ECO mode NISSAN NOTE 2012 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2012, Model line: NOTE, Model: NISSAN NOTE 2012Pages: 235, PDF Size: 2.29 MB

Page 154 of 235

•If engine related parts, such as a muffler, are

not standard equipment or are extremely de-

teriorated, the ESP OFF indicator light (

)

and/or the “SLIP” indicator light ()may

illuminate.

•If brake related parts, such as brake pads,

rotors and callipers, are not standard equip-

ment or are extremely deteriorated, the ESP

system may not operate properly and the ESP

OFF indicator light (

) and/or the “SLIP” indi-

cator light () may illuminate.

•Do not modify the vehicle’s suspension. If

suspension parts, such as shock absorbers,

struts, springs, stabilizer bars and bushings,

are not NISSAN-approved or are extremely

deteriorated, the ESP system may not oper-

ate properly. This could adversely affect ve-

hicle handling performance and the ESP OFF

indicator light (

) and/or the “SLIP” indicator

light () may illuminate.

•When driving on extremely inclined surfaces,

such as higher banked corners, the ESP sys-

tem may not operate properly and the ESP

OFF indicator light (

) and/or the “SLIP” indi-

cator light () may illuminate. Do not drive

on these types of roads. If ESP OFF indicator

light

does illuminate after driving on ex-

treme surfaces, restart the engine to reset

the ESP system.

•If wheels or tyres other than the

recommended ones are used, the ESP sys-tem may not operate properly and the ESP

OFF indicator light (

) and/or the “SLIP” indi-

cator light () may illuminate.

•The ESP system is not a substitute for winter

tyres or snow chains on a snow covered road.

NOTE

•The ESP system should be switched on under

normal circumstances although it may be ad-

vantageous to switch off the ESP system to

allow wheelspin under the following condi-

tions:

– when driving in deep snow or mud

– when trying to rock a vehicle free that is

stuck in snow

– when driving with snow chains

•If the ESP system has been switched off, drive

carefully with reduced speed. When road con-

ditions allow, ESP should be switched back

on.

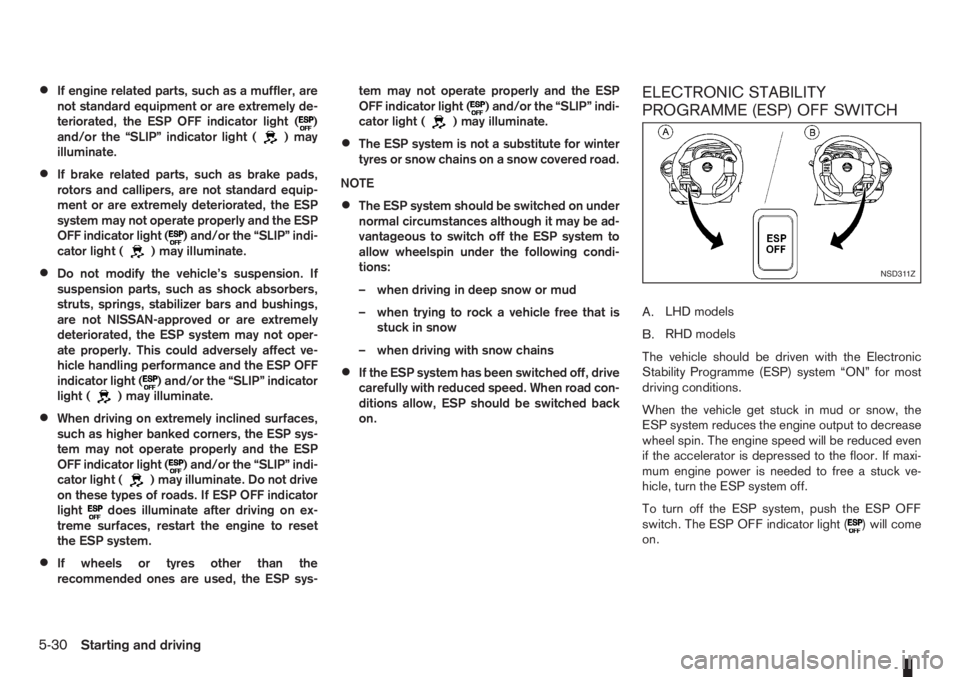

ELECTRONIC STABILITY

PROGRAMME (ESP) OFF SWITCH

A.LHD models

B.RHD models

The vehicle should be driven with the Electronic

Stability Programme (ESP) system “ON” for most

driving conditions.

