NISSAN NOTE 2008 Owners Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: NOTE, Model: NISSAN NOTE 2008Pages: 235, PDF Size: 2.29 MB

Page 161 of 235

•Never use blocks on or under the jack.

•Do not start or run the engine while the ve-

hicle is on the jack. The vehicle may move

suddenly, and this may cause an accident.

•Never allow passengers to stay in the vehicle

while it is on the jack.

•Remove all loads before lifting the vehicle with

the jack.

•Make sure to block the wheel diagonally op-

posite the flat tyre as described earlier in this

section.

CAUTION

The jack should be used on firm, level ground.

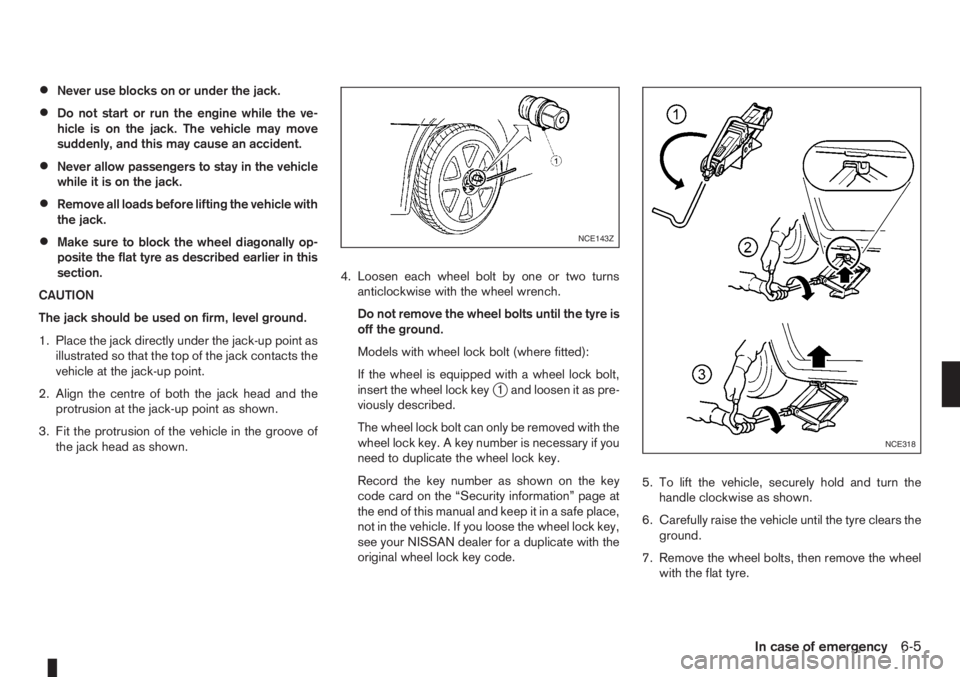

1. Place the jack directly under the jack-up point as

illustrated so that the top of the jack contacts the

vehicle at the jack-up point.

2. Align the centre of both the jack head and the

protrusion at the jack-up point as shown.

3. Fit the protrusion of the vehicle in the groove of

the jack head as shown.4. Loosen each wheel bolt by one or two turns

anticlockwise with the wheel wrench.

Do not remove the wheel bolts until the tyre is

off the ground.

Models with wheel lock bolt (where fitted):

If the wheel is equipped with a wheel lock bolt,

insert the wheel lock key

j1 and loosen it as pre-

viously described.

The wheel lock bolt can only be removed with the

wheel lock key. A key number is necessary if you

need to duplicate the wheel lock key.

Record the key number as shown on the key

code card on the “Security information” page at

the end of this manual and keep it in a safe place,

not in the vehicle. If you loose the wheel lock key,

see your NISSAN dealer for a duplicate with the

original wheel lock key code.5. To lift the vehicle, securely hold and turn the

handle clockwise as shown.

6. Carefully raise the vehicle until the tyre clears the

ground.

7. Remove the wheel bolts, then remove the wheel

with the flat tyre.

