check engine NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 489 of 1033

Diagnostic Procedure

1 CHECK OVERALL FUNCTION

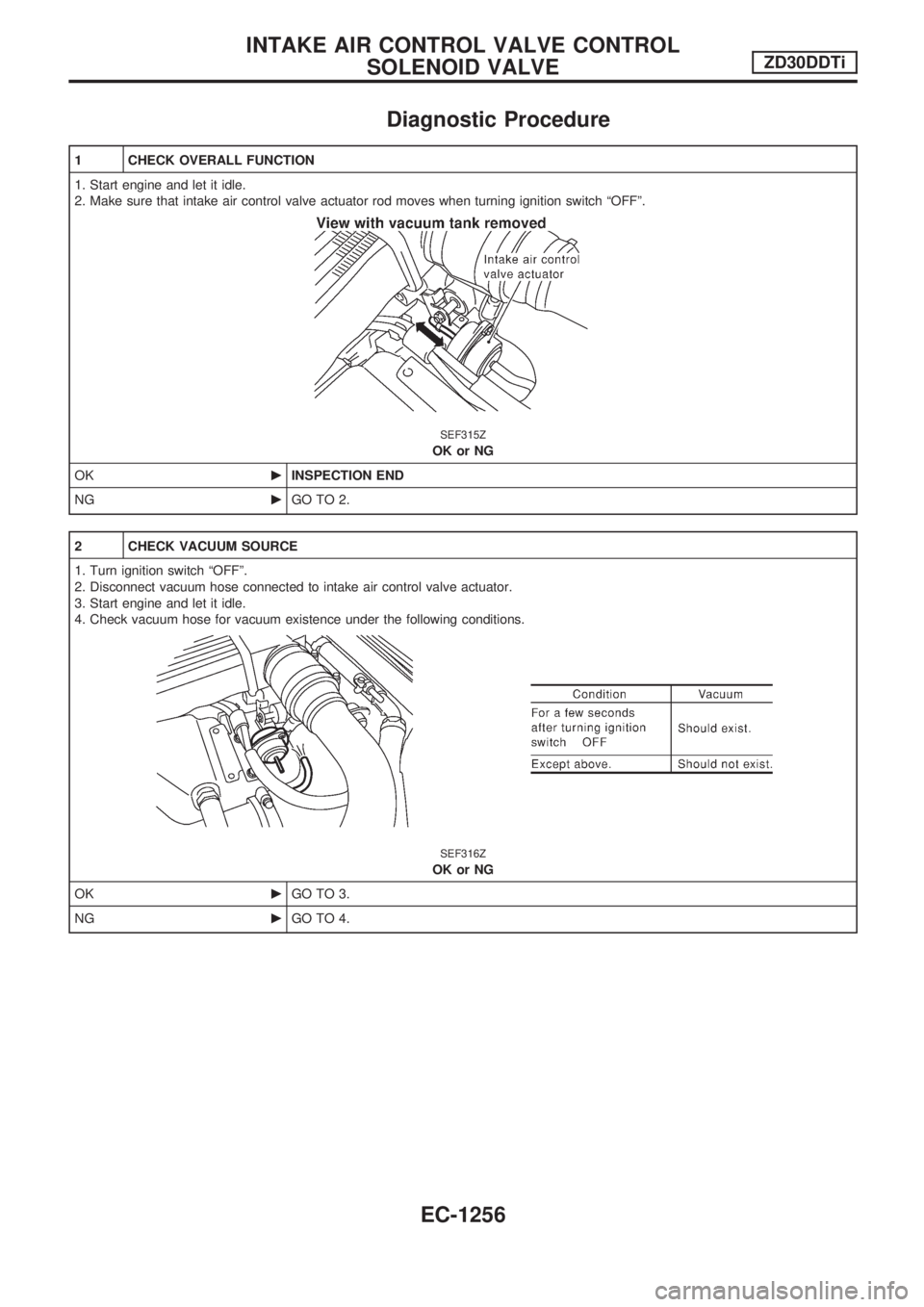

1. Start engine and let it idle.

2. Make sure that intake air control valve actuator rod moves when turning ignition switch ªOFFº.

SEF315Z

OK or NG

OKcINSPECTION END

NGcGO TO 2.

2 CHECK VACUUM SOURCE

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum hose connected to intake air control valve actuator.

3. Start engine and let it idle.

4. Check vacuum hose for vacuum existence under the following conditions.

SEF316Z

OK or NG

OKcGO TO 3.

NGcGO TO 4.

