Oil fill NISSAN NOTE 2012 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2012, Model line: NOTE, Model: NISSAN NOTE 2012Pages: 235, PDF Size: 2.29 MB

Page 15 of 235

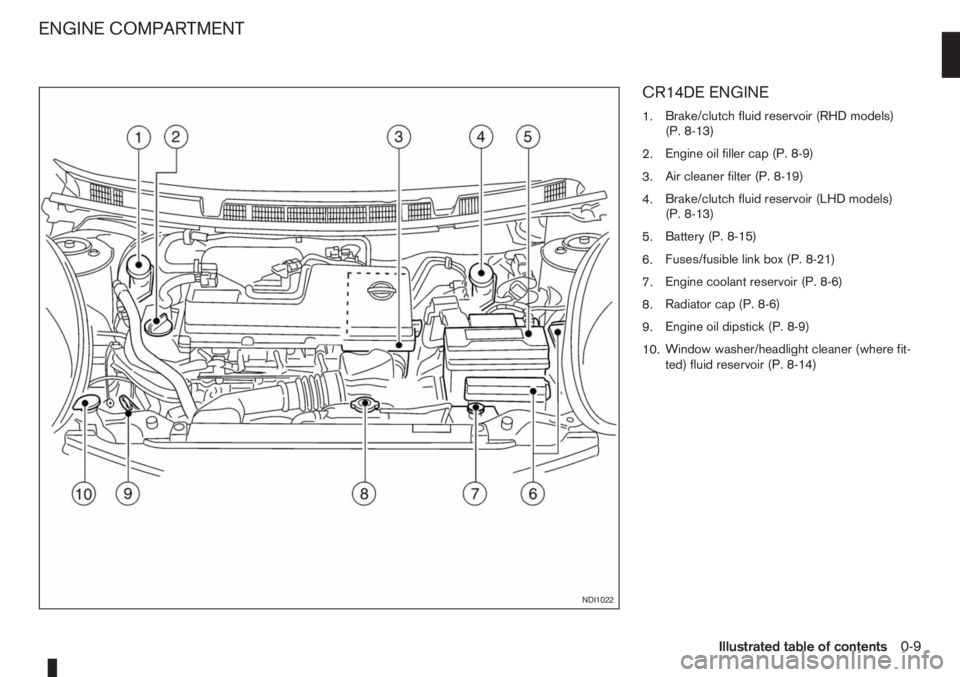

CR14DE ENGINE

1.Brake/clutch fluid reservoir (RHD models)

(P. 8-13)

2.Engine oil filler cap (P. 8-9)

3.Air cleaner filter (P. 8-19)

4.Brake/clutch fluid reservoir (LHD models)

(P. 8-13)

5.Battery (P. 8-15)

6.Fuses/fusible link box (P. 8-21)

7.Engine coolant reservoir (P. 8-6)

8.Radiator cap (P. 8-6)

9.Engine oil dipstick (P. 8-9)

10.Window washer/headlight cleaner (where fit-

ted) fluid reservoir (P. 8-14)

