clock NISSAN PATHFINDER 2010 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: PATHFINDER, Model: NISSAN PATHFINDER 2010Pages: 463, PDF Size: 5.69 MB

Page 224 of 463

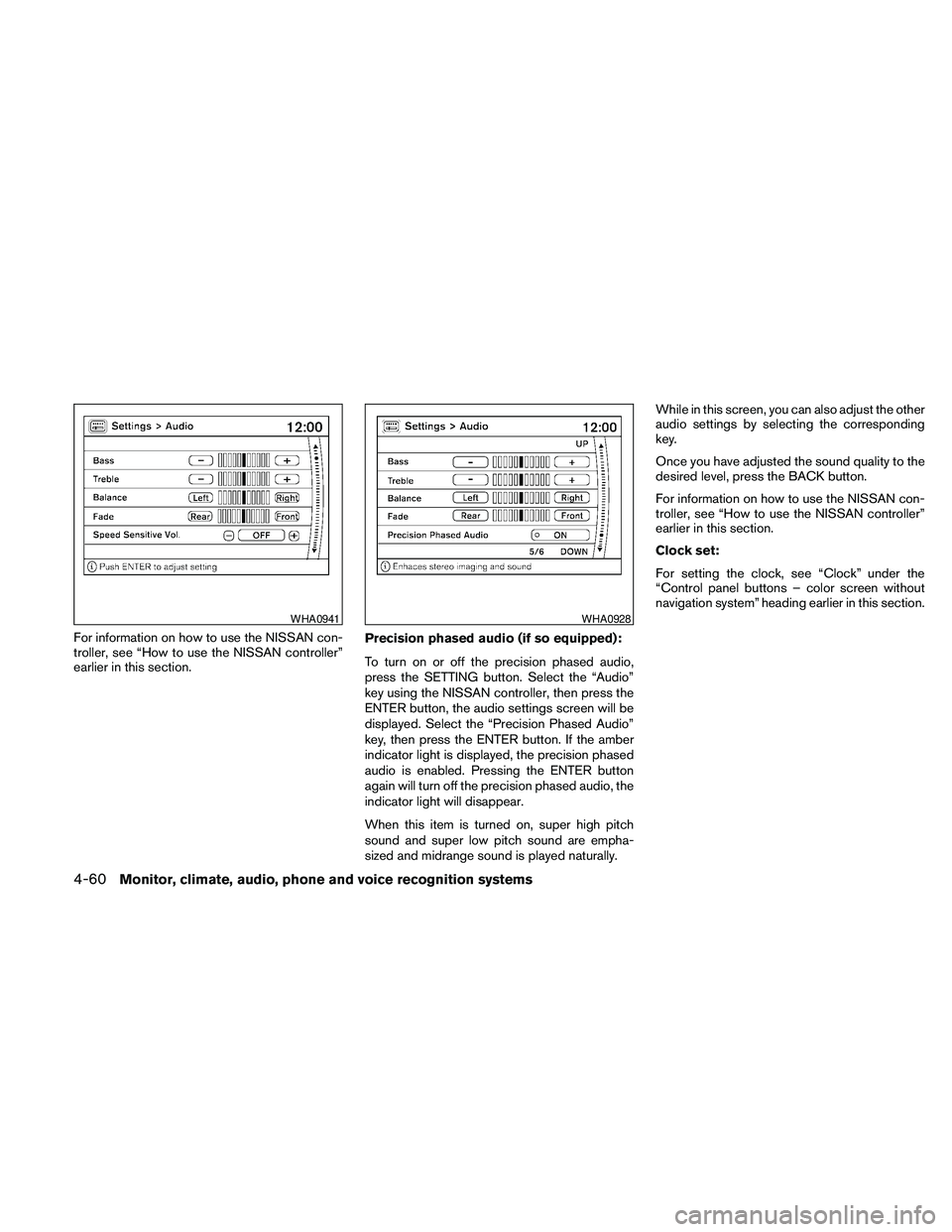

For information on how to use the NISSAN con-

troller, see “How to use the NISSAN controller”

earlier in this section.Precision phased audio (if so equipped):

To turn on or off the precision phased audio,

press the SETTING button. Select the “Audio”

key using the NISSAN controller, then press the

ENTER button, the audio settings screen will be

displayed. Select the “Precision Phased Audio”

key, then press the ENTER button. If the amber

indicator light is displayed, the precision phased

audio is enabled. Pressing the ENTER button

again will turn off the precision phased audio, the

indicator light will disappear.

When this item is turned on, super high pitch

sound and super low pitch sound are empha-

sized and midrange sound is played naturally.While in this screen, you can also adjust the other

audio settings by selecting the corresponding

key.

Once you have adjusted the sound quality to the

desired level, press the BACK button.

