Engine harness NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 62 of 1033

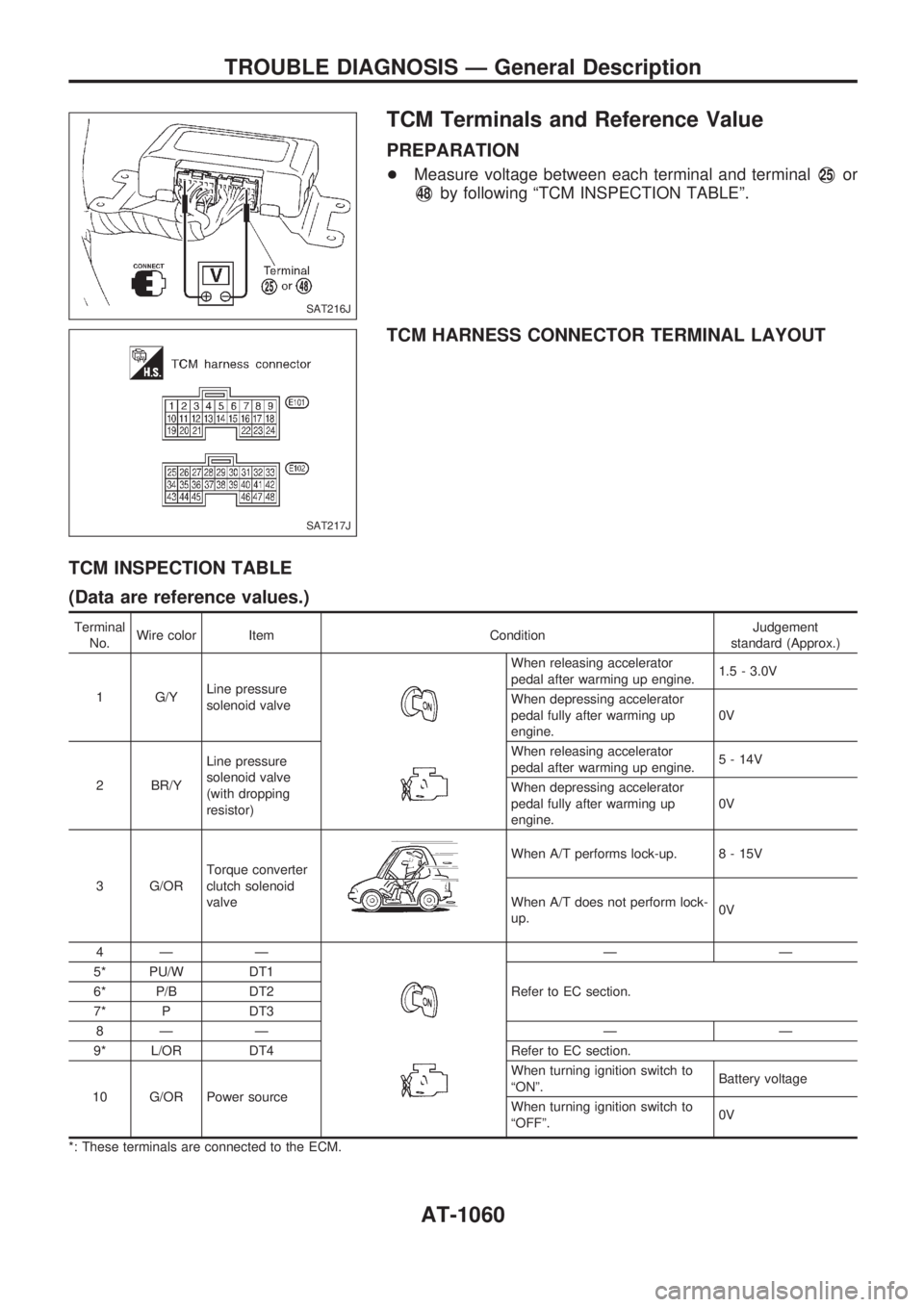

TCM Terminals and Reference Value

PREPARATION

+Measure voltage between each terminal and terminalV25or

V48by following ªTCM INSPECTION TABLEº.

TCM HARNESS CONNECTOR TERMINAL LAYOUT

TCM INSPECTION TABLE

(Data are reference values.)

Terminal

No.Wire color Item ConditionJudgement

standard (Approx.)

1 G/YLine pressure

solenoid valve

When releasing accelerator

pedal after warming up engine.1.5 - 3.0V

When depressing accelerator

pedal fully after warming up

engine.0V

2 BR/YLine pressure

solenoid valve

(with dropping

resistor)When releasing accelerator

pedal after warming up engine.5 - 14V

When depressing accelerator

pedal fully after warming up

engine.0V

3 G/ORTorque converter

clutch solenoid

valve

When A/T performs lock-up. 8 - 15V

When A/T does not perform lock-

up.0V

4Ð Ð

ÐÐ

5* PU/W DT1

Refer to EC section. 6* P/B DT2

7* P DT3

8Ð Ð Ð Ð

9* L/OR DT4 Refer to EC section.

10 G/OR Power sourceWhen turning ignition switch to

ªONº.Battery voltage

When turning ignition switch to

ªOFFº.0V

*: These terminals are connected to the ECM.

