Rpm NISSAN NOTE 2008 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: NOTE, Model: NISSAN NOTE 2008Pages: 235, PDF Size: 2.29 MB

Page 128 of 235

NISSAN GREEN PROGRAM

The three-way catalyst is an emission control device

installed in the exhaust system. In the converter,

exhaust gases are burned at high temperatures to

help reduce pollutants.

CAUTION

•The exhaust gas and the exhaust system are

very hot. While the engine is running, keep

people or flammable materials away from the

exhaust pipe.

•Do not stop or park the vehicle over flam-

mable materials such as dry grass, waste pa-

per or rags, as they may burn easily.

•When parking, ensure that people or flam-

mable materials are kept away from the ex-

haust pipe.

TO HELP PREVENT DAMAGE

CAUTION

•Use UNLEADED PETROL ONLY, specifically

the recommended type. For details, see “Ca-

pacities and recommended fuel/lubricants” in

the “9. Technical information” section.

•Do not use leaded petrol. Leaded petrol will

seriously damage three-way catalyst.

Deposits from leaded petrol will seriously re-

duce the three-way catalyst’s ability to help

reduce exhaust pollutants.

•Keep your engine tuned up. Malfunctions in

the ignition, fuel injection, or electrical sys-

tems can cause over-rich fuel flow into the

converter, causing it to overheat.

•Avoid driving with an extremely low fuel level.

Running out of fuel could cause the engine to

misfire, damaging the three-way catalyst.

•Do not keep driving if the engine misfires, or

if noticeable loss of performance or other un-

usual operating conditions are detected. Have

the vehicle inspected promptly by a NISSAN

dealer or qualified workshop.

•Do not race the engine while warming it up.

•Do not push or tow your vehicle to start the

engine.The turbocharger system uses engine oil for lubrica-

tion and cooling of its rotating components. The tur-

bocharger turbine turns at extremely high speeds

and it can reach an extremely high temperature. It is

essential to maintain a flow of clean oil through the

turbocharger system. A sudden interruption to the

oil supply may cause a malfunction in the turbo-

charger.

To ensure prolonged life and performance of the

turbocharger, it is essential to comply with the fol-

lowing maintenance procedure:

CAUTION

•Change the engine oil of the turbo-charged

diesel engine as prescribed. See the sepa-

rately provided Warranty Information & Main-

tenance Booklet for additional information.

•Use only the recommended engine oil. See

“Capacities and recommended fuel/

lubricants” in the “9. Technical information”

section.

•If the engine has been operating at high rpm

for an extended period of time, let it idle for a

few minutes prior to shutdown.

•Do not accelerate the engine to high rpm im-

mediately after starting it.

THREE-WAY CATALYST (Petrol

engine models)TURBOCHARGER SYSTEM

(Diesel engine models)

5-4Starting and driving

Page 166 of 235

•Never lean over the battery while jump-start-

ing.

•Never allow battery fluid to come into contact

with eyes, skin, clothes or the vehicle’s

painted surfaces. Battery fluid is a corrosive

sulphuric acid which can cause severe burns.

If the fluid comes into contact with anything,

immediately flush the contacted area with

plenty of water.

•Keep the battery out of the reach of children.

•The booster battery must be rated at 12 volts.

Use of an incorrectly rated battery will dam-

age your vehicle.

•Never attempt to jump-start a frozen battery.

It could explode and cause serious injury.

1. Prepare vehicle

jA with the booster battery for

the vehiclejB being jump-started.

CAUTION

Do not allow the two vehicles to touch.

2. Apply the handbrake.

3. Shift the gear lever (MT models) into the N (Neu-

tral) position [AT models, move the selector lever

to the P (Park) position].

4. Switch off all unnecessary electrical systems

(headlights, hazard lights etc,).

5. Ensure that the ignition switch of the vehicle be-

ing jump-started is in the LOCK position.6. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

7. Remove the vent caps (where fitted) on the bat-

tery and cover the battery with an old cloth.

