engine oil NISSAN PATROL 2000 Electronic Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 910 of 1033

Removal

WATER PUMP, ALTERNATOR AND AIR

CONDITIONER BELT

1. Remove radiator shroud.

2. Contract and hold the auto tensioner using the following pro-

cedure.

a. Securely hold the 19 mm (0.75 in) hexagonal portion A of

auto tensioner with a closed wrench.

+Preferably use a tool with a handhold of 500 mm (19.69 in)

or more in length.

+No bolts or nuts are required to be loosened during the

operation.

b. Turn the hexagonal portion A in the direction shown by the

arrow to contract the damper unit of the auto tensioner.

CAUTION:

+Because the tensioner has a high tension, it shall be

securely held and turned with a closed wrench.

+Because the hexagonal portion A of the tensioner is

made of aluminum and may be damaged by sudden

input, turn it slowly according to the contraction of the

damper unit.

3. Remove the belt from the alternator pulley first, and then

remove it from the other pulleys.

+If the tensioner is not held firmly, your finger may get caught

between the belt and the pulleys. Confirm the holding of the

tensioner, and then hold the belt side in the place away from

the pulleys to attach or remove the belt, paying attention to

prevent your finger from being caught.

CAUTION:

+When handling the belt, pay attention to prevent the oil

or coolant from adhering to the belt.

+Do not distort or bend the belt intensively.

Installation

+Install the belt in the reverse order of removal.

+After installation of the belt, confirm that the belt engages the

pulleys securely.

+Depending on the engagement between the belt and the idler

pulley, noise (belt noise) may be heard when the engine is

started just after installation. This noise will stop with time.