When the vehicle get stuck in mud or snow, the

ESP system reduces the engine output to decrease

wheel spin. The engine speed will be reduced even

if the accelerator is depressed to the floor. If maxi-

mum engine power is needed to free a stuck ve-

hicle, turn the ESP system off.

To turn off the ESP system, push the ESP OFF

switch. The ESP OFF indicator light (

) will come

on.

NSD311Z

5-30Starting and driving

Page 157 of 235

6In case of emergencyIn case of emergency

Spare tyre................................................................ 6-2

Temporary-use spare tyre ................................... 6-2

Flat tyre ................................................................... 6-3

Stopping the vehicle ........................................... 6-3

Changing flat tyre (Models with spare wheel,

where fitted) ....................................................... 6-3

Repairing flat tyre (Models with emergency

tyre puncture repair kit, where fitted) ................... 6-7Jump-starting ........................................................... 6-9

Push-starting ........................................................... 6-11

Engine overheat ....................................................... 6-11

Tow truck towing ..................................................... 6-12

Towing precautions ............................................ 6-12

Recommended towing ........................................ 6-13

Towing eye ......................................................... 6-13

Freeing the vehicle from sand, snow or mud ....... 6-14

Page 161 of 235

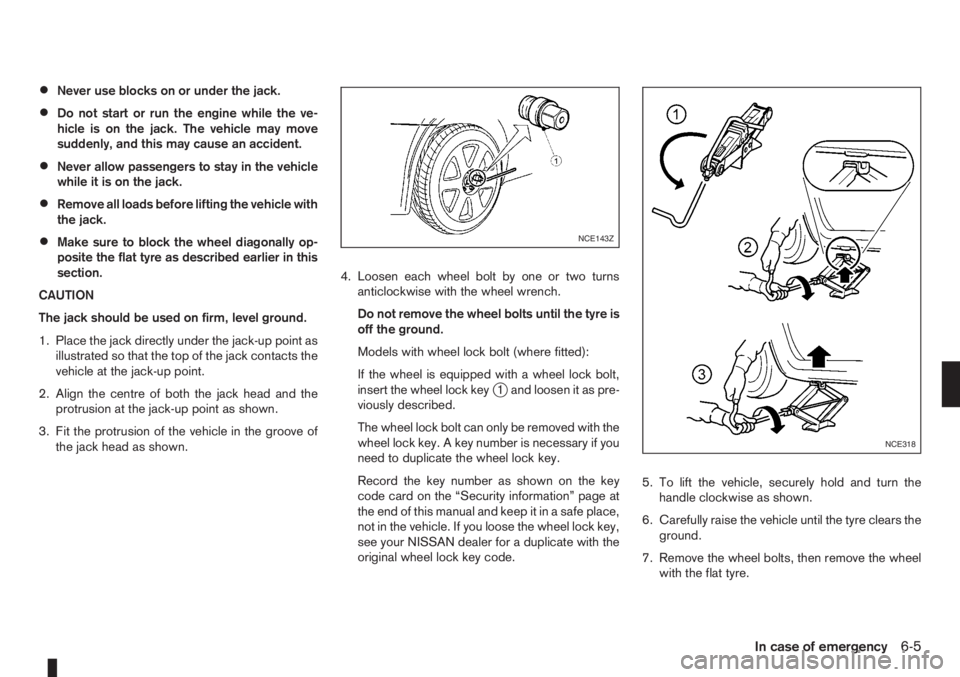

•Never use blocks on or under the jack.

•Do not start or run the engine while the ve-

hicle is on the jack. The vehicle may move

suddenly, and this may cause an accident.

•Never allow passengers to stay in the vehicle

while it is on the jack.

•Remove all loads before lifting the vehicle with

the jack.

•Make sure to block the wheel diagonally op-

posite the flat tyre as described earlier in this

section.

CAUTION

The jack should be used on firm, level ground.

1. Place the jack directly under the jack-up point as

illustrated so that the top of the jack contacts the

vehicle at the jack-up point.

2. Align the centre of both the jack head and the

protrusion at the jack-up point as shown.