For information on how to use the NISSAN con-

troller, see “How to use the NISSAN controller”

earlier in this section.

Clock set:

For setting the clock, see “Clock” under the

“Control panel buttons – color screen without

navigation system” heading earlier in this section.

WHA0941WHA0928

4-60Monitor, climate, audio, phone and voice recognition systems

Page 232 of 463

Precision phased audio (if so equipped):

To turn on or off the precision phased audio,

press the SETTING button. Then touch the “Au-

dio” key; the audio settings screen will be dis-

played. Touch the “Precision Phased Audio ON”

key. If the amber indicator light is displayed, the

precision phased audio is enabled. Touching the

“Precision Phased Audio ON” key again will turn

off the precision phased audio; the indicator light

will disappear.

When this item is turned on, super high pitch

sound and super low pitch sound are empha-

sized and midrange sound is played naturally.While in this screen, you can also adjust the other

audio settings by touching the corresponding

key.

Once you have adjusted the sound quality to the

desired level, touch the “BACK” key.

Clock set:

For setting the clock, see “Clock” under the

“Control panel buttons – color screen without

navigation system” heading earlier in this section.

LHA0900WHA0942

4-68Monitor, climate, audio, phone and voice recognition systems

Page 326 of 463

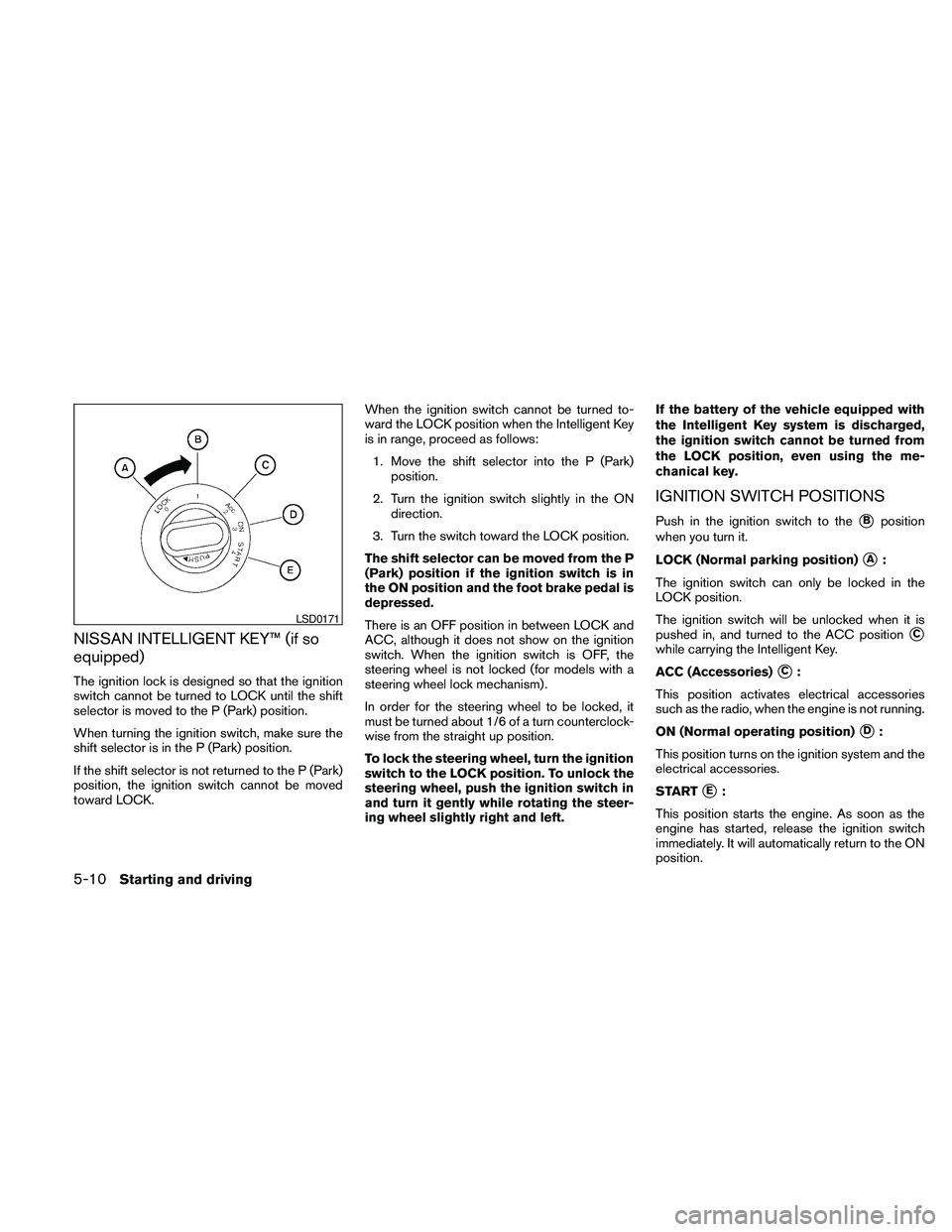

NISSAN INTELLIGENT KEY™ (if so

equipped)

The ignition lock is designed so that the ignition

switch cannot be turned to LOCK until the shift

selector is moved to the P (Park) position.