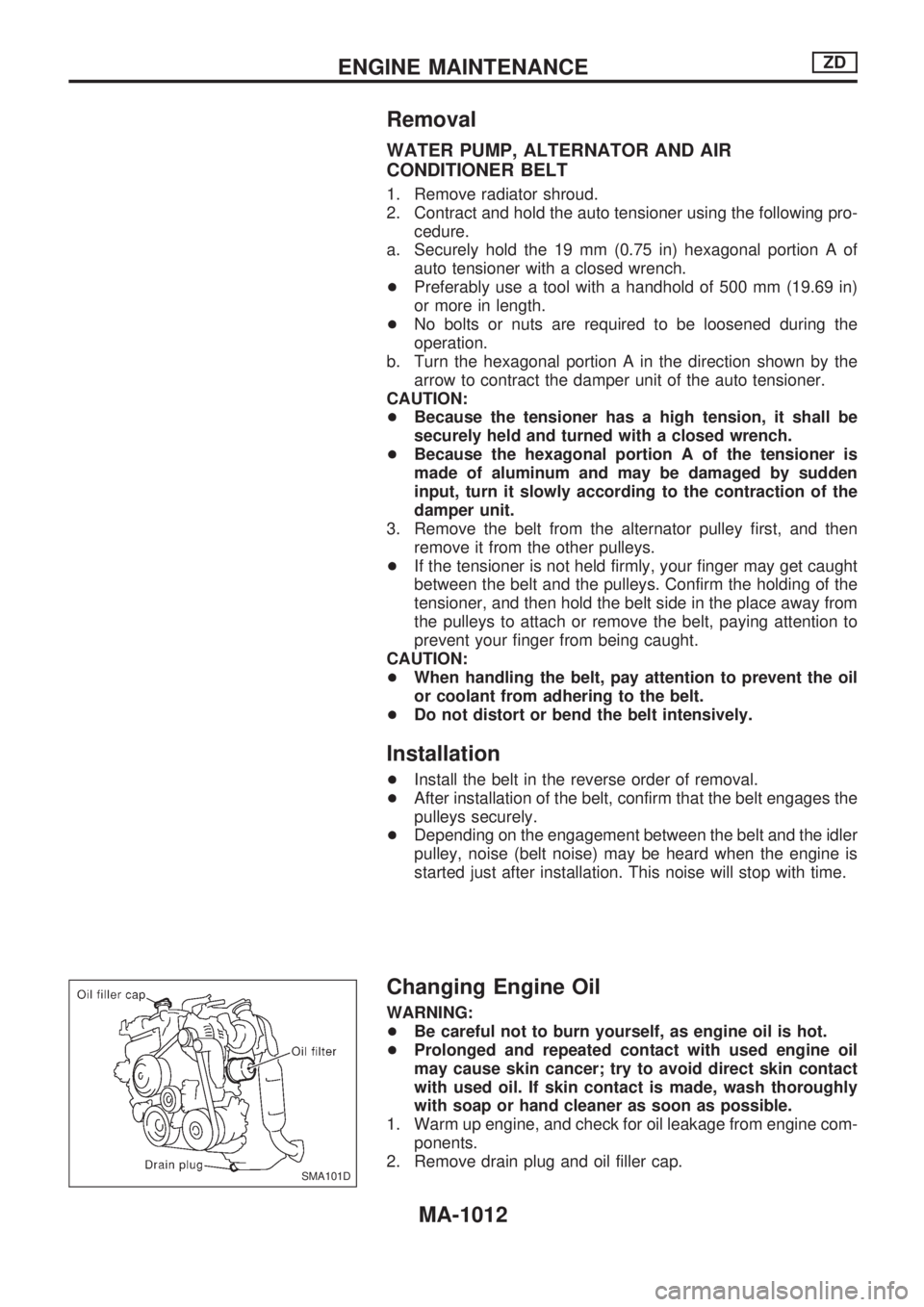

Changing Engine Oil

WARNING:

+Be careful not to burn yourself, as engine oil is hot.

+Prolonged and repeated contact with used engine oil

may cause skin cancer; try to avoid direct skin contact

with used oil. If skin contact is made, wash thoroughly

with soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Remove drain plug and oil filler cap.

SMA101D

ENGINE MAINTENANCEZD

MA-1012

Page 911 of 1033

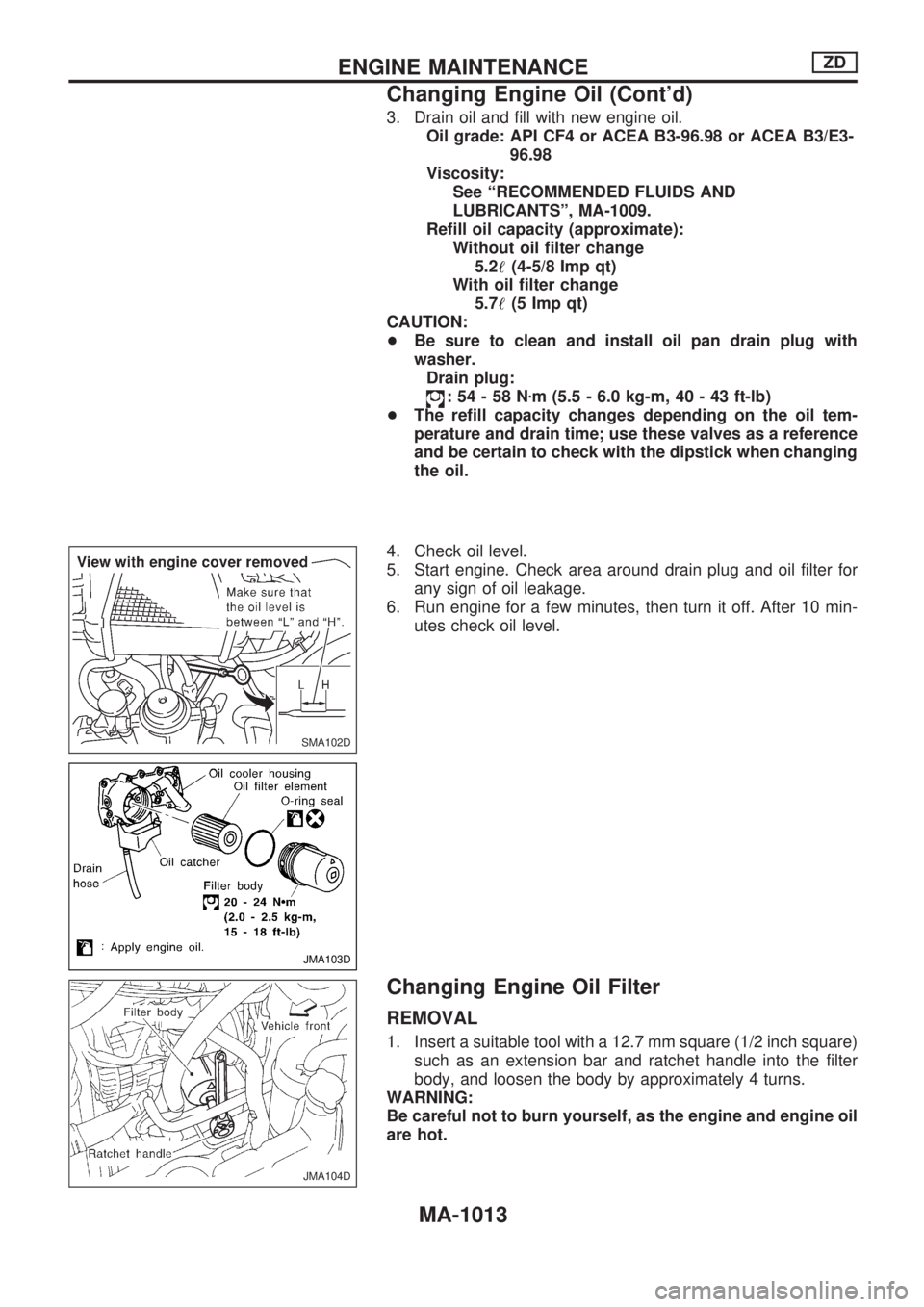

3. Drain oil and fill with new engine oil.

Oil grade: API CF4 or ACEA B3-96.98 or ACEA B3/E3-

96.98

Viscosity:

See ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-1009.