SAT216J

SAT217J

TROUBLE DIAGNOSIS Ð General Description

AT-1060

Page 66 of 1033

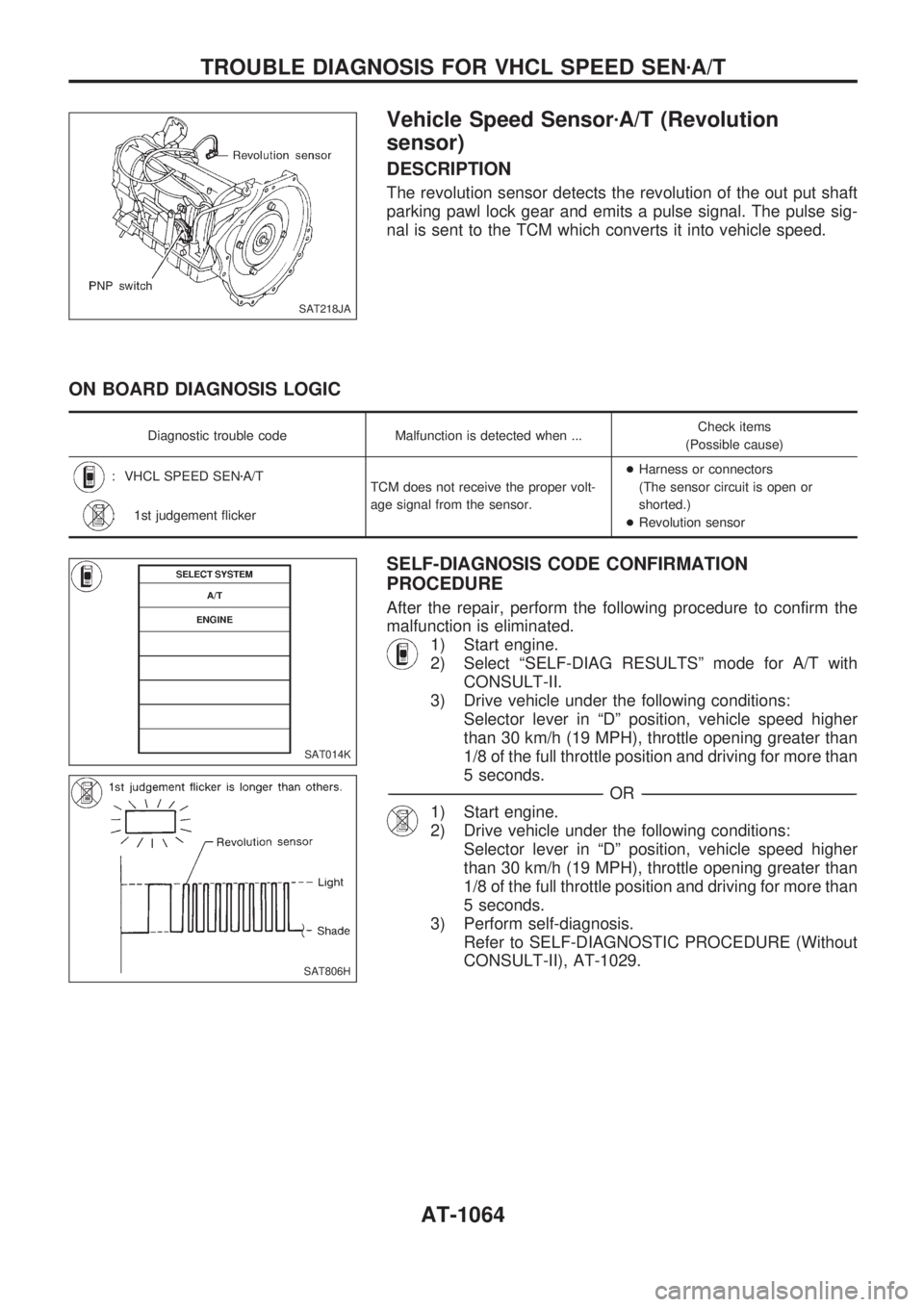

Vehicle Speed SensorzA/T (Revolution

sensor)

DESCRIPTION

The revolution sensor detects the revolution of the out put shaft

parking pawl lock gear and emits a pulse signal. The pulse sig-

nal is sent to the TCM which converts it into vehicle speed.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

: VHCL SPEED SENzA/T

TCM does not receive the proper volt-

age signal from the sensor.+Harness or connectors

(The sensor circuit is open or

shorted.)

+Revolution sensor

: 1st judgement flicker

SELF-DIAGNOSIS CODE CONFIRMATION

PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with

CONSULT-II.

3) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher

than 30 km/h (19 MPH), throttle opening greater than

1/8 of the full throttle position and driving for more than

5 seconds.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher

than 30 km/h (19 MPH), throttle opening greater than

1/8 of the full throttle position and driving for more than

5 seconds.

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-1029.