When turning the ignition switch, make sure the

shift selector is in the P (Park) position.

If the shift selector is not returned to the P (Park)

position, the ignition switch cannot be moved

toward LOCK.When the ignition switch cannot be turned to-

ward the LOCK position when the Intelligent Key

is in range, proceed as follows:

1. Move the shift selector into the P (Park)

position.

2. Turn the ignition switch slightly in the ON

direction.

3. Turn the switch toward the LOCK position.

The shift selector can be moved from the P

(Park) position if the ignition switch is in

the ON position and the foot brake pedal is

depressed.

There is an OFF position in between LOCK and

ACC, although it does not show on the ignition

switch. When the ignition switch is OFF, the

steering wheel is not locked (for models with a

steering wheel lock mechanism) .

In order for the steering wheel to be locked, it

must be turned about 1/6 of a turn counterclock-

wise from the straight up position.

To lock the steering wheel, turn the ignition

switch to the LOCK position. To unlock the

steering wheel, push the ignition switch in

and turn it gently while rotating the steer-

ing wheel slightly right and left.If the battery of the vehicle equipped with

the Intelligent Key system is discharged,

the ignition switch cannot be turned from

the LOCK position, even using the me-

chanical key.

IGNITION SWITCH POSITIONS

Push in the ignition switch to thesBposition

when you turn it.

LOCK (Normal parking position)

sA:

The ignition switch can only be locked in the

LOCK position.

The ignition switch will be unlocked when it is

pushed in, and turned to the ACC position

sC

while carrying the Intelligent Key.

ACC (Accessories)

sC:

This position activates electrical accessories

such as the radio, when the engine is not running.

ON (Normal operating position)

sD:

This position turns on the ignition system and the

electrical accessories.

START

sE:

This position starts the engine. As soon as the

engine has started, release the ignition switch

immediately. It will automatically return to the ON

position.

LSD0171

5-10Starting and driving

Page 328 of 463

The shift selector can be moved if the igni-

tion switch is in the ON position and the

foot brake pedal is depressed.

There is an OFF position between the

LOCK and ACC positions. The OFF position

is indicated by a “1” on the key cylinder. For

models with steering wheel lock mecha-

nism: when the ignition switch is in the OFF

position, the steering wheel is not locked .

In order for the steering wheel to be locked, it

must be turned about 1/8 of a turn clockwise

from the straight up position.

To lock the steering wheel, turn the ignition

to the LOCK position. Remove the key. To

unlock the steering wheel, insert the key

and turn it gently while rotating the steer-

ing wheel slightly right and left.

If the key will not turn from the LOCK posi-

tion, turn the steering wheel to the left or

right while turning the key to unlock the

key cylinder.

KEY POSITIONS

LOCK: Normal parking position (0)

OFF: (Not used) (1)

ACC: (Accessories) (2)This position activates electrical accessories

such as the radio when the engine is not running.

ON: Normal operating position (3)

This position turns on the ignition system and the

electrical accessories.

START: (4)

This position starts the engine. As soon as the

engine has started, release the key. It automati-

cally returns to the ON position.

NISSAN VEHICLE IMMOBILIZER

SYSTEM

The NISSAN Vehicle Immobilizer system will not

allow the engine to start without the use of the

registered key.

If the engine fails to start using a registered key

(for example, when interference is caused by

another registered key, an automated toll road

device or automatic payment device on the key

ring) , restart the engine using the following pro-

cedure:

1. Leave the ignition switch in the ON position

for approximately 5 seconds.

2. Place the ignition switch in the OFF or

LOCK position, and wait approximately 10

seconds.3. Repeat steps 1 and 2.

4. Restart the engine while holding the device

(which may have caused the interference)

separate from the registered key.

If the no start condition re-occurs, NISSAN rec-

ommends placing the registered key on a sepa-

rate key ring to avoid interference from other

devices.

