water pump NISSAN PATHFINDER 1999 R50 / 2.G Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PATHFINDER, Model: NISSAN PATHFINDER 1999 R50 / 2.GPages: 274, PDF Size: 2.34 MB

Page 118 of 274

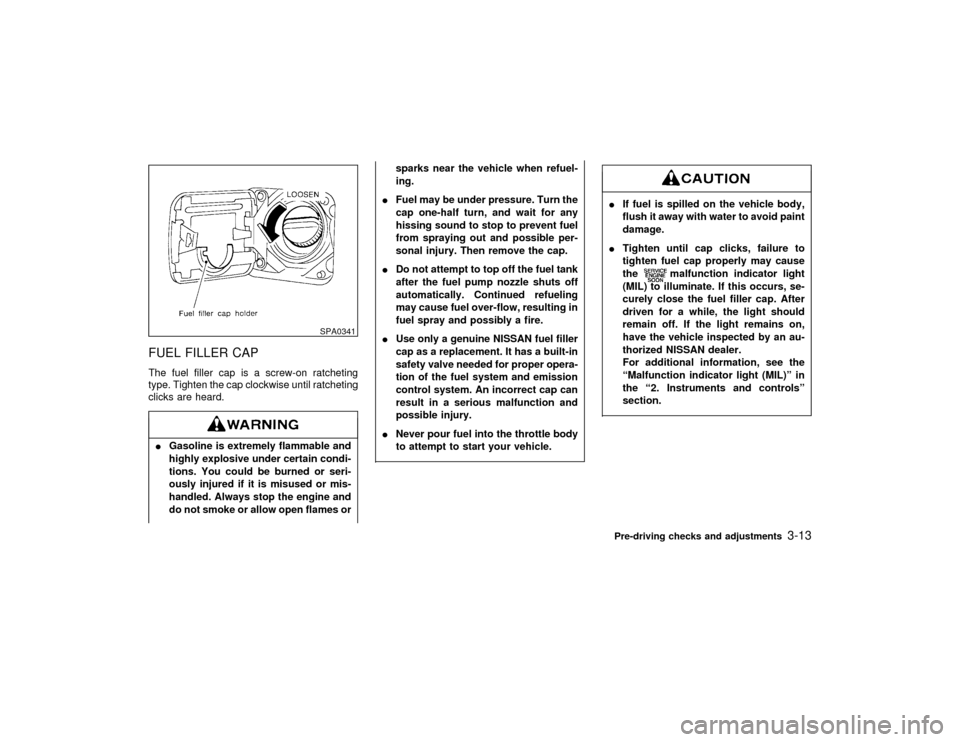

FUEL FILLER CAPThe fuel filler cap is a screw-on ratcheting

type. Tighten the cap clockwise until ratcheting

clicks are heard.IGasoline is extremely flammable and

highly explosive under certain condi-

tions. You could be burned or seri-

ously injured if it is misused or mis-

handled. Always stop the engine and

do not smoke or allow open flames orsparks near the vehicle when refuel-

ing.

IFuel may be under pressure. Turn the

cap one-half turn, and wait for any

hissing sound to stop to prevent fuel

from spraying out and possible per-

sonal injury. Then remove the cap.

IDo not attempt to top off the fuel tank

after the fuel pump nozzle shuts off

automatically. Continued refueling

may cause fuel over-flow, resulting in

fuel spray and possibly a fire.

IUse only a genuine NISSAN fuel filler

cap as a replacement. It has a built-in

safety valve needed for proper opera-

tion of the fuel system and emission

control system. An incorrect cap can

result in a serious malfunction and

possible injury.

INever pour fuel into the throttle body

to attempt to start your vehicle.

IIf fuel is spilled on the vehicle body,

flush it away with water to avoid paint

damage.

ITighten until cap clicks, failure to

tighten fuel cap properly may cause

the

malfunction indicator light

(MIL) to illuminate. If this occurs, se-

curely close the fuel filler cap. After

driven for a while, the light should

remain off. If the light remains on,

have the vehicle inspected by an au-

thorized NISSAN dealer.