INTAKE AIR CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1256

Page 497 of 1033

Diagnostic Procedure

1 CHECK OVERALL FUNCTION

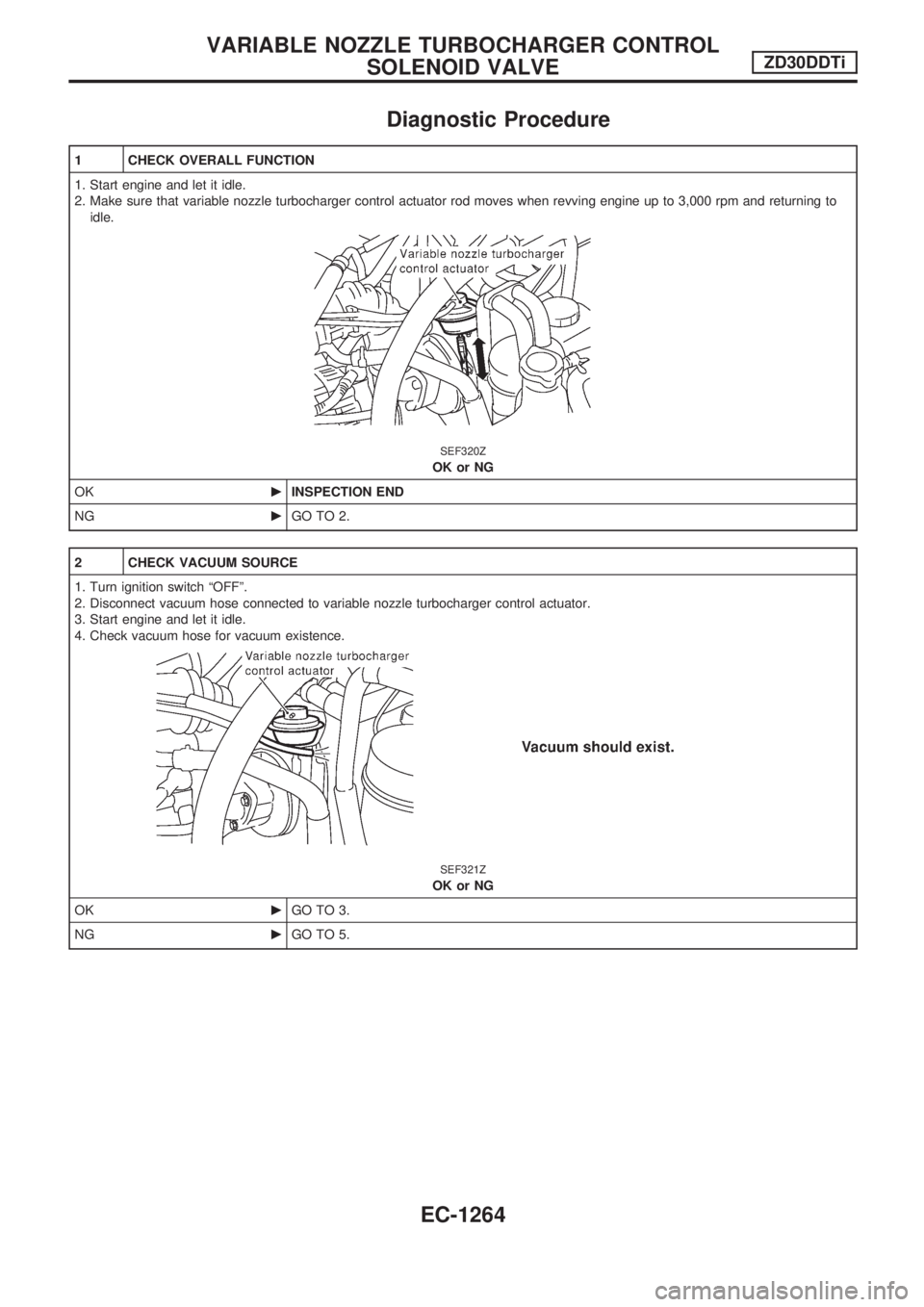

1. Start engine and let it idle.

2. Make sure that variable nozzle turbocharger control actuator rod moves when revving engine up to 3,000 rpm and returning to

idle.

SEF320Z

OK or NG

OKcINSPECTION END

NGcGO TO 2.

2 CHECK VACUUM SOURCE

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum hose connected to variable nozzle turbocharger control actuator.

3. Start engine and let it idle.

4. Check vacuum hose for vacuum existence.

SEF321Z

OK or NG

OKcGO TO 3.

NGcGO TO 5.

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

EC-1264

Page 504 of 1033

Diagnostic Procedure

1 INSPECTION START

Do you have CONSULT-II?

Yes or No

YescGO TO 2.

NocGO TO 3.

2 CHECK OVERALL FUNCTION-I

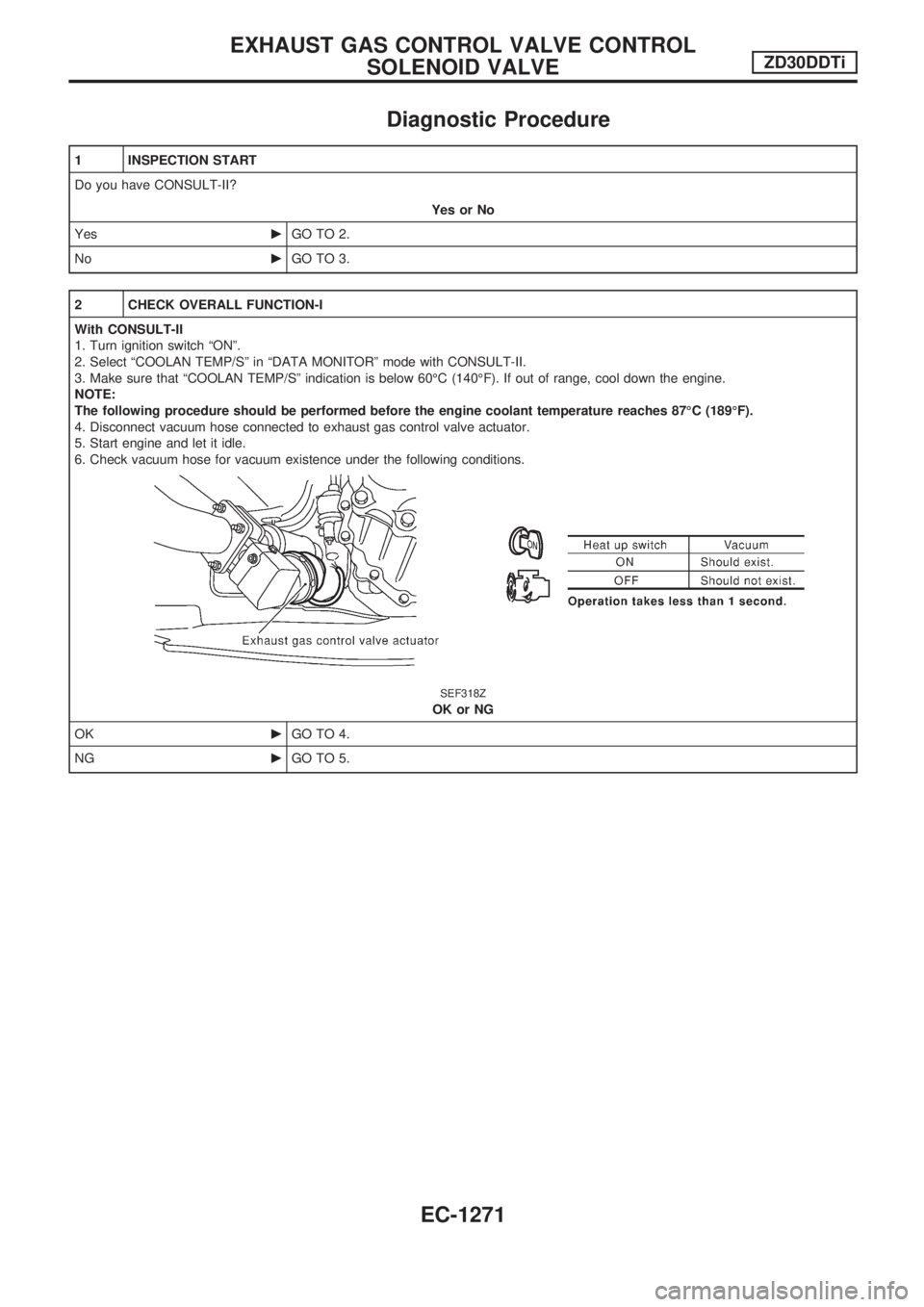

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªCOOLAN TEMP/Sº in ªDATA MONITORº mode with CONSULT-II.

3. Make sure that ªCOOLAN TEMP/Sº indication is below 60ÉC (140ÉF). If out of range, cool down the engine.

NOTE:

The following procedure should be performed before the engine coolant temperature reaches 87ÉC (189ÉF).

4. Disconnect vacuum hose connected to exhaust gas control valve actuator.

5. Start engine and let it idle.

6. Check vacuum hose for vacuum existence under the following conditions.

SEF318Z

OK or NG

OKcGO TO 4.

NGcGO TO 5.