5-12Starting and driving

Page 360 of 463

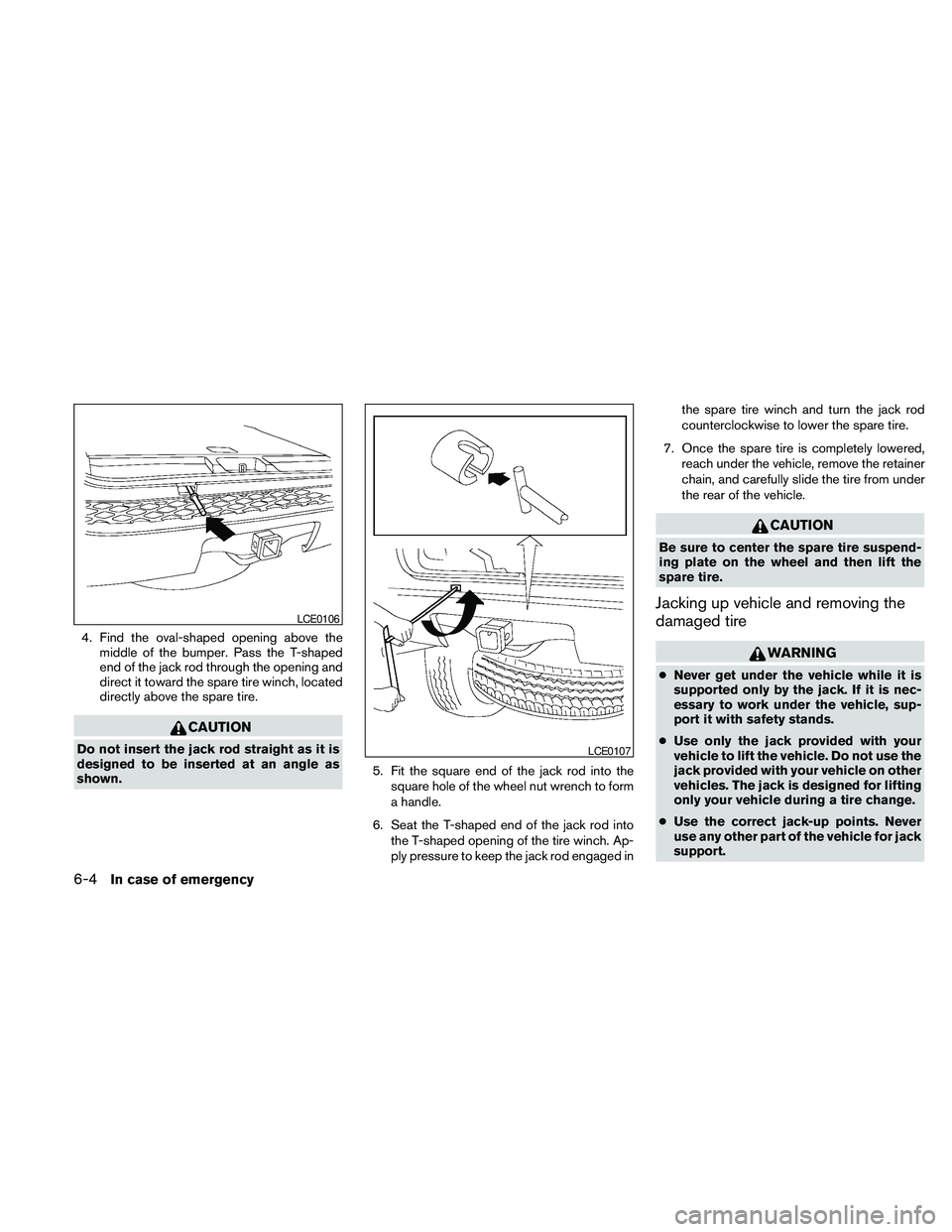

4. Find the oval-shaped opening above the

middle of the bumper. Pass the T-shaped

end of the jack rod through the opening and

direct it toward the spare tire winch, located

directly above the spare tire.

CAUTION

Do not insert the jack rod straight as it is

designed to be inserted at an angle as

shown.5. Fit the square end of the jack rod into the

square hole of the wheel nut wrench to form

a handle.

6. Seat the T-shaped end of the jack rod into

the T-shaped opening of the tire winch. Ap-

ply pressure to keep the jack rod engaged inthe spare tire winch and turn the jack rod

counterclockwise to lower the spare tire.

7. Once the spare tire is completely lowered,

reach under the vehicle, remove the retainer

chain, and carefully slide the tire from under

the rear of the vehicle.

CAUTION

Be sure to center the spare tire suspend-

ing plate on the wheel and then lift the

spare tire.

Jacking up vehicle and removing the

damaged tire

WARNING

cNever get under the vehicle while it is

supported only by the jack. If it is nec-

essary to work under the vehicle, sup-

port it with safety stands.

cUse only the jack provided with your

vehicle to lift the vehicle. Do not use the

jack provided with your vehicle on other

vehicles. The jack is designed for lifting

only your vehicle during a tire change.

cUse the correct jack-up points. Never

use any other part of the vehicle for jack

support.