Refill oil capacity (approximate):

Without oil filter change

5.2!(4-5/8 Imp qt)

With oil filter change

5.7!(5 Imp qt)

CAUTION:

+Be sure to clean and install oil pan drain plug with

washer.

Drain plug:

:54-58Nzm (5.5 - 6.0 kg-m, 40 - 43 ft-lb)

+The refill capacity changes depending on the oil tem-

perature and drain time; use these valves as a reference

and be certain to check with the dipstick when changing

the oil.

4. Check oil level.

5. Start engine. Check area around drain plug and oil filter for

any sign of oil leakage.

6. Run engine for a few minutes, then turn it off. After 10 min-

utes check oil level.

Changing Engine Oil Filter

REMOVAL

1. Insert a suitable tool with a 12.7 mm square (1/2 inch square)

such as an extension bar and ratchet handle into the filter

body, and loosen the body by approximately 4 turns.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

SMA102D

JMA103D

JMA104D

ENGINE MAINTENANCEZD

Changing Engine Oil (Cont'd)

MA-1013

Page 912 of 1033

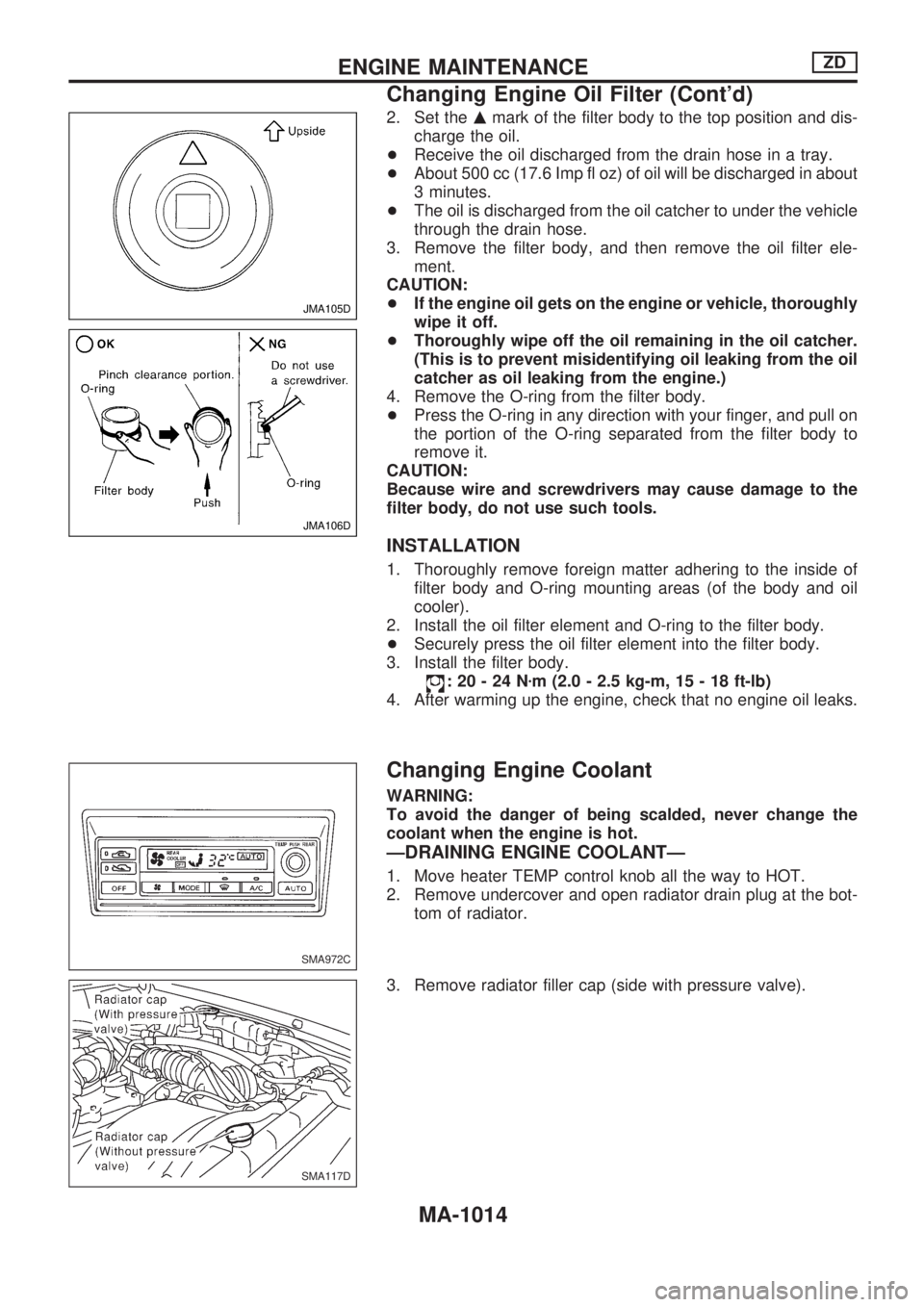

2. Set themmark of the filter body to the top position and dis-

charge the oil.

+Receive the oil discharged from the drain hose in a tray.

+About 500 cc (17.6 Imp fl oz) of oil will be discharged in about

3 minutes.

+The oil is discharged from the oil catcher to under the vehicle

through the drain hose.

3. Remove the filter body, and then remove the oil filter ele-

ment.

CAUTION:

+If the engine oil gets on the engine or vehicle, thoroughly

wipe it off.

+Thoroughly wipe off the oil remaining in the oil catcher.

(This is to prevent misidentifying oil leaking from the oil

catcher as oil leaking from the engine.)

4. Remove the O-ring from the filter body.

+Press the O-ring in any direction with your finger, and pull on

the portion of the O-ring separated from the filter body to

remove it.

CAUTION:

Because wire and screwdrivers may cause damage to the

filter body, do not use such tools.

INSTALLATION

1. Thoroughly remove foreign matter adhering to the inside of

filter body and O-ring mounting areas (of the body and oil

cooler).

2. Install the oil filter element and O-ring to the filter body.

+Securely press the oil filter element into the filter body.

3. Install the filter body.

:20-24Nzm (2.0 - 2.5 kg-m, 15 - 18 ft-lb)

4. After warming up the engine, check that no engine oil leaks.

Changing Engine Coolant

WARNING:

To avoid the danger of being scalded, never change the

coolant when the engine is hot.

ÐDRAINING ENGINE COOLANTÐ

1. Move heater TEMP control knob all the way to HOT.

2. Remove undercover and open radiator drain plug at the bot-

tom of radiator.

3. Remove radiator filler cap (side with pressure valve).

JMA105D

JMA106D

SMA972C

SMA117D

ENGINE MAINTENANCEZD

Changing Engine Oil Filter (Cont'd)