8. Connect the jump leads in the sequence (

j1→j2→j3→j4 ) as illustrated.

CAUTION

•Always connect positivej+ to positivej+

and negativej- to body ground (for ex-

ample, engine lift bracket, etc.) – not to

the battery’s negative

j-.

•An incorrect connection could damage the

charging system.

•Be sure that the jumper cables do not

touch moving parts in the engine compart-

ment.

•Be careful not to allow contact between

the positive jump lead connector and the

vehicle or the negative lead during con-

nection and disconnection.

9. Start the engine of the other vehicle

jA and let it

run for a few minutes. Keep the engine speed at

about 2,000 rpm.

10. Start the engine of your vehicle

jB in the nor-

mal way.

CAUTION

Do not keep the starter motor engaged formore than 10 seconds. If the engine does not

start immediately, turn the ignition switch to

“OFF” and wait 10 seconds before trying

again.

11. After starting the engine of your vehicle, care-

fully disconnect the negative lead and then the

positive lead (

j4→j3→j2→j1).

12. Remove and dispose of the cloth that was used

to cover the vent holes as it may be contami-

nated with corrosive acid.

13. Install the vent caps (where fitted).

14. Close the bonnet.

6-10In case of emergency

Page 183 of 235

WARNING

•To avoid the danger of being scalded, never

change the coolant when the engine is hot.

•Avoid direct skin contact with used coolant. If

skin contact is made, wash thoroughly with

soap or hand cleaner and plenty of water as

soon as possible.

•Keep coolant out of reach of children and

pets.

NISSAN GREEN PROGRAM

Engine coolant must be disposed of properly.

Check your local regulations.

CR14DE or HR16DE engine

1. Set the heater or air conditioner temperature

control to the maximum “HOT” position.

2. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

3. Open the radiator cap

j1 (where fitted) or en-

gine coolant reservoir cap to help to drain the

coolant.

4. Slacken off the radiator lower hose clip

j2and

remove the lower hosej3 to drain the coolant.

5. Flush the cooling system by running clean water

through the radiator filler opening (where fitted)

or engine coolant reservoir.

6. Install the radiator lower hose on the radiator

securely.7. Fill the radiator through the filler opening (where

applicable) slowly with coolant and fill the cool-

ant reservoir up to the MAX level. See “Capaci-

ties and recommended fuel/lubricants” in the

“9. Technical information” section for cooling

system capacity.

8. Install the radiator cap (where fitted) and the en-

gine coolant reservoir cap.

9. Start the engine, and warm it up until the radiator

fan operates. Then rev the engine two or three

times under no load. Observe the coolant tem-

perature warning light for signs of overheating.

10. Stop the engine. After it has completely cooled

down, refill the radiator up to the filler opening

(where fitted). If the coolant level lowered, fill

the engine coolant reservoir up to the MAX level.

11. Check radiator lower hose for any signs of leak-

age.

12. Close the bonnet.

K9K engine

1. Set the heater or air conditioner temperature

control to the maximum “HOT” position.

2. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

3. Disconnect the radiator lower hose

j1 and open

the drain plugj2 on the engine block.

4. Open the engine coolant reservoir cap to help to

drain the coolant.

5. Flush the cooling system by running fresh water

through the radiator.

6. Install the radiator lower hose to the radiator and

securely tighten the engine block drain plug.

7. Fill the reservoir up to the MAX level with cool-

ant. See “Capacities and recommended

fuel/lubricants” in the “9. Technical information”

section for cooling system capacity.

8. Install the engine coolant reservoir cap.

9. Start the engine and run the engine at about

2,000 rpm for 1 minute.

10. Stop the engine and check coolant level, allow

to cool and refill up to the MAX level.

11. Warm up the engine at about 2,000 rpm until it

reaches the normal operational temperature

(fan cycles).

Check heater core (below instrument panel) for

gurgling, refill if necessary.