NCE143Z

NCE318

In case of emergency6-5

Page 162 of 235

CAUTION

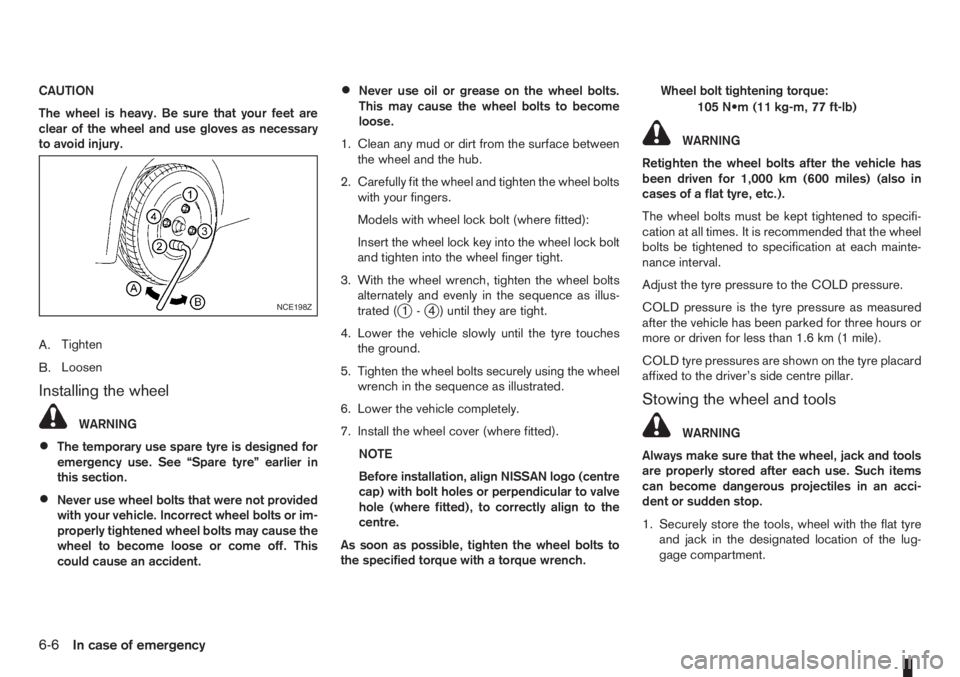

The wheel is heavy. Be sure that your feet are

clear of the wheel and use gloves as necessary

to avoid injury.

A.Tighten

B.Loosen

Installing the wheel

WARNING

•The temporary use spare tyre is designed for

emergency use. See “Spare tyre” earlier in

this section.

•Never use wheel bolts that were not provided

with your vehicle. Incorrect wheel bolts or im-

properly tightened wheel bolts may cause the

wheel to become loose or come off. This

could cause an accident.

•Never use oil or grease on the wheel bolts.

This may cause the wheel bolts to become

loose.

1. Clean any mud or dirt from the surface between

the wheel and the hub.

2. Carefully fit the wheel and tighten the wheel bolts

with your fingers.

Models with wheel lock bolt (where fitted):

Insert the wheel lock key into the wheel lock bolt

and tighten into the wheel finger tight.

3. With the wheel wrench, tighten the wheel bolts

alternately and evenly in the sequence as illus-

trated (

j1-j4 ) until they are tight.

4. Lower the vehicle slowly until the tyre touches

the ground.

5. Tighten the wheel bolts securely using the wheel

wrench in the sequence as illustrated.

6. Lower the vehicle completely.

7. Install the wheel cover (where fitted).

NOTE

Before installation, align NISSAN logo (centre

cap) with bolt holes or perpendicular to valve

hole (where fitted), to correctly align to the

centre.

As soon as possible, tighten the wheel bolts to

the specified torque with a torque wrench.Wheel bolt tightening torque:

105 N•m (11 kg-m, 77 ft-lb)

WARNING

Retighten the wheel bolts after the vehicle has

been driven for 1,000 km (600 miles) (also in

cases of a flat tyre, etc.).

The wheel bolts must be kept tightened to specifi-

cation at all times. It is recommended that the wheel

bolts be tightened to specification at each mainte-

nance interval.