SAT218JA

SAT014K

SAT806H

TROUBLE DIAGNOSIS FOR VHCL SPEED SENzA/T

AT-1064

Page 67 of 1033

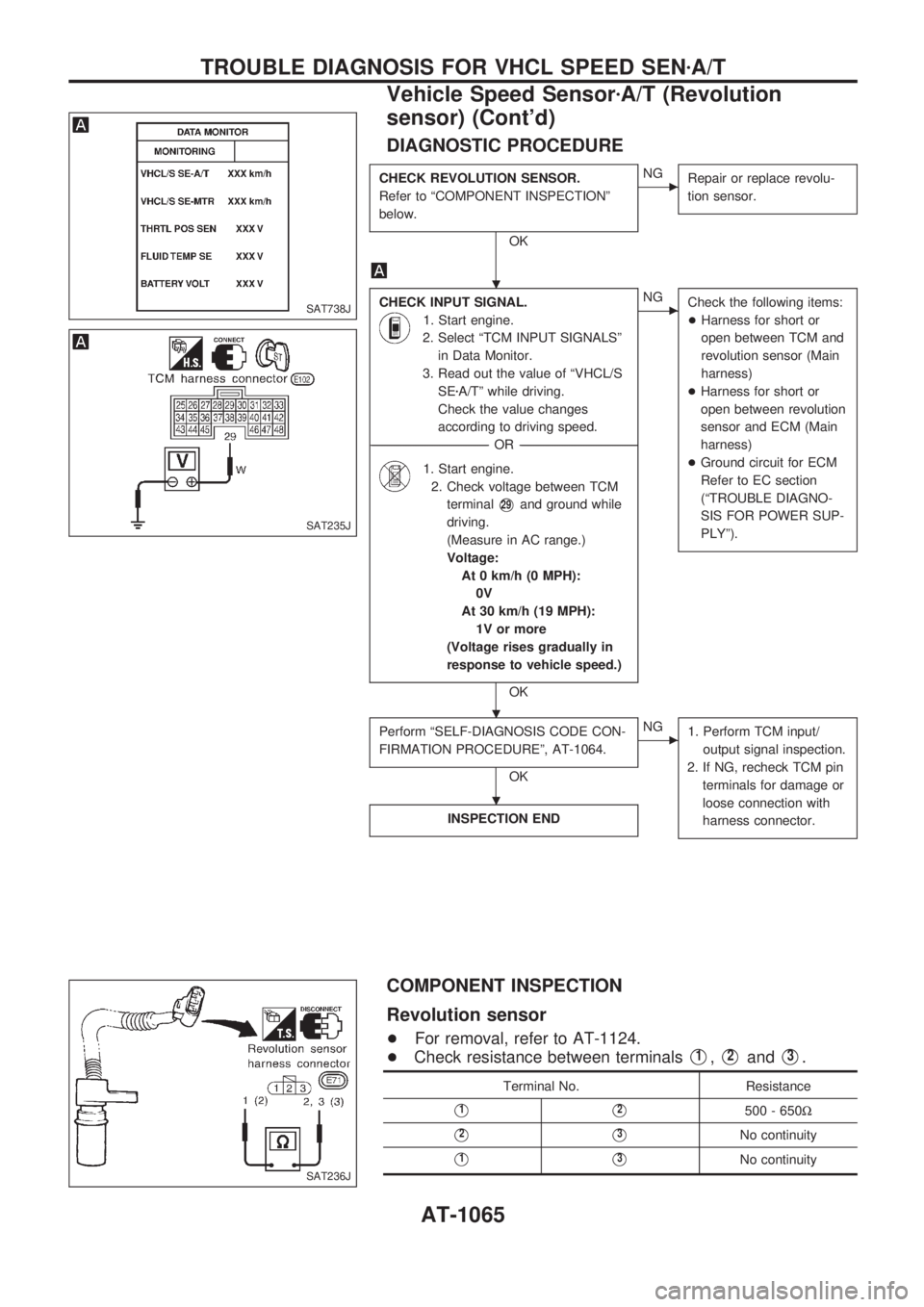

DIAGNOSTIC PROCEDURE

CHECK REVOLUTION SENSOR.

Refer to ªCOMPONENT INSPECTIONº

below.

OK

cNG

Repair or replace revolu-

tion sensor.

CHECK INPUT SIGNAL.

1. Start engine.

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªVHCL/S

SEzA/Tº while driving.

Check the value changes

according to driving speed.

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM

terminal

V29and ground while

driving.

(Measure in AC range.)

Voltage:

At 0 km/h (0 MPH):

0V

At 30 km/h (19 MPH):

1V or more

(Voltage rises gradually in

response to vehicle speed.)

OK

cNG

Check the following items:

+Harness for short or

open between TCM and

revolution sensor (Main

harness)

+Harness for short or

open between revolution

sensor and ECM (Main

harness)

+Ground circuit for ECM

Refer to EC section

(ªTROUBLE DIAGNO-

SIS FOR POWER SUP-

PLYº).

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1064.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

Revolution sensor

+For removal, refer to AT-1124.

+Check resistance between terminals

V1,V2andV3.

Terminal No. Resistance

V1V2500 - 650W

V2V3No continuity

V1V3No continuity

SAT738J

SAT235J

SAT236J

.

.

.

TROUBLE DIAGNOSIS FOR VHCL SPEED SENzA/T

Vehicle Speed SensorzA/T (Revolution

sensor) (Cont'd)