NDI671Z

K9K engine

Maintenance and do-it-yourself8-7

Page 185 of 235

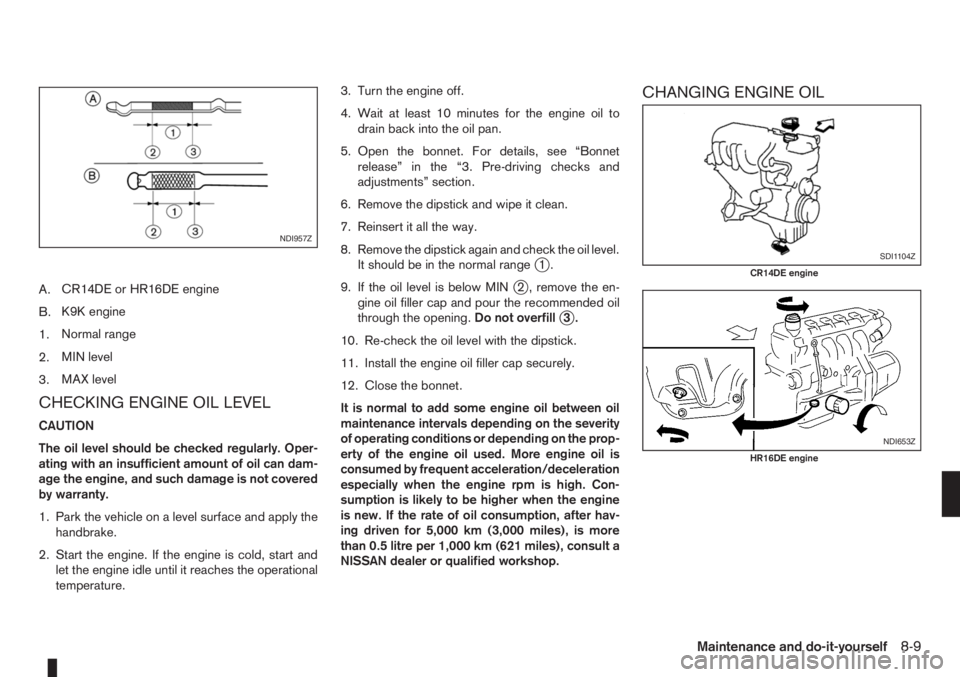

A.CR14DE or HR16DE engine

B.K9K engine

1.Normal range

2.MIN level

3.MAX level

CHECKING ENGINE OIL LEVEL

CAUTION

The oil level should be checked regularly. Oper-

ating with an insufficient amount of oil can dam-

age the engine, and such damage is not covered

by warranty.

1. Park the vehicle on a level surface and apply the

handbrake.

2. Start the engine. If the engine is cold, start and

let the engine idle until it reaches the operational

temperature.3. Turn the engine off.

4. Wait at least 10 minutes for the engine oil to

drain back into the oil pan.

5. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

6. Remove the dipstick and wipe it clean.

7. Reinsert it all the way.

8. Remove the dipstick again and check the oil level.

It should be in the normal range

j1.

9. If the oil level is below MIN

j2 , remove the en-

gine oil filler cap and pour the recommended oil

through the opening.Do not overfill

j3.

10. Re-check the oil level with the dipstick.

11. Install the engine oil filler cap securely.

12. Close the bonnet.

It is normal to add some engine oil between oil

maintenance intervals depending on the severity

of operating conditions or depending on the prop-

erty of the engine oil used. More engine oil is

consumed by frequent acceleration/deceleration

especially when the engine rpm is high. Con-

sumption is likely to be higher when the engine

is new. If the rate of oil consumption, after hav-

ing driven for 5,000 km (3,000 miles), is more

than 0.5 litre per 1,000 km (621 miles), consult a

NISSAN dealer or qualified workshop.