Adjust the tyre pressure to the COLD pressure.

COLD pressure is the tyre pressure as measured

after the vehicle has been parked for three hours or

more or driven for less than 1.6 km (1 mile).

COLD tyre pressures are shown on the tyre placard

affixed to the driver’s side centre pillar.

Stowing the wheel and tools

WARNING

Always make sure that the wheel, jack and tools

are properly stored after each use. Such items

can become dangerous projectiles in an acci-

dent or sudden stop.

1. Securely store the tools, wheel with the flat tyre

and jack in the designated location of the lug-

gage compartment.

NCE198Z

6-6In case of emergency

Page 163 of 235

NOTE

The flat tyre may not fit into the temporary use

spare tyre location. Have the flat tyre repaired

and fitted as soon as possible.

2. Reinstall the floor carpet then the “flexi-board”

system (where fitted).

3. Close the back door.

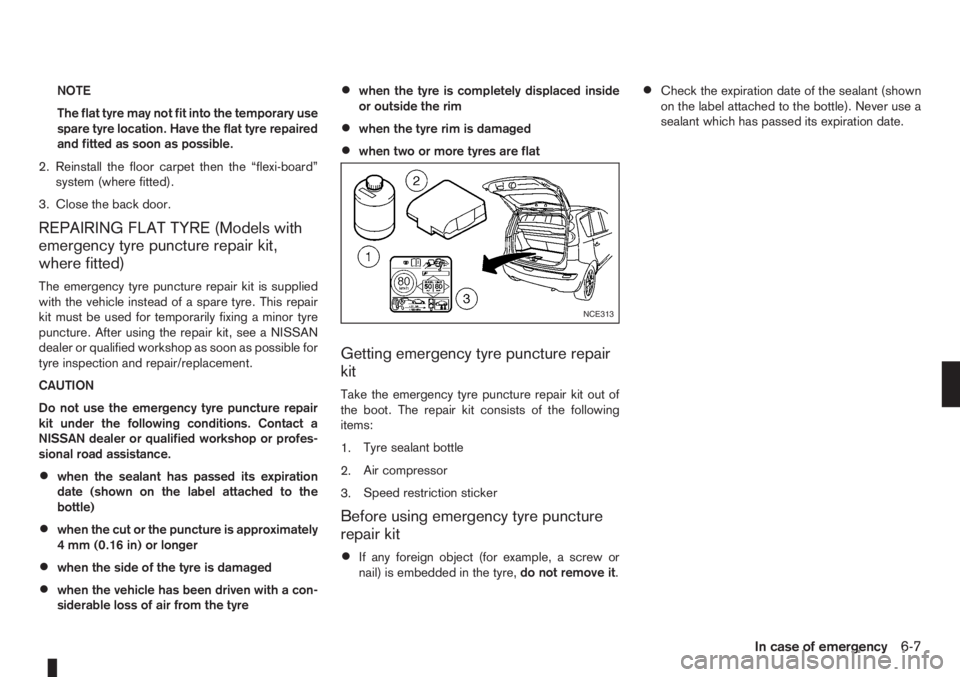

REPAIRING FLAT TYRE (Models with

emergency tyre puncture repair kit,

where fitted)

The emergency tyre puncture repair kit is supplied

with the vehicle instead of a spare tyre. This repair

kit must be used for temporarily fixing a minor tyre

puncture. After using the repair kit, see a NISSAN

dealer or qualified workshop as soon as possible for

tyre inspection and repair/replacement.

CAUTION

Do not use the emergency tyre puncture repair

kit under the following conditions. Contact a

NISSAN dealer or qualified workshop or profes-

sional road assistance.