LCE0106

LCE0107

6-4In case of emergency

Page 361 of 463

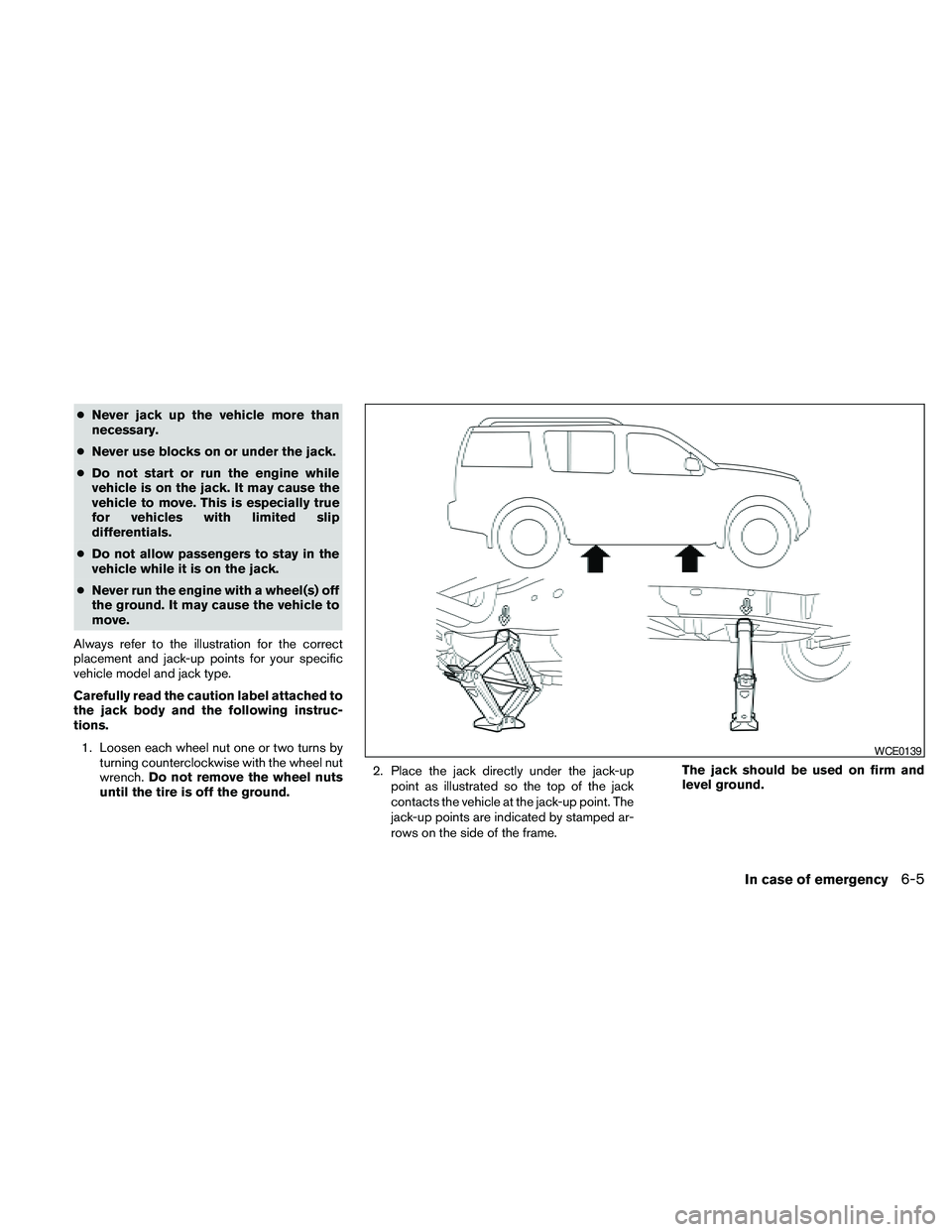

cNever jack up the vehicle more than

necessary.

cNever use blocks on or under the jack.

cDo not start or run the engine while

vehicle is on the jack. It may cause the

vehicle to move. This is especially true

for vehicles with limited slip

differentials.

cDo not allow passengers to stay in the

vehicle while it is on the jack.

cNever run the engine with a wheel(s) off

the ground. It may cause the vehicle to

move.

Always refer to the illustration for the correct

placement and jack-up points for your specific

vehicle model and jack type.

Carefully read the caution label attached to

the jack body and the following instruc-

tions.

1. Loosen each wheel nut one or two turns by

turning counterclockwise with the wheel nut

wrench.Do not remove the wheel nuts

until the tire is off the ground.2. Place the jack directly under the jack-up

point as illustrated so the top of the jack

contacts the vehicle at the jack-up point. The

jack-up points are indicated by stamped ar-

rows on the side of the frame.The jack should be used on firm and

level ground.