NDI1022

ENGINE COMPARTMENT

Illustrated table of contents0-9

Page 16 of 235

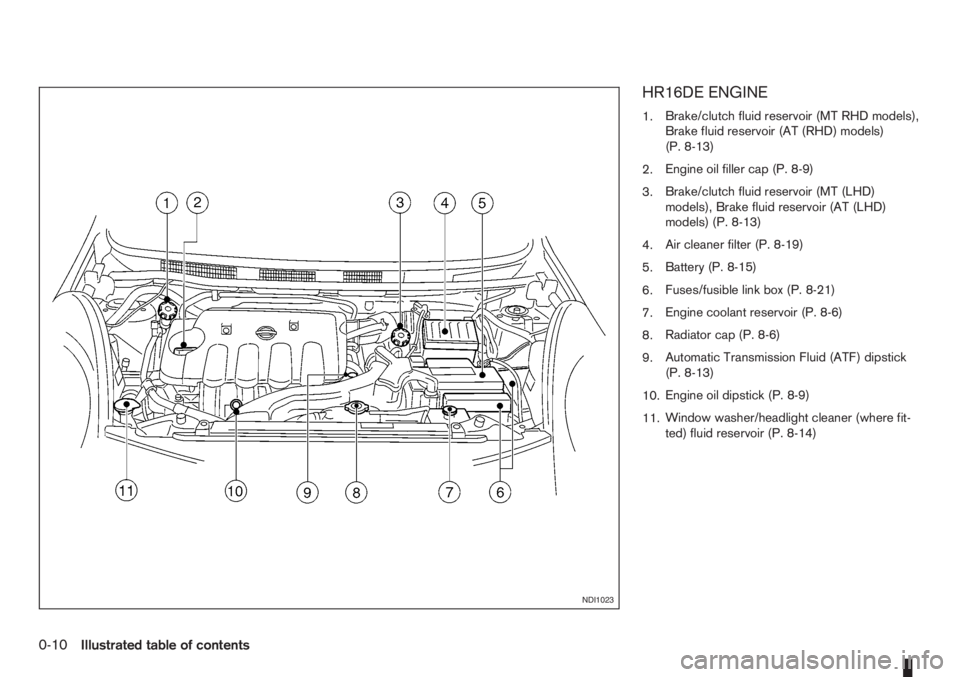

HR16DE ENGINE

1.Brake/clutch fluid reservoir (MT RHD models),

Brake fluid reservoir (AT (RHD) models)

(P. 8-13)

2.Engine oil filler cap (P. 8-9)

3.Brake/clutch fluid reservoir (MT (LHD)

models), Brake fluid reservoir (AT (LHD)

models) (P. 8-13)

4.Air cleaner filter (P. 8-19)

5.Battery (P. 8-15)

6.Fuses/fusible link box (P. 8-21)

7.Engine coolant reservoir (P. 8-6)

8.Radiator cap (P. 8-6)

9.Automatic Transmission Fluid (ATF) dipstick

(P. 8-13)

10.Engine oil dipstick (P. 8-9)

11.Window washer/headlight cleaner (where fit-

ted) fluid reservoir (P. 8-14)

NDI1023

0-10Illustrated table of contents

Page 17 of 235

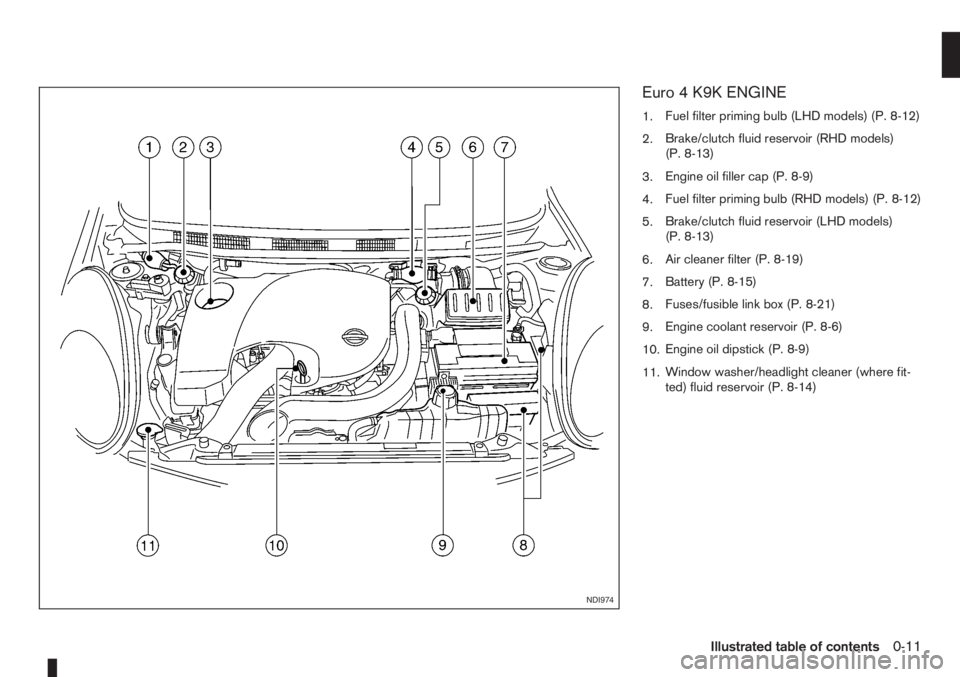

Euro 4 K9K ENGINE

1.Fuel filter priming bulb (LHD models) (P. 8-12)

2.Brake/clutch fluid reservoir (RHD models)

(P. 8-13)

3.Engine oil filler cap (P. 8-9)

4.Fuel filter priming bulb (RHD models) (P. 8-12)

5.Brake/clutch fluid reservoir (LHD models)

(P. 8-13)

6.Air cleaner filter (P. 8-19)

7.Battery (P. 8-15)

8.Fuses/fusible link box (P. 8-21)

