ABS NISSAN PATROL 2000 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 848 of 1033

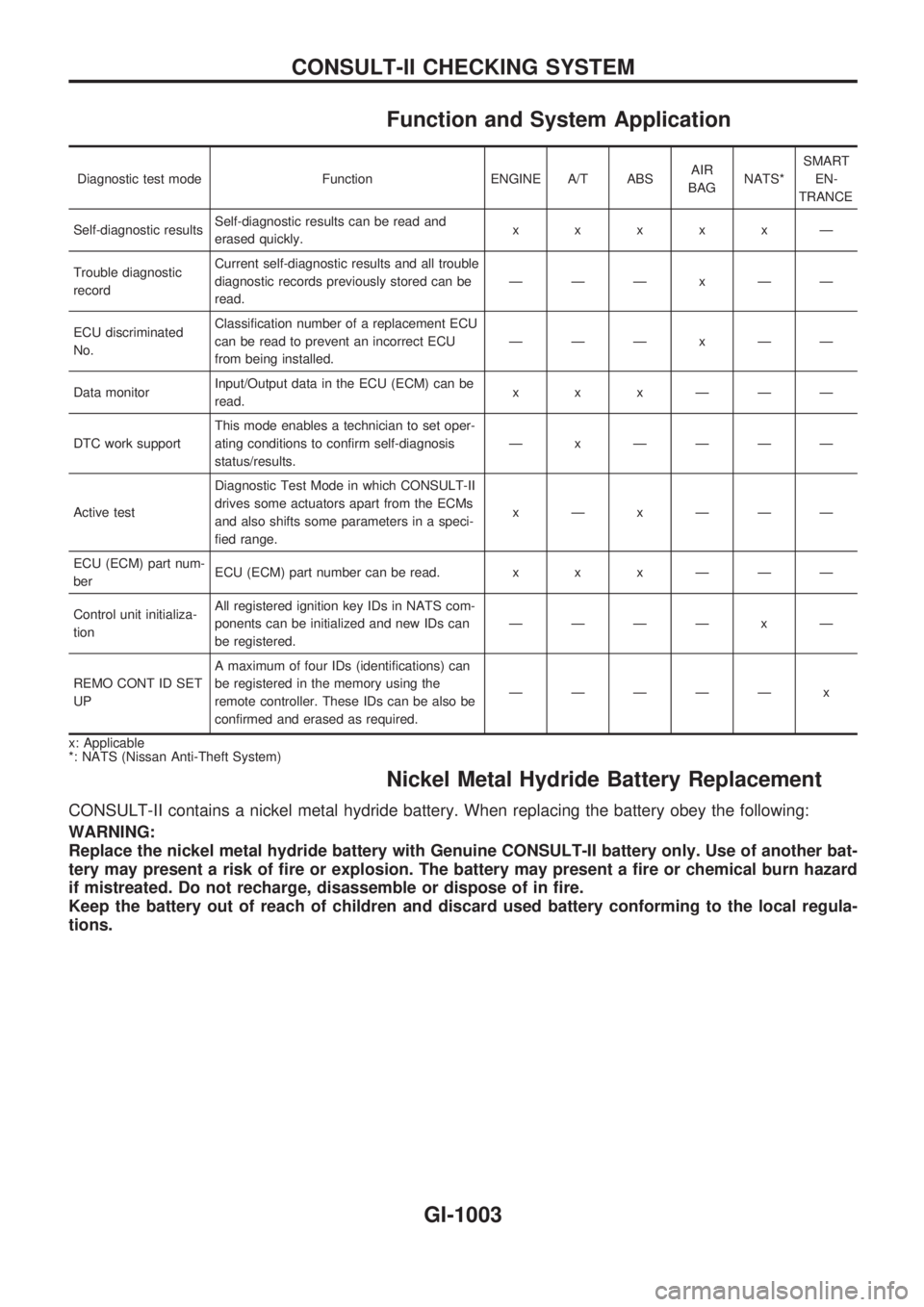

Function and System Application

Diagnostic test mode Function ENGINE A/T ABSAIR

BAGNATS*SMART

EN-

TRANCE

Self-diagnostic resultsSelf-diagnostic results can be read and

erased quickly.xxxxxÐ

Trouble diagnostic

recordCurrent self-diagnostic results and all trouble

diagnostic records previously stored can be

read.ÐÐÐxÐÐ

ECU discriminated

No.Classification number of a replacement ECU

can be read to prevent an incorrect ECU

from being installed.ÐÐÐxÐÐ

Data monitorInput/Output data in the ECU (ECM) can be

read.xxxÐÐÐ

DTC work supportThis mode enables a technician to set oper-

ating conditions to confirm self-diagnosis

status/results.Ð x ÐÐÐÐ

Active testDiagnostic Test Mode in which CONSULT-II

drives some actuators apart from the ECMs

and also shifts some parameters in a speci-

fied range.xÐxÐÐÐ

ECU (ECM) part num-

berECU (ECM) part number can be read. x x x Ð Ð Ð

Control unit initializa-

tionAll registered ignition key IDs in NATS com-

ponents can be initialized and new IDs can

be registered.ÐÐÐÐ x Ð

REMO CONT ID SET

UPA maximum of four IDs (identifications) can

be registered in the memory using the

remote controller. These IDs can be also be

confirmed and erased as required.ÐÐÐÐÐ x

x: Applicable

*: NATS (Nissan Anti-Theft System)

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with Genuine CONSULT-II battery only. Use of another bat-

tery may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard

if mistreated. Do not recharge, disassemble or dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regula-

tions.

