din NISSAN NOTE 2007 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: NOTE, Model: NISSAN NOTE 2007Pages: 235, PDF Size: 2.29 MB

Page 160 of 235

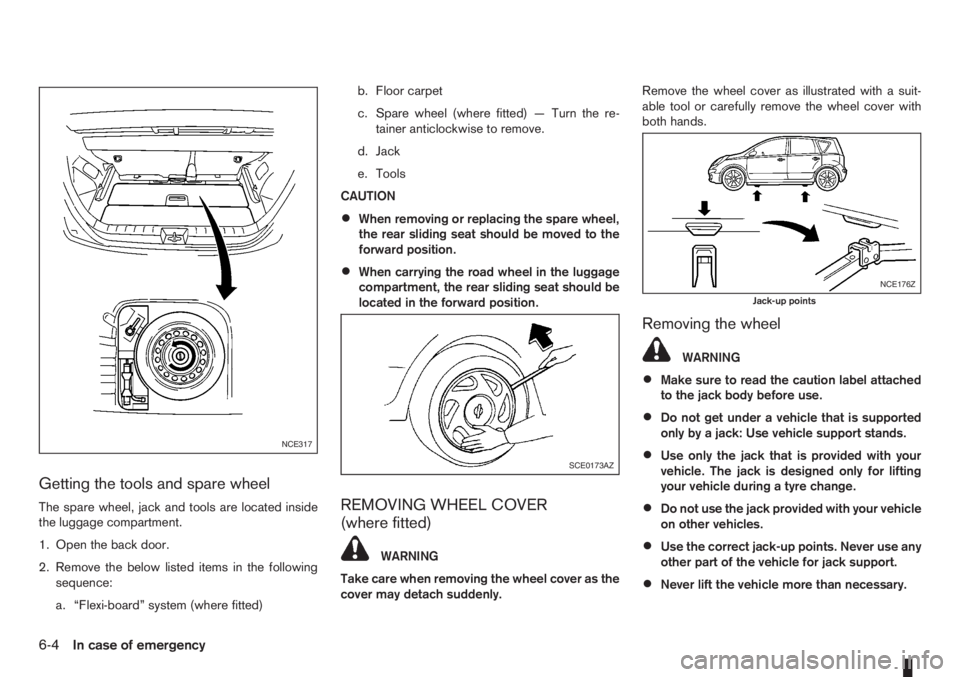

Getting the tools and spare wheel

The spare wheel, jack and tools are located inside

the luggage compartment.

1. Open the back door.

2. Remove the below listed items in the following

sequence:

a. “Flexi-board” system (where fitted)b. Floor carpet

c. Spare wheel (where fitted) — Turn the re-

tainer anticlockwise to remove.

d. Jack

e. Tools

CAUTION

•When removing or replacing the spare wheel,

the rear sliding seat should be moved to the

forward position.

•When carrying the road wheel in the luggage

compartment, the rear sliding seat should be

located in the forward position.

