

escape. If the hissing sound of air

escaping from the tire is heard while

checking the pressure, reposition the

gauge to eliminate this leakage.

3.

Remove the gauge.

4.

Read the tire pressure on the gauge

stem and compare it to the specifica-tion shown on the Tire and Loading

Information label.

5.

Add air to the tire as needed. If too

much air is added, press the core of the

valve stem briefly with the tip of the

gauge stem to release pressure. Re-

check the pressure and add or release

air as needed.

6.

Install the valve stem cap.

7.

Check the pressure of all other tires,

including the spare.

SIZE

COLD TIRE

INFLATION

PRESSURE

FRONT

ORIGINAL TIRE P235/65R18

104T

230 kPa,

33 PSI

P235/55R20

102T 230 kPa,

33 PSI

REAR

ORIGINAL

TIRE P235/65R18

104T

230 kPa,

33 PSI

P235/55R20

102T 230 kPa,

33 PSI

SPARE TIRE Original tire

230 kPa,

33 PSI

T165/90D18

107M 420 kPa,

60 PSI

8-32

Maintenance and do-it-yourself

Page 390 of 433

Black plate (392,1)

Model "Z51-D" EDITED: 2010/ 7/ 23

SDI1607

Example

*2

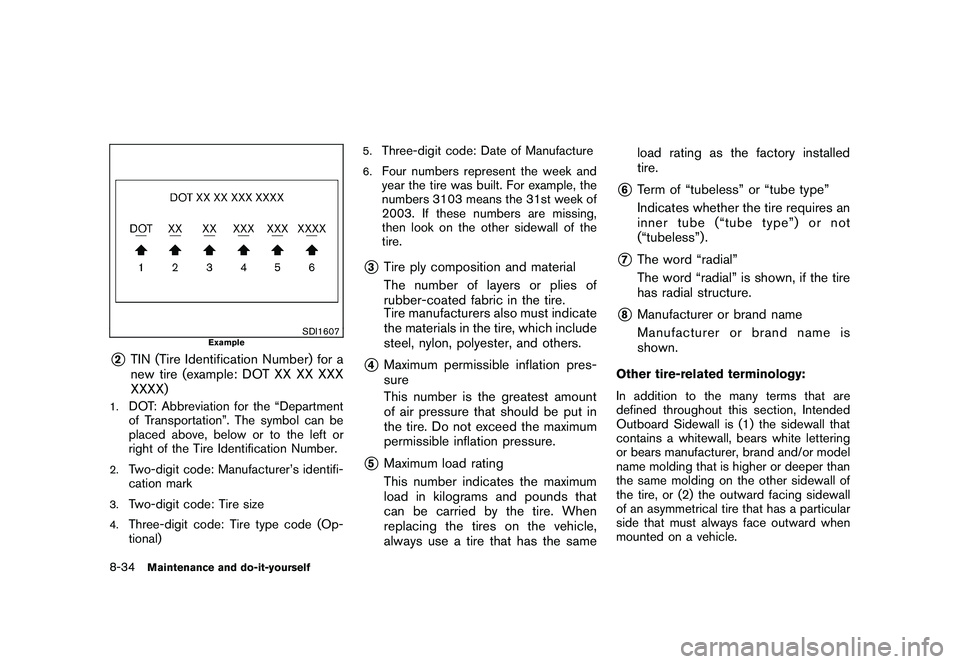

TIN (Tire Identification Number) for a

new tire (example: DOT XX XX XXX

XXXX)

1.

DOT: Abbreviation for the “Department

of Transportation”. The symbol can be

placed above, below or to the left or

right of the Tire Identification Number.

2.

Two-digit code: Manufacturer’s identifi-

cation mark

3.

Two-digit code: Tire size

4.

Three-digit code: Tire type code (Op-

tional)

5.

Three-digit code: Date of Manufacture

6.

Four numbers represent the week and

year the tire was built. For example, the

numbers 3103 means the 31st week of

2003. If these numbers are missing,

then look on the other sidewall of the

tire.

*3

Tire ply composition and material

The number of layers or plies of

rubber-coated fabric in the tire.

Tire manufacturers also must indicate

the materials in the tire, which include

steel, nylon, polyester, and others.

*4

Maximum permissible inflation pres-

sure

This number is the greatest amount

of air pressure that should be put in

the tire. Do not exceed the maximum

permissible inflation pressure.

*5

Maximum load rating

This number indicates the maximum

load in kilograms and pounds that

can be carried by the tire. When

replacing the tires on the vehicle,

always use a tire that has the sameload rating as the factory installed

tire.