3. Fit the protrusion of the vehicle in the groove of

the jack head as shown.4. Loosen each wheel bolt by one or two turns

anticlockwise with the wheel wrench.

Do not remove the wheel bolts until the tyre is

off the ground.

Models with wheel lock bolt (where fitted):

If the wheel is equipped with a wheel lock bolt,

insert the wheel lock key

j1 and loosen it as pre-

viously described.

The wheel lock bolt can only be removed with the

wheel lock key. A key number is necessary if you

need to duplicate the wheel lock key.

Record the key number as shown on the key

code card on the “Security information” page at

the end of this manual and keep it in a safe place,

not in the vehicle. If you loose the wheel lock key,

see your NISSAN dealer for a duplicate with the

original wheel lock key code.5. To lift the vehicle, securely hold and turn the

handle clockwise as shown.

6. Carefully raise the vehicle until the tyre clears the

ground.

7. Remove the wheel bolts, then remove the wheel

with the flat tyre.

NCE143Z

NCE318

In case of emergency6-5

Page 162 of 235

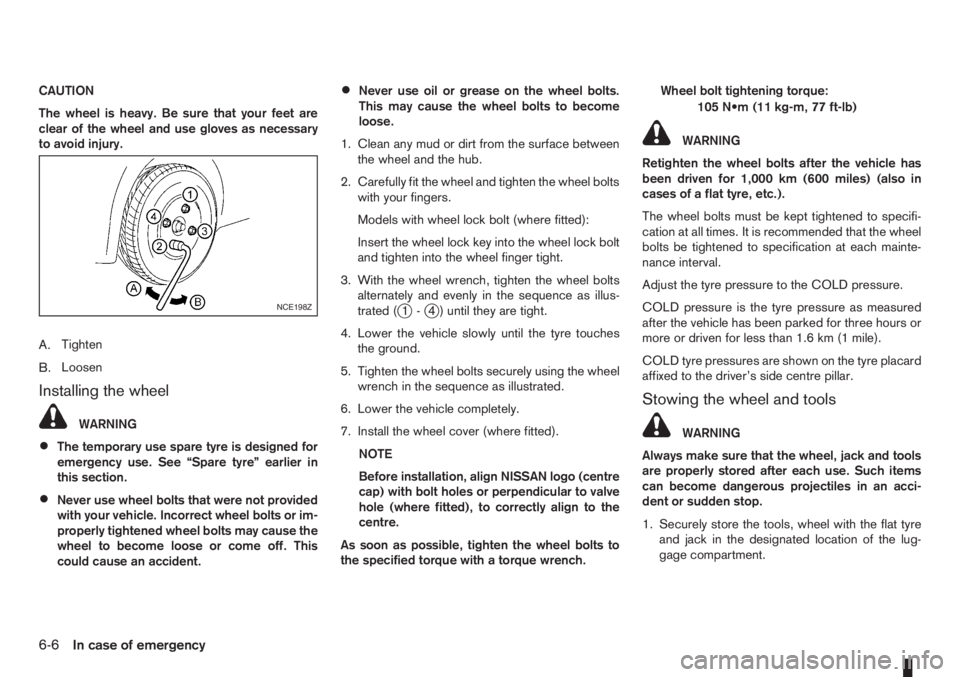

CAUTION

The wheel is heavy. Be sure that your feet are

clear of the wheel and use gloves as necessary

to avoid injury.

A.Tighten

B.Loosen

Installing the wheel

WARNING

•The temporary use spare tyre is designed for

emergency use. See “Spare tyre” earlier in

this section.

•Never use wheel bolts that were not provided

with your vehicle. Incorrect wheel bolts or im-

properly tightened wheel bolts may cause the

wheel to become loose or come off. This

could cause an accident.

•Never use oil or grease on the wheel bolts.

This may cause the wheel bolts to become

loose.

1. Clean any mud or dirt from the surface between

the wheel and the hub.

2. Carefully fit the wheel and tighten the wheel bolts

with your fingers.

Models with wheel lock bolt (where fitted):

Insert the wheel lock key into the wheel lock bolt

and tighten into the wheel finger tight.

3. With the wheel wrench, tighten the wheel bolts

alternately and evenly in the sequence as illus-

trated (

j1-j4 ) until they are tight.

4. Lower the vehicle slowly until the tyre touches

the ground.