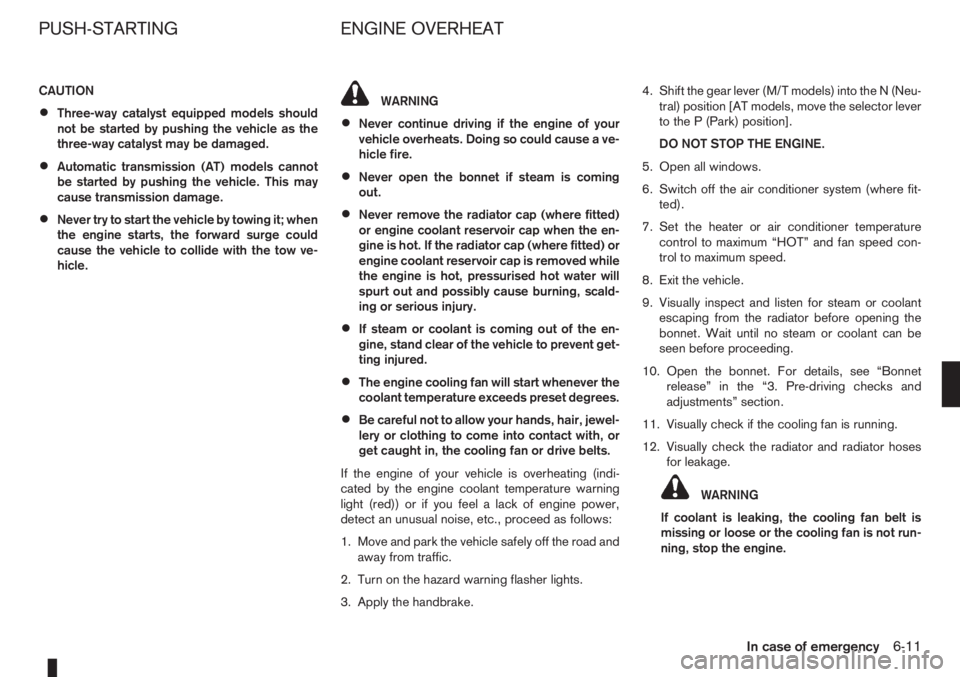

REMOVING WHEEL COVER

(where fitted)

WARNING

Take care when removing the wheel cover as the

cover may detach suddenly.Remove the wheel cover as illustrated with a suit-

able tool or carefully remove the wheel cover with

both hands.

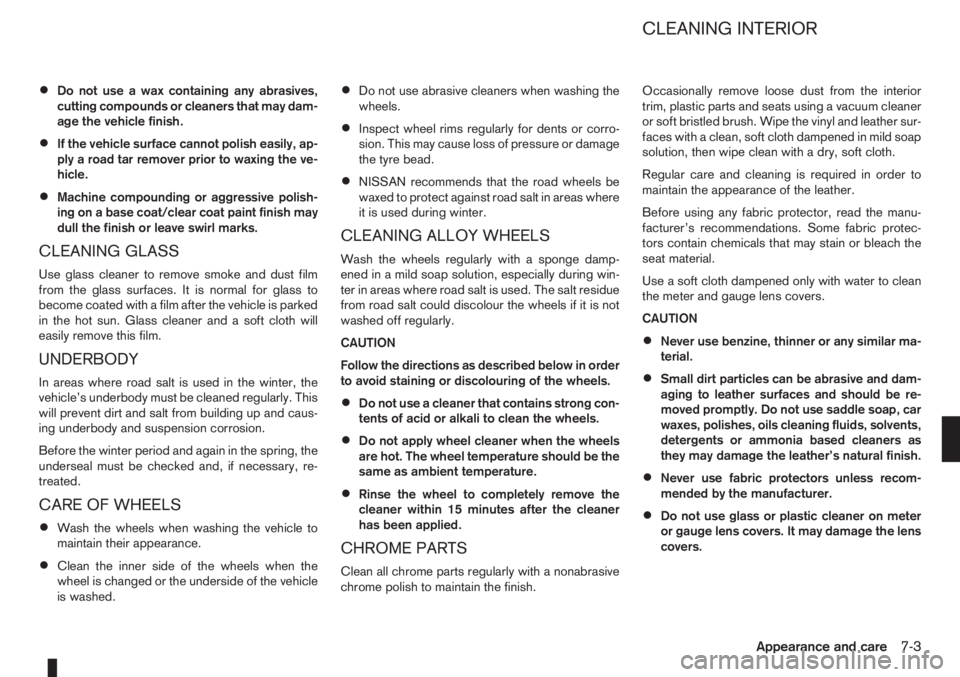

Removing the wheel

WARNING

•Make sure to read the caution label attached

to the jack body before use.

•Do not get under a vehicle that is supported

only by a jack: Use vehicle support stands.

•Use only the jack that is provided with your

vehicle. The jack is designed only for lifting

your vehicle during a tyre change.

•Do not use the jack provided with your vehicle

on other vehicles.

•Use the correct jack-up points. Never use any

other part of the vehicle for jack support.

•Never lift the vehicle more than necessary.

NCE317

SCE0173AZ

NCE176Z

Jack-up points

6-4In case of emergency

Page 167 of 235

CAUTION

•Three-way catalyst equipped models should

not be started by pushing the vehicle as the

three-way catalyst may be damaged.

•Automatic transmission (AT) models cannot

be started by pushing the vehicle. This may

cause transmission damage.

•Never try to start the vehicle by towing it; when

the engine starts, the forward surge could

cause the vehicle to collide with the tow ve-

hicle.

WARNING

•Never continue driving if the engine of your

vehicle overheats. Doing so could cause a ve-

hicle fire.

•Never open the bonnet if steam is coming

out.