EXHAUST GAS CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1271

Page 505 of 1033

3 CHECK OVERALL FUNCTION-I

Without CONSULT-II

7. Turn ignition switch ªONº.

8. Make sure that voltage between ECM terminal 19 and ground is more than 1.88V. If out of range, cool down the engine.

NOTE:

The following procedure should be performed before the voltage becomes less than 1.06V.

9. Disconnect vacuum hose connected to exhaust gas control valve actuator.

10. Start engine and let it idle.

11. Check vacuum hose for vacuum existence under the following conditions.

SEF318Z

OK or NG

OKcGO TO 4.

NGcGO TO 5.

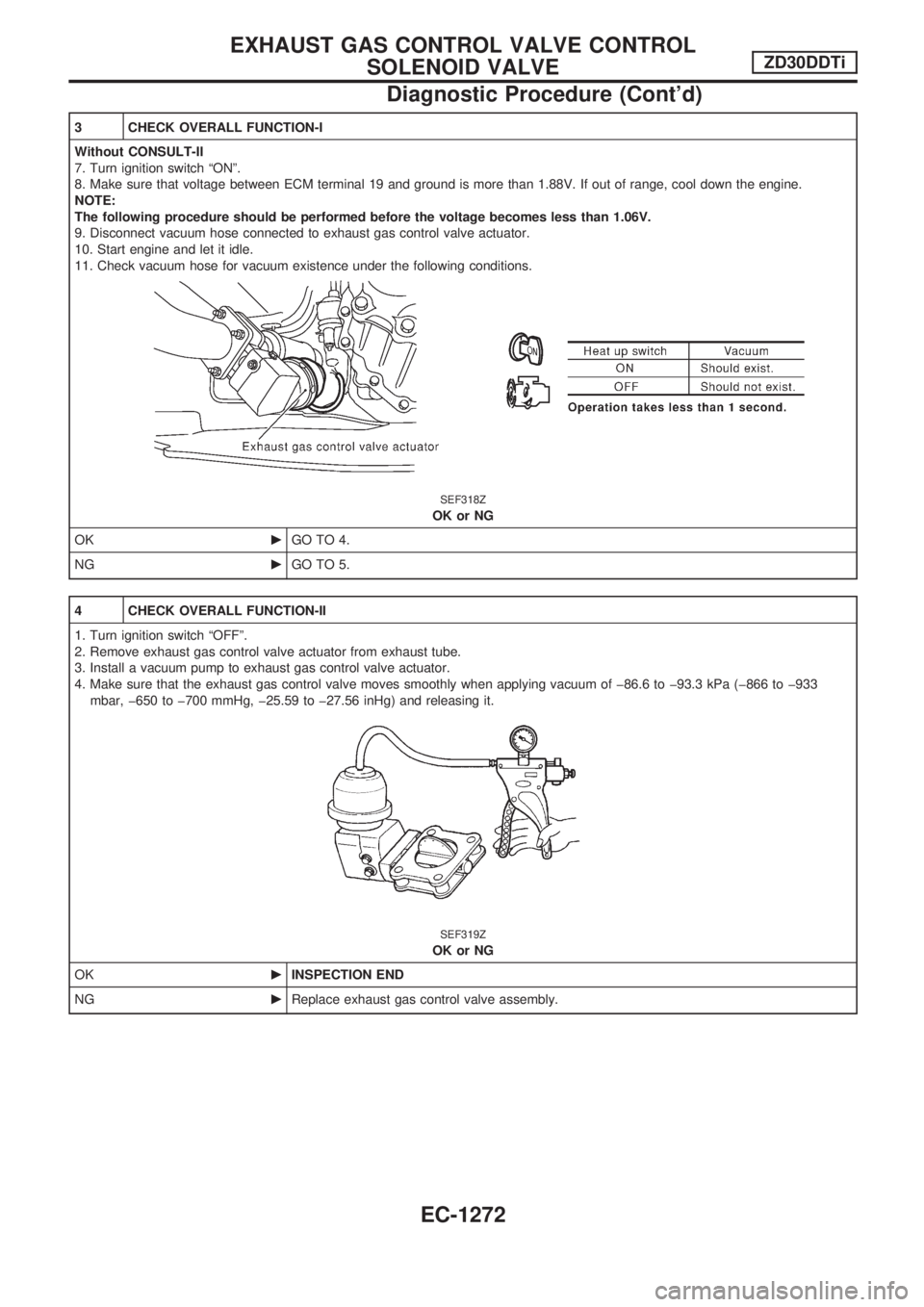

4 CHECK OVERALL FUNCTION-II

1. Turn ignition switch ªOFFº.

2. Remove exhaust gas control valve actuator from exhaust tube.

3. Install a vacuum pump to exhaust gas control valve actuator.

4. Make sure that the exhaust gas control valve moves smoothly when applying vacuum of þ86.6 to þ93.3 kPa (þ866 to þ933

mbar, þ650 to þ700 mmHg, þ25.59 to þ27.56 inHg) and releasing it.

SEF319Z

OK or NG

OKcINSPECTION END

NGcReplace exhaust gas control valve assembly.