•when the sealant has passed its expiration

date (shown on the label attached to the

bottle)

•when the cut or the puncture is approximately

4 mm (0.16 in) or longer

•when the side of the tyre is damaged

•when the vehicle has been driven with a con-

siderable loss of air from the tyre

•when the tyre is completely displaced inside

or outside the rim

•when the tyre rim is damaged

•when two or more tyres are flat

Getting emergency tyre puncture repair

kit

Take the emergency tyre puncture repair kit out of

the boot. The repair kit consists of the following

items:

1.Tyre sealant bottle

2.Air compressor

3.Speed restriction sticker

Before using emergency tyre puncture

repair kit

•If any foreign object (for example, a screw or

nail) is embedded in the tyre,do not remove it.

•Check the expiration date of the sealant (shown

on the label attached to the bottle). Never use a

sealant which has passed its expiration date.

NCE313

In case of emergency6-7

Page 164 of 235

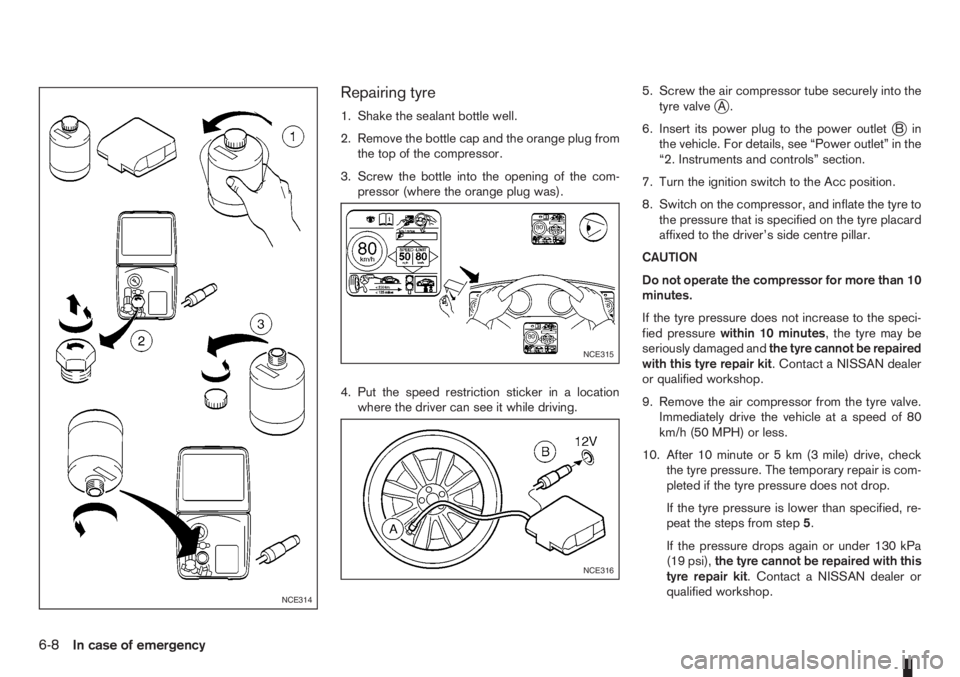

Repairing tyre

1. Shake the sealant bottle well.

2. Remove the bottle cap and the orange plug from

the top of the compressor.

3. Screw the bottle into the opening of the com-

pressor (where the orange plug was).

4. Put the speed restriction sticker in a location

where the driver can see it while driving.5. Screw the air compressor tube securely into the

tyre valvejA.

6. Insert its power plug to the power outlet

jBin

the vehicle. For details, see “Power outlet” in the

“2. Instruments and controls” section.

7. Turn the ignition switch to the Acc position.

8. Switch on the compressor, and inflate the tyre to

the pressure that is specified on the tyre placard

affixed to the driver’s side centre pillar.

CAUTION

Do not operate the compressor for more than 10

minutes.

If the tyre pressure does not increase to the speci-

fied pressurewithin 10 minutes, the tyre may be

seriously damaged andthe tyre cannot be repaired

with this tyre repair kit. Contact a NISSAN dealer

or qualified workshop.

9. Remove the air compressor from the tyre valve.

Immediately drive the vehicle at a speed of 80

km/h (50 MPH) or less.

10. After 10 minute or 5 km (3 mile) drive, check

the tyre pressure. The temporary repair is com-

pleted if the tyre pressure does not drop.

If the tyre pressure is lower than specified, re-

peat the steps from step5.