•Never remove the radiator cap (where fitted)

or engine coolant reservoir cap when the en-

gine is hot. If the radiator cap (where fitted) or

engine coolant reservoir cap is removed while

the engine is hot, pressurised hot water will

spurt out and possibly cause burning, scald-

ing or serious injury.

•If steam or coolant is coming out of the en-

gine, stand clear of the vehicle to prevent get-

ting injured.

•The engine cooling fan will start whenever the

coolant temperature exceeds preset degrees.

•Be careful not to allow your hands, hair, jewel-

lery or clothing to come into contact with, or

get caught in, the cooling fan or drive belts.

If the engine of your vehicle is overheating (indi-

cated by the engine coolant temperature warning

light (red)) or if you feel a lack of engine power,

detect an unusual noise, etc., proceed as follows:

1. Move and park the vehicle safely off the road and

away from traffic.

2. Turn on the hazard warning flasher lights.

3. Apply the handbrake.4. Shift the gear lever (M/T models) into the N (Neu-

tral) position [AT models, move the selector lever

to the P (Park) position].

DO NOT STOP THE ENGINE.

5. Open all windows.

6. Switch off the air conditioner system (where fit-

ted).

7. Set the heater or air conditioner temperature

control to maximum “HOT” and fan speed con-

trol to maximum speed.

8. Exit the vehicle.

9. Visually inspect and listen for steam or coolant

escaping from the radiator before opening the

bonnet. Wait until no steam or coolant can be

seen before proceeding.

10. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

11. Visually check if the cooling fan is running.

12. Visually check the radiator and radiator hoses

for leakage.

WARNING

If coolant is leaking, the cooling fan belt is

missing or loose or the cooling fan is not run-

ning, stop the engine.

PUSH-STARTING ENGINE OVERHEAT

In case of emergency6-11

Page 173 of 235

•Do not use a wax containing any abrasives,

cutting compounds or cleaners that may dam-

age the vehicle finish.

•If the vehicle surface cannot polish easily, ap-

ply a road tar remover prior to waxing the ve-

hicle.

•Machine compounding or aggressive polish-

ing on a base coat/clear coat paint finish may

dull the finish or leave swirl marks.

CLEANING GLASS

Use glass cleaner to remove smoke and dust film

from the glass surfaces. It is normal for glass to

become coated with a film after the vehicle is parked

in the hot sun. Glass cleaner and a soft cloth will

easily remove this film.

UNDERBODY

In areas where road salt is used in the winter, the

vehicle’s underbody must be cleaned regularly. This

will prevent dirt and salt from building up and caus-

ing underbody and suspension corrosion.

Before the winter period and again in the spring, the

underseal must be checked and, if necessary, re-

treated.

CARE OF WHEELS

•Wash the wheels when washing the vehicle to

maintain their appearance.

•Clean the inner side of the wheels when the

wheel is changed or the underside of the vehicle

is washed.

•Do not use abrasive cleaners when washing the

wheels.

•Inspect wheel rims regularly for dents or corro-

sion. This may cause loss of pressure or damage

the tyre bead.

•NISSAN recommends that the road wheels be

waxed to protect against road salt in areas where

it is used during winter.

CLEANING ALLOY WHEELS

Wash the wheels regularly with a sponge damp-

ened in a mild soap solution, especially during win-

ter in areas where road salt is used. The salt residue

from road salt could discolour the wheels if it is not

washed off regularly.

CAUTION

Follow the directions as described below in order

to avoid staining or discolouring of the wheels.

•Do not use a cleaner that contains strong con-

tents of acid or alkali to clean the wheels.

•Do not apply wheel cleaner when the wheels

are hot. The wheel temperature should be the

same as ambient temperature.

•Rinse the wheel to completely remove the

cleaner within 15 minutes after the cleaner

has been applied.

CHROME PARTS

Clean all chrome parts regularly with a nonabrasive

chrome polish to maintain the finish.Occasionally remove loose dust from the interior

trim, plastic parts and seats using a vacuum cleaner

or soft bristled brush. Wipe the vinyl and leather sur-

faces with a clean, soft cloth dampened in mild soap

solution, then wipe clean with a dry, soft cloth.

Regular care and cleaning is required in order to

maintain the appearance of the leather.

Before using any fabric protector, read the manu-

facturer’s recommendations. Some fabric protec-

tors contain chemicals that may stain or bleach the

seat material.