*6

Term of “tubeless” or “tube type”

Indicates whether the tire requires an

inner tube (“tube type”) or not

(“tubeless”) .

*7

The word “radial”

The word “radial” is shown, if the tire

has radial structure.

*8

Manufacturer or brand name

Manufacturer or brand name is

shown.

Other tire-related terminology:

In addition to the many terms that are

defined throughout this section, Intended

Outboard Sidewall is (1) the sidewall that

contains a whitewall, bears white lettering

or bears manufacturer, brand and/or model

name molding that is higher or deeper than

the same molding on the other sidewall of

the tire, or (2) the outward facing sidewall

of an asymmetrical tire that has a particular

side that must always face outward when

mounted on a vehicle.

8-34

Maintenance and do-it-yourself

Page 392 of 433

Black plate (394,1)

Model "Z51-D" EDITED: 2010/ 7/ 23

.ONLY use spare tires specified for

the AWD model.

If excessive tire wear is found, it is recom-

mended that all four tires be replaced with tires

of the same size, brand, construction and tread

pattern. The tire pressure and wheel alignment

should also be checked and corrected as

necessary. Contact a NISSAN dealer.TIRE CHAINSUse of tire chains may be prohibited according

to location. Check the local laws before instal-

ling tire chains. When installing tire chains, make

sure they are the proper size for the tires on your

vehicle and are installed according to the chain

manufacturer’s suggestions. Use only SAE

Class S chains. Class “S” chains are used on

vehicles with restricted tire to vehicle clearance.

Vehicles that can use Class “S” chains are

designed to meet the SAE standard minimum

clearances between the tire and the closest

vehicle suspension or body component required

to accommodate the use of a winter traction

device (tire chains or cables) . The minimum

clearances are determined using the factory

equipped tire size. Other types may damage

your vehicle. Use chain tensioners when re-

commended by the tire chain manufacturer to

ensure a tight fit. Loose end links of the tire

chain must be secured or removed to prevent

the possibility of whipping action damage to the fenders or underbody. If possible, avoid fully

loading your vehicle when using tire chains. In

addition, drive at a reduced speed. Otherwise,

your vehicle may be damaged and/or vehicle

handling and performance may be adversely

affected.

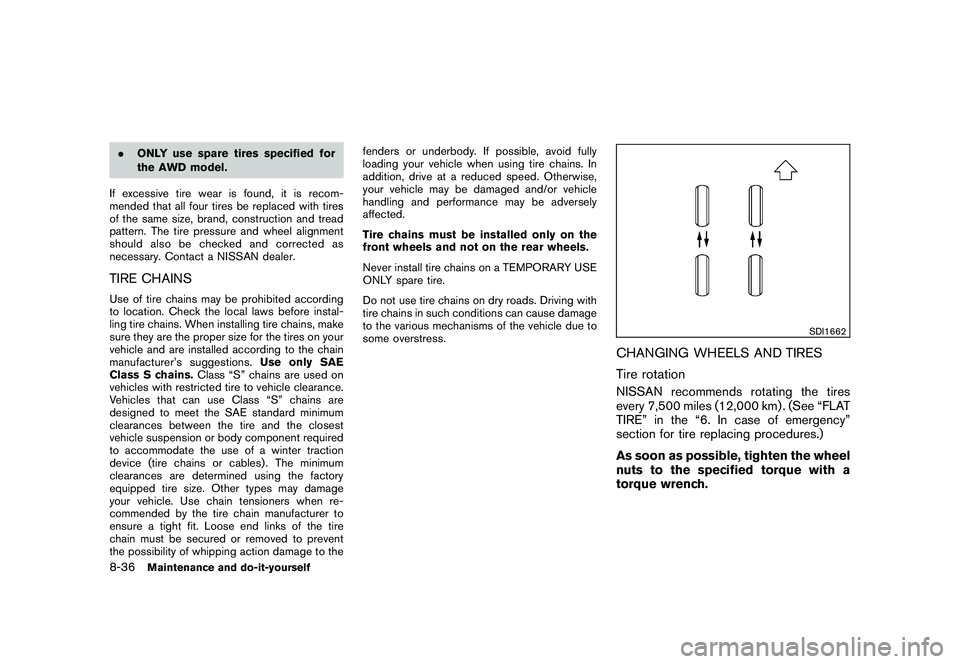

Tire chains must be installed only on the

front wheels and not on the rear wheels.

Never install tire chains on a TEMPORARY USE

ONLY spare tire.

Do not use tire chains on dry roads. Driving with

tire chains in such conditions can cause damage

to the various mechanisms of the vehicle due to

some overstress.