WCE0139

In case of emergency6-5

Page 387 of 463

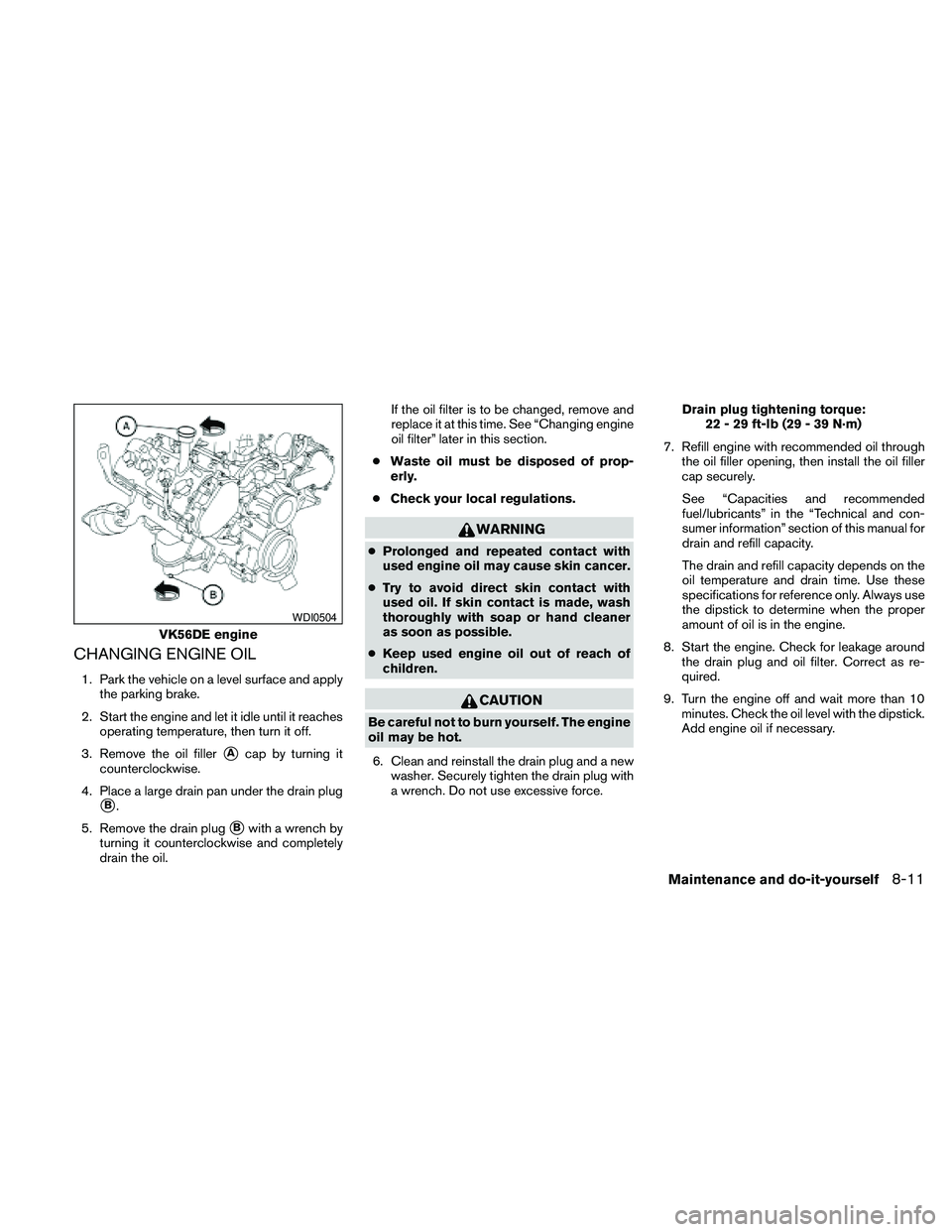

CHANGING ENGINE OIL

1. Park the vehicle on a level surface and apply

the parking brake.

2. Start the engine and let it idle until it reaches

operating temperature, then turn it off.

3. Remove the oil filler

sAcap by turning it

counterclockwise.

4. Place a large drain pan under the drain plug

sB.

5. Remove the drain plug

sBwith a wrench by

turning it counterclockwise and completely

drain the oil.If the oil filter is to be changed, remove and

replace it at this time. See “Changing engine

oil filter” later in this section.

cWaste oil must be disposed of prop-

erly.

cCheck your local regulations.

WARNING

cProlonged and repeated contact with

used engine oil may cause skin cancer.

cTry to avoid direct skin contact with

used oil. If skin contact is made, wash

thoroughly with soap or hand cleaner

as soon as possible.

cKeep used engine oil out of reach of

children.