9.Engine coolant reservoir (P. 8-6)

10.Engine oil dipstick (P. 8-9)

11.Window washer/headlight cleaner (where fit-

ted) fluid reservoir (P. 8-14)

NDI974

Illustrated table of contents0-11

Page 18 of 235

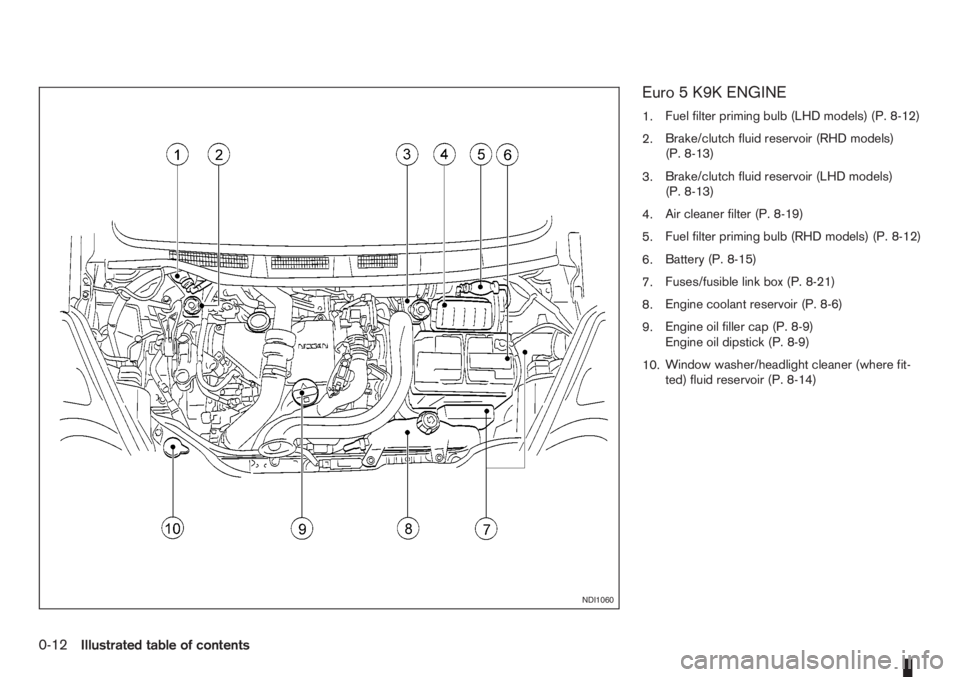

Euro 5 K9K ENGINE

1.Fuel filter priming bulb (LHD models) (P. 8-12)

2.Brake/clutch fluid reservoir (RHD models)

(P. 8-13)

3.Brake/clutch fluid reservoir (LHD models)

(P. 8-13)

4.Air cleaner filter (P. 8-19)

5.Fuel filter priming bulb (RHD models) (P. 8-12)

6.Battery (P. 8-15)

7.Fuses/fusible link box (P. 8-21)

8.Engine coolant reservoir (P. 8-6)

9.Engine oil filler cap (P. 8-9)

Engine oil dipstick (P. 8-9)

10.Window washer/headlight cleaner (where fit-

ted) fluid reservoir (P. 8-14)

NDI1060

0-12Illustrated table of contents

Page 47 of 235

puter (where fitted) mode that was displayed before

the ignition switch was turned to the Acc, “OFF” or

LOCK position.