AT-1065

Page 68 of 1033

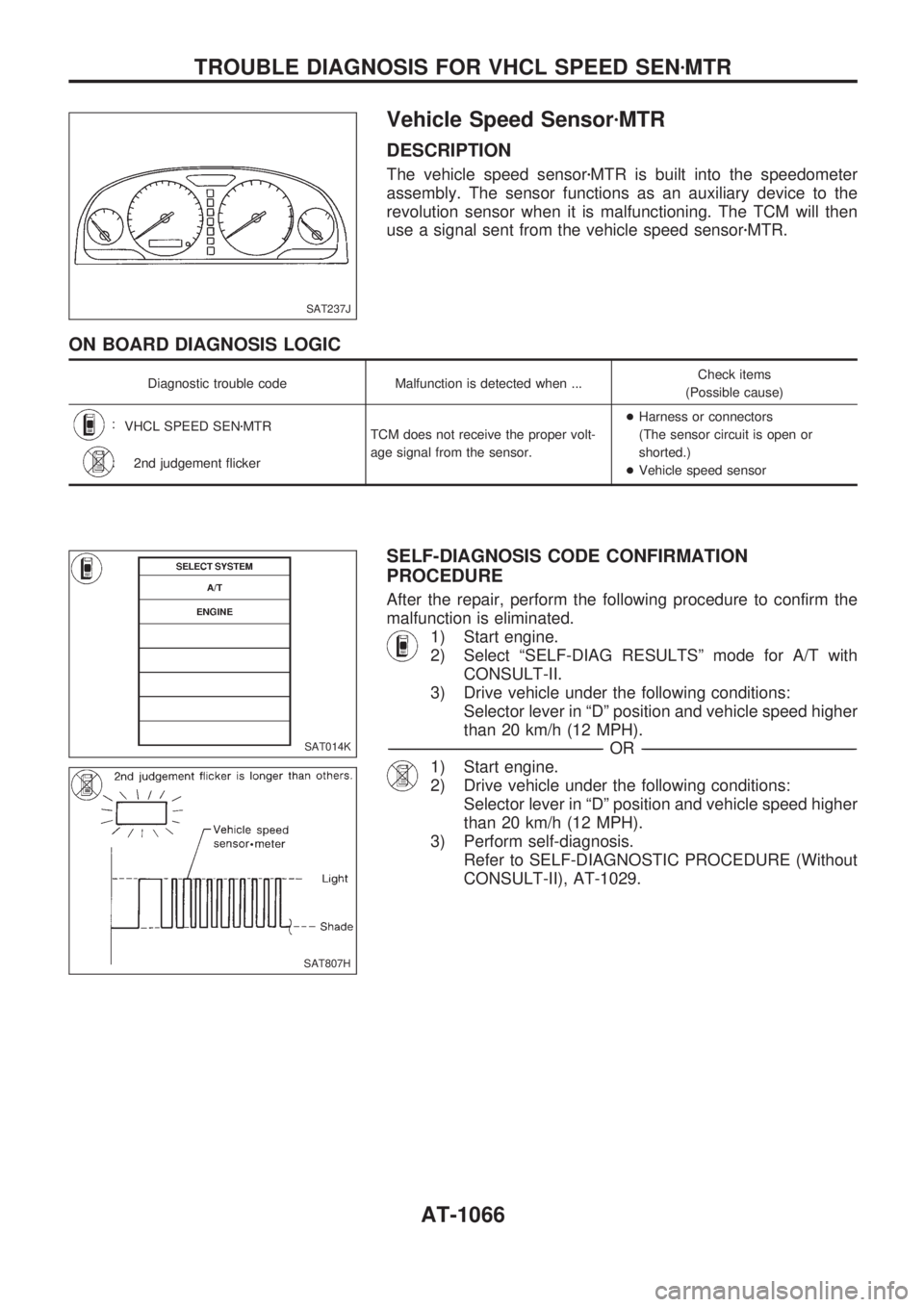

Vehicle Speed SensorzMTR

DESCRIPTION

The vehicle speed sensorzMTR is built into the speedometer

assembly. The sensor functions as an auxiliary device to the

revolution sensor when it is malfunctioning. The TCM will then

use a signal sent from the vehicle speed sensorzMTR.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

:

VHCL SPEED SENzMTR

TCM does not receive the proper volt-

age signal from the sensor.+Harness or connectors

(The sensor circuit is open or

shorted.)

+Vehicle speed sensor

:

2nd judgement flicker

SELF-DIAGNOSIS CODE CONFIRMATION

PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with

CONSULT-II.

3) Drive vehicle under the following conditions:

Selector lever in ªDº position and vehicle speed higher

than 20 km/h (12 MPH).

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº position and vehicle speed higher

than 20 km/h (12 MPH).

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-1029.