5. Tighten the wheel bolts securely using the wheel

wrench in the sequence as illustrated.

6. Lower the vehicle completely.

7. Install the wheel cover (where fitted).

NOTE

Before installation, align NISSAN logo (centre

cap) with bolt holes or perpendicular to valve

hole (where fitted), to correctly align to the

centre.

As soon as possible, tighten the wheel bolts to

the specified torque with a torque wrench.Wheel bolt tightening torque:

105 N•m (11 kg-m, 77 ft-lb)

WARNING

Retighten the wheel bolts after the vehicle has

been driven for 1,000 km (600 miles) (also in

cases of a flat tyre, etc.).

The wheel bolts must be kept tightened to specifi-

cation at all times. It is recommended that the wheel

bolts be tightened to specification at each mainte-

nance interval.

Adjust the tyre pressure to the COLD pressure.

COLD pressure is the tyre pressure as measured

after the vehicle has been parked for three hours or

more or driven for less than 1.6 km (1 mile).

COLD tyre pressures are shown on the tyre placard

affixed to the driver’s side centre pillar.

Stowing the wheel and tools

WARNING

Always make sure that the wheel, jack and tools

are properly stored after each use. Such items

can become dangerous projectiles in an acci-

dent or sudden stop.

1. Securely store the tools, wheel with the flat tyre

and jack in the designated location of the lug-

gage compartment.

NCE198Z

6-6In case of emergency

Page 166 of 235

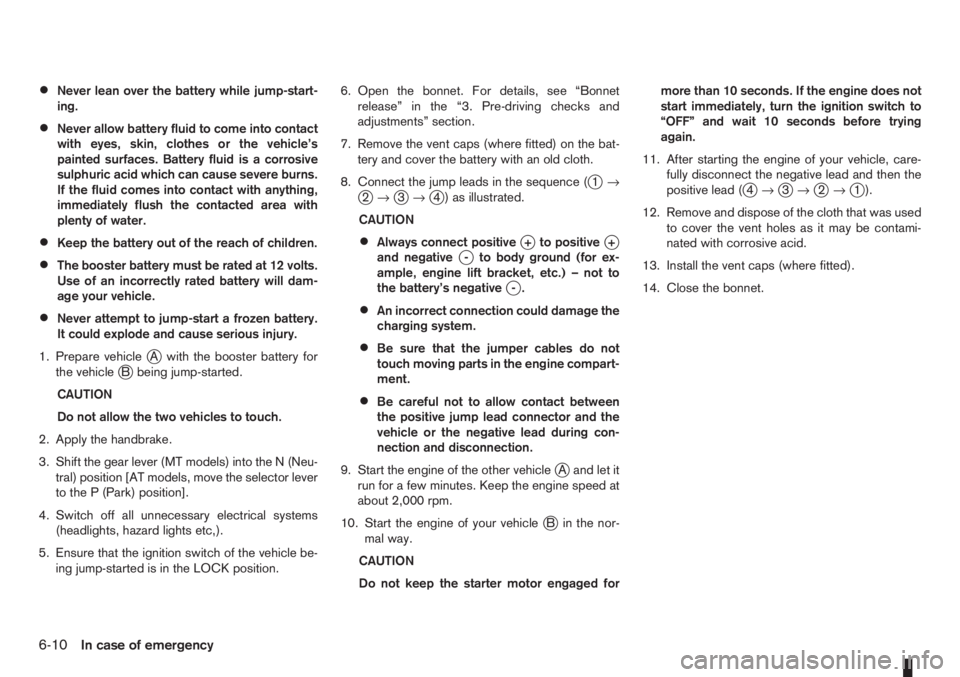

•Never lean over the battery while jump-start-

ing.

•Never allow battery fluid to come into contact

with eyes, skin, clothes or the vehicle’s

painted surfaces. Battery fluid is a corrosive

sulphuric acid which can cause severe burns.

If the fluid comes into contact with anything,

immediately flush the contacted area with

plenty of water.

•Keep the battery out of the reach of children.

•The booster battery must be rated at 12 volts.

Use of an incorrectly rated battery will dam-

age your vehicle.

•Never attempt to jump-start a frozen battery.

It could explode and cause serious injury.

1. Prepare vehicle

jA with the booster battery for

the vehiclejB being jump-started.