EXHAUST GAS CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1272

Page 511 of 1033

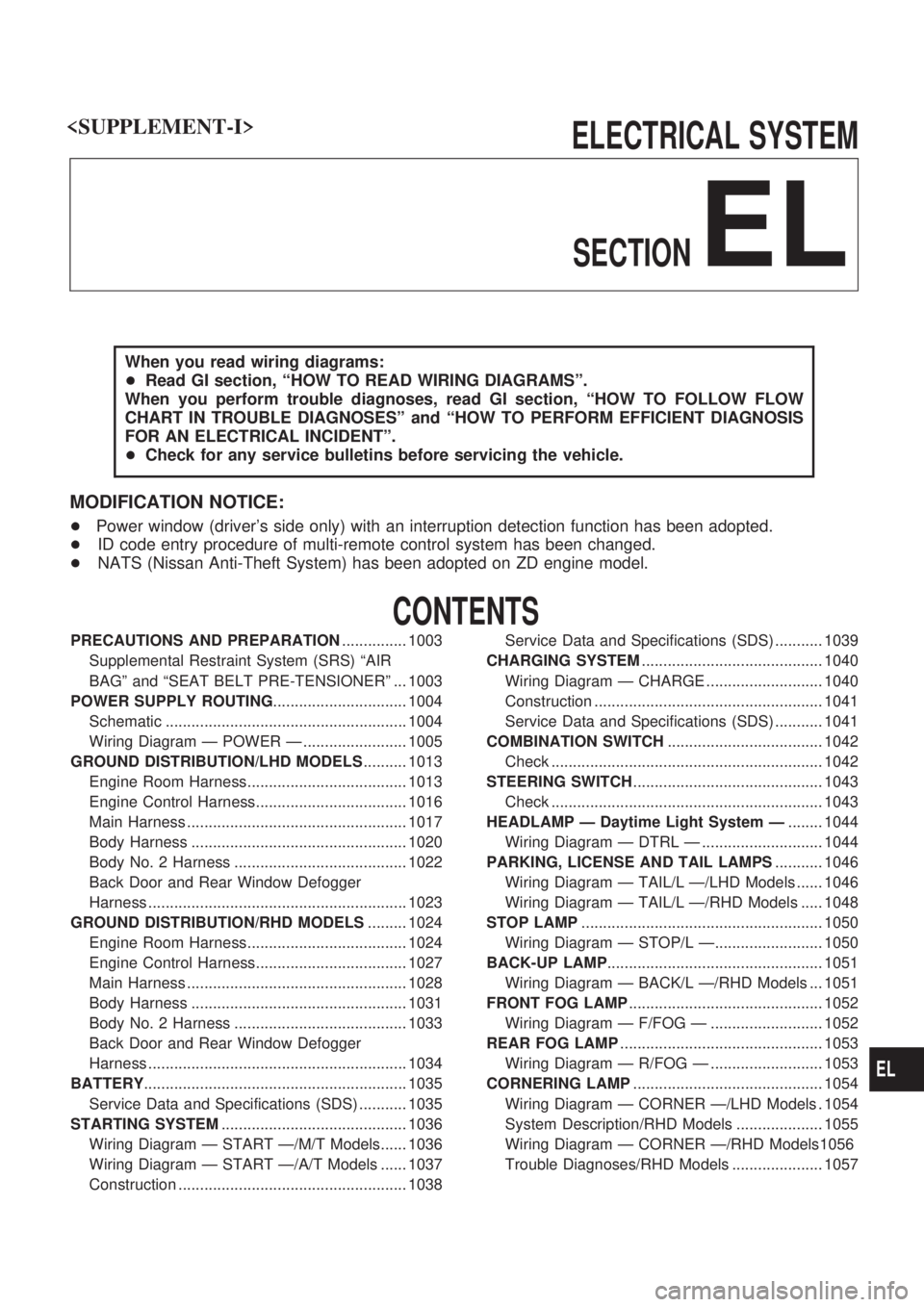

ELECTRICAL SYSTEM

SECTION

EL

When you read wiring diagrams:

+Read GI section, ªHOW TO READ WIRING DIAGRAMSº.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENTº.

+Check for any service bulletins before servicing the vehicle.

MODIFICATION NOTICE:

+Power window (driver's side only) with an interruption detection function has been adopted.

+ID code entry procedure of multi-remote control system has been changed.

+NATS (Nissan Anti-Theft System) has been adopted on ZD engine model.

CONTENTS

PRECAUTIONS AND PREPARATION............... 1003

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº ... 1003

POWER SUPPLY ROUTING............................... 1004

Schematic ........................................................ 1004

Wiring Diagram Ð POWER Ð ........................ 1005

GROUND DISTRIBUTION/LHD MODELS.......... 1013

Engine Room Harness..................................... 1013

Engine Control Harness................................... 1016

Main Harness ................................................... 1017

Body Harness .................................................. 1020

Body No. 2 Harness ........................................ 1022

Back Door and Rear Window Defogger

Harness ............................................................ 1023

GROUND DISTRIBUTION/RHD MODELS......... 1024

Engine Room Harness..................................... 1024

Engine Control Harness................................... 1027

Main Harness ................................................... 1028

Body Harness .................................................. 1031

Body No. 2 Harness ........................................ 1033

Back Door and Rear Window Defogger

Harness ............................................................ 1034

BATTERY............................................................. 1035

Service Data and Specifications (SDS) ........... 1035

STARTING SYSTEM........................................... 1036

Wiring Diagram Ð START Ð/M/T Models...... 1036

Wiring Diagram Ð START Ð/A/T Models ...... 1037

Construction ..................................................... 1038Service Data and Specifications (SDS) ........... 1039