MA-1014

Page 920 of 1033

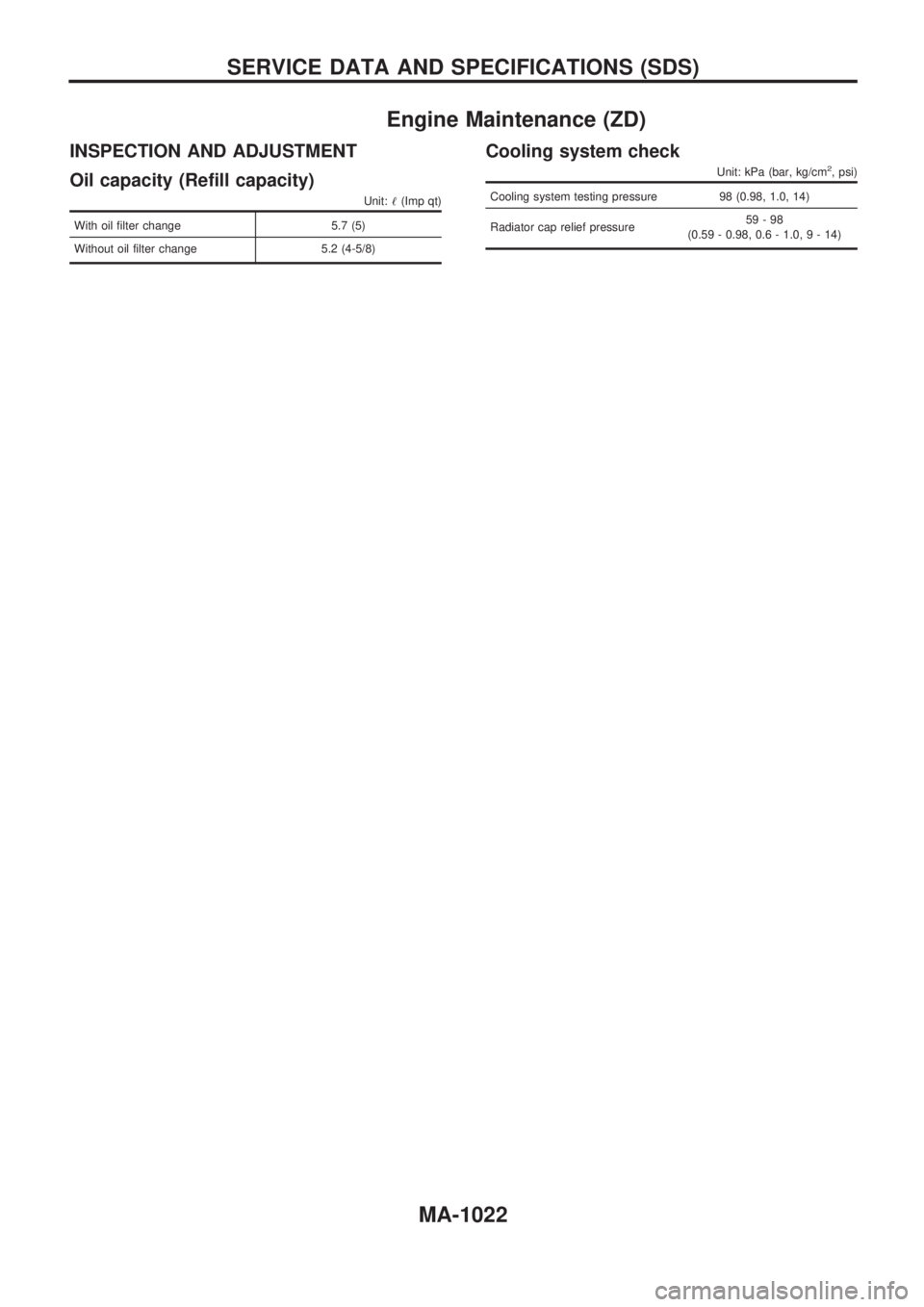

Engine Maintenance (ZD)

INSPECTION AND ADJUSTMENT

Oil capacity (Refill capacity)

Unit:!(Imp qt)

With oil filter change 5.7 (5)

Without oil filter change 5.2 (4-5/8)

Cooling system check

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 98 (0.98, 1.0, 14)

Radiator cap relief pressure59-98

(0.59 - 0.98, 0.6 - 1.0,9-14)