CHANGING ENGINE OIL

NDI957Z

SDI1104Z

CR14DE engine

NDI653Z

HR16DE engine

Maintenance and do-it-yourself8-9

Page 213 of 235

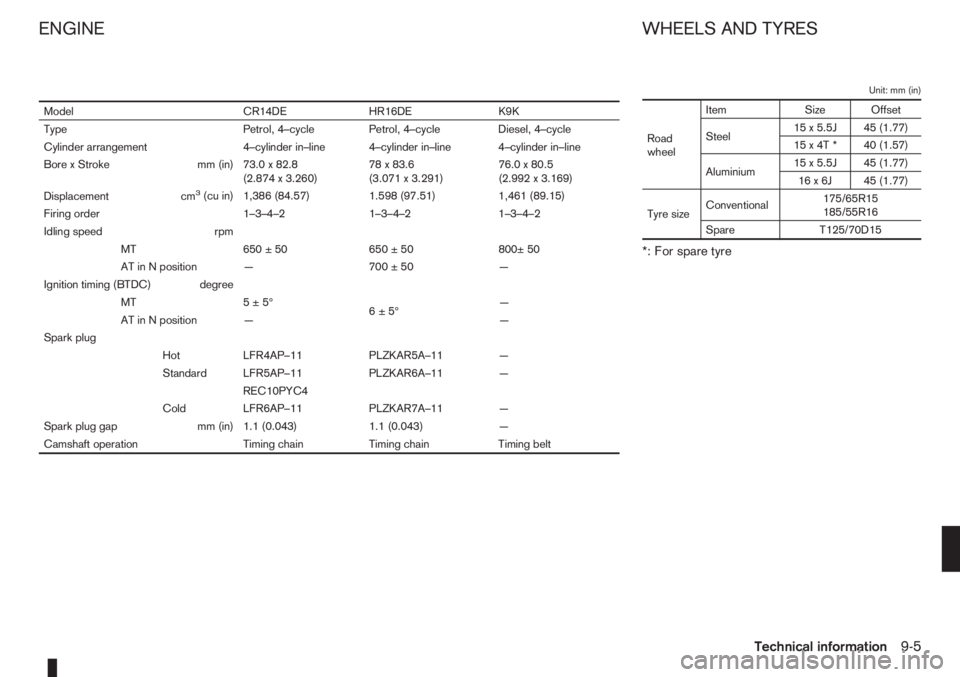

Unit: mm (in)

Road

wheelItem Size Offset

Steel15 x 5.5J 45 (1.77)

15 x 4T * 40 (1.57)

Aluminium15 x 5.5J 45 (1.77)

16 x 6J 45 (1.77)

Tyre sizeConventional175/65R15

185/55R16

Spare T125/70D15

*: For spare tyre

Model CR14DE HR16DE K9K

Type Petrol, 4–cycle Petrol, 4–cycle Diesel, 4–cycle

Cylinder arrangement 4–cylinder in–line 4–cylinder in–line 4–cylinder in–line

Bore x Stroke mm (in) 73.0 x 82.8

(2.874 x 3.260)78 x 83.6

(3.071 x 3.291)76.0 x 80.5

(2.992 x 3.169)

Displacement cm

3(cu in) 1,386 (84.57) 1.598 (97.51) 1,461 (89.15)

Firing order 1–3–4–2 1–3–4–2 1–3–4–2

Idling speed rpm

MT 650 ± 50 650 ± 50 800± 50

AT in N position — 700 ± 50 —

Ignition timing (BTDC) degree

MT 5±5°

6±5°—

AT in N position — —

Spark plug

Hot LFR4AP–11 PLZKAR5A–11 —

Standard LFR5AP–11 PLZKAR6A–11 —

REC10PYC4

Cold LFR6AP–11 PLZKAR7A–11 —

Spark plug gap mm (in) 1.1 (0.043) 1.1 (0.043) —

Camshaft operation Timing chain Timing chain Timing belt

ENGINE WHEELS AND TYRES

Technical information9-5