Use a soft cloth dampened only with water to clean

the meter and gauge lens covers.

CAUTION

•Never use benzine, thinner or any similar ma-

terial.

•Small dirt particles can be abrasive and dam-

aging to leather surfaces and should be re-

moved promptly. Do not use saddle soap, car

waxes, polishes, oils cleaning fluids, solvents,

detergents or ammonia based cleaners as

they may damage the leather’s natural finish.

•Never use fabric protectors unless recom-

mended by the manufacturer.

•Do not use glass or plastic cleaner on meter

or gauge lens covers. It may damage the lens

covers.

CLEANING INTERIOR

Appearance and care7-3

Page 176 of 235

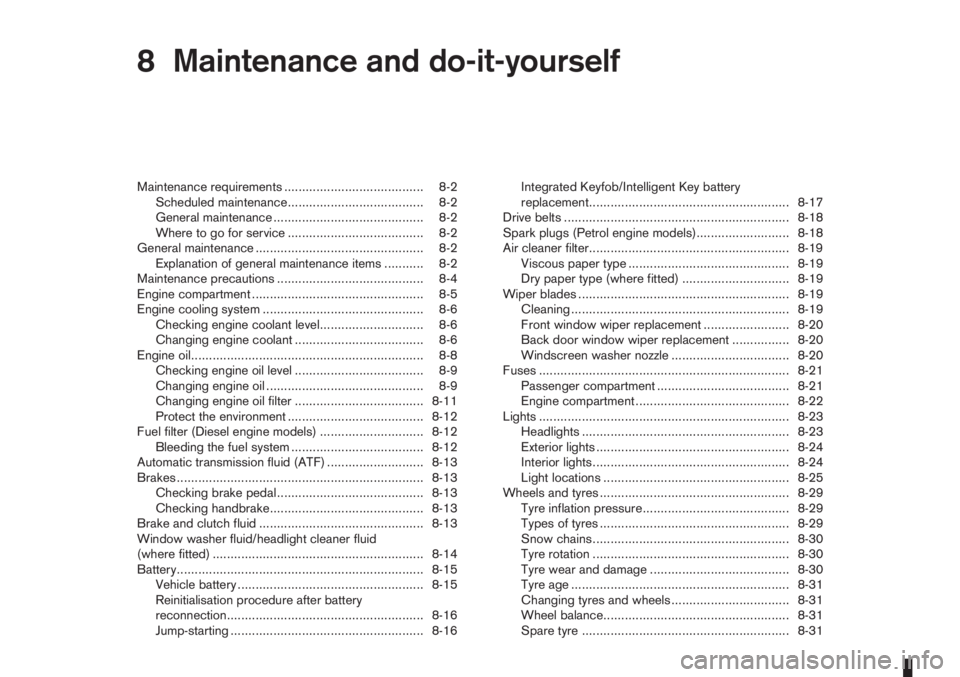

8Maintenance and do-it-yourselfMaintenance and do-it-yourself

Maintenance requirements ....................................... 8-2

Scheduled maintenance...................................... 8-2

General maintenance .......................................... 8-2

Where to go for service ...................................... 8-2

General maintenance ............................................... 8-2

Explanation of general maintenance items ........... 8-2

Maintenance precautions ......................................... 8-4

Engine compartment ................................................ 8-5

Engine cooling system ............................................. 8-6

Checking engine coolant level............................. 8-6

Changing engine coolant .................................... 8-6

Engine oil................................................................. 8-8

Checking engine oil level .................................... 8-9

Changing engine oil ............................................ 8-9

Changing engine oil filter .................................... 8-11

Protect the environment ...................................... 8-12

Fuel filter (Diesel engine models) ............................. 8-12

Bleeding the fuel system ..................................... 8-12

Automatic transmission fluid (ATF) ........................... 8-13

Brakes ..................................................................... 8-13

Checking brake pedal......................................... 8-13

Checking handbrake........................................... 8-13

Brake and clutch fluid .............................................. 8-13

Window washer fluid/headlight cleaner fluid

(where fitted) ........................................................... 8-14

Battery..................................................................... 8-15