CHARGING SYSTEM.......................................... 1040

Wiring Diagram Ð CHARGE ........................... 1040

Construction ..................................................... 1041

Service Data and Specifications (SDS) ........... 1041

COMBINATION SWITCH.................................... 1042

Check ............................................................... 1042

STEERING SWITCH............................................ 1043

Check ............................................................... 1043

HEADLAMP Ð Daytime Light System Ð........ 1044

Wiring Diagram Ð DTRL Ð ............................ 1044

PARKING, LICENSE AND TAIL LAMPS........... 1046

Wiring Diagram Ð TAIL/L Ð/LHD Models ...... 1046

Wiring Diagram Ð TAIL/L Ð/RHD Models ..... 1048

STOP LAMP........................................................ 1050

Wiring Diagram Ð STOP/L Ð......................... 1050

BACK-UP LAMP.................................................. 1051

Wiring Diagram Ð BACK/L Ð/RHD Models ... 1051

FRONT FOG LAMP............................................. 1052

Wiring Diagram Ð F/FOG Ð .......................... 1052

REAR FOG LAMP............................................... 1053

Wiring Diagram Ð R/FOG Ð .......................... 1053

CORNERING LAMP............................................ 1054

Wiring Diagram Ð CORNER Ð/LHD Models . 1054

System Description/RHD Models .................... 1055

Wiring Diagram Ð CORNER Ð/RHD Models1056

Trouble Diagnoses/RHD Models ..................... 1057

EL

Page 657 of 1033

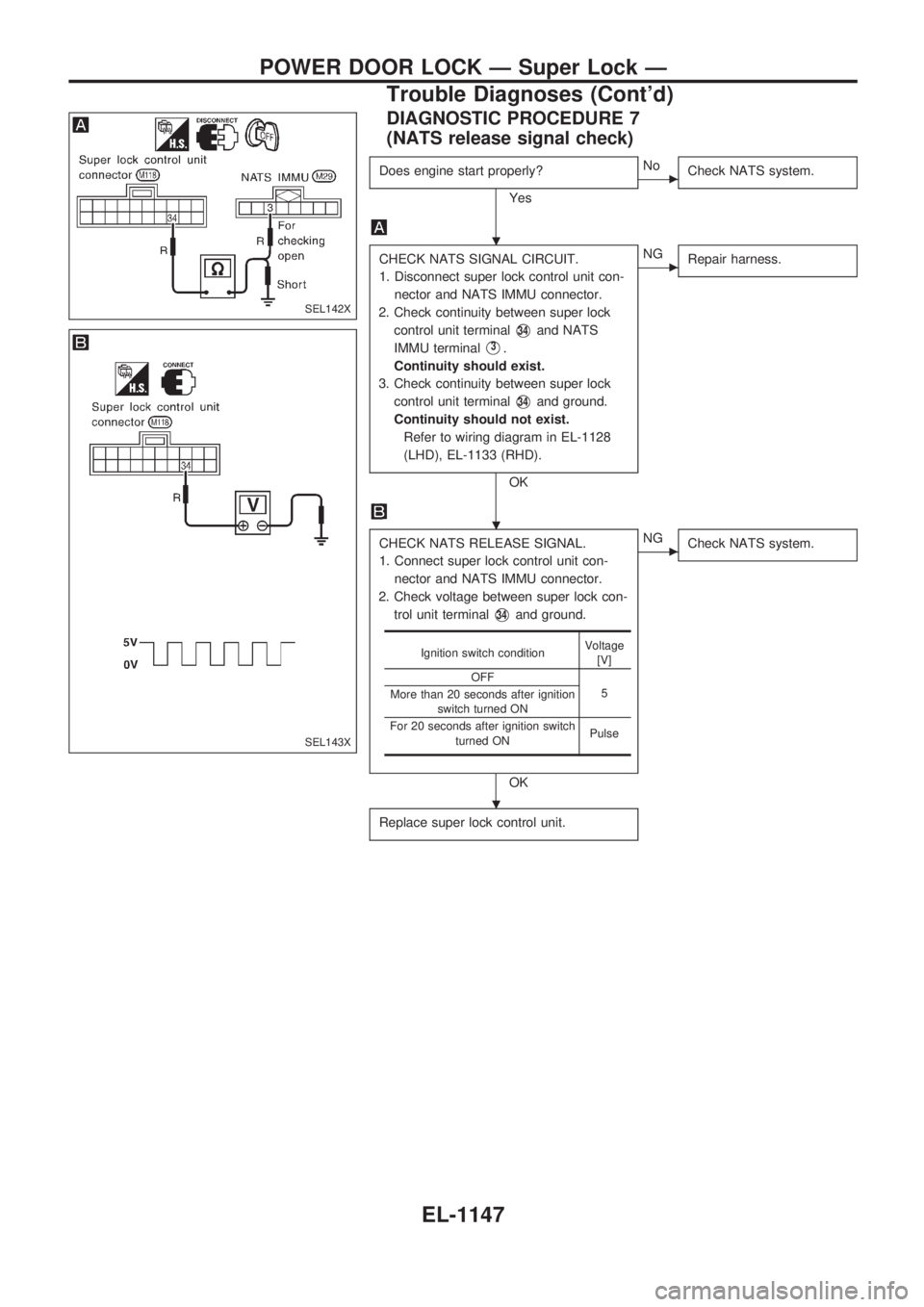

DIAGNOSTIC PROCEDURE 7

(NATS release signal check)

Does engine start properly?

Yes

cNo

Check NATS system.

CHECK NATS SIGNAL CIRCUIT.

1. Disconnect super lock control unit con-

nector and NATS IMMU connector.

2. Check continuity between super lock

control unit terminal

V34and NATS

IMMU terminal

V3.

Continuity should exist.

3. Check continuity between super lock

control unit terminal

V34and ground.

Continuity should not exist.

Refer to wiring diagram in EL-1128

(LHD), EL-1133 (RHD).

OK

cNG

Repair harness.

CHECK NATS RELEASE SIGNAL.

1. Connect super lock control unit con-

nector and NATS IMMU connector.

2. Check voltage between super lock con-

trol unit terminal

V34and ground.

OK

cNG

Check NATS system.

Replace super lock control unit.

Ignition switch conditionVoltage

[V]

OFF

5

More than 20 seconds after ignition

switch turned ON

For 20 seconds after ignition switch

turned ONPulse

SEL142X

SEL143X

.

.

.

POWER DOOR LOCK Ð Super Lock Ð

Trouble Diagnoses (Cont'd)

EL-1147

Page 681 of 1033

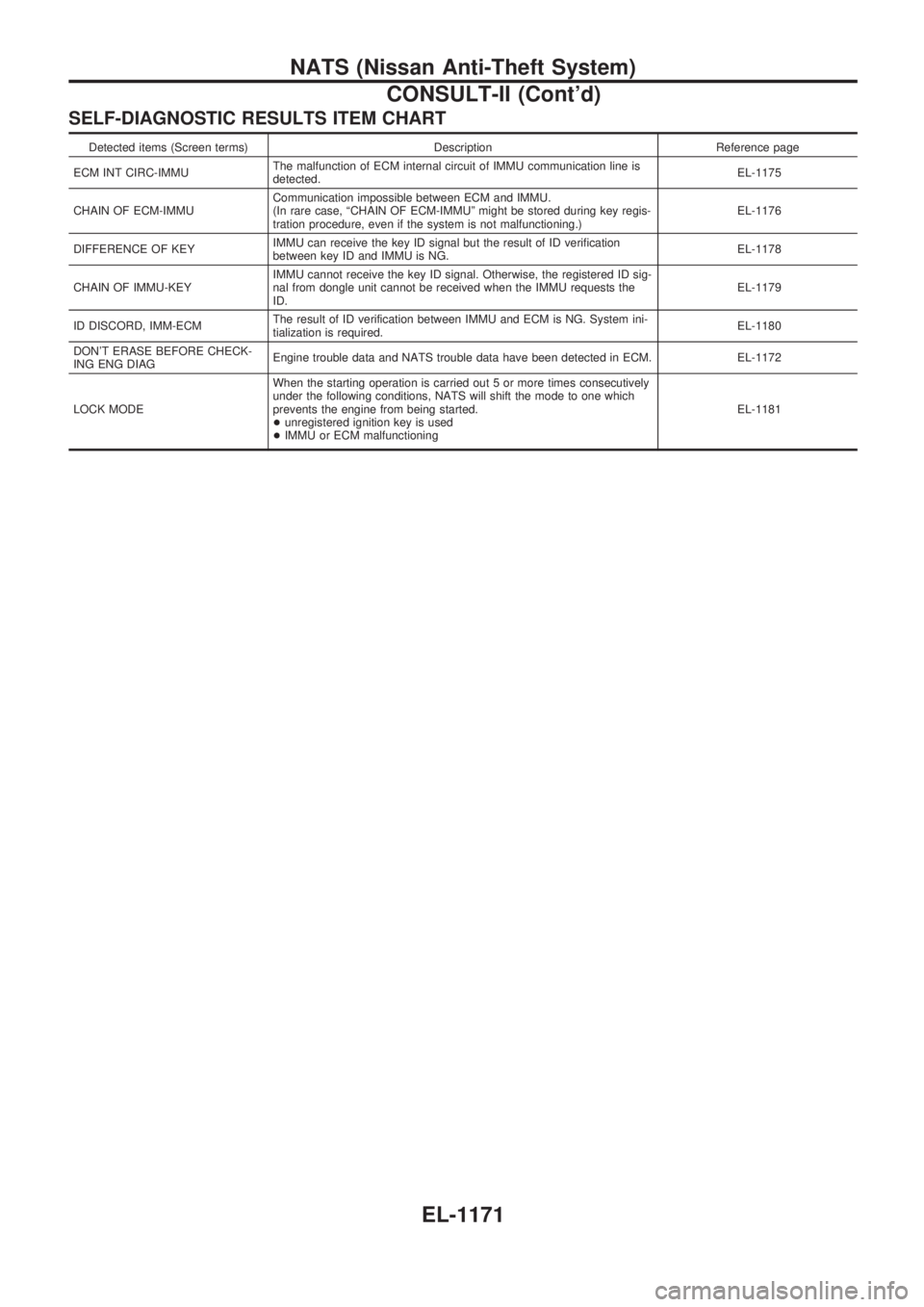

SELF-DIAGNOSTIC RESULTS ITEM CHART

Detected items (Screen terms) Description Reference page

ECM INT CIRC-IMMUThe malfunction of ECM internal circuit of IMMU communication line is

detected.EL-1175

CHAIN OF ECM-IMMUCommunication impossible between ECM and IMMU.