For additional information, see the

ªMalfunction indicator light (MIL)º in

the ª2. Instruments and controlsº

section.

SPA0341

Pre-driving checks and adjustments

3-13

Z

01.1.22/R50-D/V5

X

Page 174 of 274

BRAKING PRECAUTIONSThe brake system has two separate hydraulic

circuits. If one circuit develops a problem, you

will still have braking at two wheels.Vacuum assisted brakeThe brake booster aids braking by using en-

gine vacuum. If the engine stops, you can stop

the vehicle by depressing the brake pedal.

However, greater foot pressure on the brake

pedal will be required to stop the vehicle and

the stopping distance will be longer.Using the brakesAvoid resting your foot on the brake pedal

while driving. This will overheat the brakes,

wear out the brake linings and pads faster and

reduce gas mileage.

To help save the brakes and to prevent the

brakes from overheating, before going down a

slope or long grade, reduce speed and down-

shift to a lower gear.Wet brakesWhen the vehicle is washed or driven through

water, the brakes may get wet. As a result,

your braking distance will be longer and the

vehicle may pull to one side during braking.To dry brakes, drive the vehicle at a safe

speed while lightly pressing the brake pedal to

heat-up the brakes. Do this until the brakes

return to normal. Avoid driving the vehicle at

high speeds until the brakes function correctly.

IWhile driving on a slippery surface,

be careful when braking, accelerating

or downshifting. Abrupt braking or

accelerating could cause the wheels

to skid and result in an accident.

IIf the engine is not running or is

turned off while driving, the power

assist for the brakes will not work.

Braking will be harder.ANTI-LOCK BRAKE SYSTEM (ABS)The anti-lock brake system controls the brakes

at each wheel so the wheels will not lock when

braking abruptly or when braking on slippery

surfaces. The system detects the rotation

speed at each wheel and varies the brake fluid

pressure to prevent each wheel from locking

and sliding. By preventing wheel lockup, the

system helps the driver maintain steering con-

trol and helps to minimize swerving and spin-ning on slippery surfaces.

Using the systemDepress the brake pedal and hold it down.Do not pump the brake pedal. Doing so

may result in increased stopping

distances.Normal operationThe anti-lock brake system will not operate at

speeds below 3 to 6 MPH (5 to 10 km/h) to

completely stop the vehicle. (The speeds will

vary according to road conditions.) When the

anti-lock system senses that one or more

wheels are close to locking up, the actuator

(under the hood) rapidly applies and releases

hydraulic pressure (like pumping the brakes

very quickly). While the actuator is working,

you may feel a pulsation in the brake pedal

and hear a noise or vibration from the actuator

under the hood. This is normal and indicates

that the anti-lock system is working properly.

However, the pulsation may indicate that road

conditions are hazardous and extra care is

required while driving.

BRAKE SYSTEM

Starting and driving

5-25

Z

01.1.22/R50-D/V5

X

Page 243 of 274

Propeller shaft(s):

Check the propeller shaft(s) for damage,

looseness and grease leakage under severe

driving condition (

only).

Propeller shaft:

Apply specified grease to the greasing points

of propeller shafts in accordance with the

maintenance schedule. In the case of driving

in water, greasing should be performed imme-

diately afterwards.

Front wheel bearing grease:

Check the wheel bearing for grease leakage

around grease seals, axial end play and

smooth turning (4x2).

Check the wheel bearing grease condition or

repack these in accordance with the mainte-

nance schedule. In case of frequent driving in

muddy water, the bearing grease inspection

should be performed more frequently (

).

Exhaust system:

Visually check the exhaust pipes, muffler, and

hangers for proper attachment, leaks, cracks,

chafing, abrasion, deterioration, etc. Under

severe driving conditions, inspection should be

performed more frequently.Supplemental air bag, and supplemental

side air bag (if so equipped) systems:

Maintenance for the supplemental air bags or

supplemental side air bags should be done by

an authorized NISSAN dealer.

Automatic Speed Control Device (ASCD)

vacuum hoses:

Check vacuum hose (between ASCD actuator

and ASCD pump) for breakage, cracks or

fracture.

9-12

Maintenance

Z

01.1.22/R50-D/V5

X