If the pressure drops again or under 130 kPa

(19 psi),the tyre cannot be repaired with this

tyre repair kit. Contact a NISSAN dealer or

qualified workshop.

NCE314

NCE315

NCE316

6-8In case of emergency

Page 165 of 235

After repairing tyre

See a NISSAN dealer or qualified workshop for tyre

repair/replacement as soon as possible.

WARNING

•Incorrect jump-starting can lead to a battery

explosion. The battery explosion may result in

severe injury or death. It may also result in

damage to the vehicle. Be sure to follow the

instructions in this section.

•Explosive hydrogen gas is always present in

the vicinity of the battery. Keep all sparks and

flames away from the battery.

•Always wear suitable eye protection glasses

and remove rings, bracelets, and any other

jewelry whenever working on or near a bat-

tery.

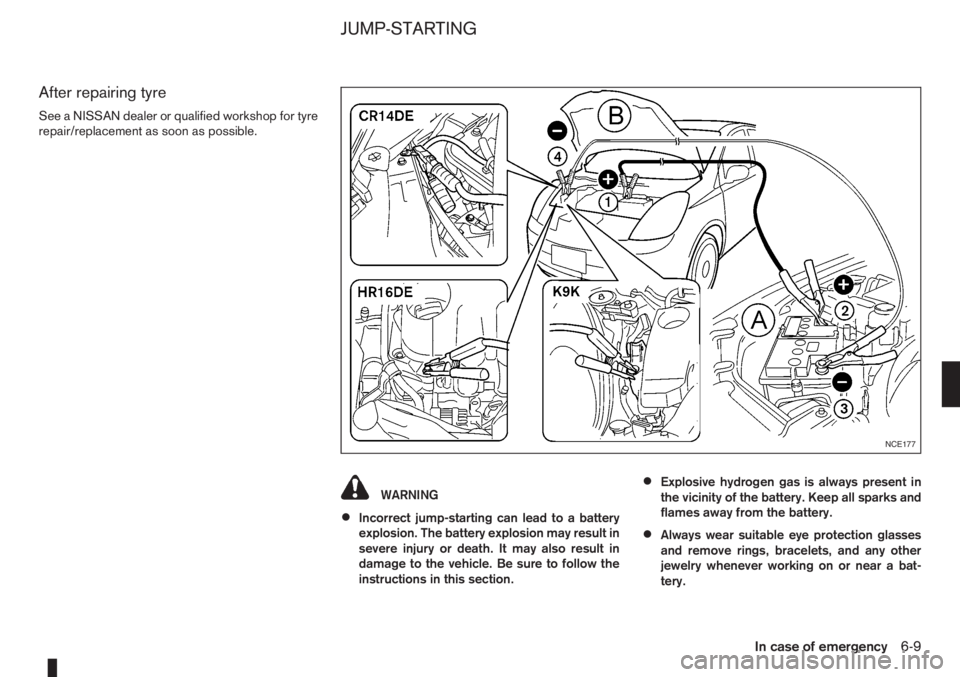

NCE177

JUMP-STARTING

In case of emergency6-9

Page 166 of 235

•Never lean over the battery while jump-start-

ing.

•Never allow battery fluid to come into contact

with eyes, skin, clothes or the vehicle’s

painted surfaces. Battery fluid is a corrosive

sulphuric acid which can cause severe burns.

If the fluid comes into contact with anything,

immediately flush the contacted area with

plenty of water.

•Keep the battery out of the reach of children.

•The booster battery must be rated at 12 volts.

Use of an incorrectly rated battery will dam-

age your vehicle.

•Never attempt to jump-start a frozen battery.

It could explode and cause serious injury.

1. Prepare vehicle

jA with the booster battery for

the vehiclejB being jump-started.

CAUTION

Do not allow the two vehicles to touch.

2. Apply the handbrake.

3. Shift the gear lever (MT models) into the N (Neu-

tral) position [AT models, move the selector lever

to the P (Park) position].

4. Switch off all unnecessary electrical systems

(headlights, hazard lights etc,).