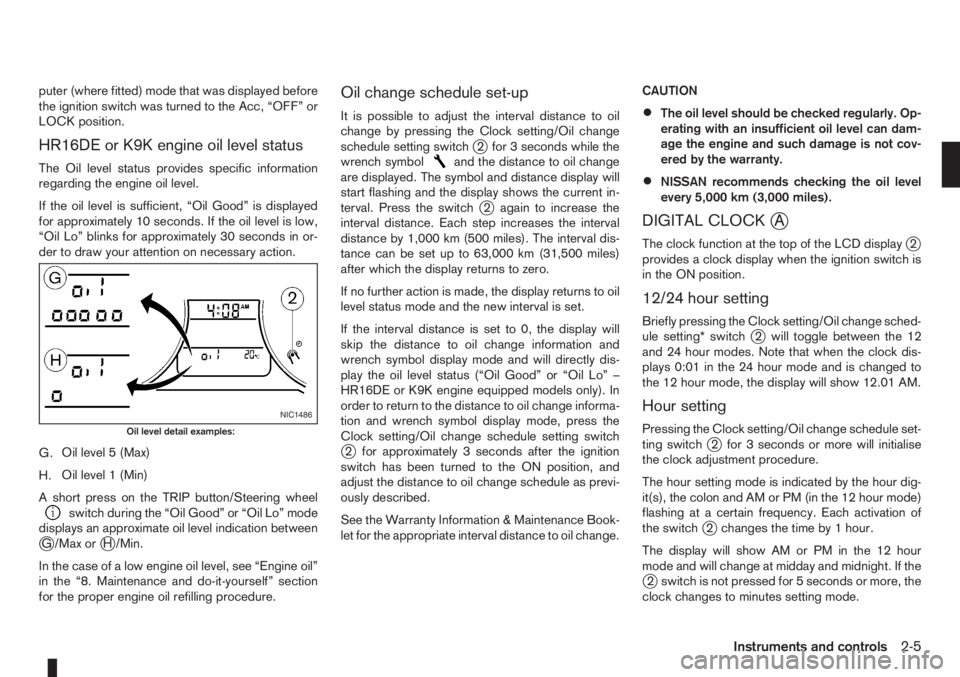

HR16DE or K9K engine oil level status

The Oil level status provides specific information

regarding the engine oil level.

If the oil level is sufficient, “Oil Good” is displayed

for approximately 10 seconds. If the oil level is low,

“Oil Lo” blinks for approximately 30 seconds in or-

der to draw your attention on necessary action.

G.Oil level 5 (Max)

H.Oil level 1 (Min)

A short press on the TRIP button/Steering wheel

switch during the “Oil Good” or “Oil Lo” mode

displays an approximate oil level indication between

jG /Max orjH /Min.

In the case of a low engine oil level, see “Engine oil”

in the “8. Maintenance and do-it-yourself” section

for the proper engine oil refilling procedure.

Oil change schedule set-up

It is possible to adjust the interval distance to oil

change by pressing the Clock setting/Oil change

schedule setting switch

j2 for 3 seconds while the

wrench symboland the distance to oil change

are displayed. The symbol and distance display will

start flashing and the display shows the current in-

terval. Press the switch

j2 again to increase the

interval distance. Each step increases the interval

distance by 1,000 km (500 miles). The interval dis-

tance can be set up to 63,000 km (31,500 miles)

after which the display returns to zero.

If no further action is made, the display returns to oil

level status mode and the new interval is set.

If the interval distance is set to 0, the display will

skip the distance to oil change information and

wrench symbol display mode and will directly dis-

play the oil level status (“Oil Good” or “Oil Lo” –

HR16DE or K9K engine equipped models only). In

order to return to the distance to oil change informa-

tion and wrench symbol display mode, press the

Clock setting/Oil change schedule setting switch

j2 for approximately 3 seconds after the ignition

switch has been turned to the ON position, and

adjust the distance to oil change schedule as previ-

ously described.

See the Warranty Information & Maintenance Book-

let for the appropriate interval distance to oil change.CAUTION

•The oil level should be checked regularly. Op-

erating with an insufficient oil level can dam-

age the engine and such damage is not cov-

ered by the warranty.

•NISSAN recommends checking the oil level

every 5,000 km (3,000 miles).

DIGITAL CLOCKjA

The clock function at the top of the LCD displayj2

provides a clock display when the ignition switch is

in the ON position.

12/24 hour setting

Briefly pressing the Clock setting/Oil change sched-

ule setting* switchj2 will toggle between the 12

and 24 hour modes. Note that when the clock dis-

plays 0:01 in the 24 hour mode and is changed to

the 12 hour mode, the display will show 12.01 AM.

Hour setting

Pressing the Clock setting/Oil change schedule set-

ting switchj2 for 3 seconds or more will initialise

the clock adjustment procedure.

The hour setting mode is indicated by the hour dig-

it(s), the colon and AM or PM (in the 12 hour mode)

flashing at a certain frequency. Each activation of

the switch

j2 changes the time by 1 hour.

The display will show AM or PM in the 12 hour

mode and will change at midday and midnight. If the

j2 switch is not pressed for 5 seconds or more, the

clock changes to minutes setting mode.

NIC1486

Oil level detail examples:

Instruments and controls2-5

Page 50 of 235

“Supplemental Restraint System (air bag system)”

in the “1. Safety — seats, seat belts and supple-

mental restraint system” section.

Brake warning light

This light functions for both the handbrake and the

footbrake systems.

Handbrake indicator:

The light comes on when the handbrake is applied.