(In rare case, ªCHAIN OF ECM-IMMUº might be stored during key regis-

tration procedure, even if the system is not malfunctioning.)EL-1176

DIFFERENCE OF KEYIMMU can receive the key ID signal but the result of ID verification

between key ID and IMMU is NG.EL-1178

CHAIN OF IMMU-KEYIMMU cannot receive the key ID signal. Otherwise, the registered ID sig-

nal from dongle unit cannot be received when the IMMU requests the

ID.EL-1179

ID DISCORD, IMM-ECMThe result of ID verification between IMMU and ECM is NG. System ini-

tialization is required.EL-1180

DON'T ERASE BEFORE CHECK-

ING ENG DIAGEngine trouble data and NATS trouble data have been detected in ECM. EL-1172

LOCK MODEWhen the starting operation is carried out 5 or more times consecutively

under the following conditions, NATS will shift the mode to one which

prevents the engine from being started.

+unregistered ignition key is used

+IMMU or ECM malfunctioningEL-1181

NATS (Nissan Anti-Theft System)

CONSULT-II (Cont'd)

EL-1171

Page 682 of 1033

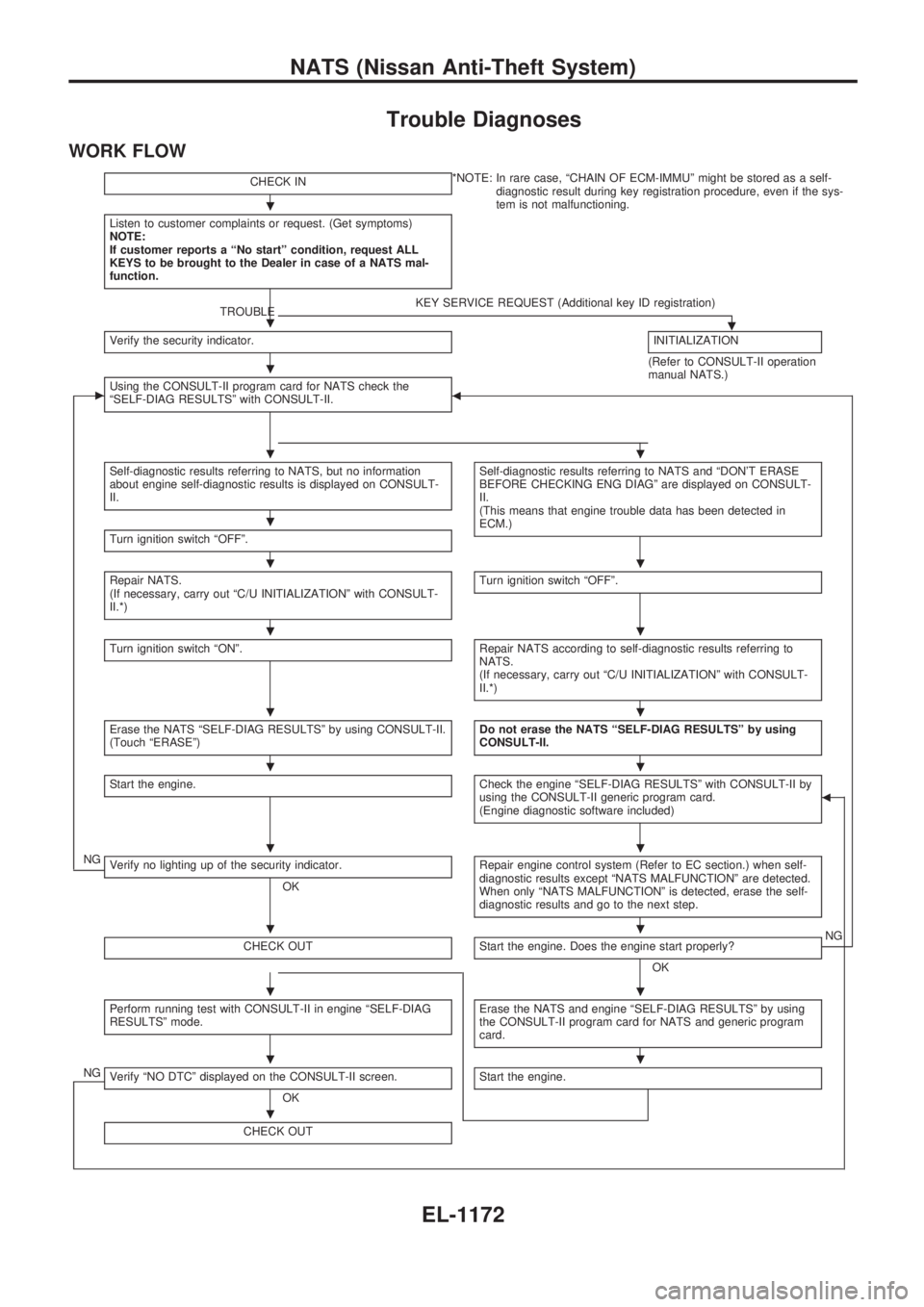

Trouble Diagnoses

WORK FLOW

CHECK IN*NOTE: In rare case, ªCHAIN OF ECM-IMMUº might be stored as a self-

diagnostic result during key registration procedure, even if the sys-

tem is not malfunctioning.

Listen to customer complaints or request. (Get symptoms)

NOTE:

If customer reports a ªNo startº condition, request ALL

KEYS to be brought to the Dealer in case of a NATS mal-

function.

TROUBLEKEY SERVICE REQUEST (Additional key ID registration).Verify the security indicator.INITIALIZATION

(Refer to CONSULT-II operation

manual NATS.)

cUsing the CONSULT-II program card for NATS check the

ªSELF-DIAG RESULTSº with CONSULT-II.b

Self-diagnostic results referring to NATS, but no information

about engine self-diagnostic results is displayed on CONSULT-

II.Self-diagnostic results referring to NATS and ªDON'T ERASE

BEFORE CHECKING ENG DIAGº are displayed on CONSULT-

II.

(This means that engine trouble data has been detected in

ECM.)