5. Ensure that the ignition switch of the vehicle be-

ing jump-started is in the LOCK position.6. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

7. Remove the vent caps (where fitted) on the bat-

tery and cover the battery with an old cloth.

8. Connect the jump leads in the sequence (

j1→j2→j3→j4 ) as illustrated.

CAUTION

•Always connect positivej+ to positivej+

and negativej- to body ground (for ex-

ample, engine lift bracket, etc.) – not to

the battery’s negative

j-.

•An incorrect connection could damage the

charging system.

•Be sure that the jumper cables do not

touch moving parts in the engine compart-

ment.

•Be careful not to allow contact between

the positive jump lead connector and the

vehicle or the negative lead during con-

nection and disconnection.

9. Start the engine of the other vehicle

jA and let it

run for a few minutes. Keep the engine speed at

about 2,000 rpm.

10. Start the engine of your vehicle

jB in the nor-

mal way.

CAUTION

Do not keep the starter motor engaged formore than 10 seconds. If the engine does not

start immediately, turn the ignition switch to

“OFF” and wait 10 seconds before trying

again.

11. After starting the engine of your vehicle, care-

fully disconnect the negative lead and then the

positive lead (

j4→j3→j2→j1).

12. Remove and dispose of the cloth that was used

to cover the vent holes as it may be contami-

nated with corrosive acid.

13. Install the vent caps (where fitted).

14. Close the bonnet.

6-10In case of emergency

Page 167 of 235

CAUTION

•Three-way catalyst equipped models should

not be started by pushing the vehicle as the

three-way catalyst may be damaged.

•Automatic transmission (AT) models cannot

be started by pushing the vehicle. This may

cause transmission damage.

•Never try to start the vehicle by towing it; when

the engine starts, the forward surge could

cause the vehicle to collide with the tow ve-

hicle.

WARNING

•Never continue driving if the engine of your

vehicle overheats. Doing so could cause a ve-

hicle fire.

•Never open the bonnet if steam is coming

out.

•Never remove the radiator cap (where fitted)

or engine coolant reservoir cap when the en-

gine is hot. If the radiator cap (where fitted) or

engine coolant reservoir cap is removed while

the engine is hot, pressurised hot water will

spurt out and possibly cause burning, scald-

ing or serious injury.

•If steam or coolant is coming out of the en-

gine, stand clear of the vehicle to prevent get-

ting injured.

•The engine cooling fan will start whenever the

coolant temperature exceeds preset degrees.

•Be careful not to allow your hands, hair, jewel-

lery or clothing to come into contact with, or

get caught in, the cooling fan or drive belts.

If the engine of your vehicle is overheating (indi-

cated by the engine coolant temperature warning

light (red)) or if you feel a lack of engine power,

detect an unusual noise, etc., proceed as follows:

1. Move and park the vehicle safely off the road and

away from traffic.

2. Turn on the hazard warning flasher lights.

3. Apply the handbrake.4. Shift the gear lever (M/T models) into the N (Neu-

tral) position [AT models, move the selector lever

to the P (Park) position].

DO NOT STOP THE ENGINE.

5. Open all windows.

6. Switch off the air conditioner system (where fit-

ted).

7. Set the heater or air conditioner temperature

control to maximum “HOT” and fan speed con-

trol to maximum speed.

8. Exit the vehicle.

9. Visually inspect and listen for steam or coolant

escaping from the radiator before opening the

bonnet. Wait until no steam or coolant can be

seen before proceeding.

10. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

11. Visually check if the cooling fan is running.

12. Visually check the radiator and radiator hoses

for leakage.

WARNING

If coolant is leaking, the cooling fan belt is

missing or loose or the cooling fan is not run-

ning, stop the engine.

PUSH-STARTING ENGINE OVERHEAT

In case of emergency6-11

Page 168 of 235

13. After the engine cools down, check the coolant

level in the engine coolant reservoir with the

engine running.Do not open the radiator cap

(where fitted).