Low brake fluid warning:

The light warns of a low brake fluid level in the brake

power assist unit. If the light comes on while the

engine is running and the handbrake is not applied,

stop the vehicle and perform the following:

1. Check the brake fluid level. Add brake fluid as

much as necessary. See “Brake and clutch fluid”

in the “8. Maintenance and do-it-yourself” sec-

tion.

WARNING

If the level is below the MIN mark on the brake

fluid reservoir, do not drive until the brake sys-

tem has been checked at a NISSAN dealer or

qualified workshop.

2. If the brake fluid level is correct:

Have the warning system checked by a NISSAN

dealer or qualified workshop.

WARNING

•Driving your vehicle could be dangerous.

Therefore have it towed to the nearest

NISSAN dealer or qualified workshop.

•Pressing the brake pedal with the engine

stopped and/or low brake fluid level could in-

crease your stopping distance and require

greater pedal effort as well as pedal travel.

Charge warning light

If the light comes on while the engine is running, it

may indicate that the charging system is malfunc-

tioning. Turn the engine off and check the alternator

belt. If the belt is loose, broken, missing or if the light

remains on, see a NISSAN dealer or qualified work-

shop immediately.

CAUTION

Do not continue driving if the belt is loose, bro-

ken or missing.

Door open warning light

This light comes on when any of the doors are not

closed securely while the ignition switch is in the

ON position.

Engine coolant temperature

warning light

The engine coolant temperature varies with the out-

side air temperature and driving condition.

When the ignition switch is turned to the ON posi-tion, the engine coolant temperature warning light

illuminates for a few seconds and then goes off.

This means the system is operational.

The engine coolant temperature warning light illumi-

nates when the engine coolant temperature reaches

an excessively high temperature of approximately

105 °C (221 °F).

CAUTION

•If the engine coolant temperature warning

light comes on, stop the vehicle as soon as

safely possible and contact a NISSAN dealer

or qualified workshop.

•When towing a trailer or driving uphill, reduce

the vehicle speed as soon as safely possible

to decrease the engine coolant temperature.

•If the engine overheats, continued operation

of the vehicle may seriously damage the en-

gine. See “Engine overheat” in the “6. In case

of emergency” section for immediate action

required.

WARNING

Do not remove the radiator cap while the engine

is hot. Otherwise, there is a danger of being

scalded by the coolant that is likely to erupt from

the filler.

Engine oil pressure warning light

This light warns of low engine oil pressure. If the

light flickers, comes on during normal driving, or

stays on once the engine is started, pull off the road

2-8Instruments and controls

Page 184 of 235

12. Stop the engine and check coolant level, allow

to cool and refill up to the MAX level.

13. Check the radiator lower hose for any signs of

leakage.