CAUTION

Do not allow the two vehicles to touch.

2. Apply the handbrake.

3. Shift the gear lever (MT models) into the N (Neu-

tral) position [AT models, move the selector lever

to the P (Park) position].

4. Switch off all unnecessary electrical systems

(headlights, hazard lights etc,).

5. Ensure that the ignition switch of the vehicle be-

ing jump-started is in the LOCK position.6. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

7. Remove the vent caps (where fitted) on the bat-

tery and cover the battery with an old cloth.

8. Connect the jump leads in the sequence (

j1→j2→j3→j4 ) as illustrated.

CAUTION

•Always connect positivej+ to positivej+

and negativej- to body ground (for ex-

ample, engine lift bracket, etc.) – not to

the battery’s negative

j-.

•An incorrect connection could damage the

charging system.

•Be sure that the jumper cables do not

touch moving parts in the engine compart-

ment.

•Be careful not to allow contact between

the positive jump lead connector and the

vehicle or the negative lead during con-

nection and disconnection.

9. Start the engine of the other vehicle

jA and let it

run for a few minutes. Keep the engine speed at

about 2,000 rpm.

10. Start the engine of your vehicle

jB in the nor-

mal way.

CAUTION

Do not keep the starter motor engaged formore than 10 seconds. If the engine does not

start immediately, turn the ignition switch to

“OFF” and wait 10 seconds before trying

again.

11. After starting the engine of your vehicle, care-

fully disconnect the negative lead and then the

positive lead (

j4→j3→j2→j1).

12. Remove and dispose of the cloth that was used

to cover the vent holes as it may be contami-

nated with corrosive acid.

13. Install the vent caps (where fitted).

14. Close the bonnet.

6-10In case of emergency

Page 168 of 235

13. After the engine cools down, check the coolant

level in the engine coolant reservoir with the

engine running.Do not open the radiator cap

(where fitted).

14. If the level is low, remove the engine coolant

reservoir cap and add coolant slowly into the

reservoir. After refilling the reservoir to the MAX

level, install the reservoir cap.

WARNING

Before removing the engine coolant reservoir

cap and to avoid the danger of being scalded,

cover the reservoir cap with a rag and loosen

the reservoir cap to the first notch to allow the

steam to escape.

15. Close the bonnet.

Have your vehicle inspected or repaired by a

NISSAN dealer or qualified workshop.When towing your vehicle, local regulations for tow-

ing must be followed. Incorrect towing equipment

could damage your vehicle. To assure proper tow-

ing and to prevent accidental damage to your ve-

hicle, NISSAN recommends that you have a service

operator tow your vehicle. It is advisable to have the

service operator carefully read the following precau-

tions.WARNING

•Do not allow any occupants in the vehicle that

is being towed.

•Never get under your vehicle after it has been

lifted by a tow truck.

TOWING PRECAUTIONS

•When towing:Make sure that the transmission,

axles, steering system and power train are in

working condition. If any unit is damaged, the

vehicle must be towed using a dolly or be placed

on a flat bed lorry.

•Release the handbrake and shift the manual

transmission (MT), or automatic transmission

(AT) into the N (Neutral) position before starting

to tow the vehicle.

•When towing manual transmission models

with the front wheels on the ground:Move the

gear lever to the N (Neutral) position and turn the

ignition switch to the “OFF” position then secure

the steering wheel in a straight ahead position

using a rope or similar device.Never place theignition switch in the LOCK position.This will

result in damage to the steering lock mecha-

nism.

•When towing with the rear wheels on the

ground, release the handbrake.

•Always attach safety chains before towing.