14. If the level is low, remove the engine coolant

reservoir cap and add coolant slowly into the

reservoir. After refilling the reservoir to the MAX

level, install the reservoir cap.

WARNING

Before removing the engine coolant reservoir

cap and to avoid the danger of being scalded,

cover the reservoir cap with a rag and loosen

the reservoir cap to the first notch to allow the

steam to escape.

15. Close the bonnet.

Have your vehicle inspected or repaired by a

NISSAN dealer or qualified workshop.When towing your vehicle, local regulations for tow-

ing must be followed. Incorrect towing equipment

could damage your vehicle. To assure proper tow-

ing and to prevent accidental damage to your ve-

hicle, NISSAN recommends that you have a service

operator tow your vehicle. It is advisable to have the

service operator carefully read the following precau-

tions.WARNING

•Do not allow any occupants in the vehicle that

is being towed.

•Never get under your vehicle after it has been

lifted by a tow truck.

TOWING PRECAUTIONS

•When towing:Make sure that the transmission,

axles, steering system and power train are in

working condition. If any unit is damaged, the

vehicle must be towed using a dolly or be placed

on a flat bed lorry.

•Release the handbrake and shift the manual

transmission (MT), or automatic transmission

(AT) into the N (Neutral) position before starting

to tow the vehicle.

•When towing manual transmission models

with the front wheels on the ground:Move the

gear lever to the N (Neutral) position and turn the

ignition switch to the “OFF” position then secure

the steering wheel in a straight ahead position

using a rope or similar device.Never place theignition switch in the LOCK position.This will

result in damage to the steering lock mecha-

nism.

•When towing with the rear wheels on the

ground, release the handbrake.

•Always attach safety chains before towing.

TOW TRUCK TOWING

6-12In case of emergency

Page 169 of 235

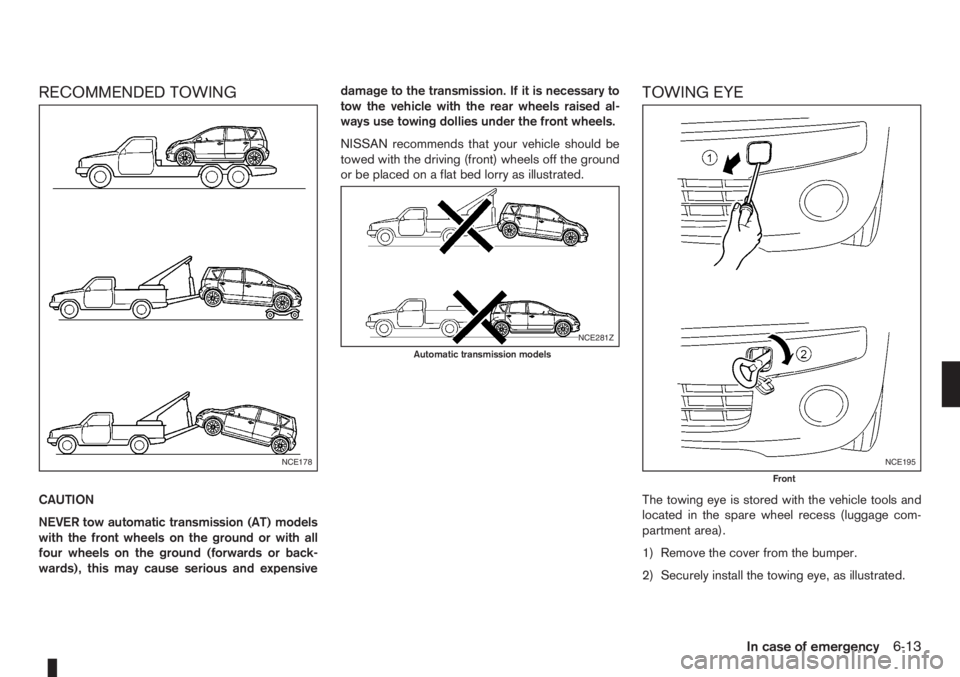

RECOMMENDED TOWING

CAUTION

NEVER tow automatic transmission (AT) models

with the front wheels on the ground or with all

four wheels on the ground (forwards or back-

wards), this may cause serious and expensivedamage to the transmission. If it is necessary to

tow the vehicle with the rear wheels raised al-

ways use towing dollies under the front wheels.