SAT237J

SAT014K

SAT807H

TROUBLE DIAGNOSIS FOR VHCL SPEED SENzMTR

AT-1066

Page 69 of 1033

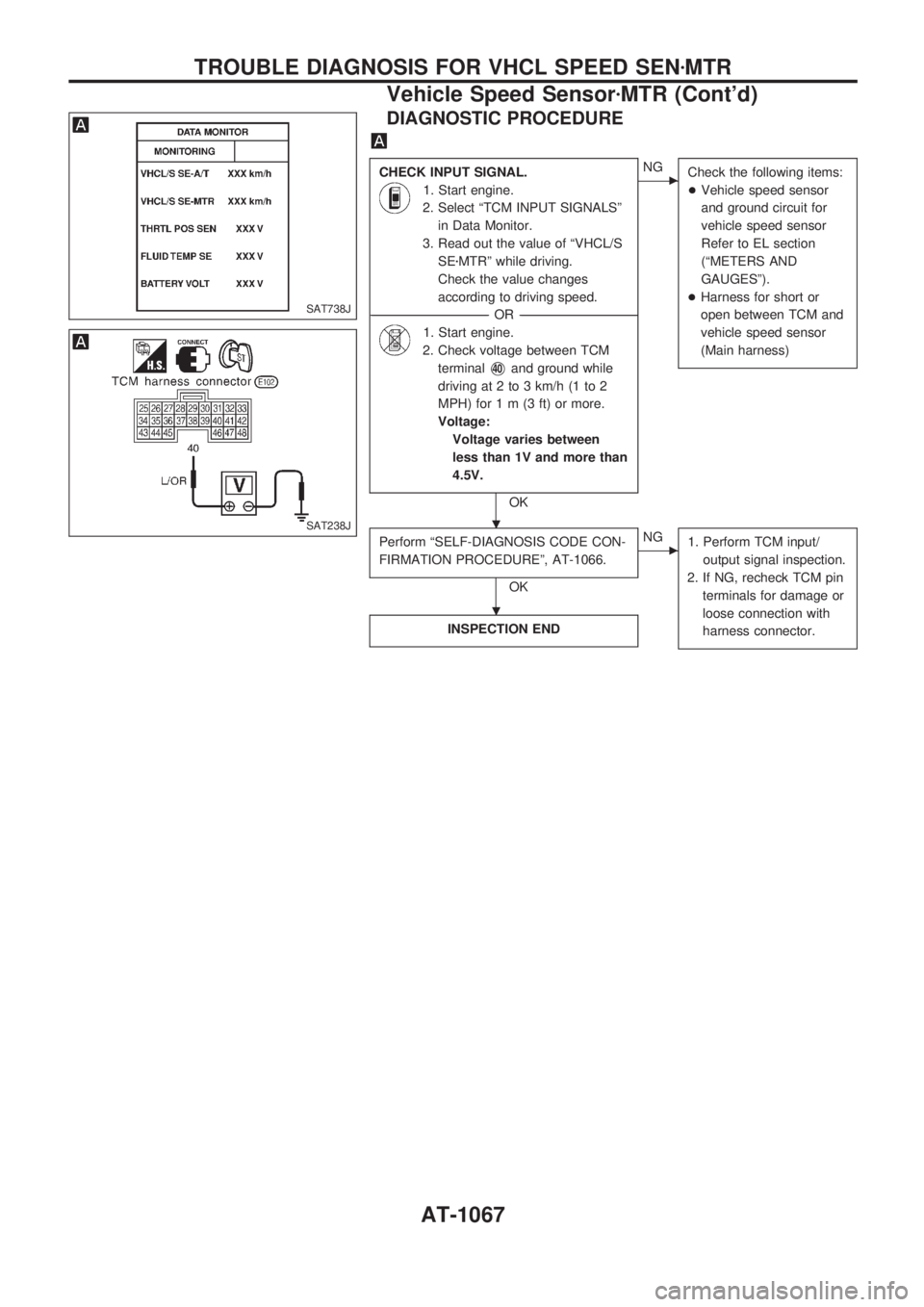

DIAGNOSTIC PROCEDURE

CHECK INPUT SIGNAL.

1. Start engine.

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªVHCL/S

SEzMTRº while driving.

Check the value changes

according to driving speed.

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM

terminal

V40and ground while

driving at 2 to 3 km/h (1 to 2

MPH) for1m(3ft)ormore.

Voltage:

Voltage varies between

less than 1V and more than

4.5V.

OK

cNG

Check the following items:

+Vehicle speed sensor

and ground circuit for

vehicle speed sensor

Refer to EL section

(ªMETERS AND

GAUGESº).

+Harness for short or

open between TCM and

vehicle speed sensor

(Main harness)

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1066.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT738J

SAT238J.

.

TROUBLE DIAGNOSIS FOR VHCL SPEED SENzMTR

Vehicle Speed SensorzMTR (Cont'd)

AT-1067

Page 70 of 1033

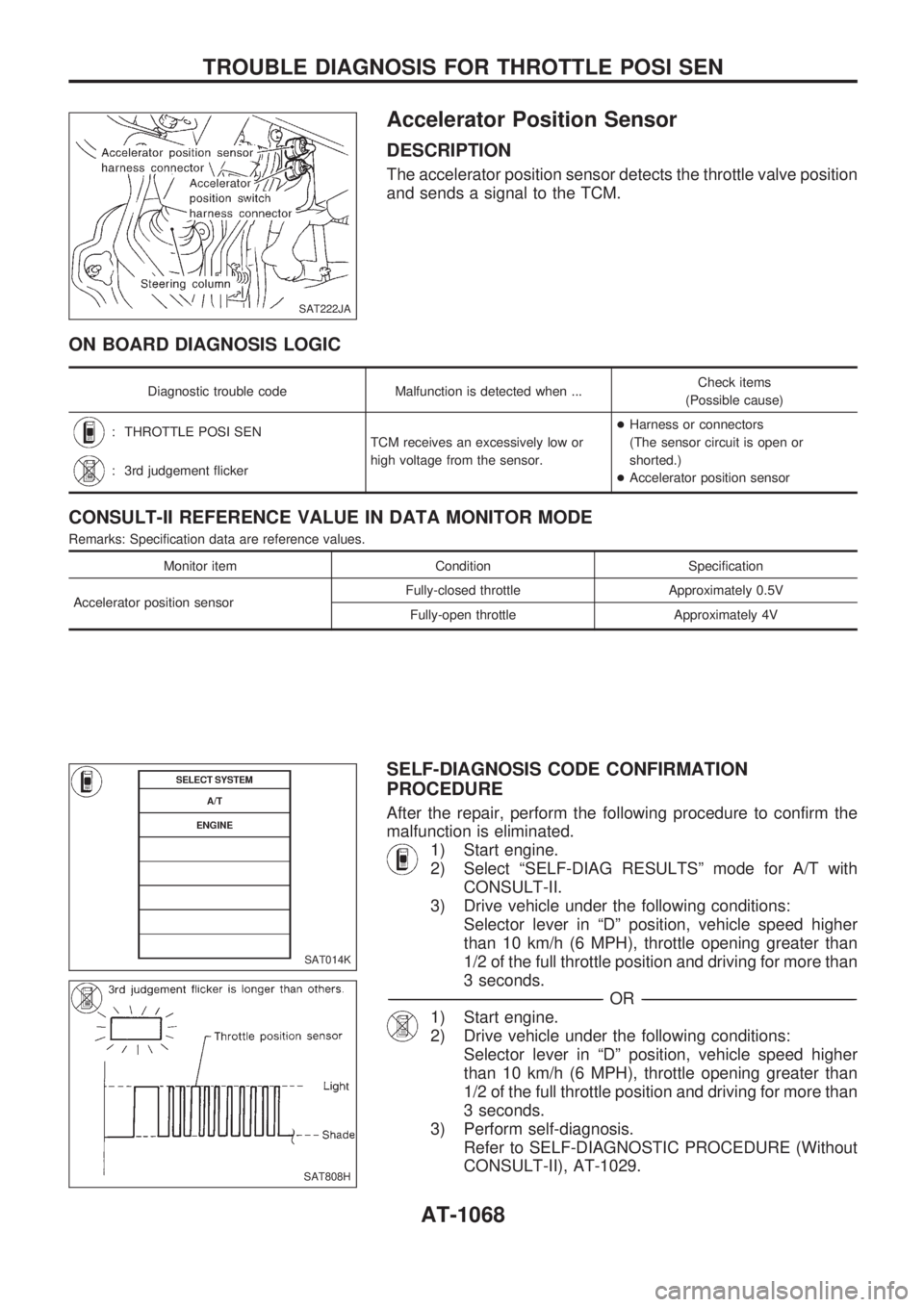

Accelerator Position Sensor

DESCRIPTION

The accelerator position sensor detects the throttle valve position

and sends a signal to the TCM.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

: THROTTLE POSI SEN

TCM receives an excessively low or

high voltage from the sensor.+Harness or connectors

(The sensor circuit is open or

shorted.)