CAUTION

Be careful not to burn yourself. The engine

oil may be hot.

6. Clean and reinstall the drain plug and a new

washer. Securely tighten the drain plug with

a wrench. Do not use excessive force.Drain plug tightening torque:

22 - 29 ft-lb (29 - 39 N·m)

7. Refill engine with recommended oil through

the oil filler opening, then install the oil filler

cap securely.

See “Capacities and recommended

fuel/lubricants” in the “Technical and con-

sumer information” section of this manual for

drain and refill capacity.

The drain and refill capacity depends on the

oil temperature and drain time. Use these

specifications for reference only. Always use

the dipstick to determine when the proper

amount of oil is in the engine.

8. Start the engine. Check for leakage around

the drain plug and oil filter. Correct as re-

quired.

9. Turn the engine off and wait more than 10

minutes. Check the oil level with the dipstick.

Add engine oil if necessary.

VK56DE engine

WDI0504

Maintenance and do-it-yourself8-11

Page 388 of 463

CHANGING ENGINE OIL FILTER

1. Park the vehicle on a level surface and apply

the parking brake.

2. Turn the engine off.

3. Place a large drain pan under the oil filter.

4. Unscrew the plate covering the oil filter ex-

posing the filter.

5. Loosen the oil filter

sAwith an oil filter

wrench by turning it counterclockwise. Then

remove the oil filter by turning it by hand.

CAUTION

Be careful not to burn yourself. The engine

oil may be hot.

6. Wipe the engine oil filter sealing surface with

a clean rag.

CAUTION

Be sure to remove any old gasket material

remaining on the sealing surface of the

engine. Failure to do so could lead to

engine damage.7. Coat the gasket on the new filter with clean

engine oil.

8. Screw on the oil filter until a slight resistance

is felt, then tighten an additional 2/3 turn.

9. Start the engine and check for leakage

around the oil filter. Correct as required.

10. Turn the engine off and wait more than 10

minutes. Check the oil level. Add engine oil if

necessary.