NISSAN recommends that your vehicle should be

towed with the driving (front) wheels off the ground

or be placed on a flat bed lorry as illustrated.

TOWING EYE

The towing eye is stored with the vehicle tools and

located in the spare wheel recess (luggage com-

partment area).

1) Remove the cover from the bumper.

2) Securely install the towing eye, as illustrated.

NCE178

NCE281Z

Automatic transmission models

NCE195

Front

In case of emergency6-13

Page 170 of 235

Make sure that the towing eye is properly stored in

its designated location after use.

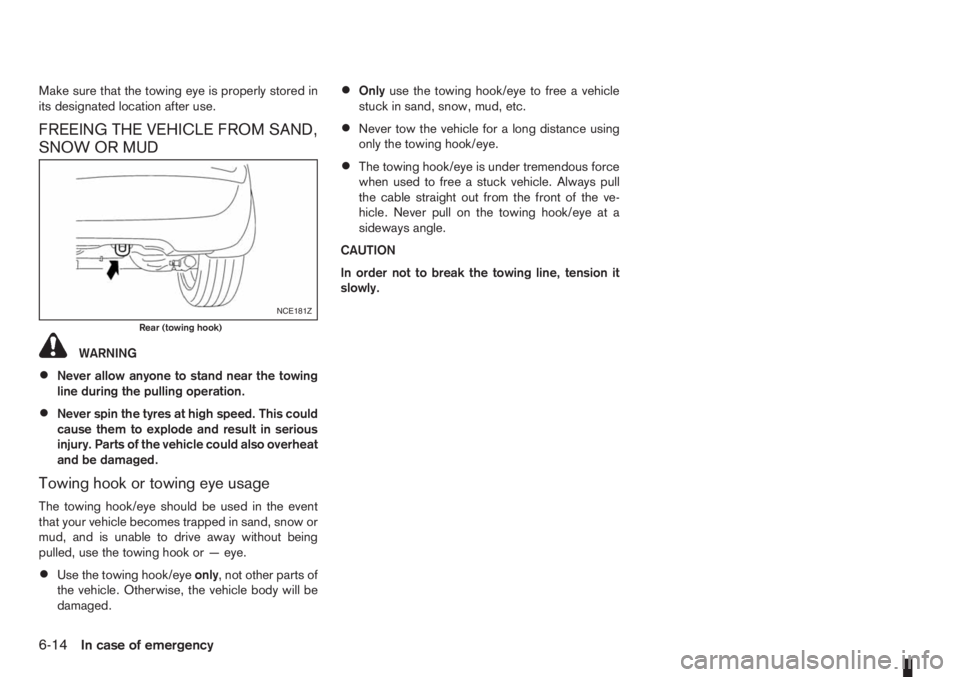

FREEING THE VEHICLE FROM SAND,

SNOW OR MUD

WARNING

•Never allow anyone to stand near the towing

line during the pulling operation.

•Never spin the tyres at high speed. This could

cause them to explode and result in serious

injury. Parts of the vehicle could also overheat

and be damaged.

Towing hook or towing eye usage

The towing hook/eye should be used in the event

that your vehicle becomes trapped in sand, snow or

mud, and is unable to drive away without being

pulled, use the towing hook or — eye.

•Use the towing hook/eyeonly, not other parts of

the vehicle. Otherwise, the vehicle body will be

damaged.

•Onlyuse the towing hook/eye to free a vehicle

stuck in sand, snow, mud, etc.

•Never tow the vehicle for a long distance using

only the towing hook/eye.

•The towing hook/eye is under tremendous force

when used to free a stuck vehicle. Always pull

the cable straight out from the front of the ve-

hicle. Never pull on the towing hook/eye at a

sideways angle.

CAUTION

In order not to break the towing line, tension it

slowly.

NCE181Z

Rear (towing hook)

6-14In case of emergency