CONSULT-II CHECKING SYSTEM

GI-1003

Page 894 of 1033

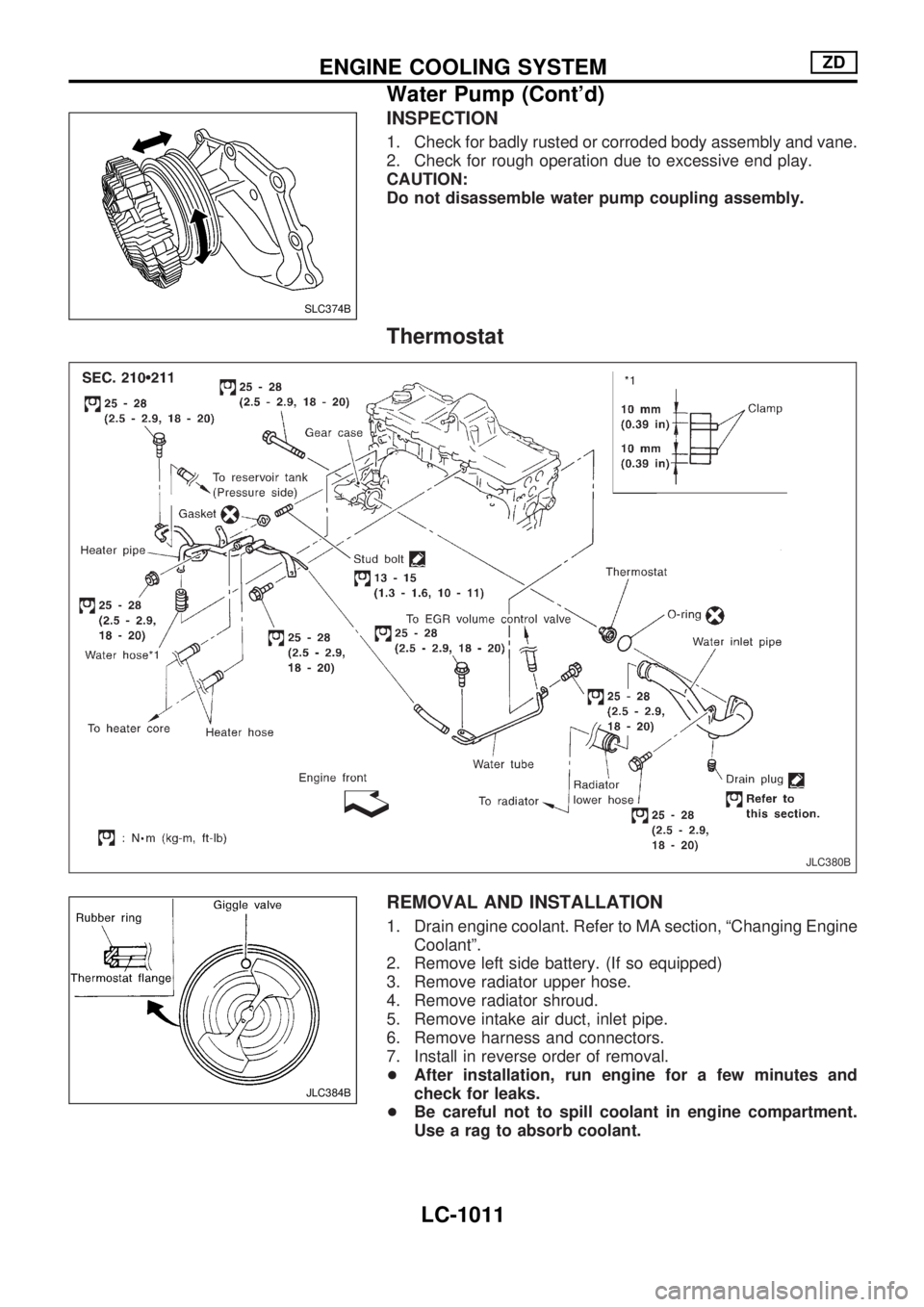

INSPECTION

1. Check for badly rusted or corroded body assembly and vane.

2. Check for rough operation due to excessive end play.

CAUTION:

Do not disassemble water pump coupling assembly.

Thermostat

REMOVAL AND INSTALLATION

1. Drain engine coolant. Refer to MA section, ªChanging Engine

Coolantº.

2. Remove left side battery. (If so equipped)

3. Remove radiator upper hose.

4. Remove radiator shroud.

5. Remove intake air duct, inlet pipe.

6. Remove harness and connectors.

7. Install in reverse order of removal.

+After installation, run engine for a few minutes and

check for leaks.