Turn ignition switch ªOFFº.

Repair NATS.

(If necessary, carry out ªC/U INITIALIZATIONº with CONSULT-

II.*)Turn ignition switch ªOFFº.

Turn ignition switch ªONº.Repair NATS according to self-diagnostic results referring to

NATS.

(If necessary, carry out ªC/U INITIALIZATIONº with CONSULT-

II.*)

Erase the NATS ªSELF-DIAG RESULTSº by using CONSULT-II.

(Touch ªERASEº)Do not erase the NATS ªSELF-DIAG RESULTSº by using

CONSULT-II.

Start the engine.Check the engine ªSELF-DIAG RESULTSº with CONSULT-II by

using the CONSULT-II generic program card.

(Engine diagnostic software included)b

NGVerify no lighting up of the security indicator.

OKRepair engine control system (Refer to EC section.) when self-

diagnostic results except ªNATS MALFUNCTIONº are detected.

When only ªNATS MALFUNCTIONº is detected, erase the self-

diagnostic results and go to the next step.

CHECK OUTStart the engine. Does the engine start properly?

OKNG

Perform running test with CONSULT-II in engine ªSELF-DIAG

RESULTSº mode.Erase the NATS and engine ªSELF-DIAG RESULTSº by using

the CONSULT-II program card for NATS and generic program

card.

NGVerify ªNO DTCº displayed on the CONSULT-II screen.

OKStart the engine.

CHECK OUT

.

.

.

..

.

..

..

..

..

..

..

..

..

.

NATS (Nissan Anti-Theft System)

EL-1172

Page 683 of 1033

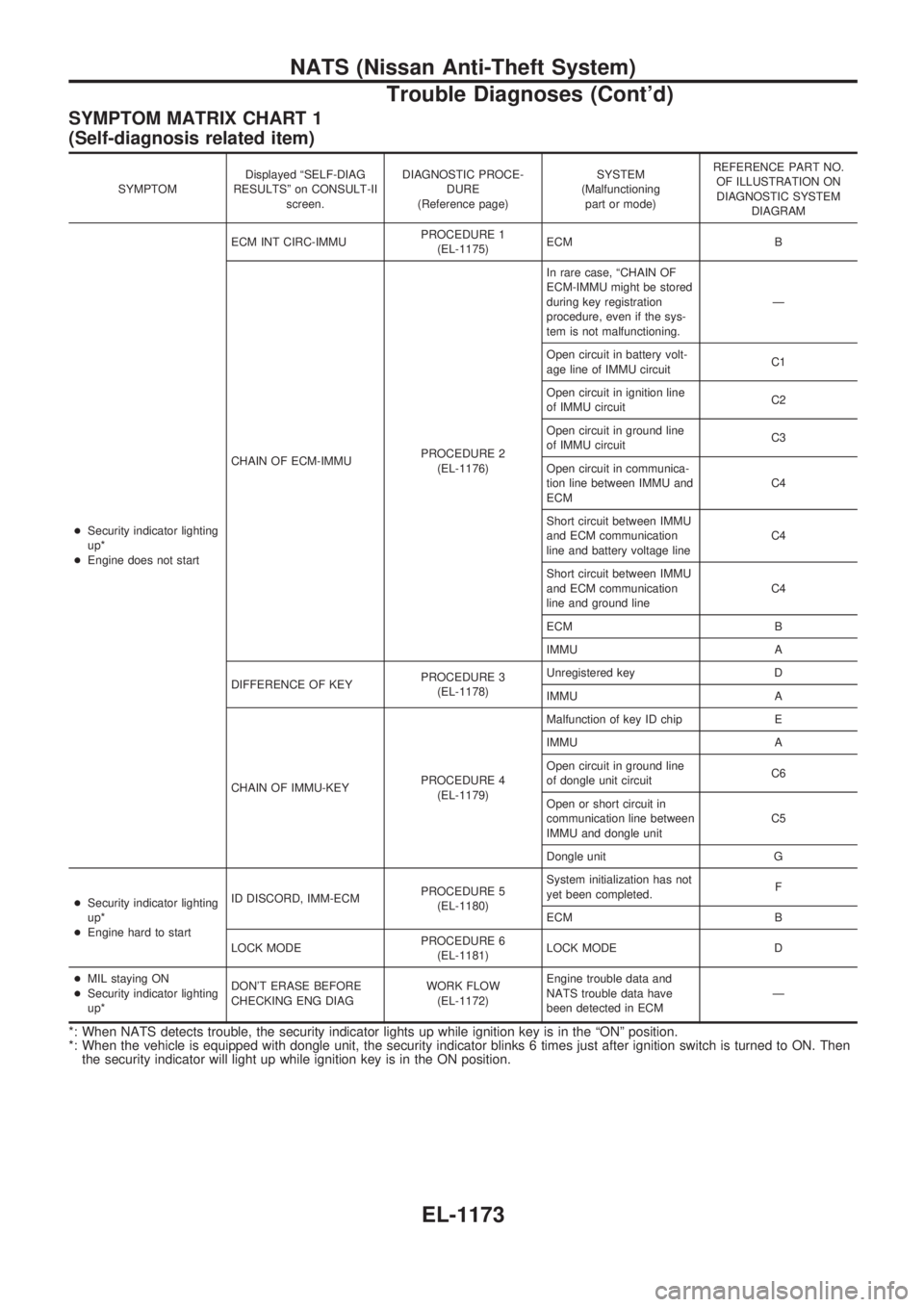

SYMPTOM MATRIX CHART 1

(Self-diagnosis related item)

SYMPTOMDisplayed ªSELF-DIAG

RESULTSº on CONSULT-II

screen.DIAGNOSTIC PROCE-

DURE

(Reference page)SYSTEM

(Malfunctioning

part or mode)REFERENCE PART NO.

OF ILLUSTRATION ON

DIAGNOSTIC SYSTEM

DIAGRAM

+Security indicator lighting

up*

+Engine does not startECM INT CIRC-IMMUPROCEDURE 1

(EL-1175)ECM B

CHAIN OF ECM-IMMUPROCEDURE 2

(EL-1176)In rare case, ªCHAIN OF

ECM-IMMU might be stored

during key registration

procedure, even if the sys-

tem is not malfunctioning.Ð

Open circuit in battery volt-

age line of IMMU circuitC1

Open circuit in ignition line

of IMMU circuitC2

Open circuit in ground line

of IMMU circuitC3

Open circuit in communica-

tion line between IMMU and

ECMC4

Short circuit between IMMU

and ECM communication

line and battery voltage lineC4

Short circuit between IMMU

and ECM communication

line and ground lineC4

ECM B

IMMU A

DIFFERENCE OF KEYPROCEDURE 3

(EL-1178)Unregistered key D

IMMU A

CHAIN OF IMMU-KEYPROCEDURE 4

(EL-1179)Malfunction of key ID chip E

IMMU A

Open circuit in ground line

of dongle unit circuitC6

Open or short circuit in

communication line between

IMMU and dongle unitC5

Dongle unit G

+Security indicator lighting

up*

+Engine hard to startID DISCORD, IMM-ECMPROCEDURE 5

(EL-1180)System initialization has not

yet been completed.F

ECM B

LOCK MODEPROCEDURE 6

(EL-1181)LOCK MODE D

+MIL staying ON

+Security indicator lighting

up*DON'T ERASE BEFORE

CHECKING ENG DIAGWORK FLOW

(EL-1172)Engine trouble data and

NATS trouble data have

been detected in ECMÐ

*: When NATS detects trouble, the security indicator lights up while ignition key is in the ªONº position.