Vehicle battery .................................................... 8-15

Reinitialisation procedure after battery

reconnection....................................................... 8-16

Jump-starting ...................................................... 8-16Integrated Keyfob/Intelligent Key battery

replacement........................................................ 8-17

Drive belts ............................................................... 8-18

Spark plugs (Petrol engine models).......................... 8-18

Air cleaner filter........................................................ 8-19

Viscous paper type ............................................. 8-19

Dry paper type (where fitted) .............................. 8-19

Wiper blades ........................................................... 8-19

Cleaning ............................................................. 8-19

Front window wiper replacement ........................ 8-20

Back door window wiper replacement ................ 8-20

Windscreen washer nozzle ................................. 8-20

Fuses ...................................................................... 8-21

Passenger compartment ..................................... 8-21

Engine compartment ........................................... 8-22

Lights ...................................................................... 8-23

Headlights .......................................................... 8-23

Exterior lights ...................................................... 8-24

Interior lights....................................................... 8-24

Light locations .................................................... 8-25

Wheels and tyres ..................................................... 8-29

Tyre inflation pressure......................................... 8-29

Types of tyres ..................................................... 8-29

Snow chains....................................................... 8-30

Tyre rotation ....................................................... 8-30

Tyre wear and damage ....................................... 8-30

Tyre age ............................................................. 8-31

Changing tyres and wheels ................................. 8-31

Wheel balance.................................................... 8-31

Spare tyre .......................................................... 8-31

Page 179 of 235

Lights*:

Clean the headlights on a regular basis. Make sure

that the headlights, stop lights, tail lights, turn signal

lights, and other lights are all operating properly and

installed securely. Also check headlight aim.

Tyres*:

Check the pressure with a gauge periodically when

at a service station (including the spare) and adjust

to the specified pressure if necessary. Check care-

fully for damage, cuts or excessive wear.

Tyre rotation*:

Tyres should be rotated at least every 10,000 km

(6,000 miles). However, the timing for tyre rotation

may vary according to your driving habits and road

surface conditions.

Wheel alignment and balance:

If the vehicle pull to either side while driving on a

straight and level road, or if you detect uneven or

abnormal tyre wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at

normal highway speeds, wheel balancing may be

needed.

Wheel bolts:

When checking the tyres, make sure no wheel bolts

are missing, and check for any loose wheel bolts.

Tighten if necessary.Windscreen:

Clean the windscreen on a regular basis. Check the

windscreen at least every six months for cracks or

other damage. Have a damaged windscreen re-

paired by a qualified repair facility.

Wiper blades*:

Check for cracks or wear if they do not wipe prop-

erly.

Under the bonnet and vehicle

The maintenance items listed here should be

checked periodically, e.g. each time you check the

engine oil or refuel.

Battery*:

Check if the green indicator on the top of the main-

tenance free battery is visible. If it is not visible,

replace the battery as soon as possible.

Vehicles operated in high temperatures or under

severe conditions, check the fluid level frequently.

Brake and clutch fluid level*:

Make sure that the brake and clutch fluid level is

between the MAX and MIN lines on the reservoir.

Engine coolant level*:

Check the coolant level when the engine is cold.

Engine drive belts*:

Make sure that the drive belts are not frayed, worn,

cracked or oily.Engine oil level*:

Check the level after parking the vehicle on a level

surface and turning off the engine.

Fluid leaks:

Check under the vehicle for fuel, oil, water or other

fluid leaks after the vehicle has been parked for a

while. Water dripping from the air conditioner after

use is normal. If you should notice any leaks or if

petrol fumes are evident, check for the cause and

have it corrected immediately.

Window washer fluid*:

Check that there is adequate fluid in the tank.

Inside the vehicle

The maintenance items listed here should be

checked on a regular basis, such as when perform-

ing periodic maintenance, cleaning the vehicle, etc.

Accelerator pedal:

Check the pedal for smooth operation and make

sure that the pedal does not catch or require uneven

effort. Keep the floor mats away from the pedal.

Brake pedal*:

Check the pedal for smooth operation. If the brake

pedal suddenly goes down further than normal, the

pedal feels spongy or the vehicle seems to take

longer to stop, contact a NISSAN dealer or qualified

workshop immediately. Keep the floor mat away

from the pedal.

Maintenance and do-it-yourself8-3

Page 181 of 235

•If you must run the engine in an enclosed

space such as a garage, be sure there is

proper ventilation for exhaust gases.

•Never get under the vehicle while it is sup-

ported only by a jack. If it is necessary to work

under the vehicle, support it with safety

stands.