14. Close the bonnet.

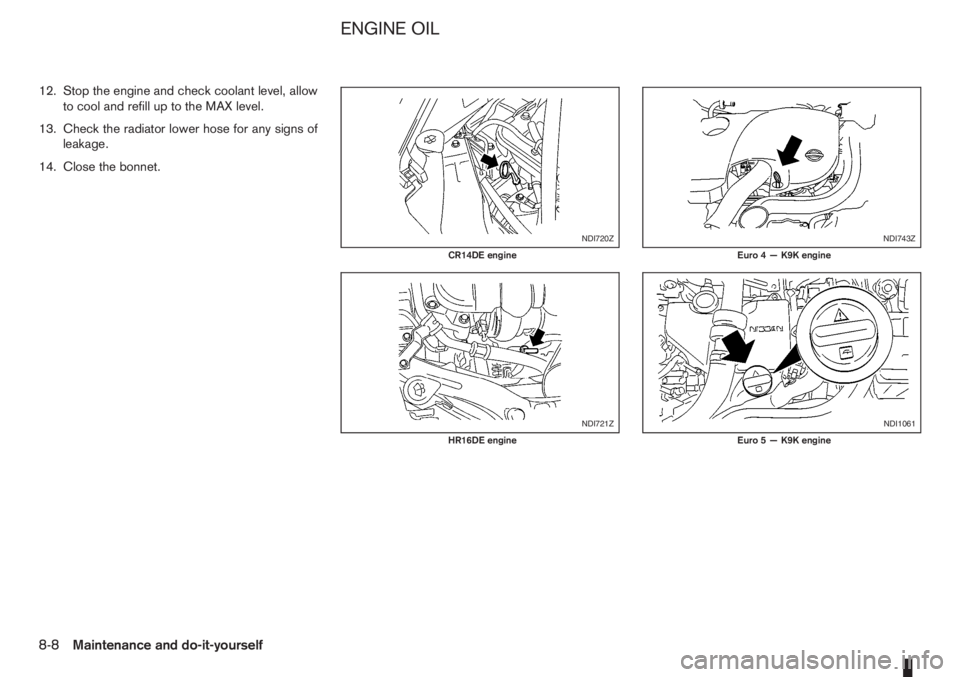

NDI720Z

CR14DE engine

NDI721Z

HR16DE engine

NDI743Z

Euro 4 — K9K engine

NDI1061

Euro 5 — K9K engine

ENGINE OIL

8-8Maintenance and do-it-yourself

Page 185 of 235

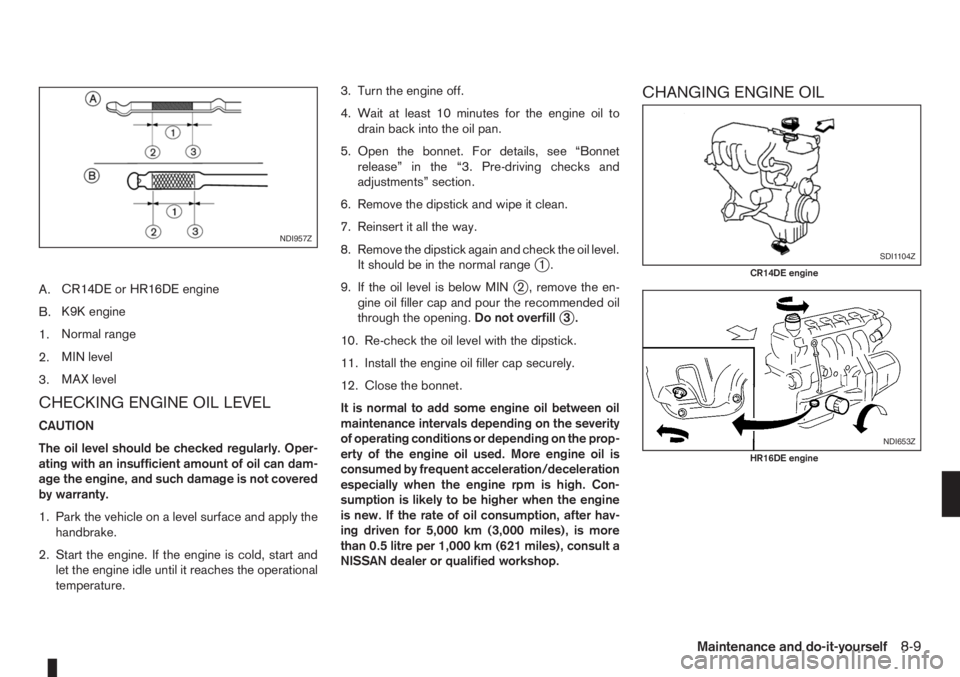

A.CR14DE or HR16DE engine

B.K9K engine

1.Normal range

2.MIN level

3.MAX level

CHECKING ENGINE OIL LEVEL

CAUTION

The oil level should be checked regularly. Oper-

ating with an insufficient amount of oil can dam-

age the engine, and such damage is not covered

by warranty.

1. Park the vehicle on a level surface and apply the

handbrake.

2. Start the engine. If the engine is cold, start and

let the engine idle until it reaches the operational

temperature.3. Turn the engine off.

4. Wait at least 10 minutes for the engine oil to

drain back into the oil pan.

5. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

6. Remove the dipstick and wipe it clean.

7. Reinsert it all the way.

8. Remove the dipstick again and check the oil level.

It should be in the normal range

j1.

9. If the oil level is below MIN

j2 , remove the en-

gine oil filler cap and pour the recommended oil

through the opening.Do not overfill

j3.

10. Re-check the oil level with the dipstick.

11. Install the engine oil filler cap securely.

12. Close the bonnet.

It is normal to add some engine oil between oil

maintenance intervals depending on the severity

of operating conditions or depending on the prop-

erty of the engine oil used. More engine oil is

consumed by frequent acceleration/deceleration

especially when the engine rpm is high. Con-

sumption is likely to be higher when the engine

is new. If the rate of oil consumption, after hav-

ing driven for 5,000 km (3,000 miles), is more

than 0.5 litre per 1,000 km (621 miles), consult a

NISSAN dealer or qualified workshop.