+Accelerator position sensor

: 3rd judgement flicker

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

Monitor item Condition Specification

Accelerator position sensorFully-closed throttle Approximately 0.5V

Fully-open throttle Approximately 4V

SELF-DIAGNOSIS CODE CONFIRMATION

PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with

CONSULT-II.

3) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher

than 10 km/h (6 MPH), throttle opening greater than

1/2 of the full throttle position and driving for more than

3 seconds.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher

than 10 km/h (6 MPH), throttle opening greater than

1/2 of the full throttle position and driving for more than

3 seconds.

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-1029.

SAT222JA

SAT014K

SAT808H

TROUBLE DIAGNOSIS FOR THROTTLE POSI SEN

AT-1068

Page 71 of 1033

![NISSAN PATROL 2000 Electronic Repair Manual DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Refer to EC section [ªMalfunction Indica-

tor (MI)º, ªON BOARD DIAGNOSTIC

SYSTEM DESCRIPTIONº].

NISSAN PATROL 2000 Electronic Repair Manual DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Refer to EC section [ªMalfunction Indica-

tor (MI)º, ªON BOARD DIAGNOSTIC

SYSTEM DESCRIPTIONº].](/img/5/57367/w960_57367-70.png)

DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Refer to EC section [ªMalfunction Indica-

tor (MI)º, ªON BOARD DIAGNOSTIC

SYSTEM DESCRIPTIONº].

OK

cNG

Check accelerator position

sensor circuit for engine

control. Refer to EC sec-

tion [ªTROUBLE DIAGNO-

SIS FOR ªTHRTL

(ACCEL) POSI SENº

(DTC 43)].

CHECK INPUT SIGNAL.

1. Turn ignition switch to ªONº

position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªTHRTL

POS SENº.

Voltage:

Fully-closed throttle:

Approximately 0.5V

Fully-open throttle:

Approximately 4V

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº

position. (Do not start engine.)

2. Check voltage between TCM

terminals

V41andV42while

accelerator pedal is depressed

slowly.

Voltage:

Fully-closed throttle valve:

Approximately 0.5 - 0.7V

Fully-open throttle valve:

Approximately 4V

(Voltage rises gradually in

response to throttle position)

OK

cNG

Check harness for short or

open between ECM and

TCM regarding accelerator

position sensor circuit.

(Main harness)

CHECK ACCELERATOR POSITION

SWITCH.

Refer to ªCHECK ACCELERATOR POSI-

TION SWITCHº, AT-1091.

OK

cNG

Repair or replace dam-

aged parts.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1068.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT738J

SAT239J

.

.

.

.

TROUBLE DIAGNOSIS FOR THROTTLE POSI SEN

Accelerator Position Sensor (Cont'd)