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-1022

Page 927 of 1033

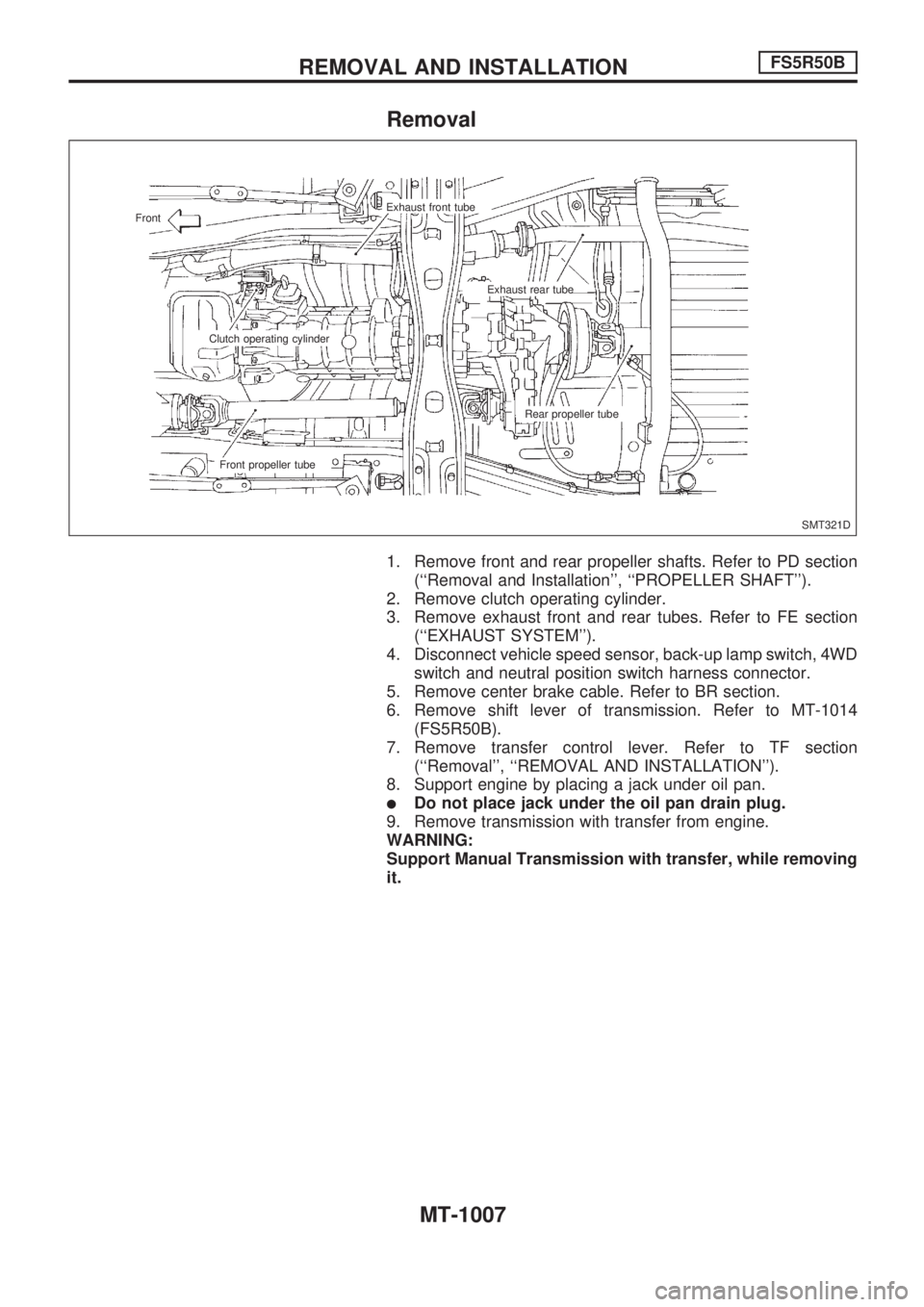

Removal

1. Remove front and rear propeller shafts. Refer to PD section

(``Removal and Installation'', ``PROPELLER SHAFT'').

2. Remove clutch operating cylinder.

3. Remove exhaust front and rear tubes. Refer to FE section

(``EXHAUST SYSTEM'').

4. Disconnect vehicle speed sensor, back-up lamp switch, 4WD

switch and neutral position switch harness connector.

5. Remove center brake cable. Refer to BR section.

6. Remove shift lever of transmission. Refer to MT-1014

(FS5R50B).

7. Remove transfer control lever. Refer to TF section

(``Removal'', ``REMOVAL AND INSTALLATION'').

8. Support engine by placing a jack under oil pan.

lDo not place jack under the oil pan drain plug.

9. Remove transmission with transfer from engine.

WARNING:

Support Manual Transmission with transfer, while removing

it.