•Keep smoking materials, flame and sparks

away from fuel and battery.

•Never connect or disconnect either the bat-

tery or any transistorised component connec-

tor while the ignition switch is in the ON posi-

tion.

•Never leave the engine or transmission re-

lated component harness connector discon-

nected while the ignition switch is in the ON

position.

•On petrol engine models with the multiport

fuel injection (MFI) system, the fuel filter or

fuel lines should be serviced by a NISSAN

dealer or qualified workshop because the fuel

lines are under high pressure even when the

engine is off.

•Always wear eye protection whenever you

work on your vehicle.

•Failure to follow these or other common sense

guidelines may lead to serious injury or ve-

hicle damage.

NISSAN GREEN PROGRAM

Improperly disposed engine oil and/or other

vehicle fluids can pollute the environment. Al-

ways conform to local regulations for disposal

of vehicle fluid.

This section gives instructions regarding only those

items which are relatively easy for an owner to per-

form.

You should be aware that incomplete or improper

servicing may result in operating difficulties or ex-

cessive emissions, and could affect your warranty

coverage.If in doubt about any servicing, have it

done by your NISSAN dealer or qualified work-

shop.For an overview of the engine compartment, see

“Engine compartment” in the “0. Illustrated table

of contents” section.

ENGINE COMPARTMENT

Maintenance and do-it-yourself8-5

Page 182 of 235

WARNING

•Never remove the engine coolant reservoir

cap or the radiator cap (where fitted) when

the engine is hot. Serious burns could be

caused by high pressure fluid escaping either

from the radiator or the engine coolant reser-

voir. Wait until the engine and radiator have

cooled down.

•Engine coolant is poisonous and should be

stored carefully in marked containers out of

the reach of children.

The engine cooling system is filled at the factory

with a high-quality, year-round and extended life en-

gine coolant. The high quality engine coolant con-

tains the specific solutions effective for the anti-cor-

rosion and the anti-freeze function. Therefore, addi-

tional cooling system additives are not necessary.

CAUTION

•When adding or replacing engine coolant, be

sure to use Genuine NISSAN anti-freeze L250

coolant or equivalent premixed type (mixture

ratio 50% for all ambient temperatures).

•The use of other types of engine coolant may

damage the engine cooling system.

•If the radiator or engine coolant reservoir tank

is equipped with a pressure cap, use a Genu-

ine NISSAN cap or its equivalent when re-

placement is required.