AT-1069

Page 72 of 1033

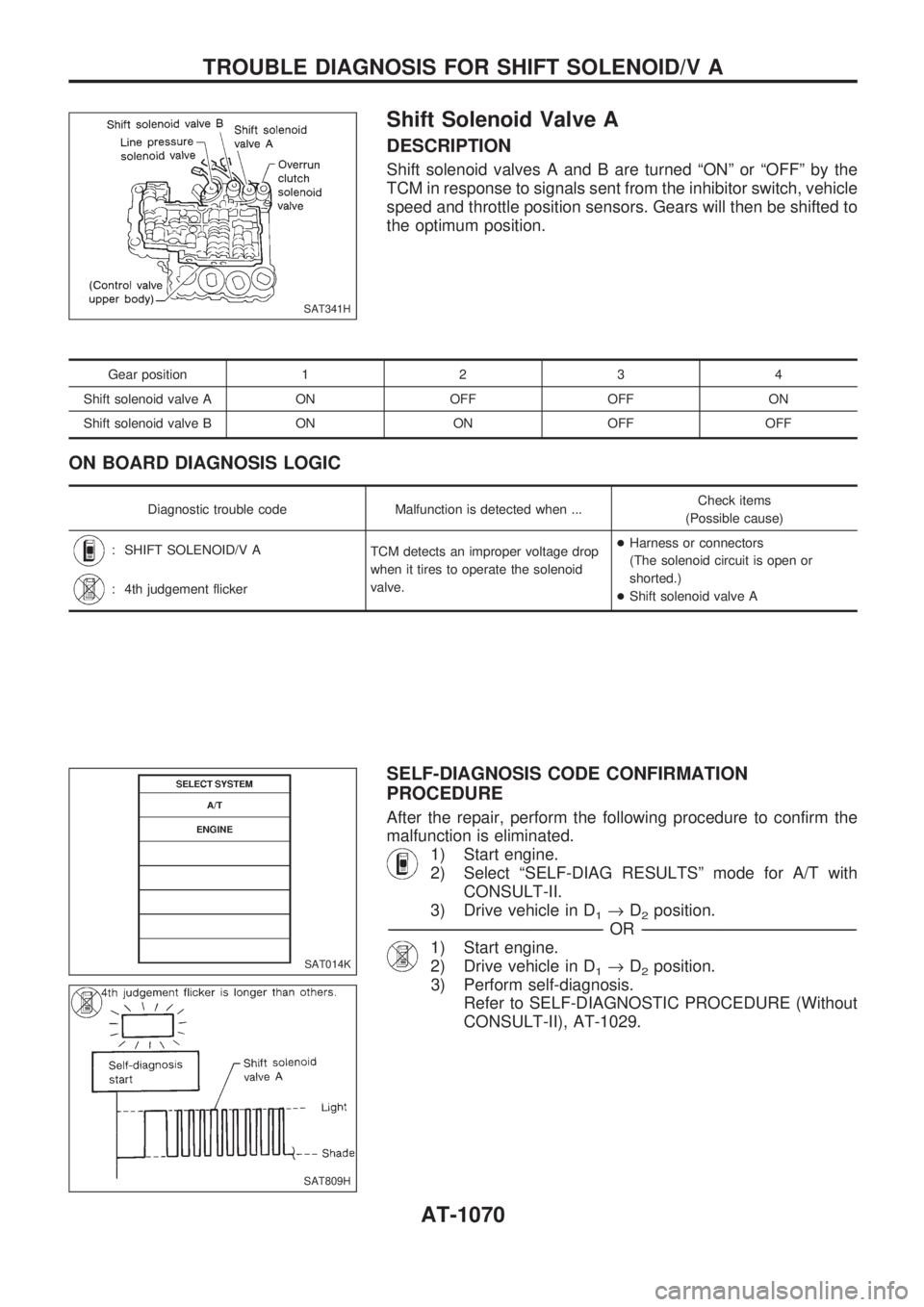

Shift Solenoid Valve A

DESCRIPTION

Shift solenoid valves A and B are turned ªONº or ªOFFº by the

TCM in response to signals sent from the inhibitor switch, vehicle

speed and throttle position sensors. Gears will then be shifted to

the optimum position.

Gear position1234

Shift solenoid valve A ON OFF OFF ON

Shift solenoid valve B ON ON OFF OFF

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

: SHIFT SOLENOID/V A

TCM detects an improper voltage drop

when it tires to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or

shorted.)

+Shift solenoid valve A

: 4th judgement flicker

SELF-DIAGNOSIS CODE CONFIRMATION

PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with

CONSULT-II.

3) Drive vehicle in D

1®D2position.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Drive vehicle in D

1®D2position.

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-1029.

SAT341H

SAT014K

SAT809H

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V A

AT-1070

Page 73 of 1033

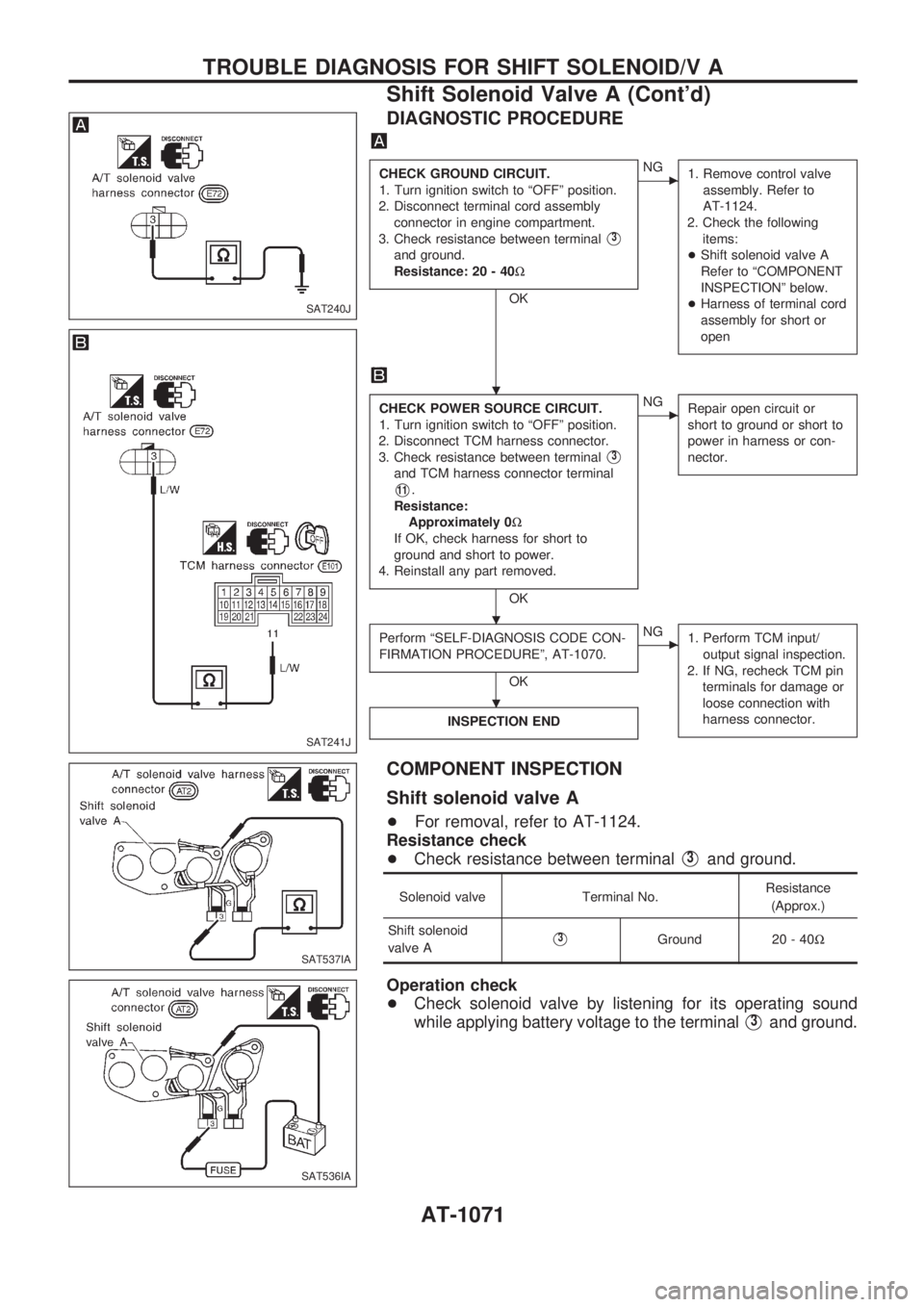

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminal

V3

and ground.