CHANGING ENGINE OIL

NDI957Z

SDI1104Z

CR14DE engine

NDI653Z

HR16DE engine

Maintenance and do-it-yourself8-9

Page 186 of 235

WARNING

•NISSAN recommends contacting a NISSAN

dealer or qualified workshop for engine oil

servicing.

NISSAN GREEN PROGRAM

A used oil filter should be disposed of at a

rubbish tip having proper facilities.

•Be careful not to burn yourself, as the engine

oil is hot.

•Prolonged and repeated contact with used

engine oil may cause skin cancer.

•Avoid direct skin contact with used oil. If skin

contact is made, wash thoroughly with soap

or hand cleaner and plenty of water as soon

as possible.

•Store used engine oil in marked containers

out of the reach of children.

1. Park the vehicle on a level surface and apply the

handbrake.

2. Start the engine. If the engine is cold, start and

let the engine idle until the engine temperature

reaches the operational temperature.

3. Turn the engine off and wait at least 10 minutes

to let the engine oil drain back into the oil pan.

4. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

5. Remove the engine oil filler cap.

6. Raise and support the vehicle using a suitable

floor jack and safety jack stands.

Place the safety jack stands under the vehicle

jack-up points.

For details, see “Flat tyre” in the “6. In case of

emergency” section.

7. Remove the engine compartment under cover

(where fitted).8. Place a large drain pan under the drain plug.

9. Remove the drain plug with a wrench and com-

pletely drain the oil.

If the engine oil filter needs to be changed, re-

move and replace it at this time. See “Changing

engine oil filter” later in this section.

10. Clean and reinstall the drain plug along with a

new washer. Securely tighten the drain plug

with a wrench.Do not use excessive force.

Drain plug tightening torques:

CR14DE or HR16DE engine:

34.3 N•m (3.5 kg-m, 25 ft-lb)

K9K engine:

20 N•m (2.0 kg-m, 15 ft-lb)

11. Refill the engine with recommended engine oil

and quantity.

See “Capacities and recommended fuel/

lubricants” in the “9. Technical information” sec-

tion.

12. Check the oil level with the dipstick. For details,

see “Checking engine oil level” earlier in this

section. If necessary, add engine oil.

13. Install the engine oil filler cap securely.

14. Start the engine.

15. Check for any leakage around the drain plug.

Correct as required.

16. Turn the engine off and wait several minutes.

17. Check the oil level again with the dipstick. If

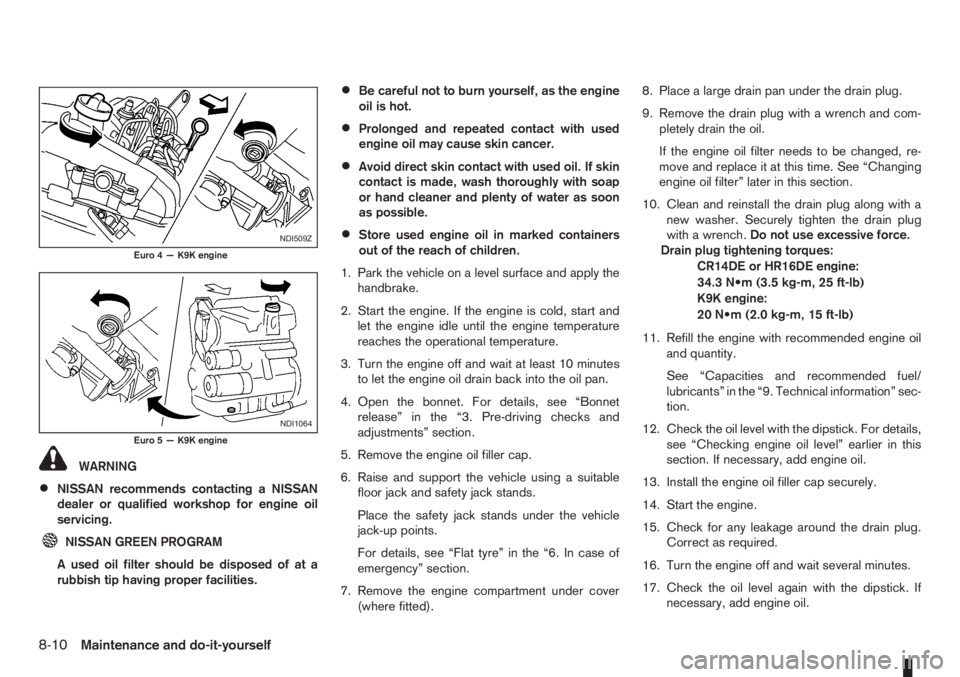

necessary, add engine oil.NDI509Z

Euro 4 — K9K engine

NDI1064

Euro 5 — K9K engine

8-10Maintenance and do-it-yourself

Page 187 of 235

18. Install the engine compartment undercover

(where fitted).