TOW TRUCK TOWING

6-12In case of emergency

Page 169 of 235

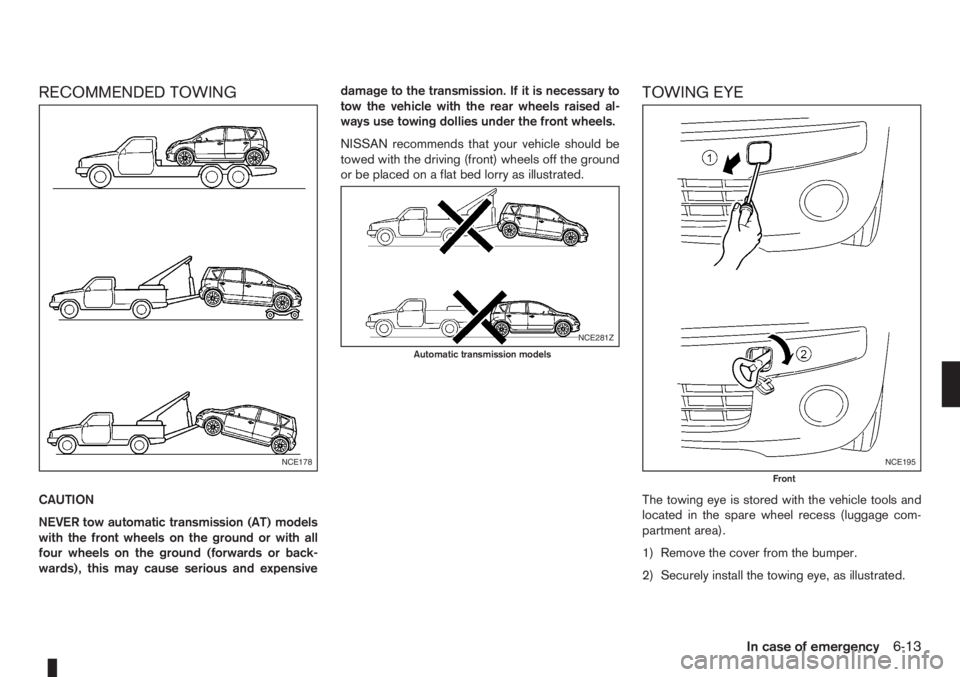

RECOMMENDED TOWING

CAUTION

NEVER tow automatic transmission (AT) models

with the front wheels on the ground or with all

four wheels on the ground (forwards or back-

wards), this may cause serious and expensivedamage to the transmission. If it is necessary to

tow the vehicle with the rear wheels raised al-

ways use towing dollies under the front wheels.

NISSAN recommends that your vehicle should be

towed with the driving (front) wheels off the ground

or be placed on a flat bed lorry as illustrated.

TOWING EYE

The towing eye is stored with the vehicle tools and

located in the spare wheel recess (luggage com-

partment area).

1) Remove the cover from the bumper.

2) Securely install the towing eye, as illustrated.

NCE178

NCE281Z

Automatic transmission models

NCE195

Front

In case of emergency6-13

Page 176 of 235

8Maintenance and do-it-yourselfMaintenance and do-it-yourself

Maintenance requirements ....................................... 8-2

Scheduled maintenance...................................... 8-2

General maintenance .......................................... 8-2

Where to go for service ...................................... 8-2

General maintenance ............................................... 8-2

Explanation of general maintenance items ........... 8-2

Maintenance precautions ......................................... 8-4

Engine compartment ................................................ 8-5

Engine cooling system ............................................. 8-6

Checking engine coolant level............................. 8-6

Changing engine coolant .................................... 8-6

Engine oil................................................................. 8-8

Checking engine oil level .................................... 8-9

Changing engine oil ............................................ 8-9

Changing engine oil filter .................................... 8-11

Protect the environment ...................................... 8-12

Fuel filter (Diesel engine models) ............................. 8-12

Bleeding the fuel system ..................................... 8-12

Automatic transmission fluid (ATF) ........................... 8-13

Brakes ..................................................................... 8-13

Checking brake pedal......................................... 8-13

Checking handbrake........................................... 8-13

Brake and clutch fluid .............................................. 8-13

Window washer fluid/headlight cleaner fluid

(where fitted) ........................................................... 8-14

Battery..................................................................... 8-15

Vehicle battery .................................................... 8-15

Reinitialisation procedure after battery

reconnection....................................................... 8-16

Jump-starting ...................................................... 8-16Integrated Keyfob/Intelligent Key battery

replacement........................................................ 8-17

Drive belts ............................................................... 8-18

Spark plugs (Petrol engine models).......................... 8-18

Air cleaner filter........................................................ 8-19

Viscous paper type ............................................. 8-19

Dry paper type (where fitted) .............................. 8-19

Wiper blades ........................................................... 8-19

Cleaning ............................................................. 8-19

Front window wiper replacement ........................ 8-20

Back door window wiper replacement ................ 8-20

Windscreen washer nozzle ................................. 8-20

Fuses ...................................................................... 8-21