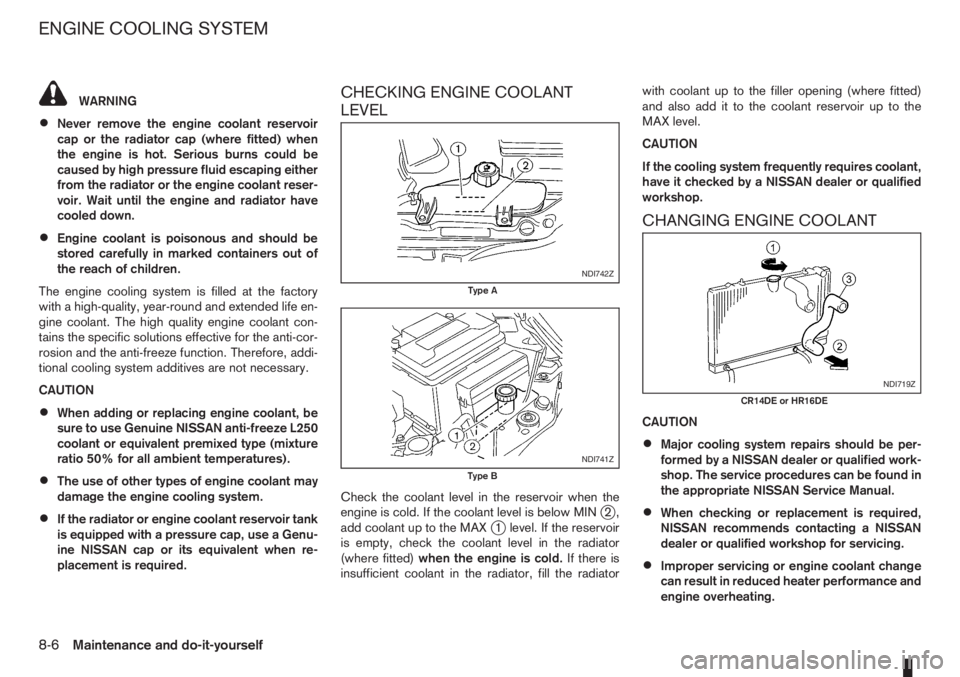

CHECKING ENGINE COOLANT

LEVEL

Check the coolant level in the reservoir when the

engine is cold. If the coolant level is below MINj2,

add coolant up to the MAXj1 level. If the reservoir

is empty, check the coolant level in the radiator

(where fitted)when the engine is cold.If there is

insufficient coolant in the radiator, fill the radiatorwith coolant up to the filler opening (where fitted)

and also add it to the coolant reservoir up to the

MAX level.

CAUTION

If the cooling system frequently requires coolant,

have it checked by a NISSAN dealer or qualified

workshop.

CHANGING ENGINE COOLANT

CAUTION

•Major cooling system repairs should be per-

formed by a NISSAN dealer or qualified work-

shop. The service procedures can be found in

the appropriate NISSAN Service Manual.

•When checking or replacement is required,

NISSAN recommends contacting a NISSAN

dealer or qualified workshop for servicing.

•Improper servicing or engine coolant change

can result in reduced heater performance and

engine overheating.

NDI742Z

Type A

NDI741Z

Type B

NDI719Z

CR14DE or HR16DE

ENGINE COOLING SYSTEM

8-6Maintenance and do-it-yourself

Page 185 of 235

A.CR14DE or HR16DE engine

B.K9K engine

1.Normal range

2.MIN level

3.MAX level

CHECKING ENGINE OIL LEVEL

CAUTION

The oil level should be checked regularly. Oper-

ating with an insufficient amount of oil can dam-

age the engine, and such damage is not covered

by warranty.

1. Park the vehicle on a level surface and apply the

handbrake.

2. Start the engine. If the engine is cold, start and

let the engine idle until it reaches the operational

temperature.3. Turn the engine off.

4. Wait at least 10 minutes for the engine oil to

drain back into the oil pan.

5. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

6. Remove the dipstick and wipe it clean.

7. Reinsert it all the way.

8. Remove the dipstick again and check the oil level.

It should be in the normal range

j1.

9. If the oil level is below MIN

j2 , remove the en-

gine oil filler cap and pour the recommended oil

through the opening.Do not overfill

j3.

10. Re-check the oil level with the dipstick.

11. Install the engine oil filler cap securely.

12. Close the bonnet.

It is normal to add some engine oil between oil

maintenance intervals depending on the severity

of operating conditions or depending on the prop-

erty of the engine oil used. More engine oil is

consumed by frequent acceleration/deceleration

especially when the engine rpm is high. Con-

sumption is likely to be higher when the engine

is new. If the rate of oil consumption, after hav-

ing driven for 5,000 km (3,000 miles), is more

than 0.5 litre per 1,000 km (621 miles), consult a

NISSAN dealer or qualified workshop.

CHANGING ENGINE OIL

NDI957Z

SDI1104Z

CR14DE engine

NDI653Z

HR16DE engine

Maintenance and do-it-yourself8-9

Page 187 of 235

18. Install the engine compartment undercover

(where fitted).