Resistance: 20 - 40W

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Shift solenoid valve A

Refer to ªCOMPONENT

INSPECTIONº below.

+Harness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal

V3

and TCM harness connector terminal

V11.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

cNG

Repair open circuit or

short to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1070.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

Shift solenoid valve A

+For removal, refer to AT-1124.

Resistance check

+Check resistance between terminal

V3and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Shift solenoid

valve A

V3Ground 20 - 40W

Operation check

+Check solenoid valve by listening for its operating sound

while applying battery voltage to the terminal

V3and ground.

SAT240J

SAT241J

SAT537IA

SAT536IA

.

.

.

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V A

Shift Solenoid Valve A (Cont'd)

AT-1071

Page 74 of 1033

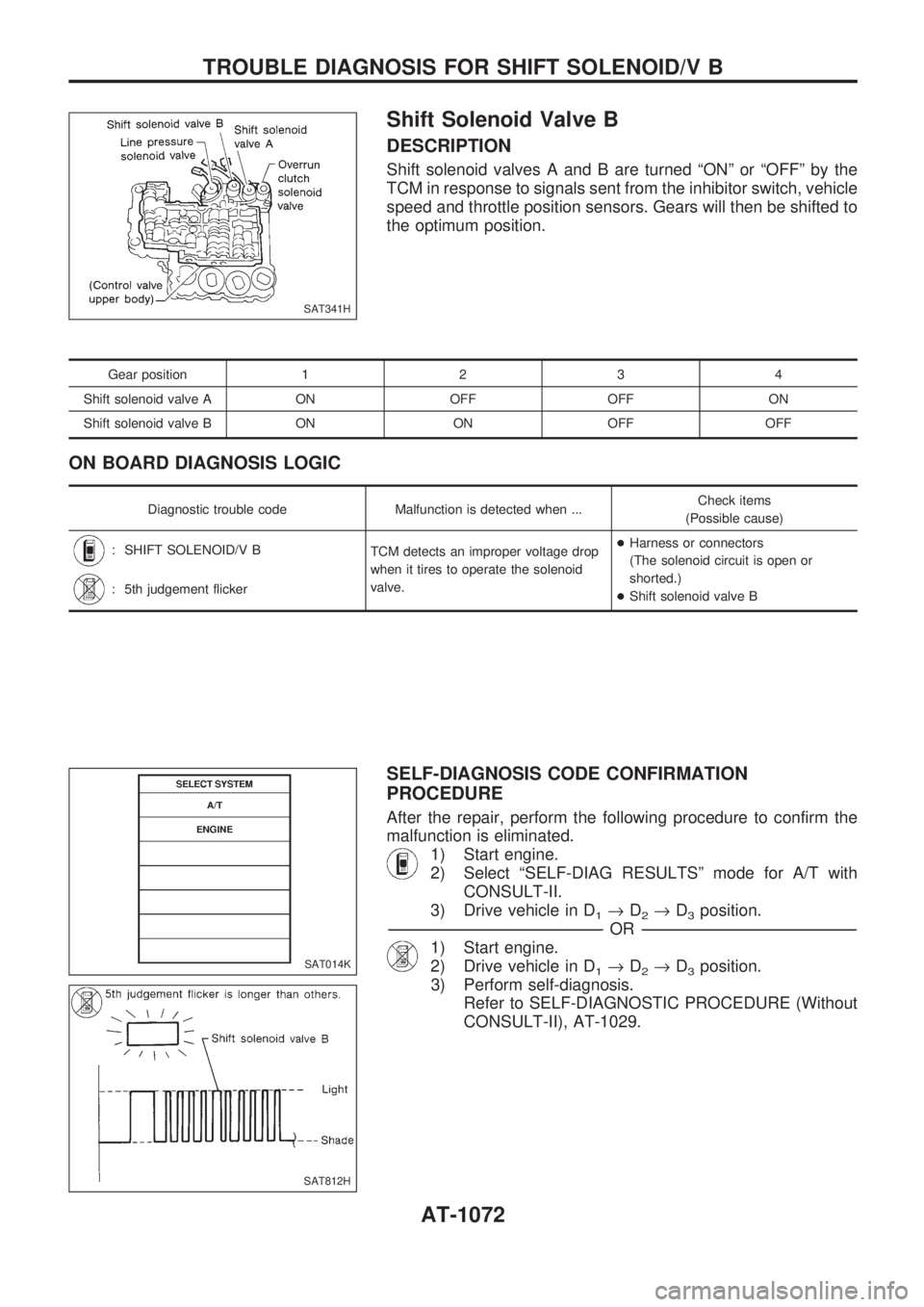

Shift Solenoid Valve B

DESCRIPTION

Shift solenoid valves A and B are turned ªONº or ªOFFº by the

TCM in response to signals sent from the inhibitor switch, vehicle

speed and throttle position sensors. Gears will then be shifted to

the optimum position.

Gear position1234

Shift solenoid valve A ON OFF OFF ON

Shift solenoid valve B ON ON OFF OFF

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

: SHIFT SOLENOID/V B

TCM detects an improper voltage drop

when it tires to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or

shorted.)

+Shift solenoid valve B

: 5th judgement flicker

SELF-DIAGNOSIS CODE CONFIRMATION

PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with

CONSULT-II.

3) Drive vehicle in D

1®D2®D3position.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Drive vehicle in D

1®D2®D3position.

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-1029.

SAT341H

SAT014K

SAT812H

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V B

AT-1072