Passenger compartment ..................................... 8-21

Engine compartment ........................................... 8-22

Lights ...................................................................... 8-23

Headlights .......................................................... 8-23

Exterior lights ...................................................... 8-24

Interior lights....................................................... 8-24

Light locations .................................................... 8-25

Wheels and tyres ..................................................... 8-29

Tyre inflation pressure......................................... 8-29

Types of tyres ..................................................... 8-29

Snow chains....................................................... 8-30

Tyre rotation ....................................................... 8-30

Tyre wear and damage ....................................... 8-30

Tyre age ............................................................. 8-31

Changing tyres and wheels ................................. 8-31

Wheel balance.................................................... 8-31

Spare tyre .......................................................... 8-31

Page 187 of 235

18. Install the engine compartment undercover

(where fitted).

19. Lower the vehicle carefully to the ground.

20. Close the bonnet.

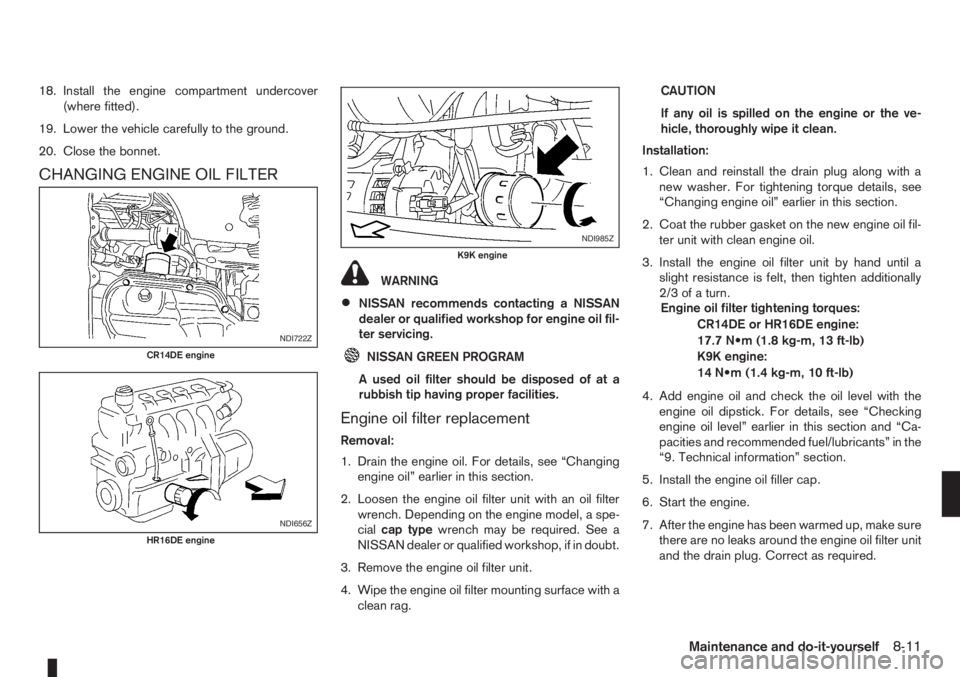

CHANGING ENGINE OIL FILTER

WARNING

•NISSAN recommends contacting a NISSAN

dealer or qualified workshop for engine oil fil-

ter servicing.

NISSAN GREEN PROGRAM

A used oil filter should be disposed of at a

rubbish tip having proper facilities.

Engine oil filter replacement

Removal:

1. Drain the engine oil. For details, see “Changing

engine oil” earlier in this section.

2. Loosen the engine oil filter unit with an oil filter

wrench. Depending on the engine model, a spe-

cialcap typewrench may be required. See a

NISSAN dealer or qualified workshop, if in doubt.

3. Remove the engine oil filter unit.

4. Wipe the engine oil filter mounting surface with a

clean rag.CAUTION

If any oil is spilled on the engine or the ve-

hicle, thoroughly wipe it clean.

Installation:

1. Clean and reinstall the drain plug along with a

new washer. For tightening torque details, see

“Changing engine oil” earlier in this section.

2. Coat the rubber gasket on the new engine oil fil-

ter unit with clean engine oil.

3. Install the engine oil filter unit by hand until a

slight resistance is felt, then tighten additionally

2/3ofaturn.