SMT321D Exhaust front tube

Front

Exhaust rear tube

Clutch operating cylinder

Rear propeller tube

Front propeller tube

REMOVAL AND INSTALLATIONFS5R50B

MT-1007

Page 928 of 1033

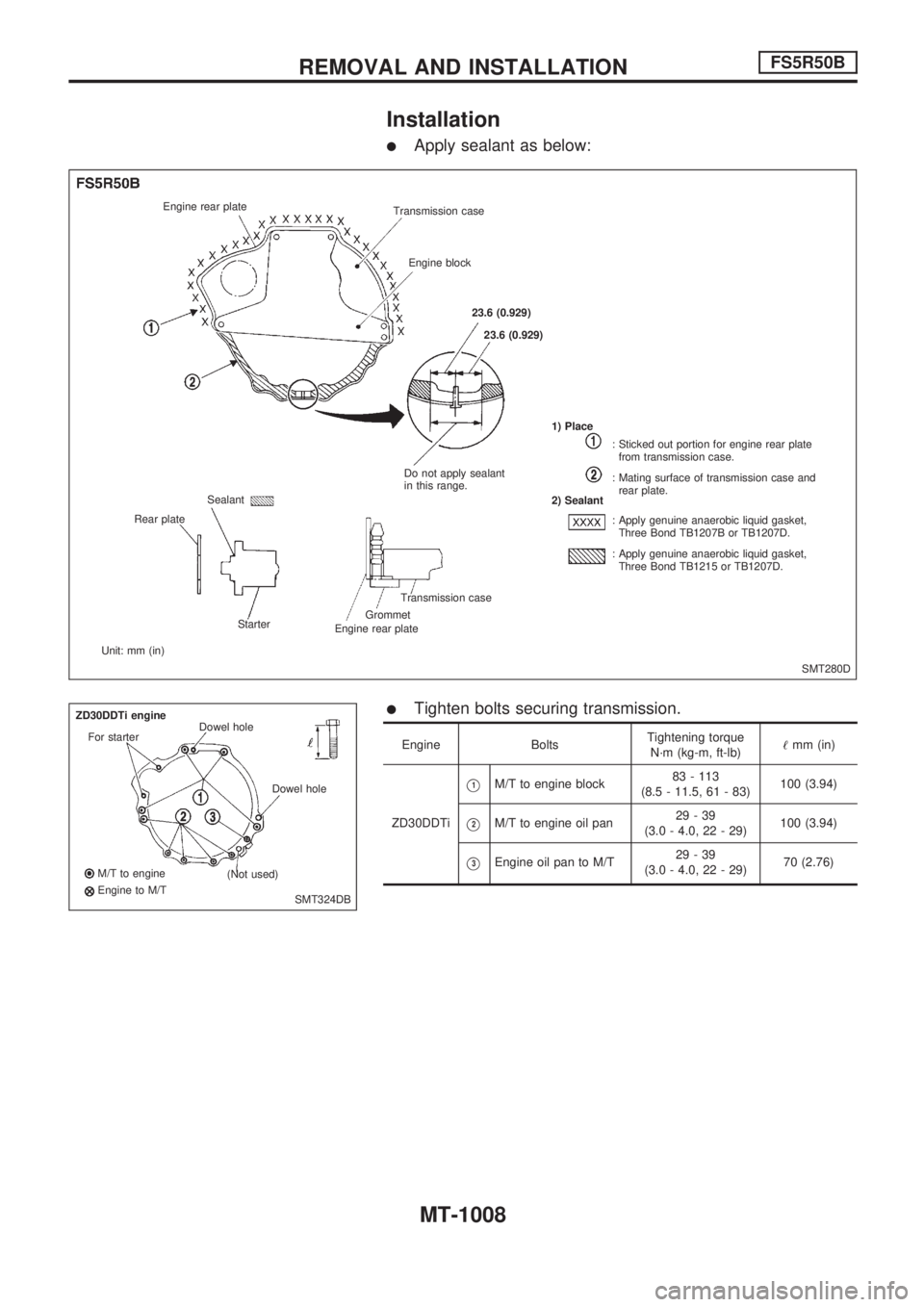

Installation

lApply sealant as below:

lTighten bolts securing transmission.

Engine BoltsTightening torque

N´m (kg-m, ft-lb)!mm (in)

ZD30DDTi

V1M/T to engine block83 - 113

(8.5 - 11.5, 61 - 83)100 (3.94)

V2M/T to engine oil pan29-39

(3.0 - 4.0, 22 - 29)100 (3.94)

V3Engine oil pan to M/T29-39

(3.0 - 4.0, 22 - 29)70 (2.76)

SMT280D Engine rear plate

Transmission case

Engine block

23.6 (0.929)

23.6 (0.929)

Do not apply sealant

in this range.1) Place

2) Sealant

: Sticked out portion for engine rear plate

from transmission case.

: Mating surface of transmission case and

rear plate.

: Apply genuine anaerobic liquid gasket,

Three Bond TB1207B or TB1207D.

: Apply genuine anaerobic liquid gasket,

Three Bond TB1215 or TB1207D.

Transmission case

Grommet

Engine rear plate Starter Sealant

Rear plate

Unit: mm (in)