SDI1662

CHANGING WHEELS AND TIRES

Tire rotationNISSAN recommends rotating the tires

every 7,500 miles (12,000 km) . (See “FLAT

TIRE” in the “6. In case of emergency”

section for tire replacing procedures.)

As soon as possible, tighten the wheel

nuts to the specified torque with a

torque wrench.

8-36

Maintenance and do-it-yourself

Page 393 of 433

Black plate (395,1)

Model "Z51-D" EDITED: 2010/ 7/ 23

Wheel nut tightening torque:80 ft-lb (108 N·m)

The wheel nuts must be kept tigh-

tened to the specification at all times.

It is recommended that wheel nuts be

tightened to the specification at each

tire rotation interval.

WARNING

.

After rotating the tires, check

and adjust the tire pressure.

.

Retighten the wheel nuts when

the vehicle has been driven for

600 miles (1,000 km) (also in

cases of a flat tire, etc.) .

.

Do not include the spare tire or

any other small size spare tire in

the tire rotation.

.

For additional information re-

garding tires, refer to “Important

Tire Safety Information” (US) or

“Tire Safety Information” (Cana-

da) in the Warranty Information

Booklet.

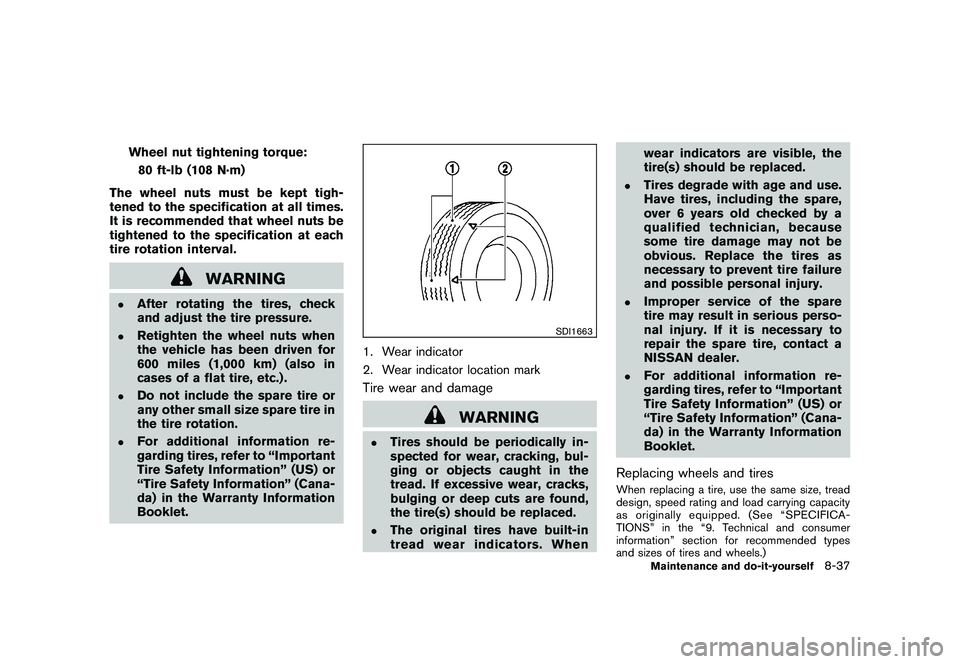

SDI1663

1. Wear indicator

2. Wear indicator location markTire wear and damage

WARNING

.

Tires should be periodically in-

spected for wear, cracking, bul-

ging or objects caught in the

tread. If excessive wear, cracks,

bulging or deep cuts are found,

the tire(s) should be replaced.

.

The original tires have built-in

tread wear indicators. When wear indicators are visible, the

tire(s) should be replaced.

.

Tires degrade with age and use.

Have tires, including the spare,

over 6 years old checked by a

qualified technician, because

some tire damage may not be

obvious. Replace the tires as

necessary to prevent tire failure

and possible personal injury.

.

Improper service of the spare

tire may result in serious perso-

nal injury. If it is necessary to

repair the spare tire, contact a

NISSAN dealer.

.

For additional information re-

garding tires, refer to “Important

Tire Safety Information” (US) or

“Tire Safety Information” (Cana-

da) in the Warranty Information

Booklet.

Replacing wheels and tiresWhen replacing a tire, use the same size, tread

design, speed rating and load carrying capacity

as originally equipped. (See “SPECIFICA-

TIONS” in the “9. Technical and consumer

information” section for recommended types

and sizes of tires and wheels.)

Maintenance and do-it-yourself

8-37