VQ40DE

WDI0502

VK56DE

WDI0505

8-12Maintenance and do-it-yourself

Page 407 of 463

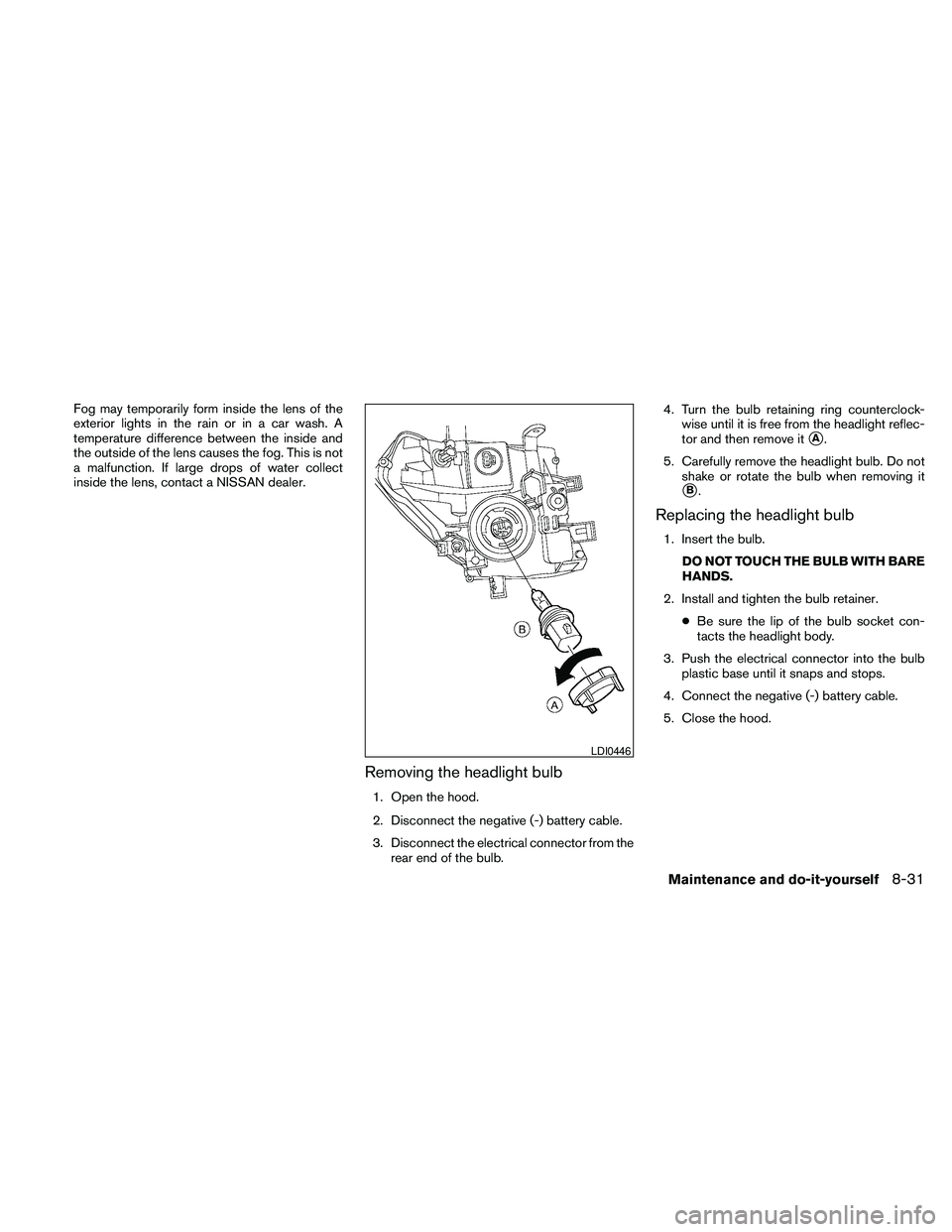

Fog may temporarily form inside the lens of the

exterior lights in the rain or in a car wash. A

temperature difference between the inside and

the outside of the lens causes the fog. This is not

a malfunction. If large drops of water collect

inside the lens, contact a NISSAN dealer.

Removing the headlight bulb

1. Open the hood.

2. Disconnect the negative (-) battery cable.

3. Disconnect the electrical connector from the

rear end of the bulb.4. Turn the bulb retaining ring counterclock-

wise until it is free from the headlight reflec-

tor and then remove it

sA.

5. Carefully remove the headlight bulb. Do not

shake or rotate the bulb when removing it

sB.

Replacing the headlight bulb

1. Insert the bulb.

DO NOT TOUCH THE BULB WITH BARE

HANDS.

2. Install and tighten the bulb retainer.

cBe sure the lip of the bulb socket con-

tacts the headlight body.

3. Push the electrical connector into the bulb

plastic base until it snaps and stops.

4. Connect the negative (-) battery cable.

5. Close the hood.

LDI0446

Maintenance and do-it-yourself8-31

Page 446 of 463

WARNING

Never connect a trailer brake system di-

rectly to the vehicle brake system.

Electric trailer brake controller

Trailers equipped with electric brakes may re-

quire the installation of an aftermarket trailer

brake controller.

A Genuine NISSAN jumper harness is available

that is specifically designed to be used when

installing an aftermarket brake controller.

Install the aftermarket electric trailer brake con-

troller according to the manufacturer’s instruc-

tions.

Pre-towing tips

cBe certain your vehicle maintains a level

position when a loaded and/or unloaded

trailer is hitched. Do not drive the vehicle if it

has an abnormal nose-up or nose-down

condition; check for improper tongue load,

overload, worn suspension or other possible

causes of either condition.

cAlways secure items in the trailer to prevent

load shift while driving.cKeep the cargo load as low as possible in

the trailer to keep the trailer center of gravity

low.

cLoad the trailer so approximately 60% of the

trailer load is in the front half and 40% is in

the back half. Also make sure the load is

balanced side to side.

cCheck your hitch, trailer tire pressure, ve-

hicle tire pressure, trailer light operation, and

trailer wheel lug nuts every time you attach a

trailer to the vehicle.

cBe certain your rearview mirrors conform to

all federal, state or local regulations. If not,

install any mirrors required for towing before

driving the vehicle.

cDetermine the overall height of the vehicle

and trailer so the required clearance is

known.

Trailer towing tips

In order to gain skill and an understanding of the

vehicle’s behavior, you should practice turning,

stopping and backing up in an area which is free

from traffic. Steering stability and braking perfor-

mance will be somewhat different than under

normal driving conditions.

cAlways secure items in the trailer to prevent

load shift while driving.cLock the trailer hitch coupler with a pin or

lock to prevent the coupler from inadvert-

ently becoming unlatched.

cAvoid abrupt starts, acceleration or stops.

cAvoid sharp turns or lane changes.

cAlways drive your vehicle at a moderate

speed.

cWhen backing up, hold the bottom of the

steering wheel with one hand. Move your

hand in the direction in which you want the

trailer to go. Make small corrections and

back up slowly. If possible, have someone

guide you when you are backing up.

Always block the wheels on both vehicle and

trailer when parking. Parking on a slope is not

recommended; however, if you must do so:

CAUTION

If you move the shift selector to the P

(Park) position before blocking the

wheels and applying the parking brake,

transmission damage could occur.

1. Apply and hold the brake pedal.

2. Have someone place blocks on the downhill

side of the vehicle and trailer wheels.

9-24Technical and consumer information