SMT324DB ZD30DDTi engine

For starterDowel hole

Dowel hole

(Not used) M/T to engine

Engine to M/T

REMOVAL AND INSTALLATIONFS5R50B

MT-1008

Page 931 of 1033

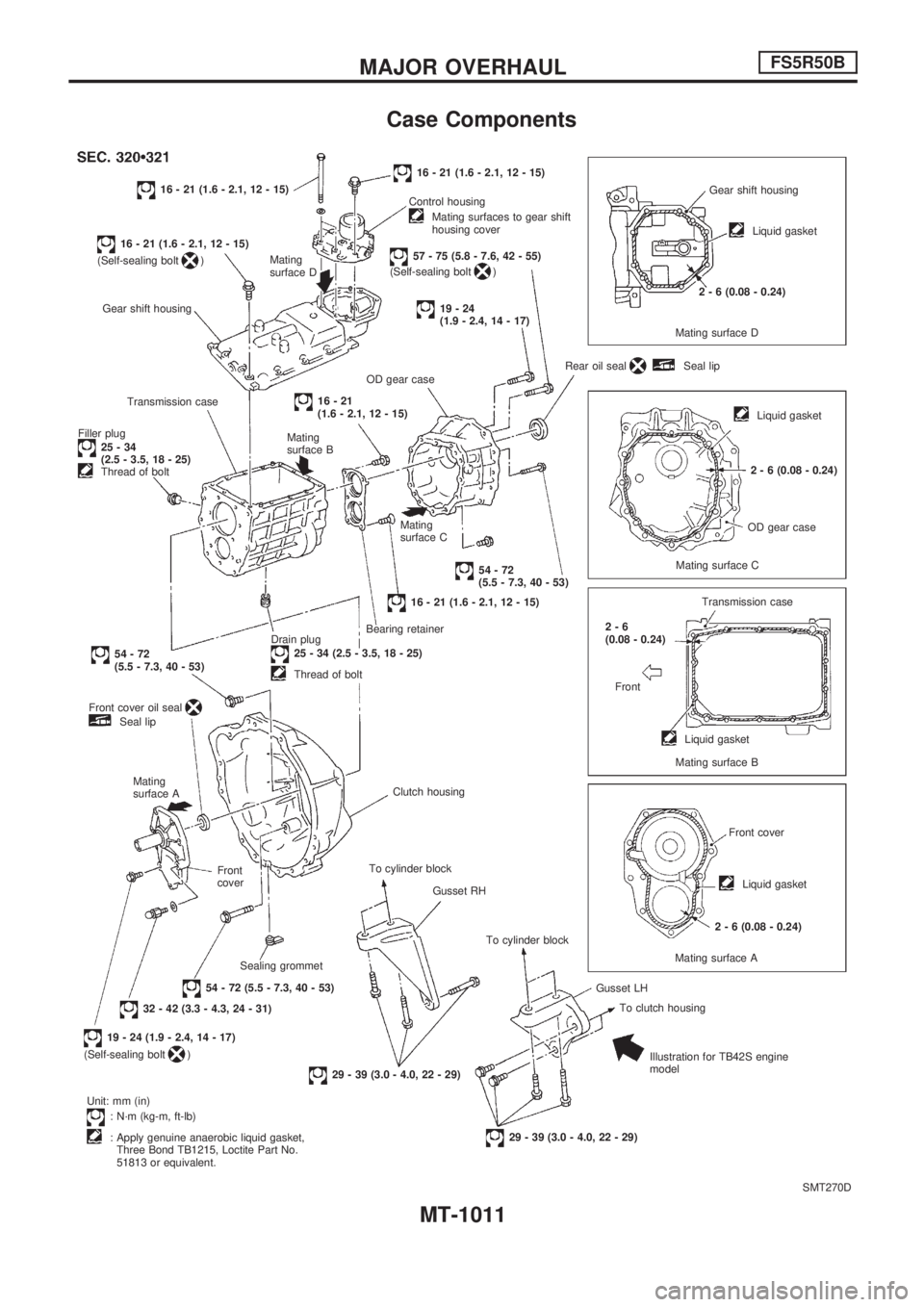

Case Components

SMT270D

16 - 21 (1.6 - 2.1, 12 - 15)

16 - 21 (1.6 - 2.1, 12 - 15)

(Self-sealing bolt

)Mating

surface D

Gear shift housing

Transmission case

Filler plug

25-34

(2.5 - 3.5, 18 - 25)

Thread of bolt

54-72

(5.5 - 7.3, 40 - 53)

Front cover oil seal

Seal lip

Mating

surface A

Front

cover

Sealing grommet

54 - 72 (5.5 - 7.3, 40 - 53)

32 - 42 (3.3 - 4.3, 24 - 31)

19 - 24 (1.9 - 2.4, 14 - 17)

(Self-sealing bolt

)

Unit: mm (in)

: N´m (kg-m, ft-lb)

: Apply genuine anaerobic liquid gasket,

Three Bond TB1215, Loctite Part No.

51813 or equivalent.

29 - 39 (3.0 - 4.0, 22 - 29)

29 - 39 (3.0 - 4.0, 22 - 29)Illustration for TB42S engine

model To clutch housing Gusset LH To cylinder block Gusset RH To cylinder blockClutch housing Drain plug

25 - 34 (2.5 - 3.5, 18 - 25)

Thread of boltBearing retainer

16 - 21 (1.6 - 2.1, 12 - 15)

54-72

(5.5 - 7.3, 40 - 53) Mating

surface C Mating

surface B

16-21

(1.6 - 2.1, 12 - 15)OD gear caseRear oil seal

Seal lip

19-24

(1.9 - 2.4, 14 - 17)

57 - 75 (5.8 - 7.6, 42 - 55)

(Self-sealing bolt) Control housing

Mating surfaces to gear shift

housing cover

16 - 21 (1.6 - 2.1, 12 - 15)

Gear shift housing

Liquid gasket

2 - 6 (0.08 - 0.24)

Mating surface D

Liquid gasket

2 - 6 (0.08 - 0.24)

OD gear case

Mating surface C

Transmission case

2-6

(0.08 - 0.24)

Front

Liquid gasket

Mating surface B

Front cover

Liquid gasket

2 - 6 (0.08 - 0.24)

Mating surface A

MAJOR OVERHAULFS5R50B

MT-1011

Page 1028 of 1033

STEERING SYSTEM

SECTION

ST

MODIFICATION NOTICE:

+Power steering oil pump for ZD30ETi engine has been adopted.

CONTENTS

POWER STEERING OIL PUMP.......................... 1002

Removal and Installation ................................. 1002

Disassembly and Assembly ............................. 1003SERVICE DATA AND SPECIFICATIONS

(SDS).................................................................... 1004

Inspection and Adjustment .............................. 1004

ST