*: When the vehicle is equipped with dongle unit, the security indicator blinks 6 times just after ignition switch is turned to ON. Then

the security indicator will light up while ignition key is in the ON position.

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-1173

Page 689 of 1033

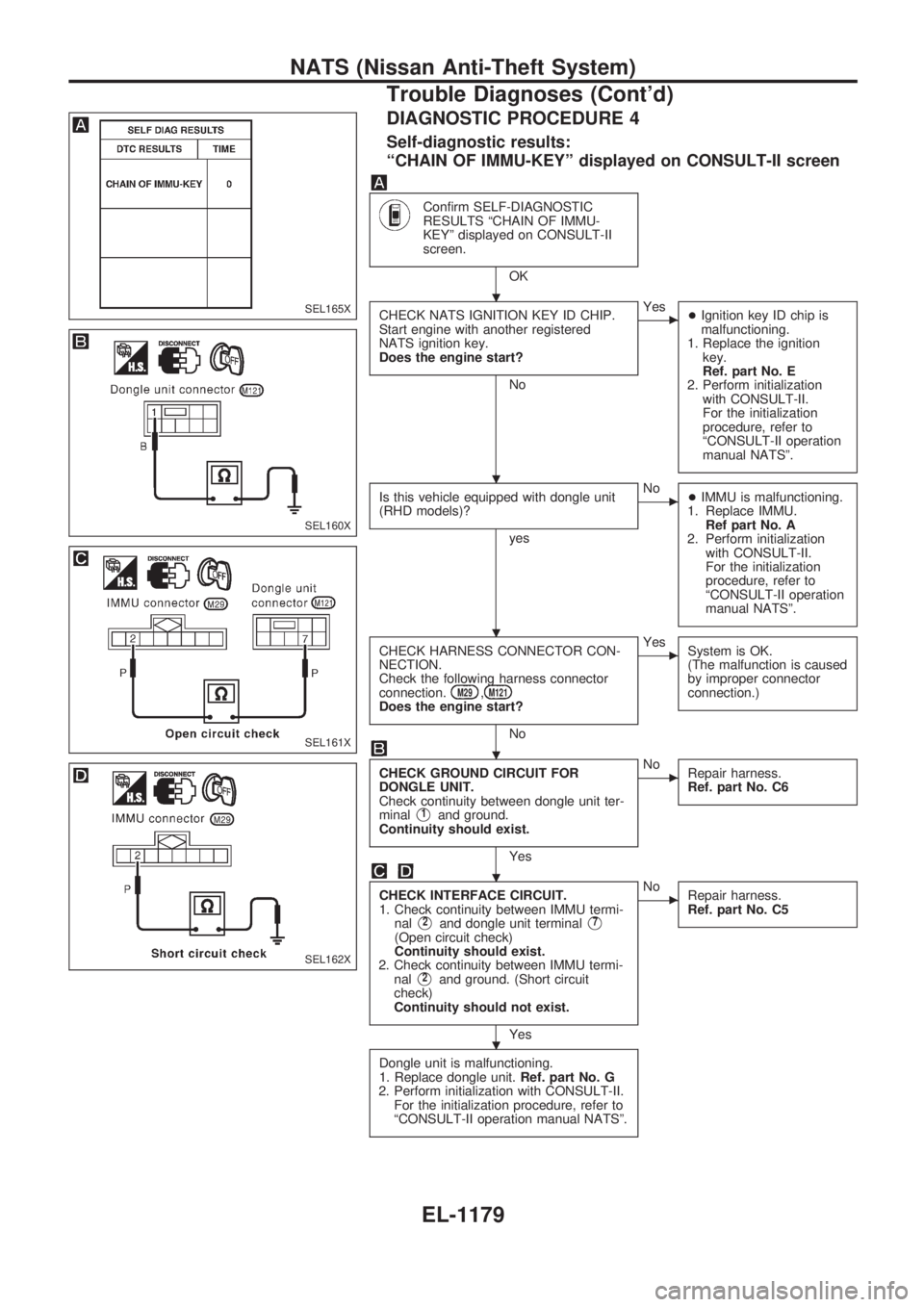

DIAGNOSTIC PROCEDURE 4

Self-diagnostic results:

ªCHAIN OF IMMU-KEYº displayed on CONSULT-II screen

Confirm SELF-DIAGNOSTIC

RESULTS ªCHAIN OF IMMU-

KEYº displayed on CONSULT-II

screen.

OK

CHECK NATS IGNITION KEY ID CHIP.

Start engine with another registered

NATS ignition key.

Does the engine start?

No

cYes

+Ignition key ID chip is

malfunctioning.

1. Replace the ignition

key.

Ref. part No. E

2. Perform initialization

with CONSULT-II.

For the initialization

procedure, refer to

ªCONSULT-II operation

manual NATSº.

Is this vehicle equipped with dongle unit

(RHD models)?

yes

cNo

+IMMU is malfunctioning.

1. Replace IMMU.

Ref part No. A

2. Perform initialization

with CONSULT-II.

For the initialization

procedure, refer to

ªCONSULT-II operation

manual NATSº.

CHECK HARNESS CONNECTOR CON-

NECTION.

Check the following harness connector

connection.

M29,M121Does the engine start?

No

cYes

System is OK.

(The malfunction is caused

by improper connector

connection.)

CHECK GROUND CIRCUIT FOR

DONGLE UNIT.

Check continuity between dongle unit ter-

minal

V1and ground.

Continuity should exist.

Yes

cNo

Repair harness.

Ref. part No. C6

CHECK INTERFACE CIRCUIT.

1. Check continuity between IMMU termi-

nal

V2and dongle unit terminalV7

(Open circuit check)

Continuity should exist.

2. Check continuity between IMMU termi-

nal

V2and ground. (Short circuit

check)

Continuity should not exist.

Yes

cNo

Repair harness.

Ref. part No. C5

Dongle unit is malfunctioning.

1. Replace dongle unit.Ref. part No. G

2. Perform initialization with CONSULT-II.

For the initialization procedure, refer to

ªCONSULT-II operation manual NATSº.

SEL165X

SEL160X

SEL161X

SEL162X

.

.

.

.

.

.

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-1179