+Be careful not to spill coolant in engine compartment.

Use a rag to absorb coolant.

SLC374B

JLC380B

JLC384B

ENGINE COOLING SYSTEMZD

Water Pump (Cont'd)

LC-1011

Page 915 of 1033

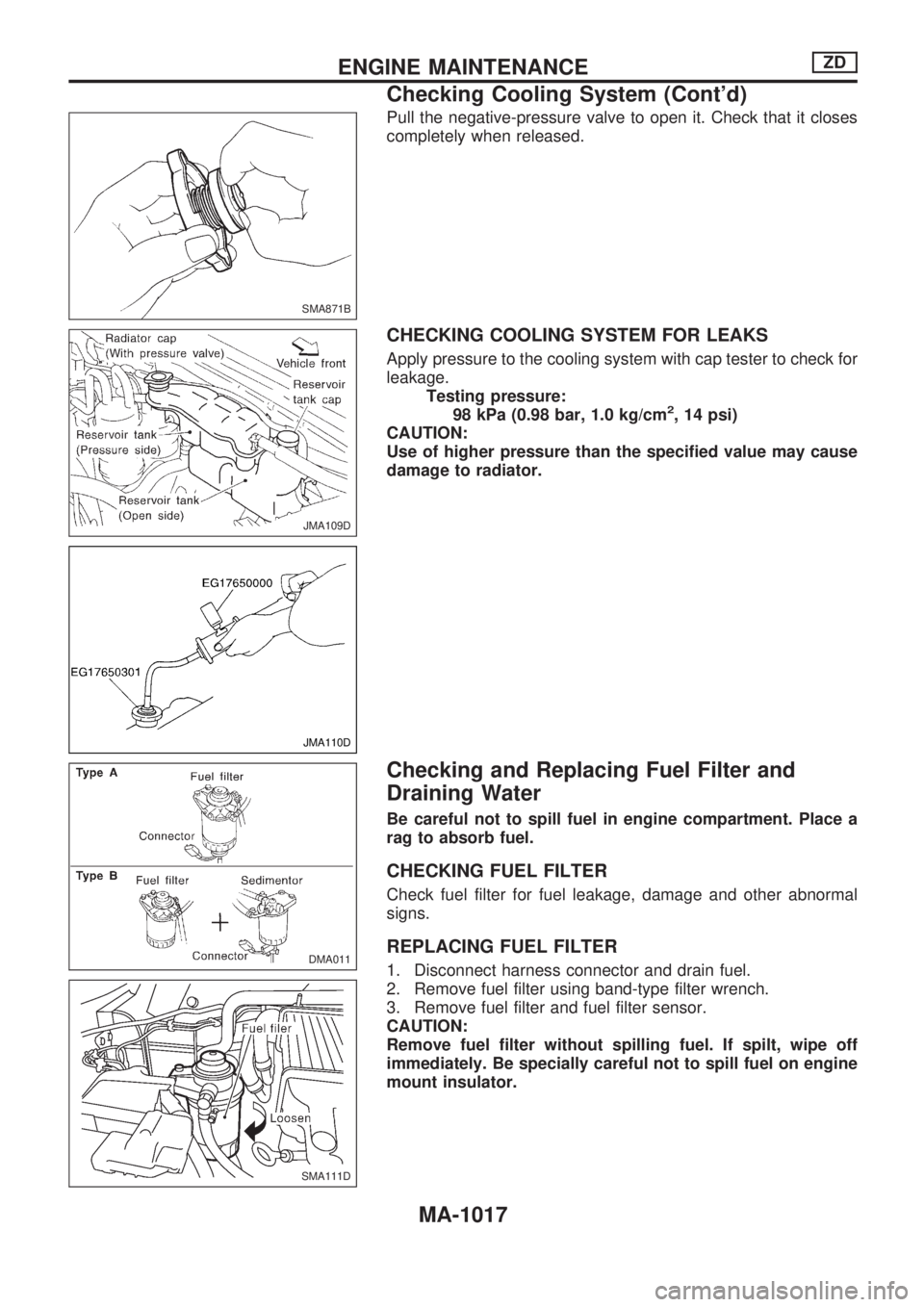

Pull the negative-pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system with cap tester to check for

leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Use of higher pressure than the specified value may cause

damage to radiator.

Checking and Replacing Fuel Filter and

Draining Water

Be careful not to spill fuel in engine compartment. Place a

rag to absorb fuel.

CHECKING FUEL FILTER

Check fuel filter for fuel leakage, damage and other abnormal

signs.

REPLACING FUEL FILTER

1. Disconnect harness connector and drain fuel.

2. Remove fuel filter using band-type filter wrench.

3. Remove fuel filter and fuel filter sensor.

CAUTION:

Remove fuel filter without spilling fuel. If spilt, wipe off

immediately. Be specially careful not to spill fuel on engine

mount insulator.

SMA871B

JMA109D

JMA110D

DMA011

SMA111D

ENGINE MAINTENANCEZD

Checking Cooling System (Cont'd)

MA-1017