Engine oil filter tightening torques:

CR14DE or HR16DE engine:

17.7 N•m (1.8 kg-m, 13 ft-lb)

K9K engine:

14 N•m (1.4 kg-m, 10 ft-lb)

4. Add engine oil and check the oil level with the

engine oil dipstick. For details, see “Checking

engine oil level” earlier in this section and “Ca-

pacities and recommended fuel/lubricants” in the

“9. Technical information” section.

5. Install the engine oil filler cap.

6. Start the engine.

7. After the engine has been warmed up, make sure

there are no leaks around the engine oil filter unit

and the drain plug. Correct as required.

NDI722Z

CR14DE engine

NDI656Z

HR16DE engine

NDI985Z

K9K engine

Maintenance and do-it-yourself8-11

Page 189 of 235

When checking or replacement is required, NISSAN

recommends contacting a NISSAN dealer or quali-

fied workshop for servicing.

CAUTION

•Use only Genuine NISSAN Matic D ATF. Do

not mix with other fluids.

•Using automatic transmission fluid other than

Genuine NISSAN Matic D ATF will cause dete-

rioration in driveability and automatic trans-

mission durability, and may damage the auto-

matic transmission, which is not covered by

the warranty.

CHECKING BRAKE PEDAL

If the brake pedal suddenly goes down further than

normal, the pedal feels “spongy” or the vehicle

seems to take longer to stop, see a NISSAN dealer

or qualified workshop.

CHECKING HANDBRAKE

Periodically check the holding ability of the hand-

brake by parking on a steep hill and restraining the

vehicle by using only the handbrake. If it does not

hold satisfactorily, see a NISSAN dealer or qualified

workshop.

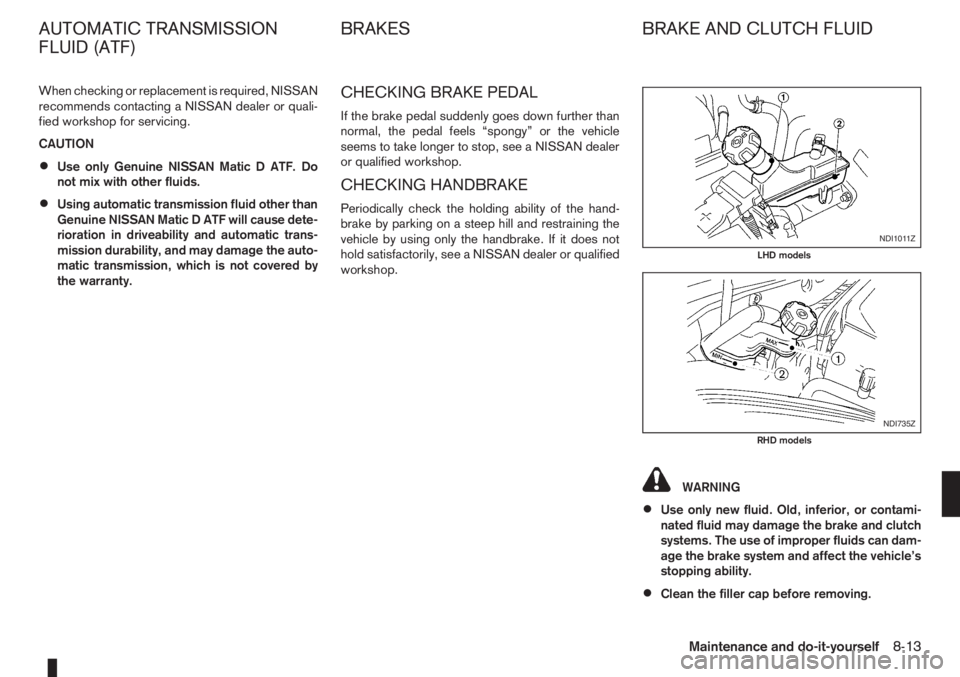

WARNING

•Use only new fluid. Old, inferior, or contami-

nated fluid may damage the brake and clutch

systems. The use of improper fluids can dam-

age the brake system and affect the vehicle’s

stopping ability.

•Clean the filler cap before removing.

NDI1011Z

LHD models

NDI735Z

RHD models

AUTOMATIC TRANSMISSION

FLUID (ATF)BRAKES BRAKE AND CLUTCH FLUID

Maintenance and do-it-yourself8-13