19. Lower the vehicle carefully to the ground.

20. Close the bonnet.

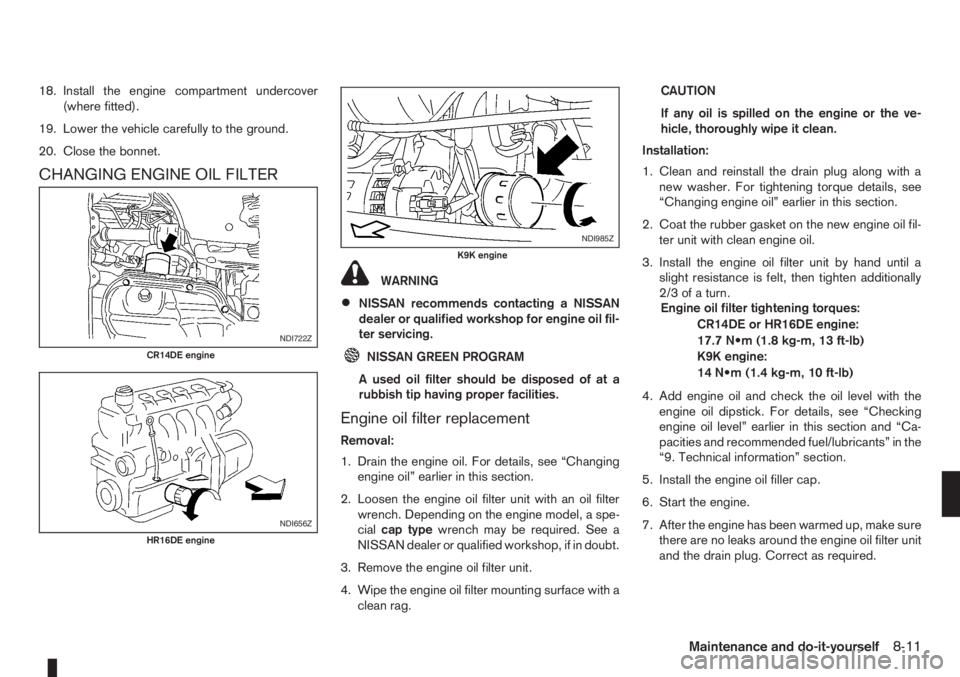

CHANGING ENGINE OIL FILTER

WARNING

•NISSAN recommends contacting a NISSAN

dealer or qualified workshop for engine oil fil-

ter servicing.

NISSAN GREEN PROGRAM

A used oil filter should be disposed of at a

rubbish tip having proper facilities.

Engine oil filter replacement

Removal:

1. Drain the engine oil. For details, see “Changing

engine oil” earlier in this section.

2. Loosen the engine oil filter unit with an oil filter

wrench. Depending on the engine model, a spe-

cialcap typewrench may be required. See a

NISSAN dealer or qualified workshop, if in doubt.

3. Remove the engine oil filter unit.

4. Wipe the engine oil filter mounting surface with a

clean rag.CAUTION

If any oil is spilled on the engine or the ve-

hicle, thoroughly wipe it clean.

Installation:

1. Clean and reinstall the drain plug along with a

new washer. For tightening torque details, see

“Changing engine oil” earlier in this section.

2. Coat the rubber gasket on the new engine oil fil-

ter unit with clean engine oil.

3. Install the engine oil filter unit by hand until a

slight resistance is felt, then tighten additionally

2/3ofaturn.

Engine oil filter tightening torques:

CR14DE or HR16DE engine:

17.7 N•m (1.8 kg-m, 13 ft-lb)

K9K engine:

14 N•m (1.4 kg-m, 10 ft-lb)

4. Add engine oil and check the oil level with the

engine oil dipstick. For details, see “Checking

engine oil level” earlier in this section and “Ca-

pacities and recommended fuel/lubricants” in the

“9. Technical information” section.

5. Install the engine oil filler cap.

6. Start the engine.

7. After the engine has been warmed up, make sure

there are no leaks around the engine oil filter unit

and the drain plug. Correct as required.

NDI722Z

CR14DE engine

NDI656Z

HR16DE engine

NDI985Z

K9K engine

Maintenance and do-it-yourself8-11

Page 188 of 235

8. Turn the engine off and wait several minutes.

Check the oil level and add engine oil, if neces-

sary.

9. Install the engine compartment under cover

(where fitted).

10. Lower the vehicle carefully to the ground.

11. Close the bonnet.

PROTECT THE ENVIRONMENT

NISSAN GREEN PROGRAM

It is illegal to pollute drains, water courses and soil.

Use authorised waste collection facilities, including

civic amenity sites and garages providing facilities

for the disposal of used oil and used oil filters. If in

doubt, contact your local authority for advice on dis-

posal.

The regulations concerning the pollution of the

environment will vary from country to country.

BLEEDING THE FUEL SYSTEM

Bleed the air out of the fuel system after refilling an

empty fuel tank by the following procedure:

1. Squeeze the priming bulb

jA several times until

there is a sudden resistance felt in the pressure,

then stop.

2. Crank the engine until the engine starts.NOTE

•If the engine does not start, stop cranking

and repeat step 1 of the procedure.

•If the engine does not operate smoothly

after it has started, race it two or three

times.

NDI1062

K9K engine (LHD models)

NDI1063

K9K engine (RHD models)

FUEL FILTER (Diesel engine

models)

8-12Maintenance and do-it-yourself