19. Lower the vehicle carefully to the ground.

20. Close the bonnet.

CHANGING ENGINE OIL FILTER

WARNING

•NISSAN recommends contacting a NISSAN

dealer or qualified workshop for engine oil fil-

ter servicing.

NISSAN GREEN PROGRAM

A used oil filter should be disposed of at a

rubbish tip having proper facilities.

Engine oil filter replacement

Removal:

1. Drain the engine oil. For details, see “Changing

engine oil” earlier in this section.

2. Loosen the engine oil filter unit with an oil filter

wrench. Depending on the engine model, a spe-

cialcap typewrench may be required. See a

NISSAN dealer or qualified workshop, if in doubt.

3. Remove the engine oil filter unit.

4. Wipe the engine oil filter mounting surface with a

clean rag.CAUTION

If any oil is spilled on the engine or the ve-

hicle, thoroughly wipe it clean.

Installation:

1. Clean and reinstall the drain plug along with a

new washer. For tightening torque details, see

“Changing engine oil” earlier in this section.

2. Coat the rubber gasket on the new engine oil fil-

ter unit with clean engine oil.

3. Install the engine oil filter unit by hand until a

slight resistance is felt, then tighten additionally

2/3ofaturn.

Engine oil filter tightening torques:

CR14DE or HR16DE engine:

17.7 N•m (1.8 kg-m, 13 ft-lb)

K9K engine:

14 N•m (1.4 kg-m, 10 ft-lb)

4. Add engine oil and check the oil level with the

engine oil dipstick. For details, see “Checking

engine oil level” earlier in this section and “Ca-

pacities and recommended fuel/lubricants” in the

“9. Technical information” section.

5. Install the engine oil filler cap.

6. Start the engine.

7. After the engine has been warmed up, make sure

there are no leaks around the engine oil filter unit

and the drain plug. Correct as required.

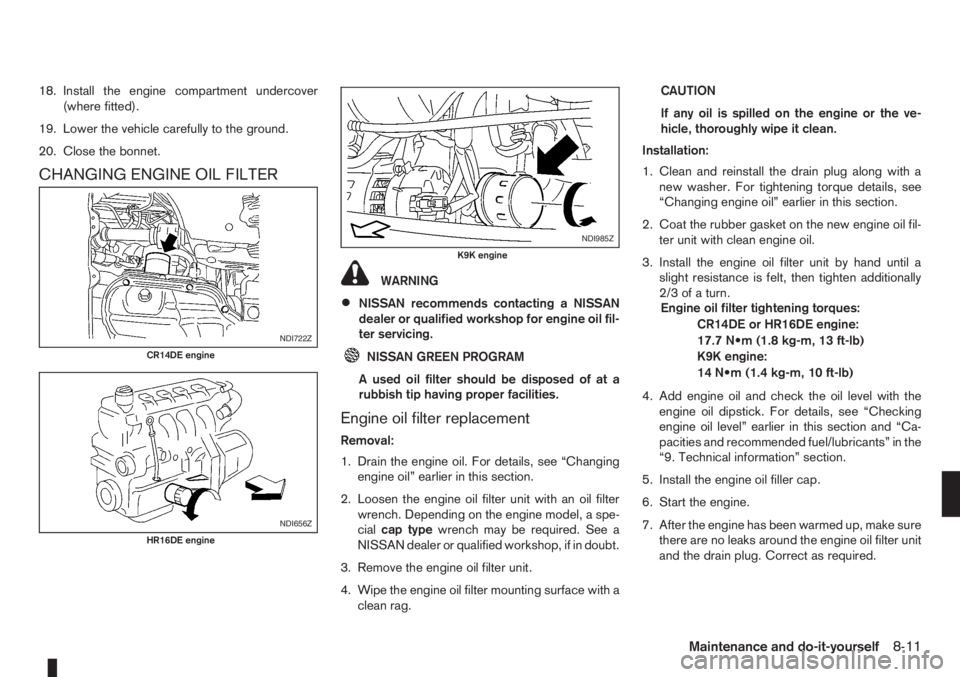

NDI722Z

CR14DE engine

NDI656Z

HR16DE engine

NDI985Z

K9K engine

Maintenance and do-it-yourself8-11