alternator NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 379 of 1033

On Board Diagnosis Logic

The ECM checks if battery voltage is within the tolerance range for the engine control system.

Malfunction is detected when ... Check Items (Possible Cause)

+ An abnormally high voltage from the battery is sent to ECM. +Incorrect jump starting

+ Battery

+ Alternator

+ ECM

DTC Confirmation Procedure

With CONSULT-II

1) Checkthefollowing.

+ Jumper cables are connected for jump starting.

+ Battery or alternator has been replaced.

If the result is ªYesº for one item or more, skip the following steps and go to ªDiagnostic Procedureº,

EC-1146.

2) Check that the positive battery terminal is connected to battery properly. If NG, reconnect it properly.

3) Check that the alternator functions properly. Refer to EL section (ªCHARGING SYSTEMº).

4) Turn ignition switch ªONº and select ªDATA MONITORº mode with CONSULT-II.

5) Wait one minute.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-1146. If DTC is not detected, go to next step.

7) Start engine and wait one minute at idle.

8) If DTC is detected, go to ªDiagnostic Procedureº, EC-1146.

Without CONSULT-II

1) Checkthefollowing.

+ Jumper cables are connected for jump starting.

+ Battery or alternator has been replaced.

If the result is ªYesº for one item or more, skip the following steps and go to ªDiagnostic Procedureº,

EC-1146.

2) Check that the positive battery terminal is connected to battery properly. If NG, reconnect it properly.

3) Check that the alternator functions properly. Refer to EL section (ªCHARGING SYSTEMº).

4) Turn ignition switch ªONº and wait one minute.

5) Turn ignition switch ªOFFº, wait 5 seconds and then turn ªONº.

6) Perform ªDiagnostic Test Mode II (Self-diagnostic result)º with ECM.

7) If DTC is detected, go to ªDiagnostic Procedureº, EC-1146. If DTC is not detected, go to next step.

8) Start engine and wait one minute at idle.

9) Turn ignition switch ªOFFº, wait 5 seconds and then turn ªONº.

10) Perform ªDiagnostic Test Mode II (Self-diagnostic result)º with ECM.

11) If DTC is detected, go to ªDiagnostic Procedureº, EC-1146.

Diagnostic Procedure

1 INSPECTION START

Are jumper cables connected for the jump starting?

Yes or No

Yes cGO TO 3.

No cGO TO 2.

DTC 0502 BATTERY VOLTAGEZD30DDTi

EC-1146

Page 380 of 1033

2 CHECK BATTERY AND ALTERNATOR

Check that the proper type of battery and alternator is installed.

Refer to EL section (ªBATTERYº and ªCHARGING SYSTEMº).

OK or NG

OKcGO TO 5.

NGcReplace with a proper one.

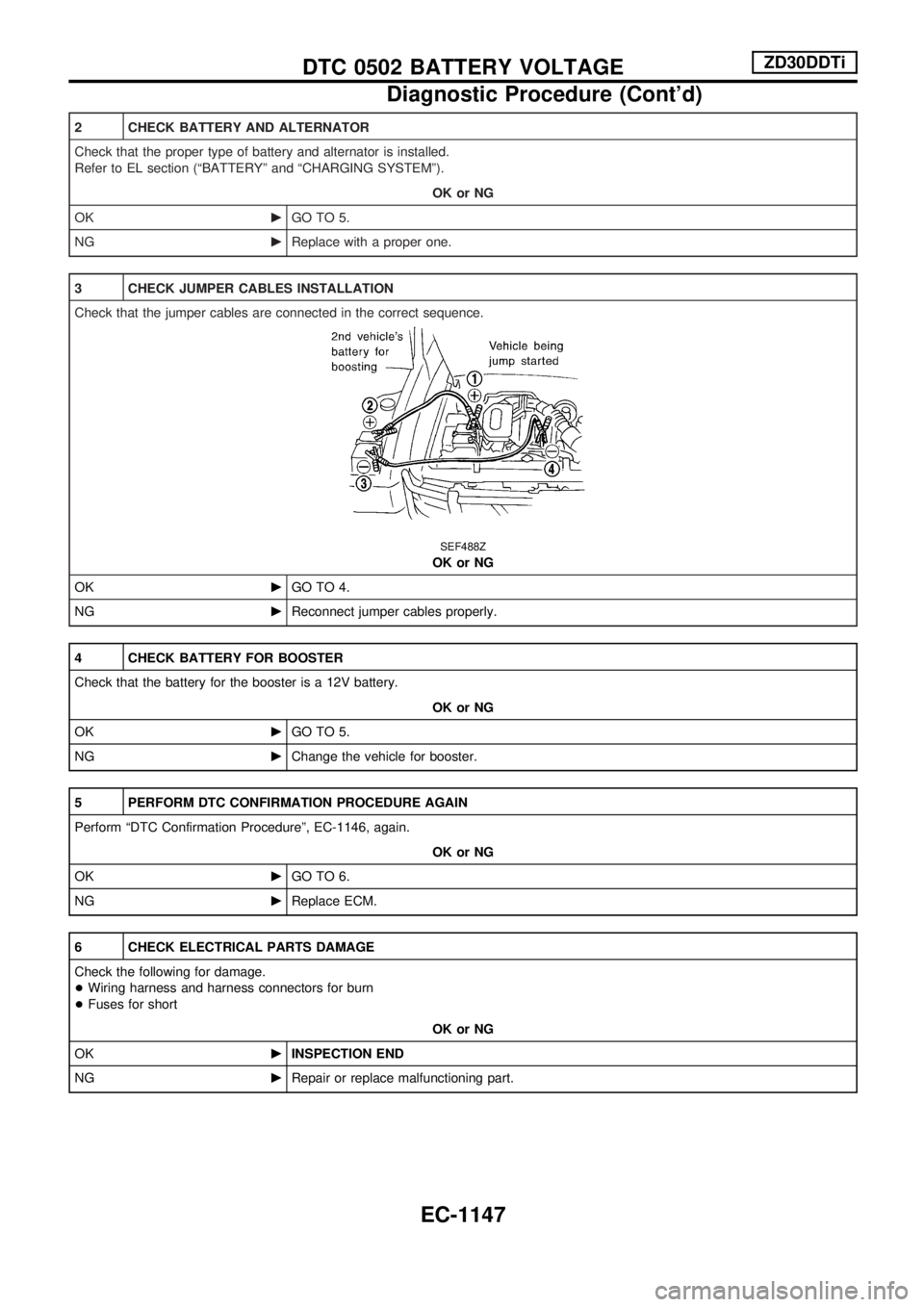

3 CHECK JUMPER CABLES INSTALLATION

Check that the jumper cables are connected in the correct sequence.

SEF488Z

OK or NG

OKcGO TO 4.

NGcReconnect jumper cables properly.

4 CHECK BATTERY FOR BOOSTER

Check that the battery for the booster is a 12V battery.

OK or NG

OKcGO TO 5.

NGcChange the vehicle for booster.

5 PERFORM DTC CONFIRMATION PROCEDURE AGAIN

Perform ªDTC Confirmation Procedureº, EC-1146, again.

OK or NG

OKcGO TO 6.

NGcReplace ECM.

6 CHECK ELECTRICAL PARTS DAMAGE

Check the following for damage.

+Wiring harness and harness connectors for burn

+Fuses for short

OK or NG

OKcINSPECTION END

NGcRepair or replace malfunctioning part.

DTC 0502 BATTERY VOLTAGEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1147

Page 551 of 1033

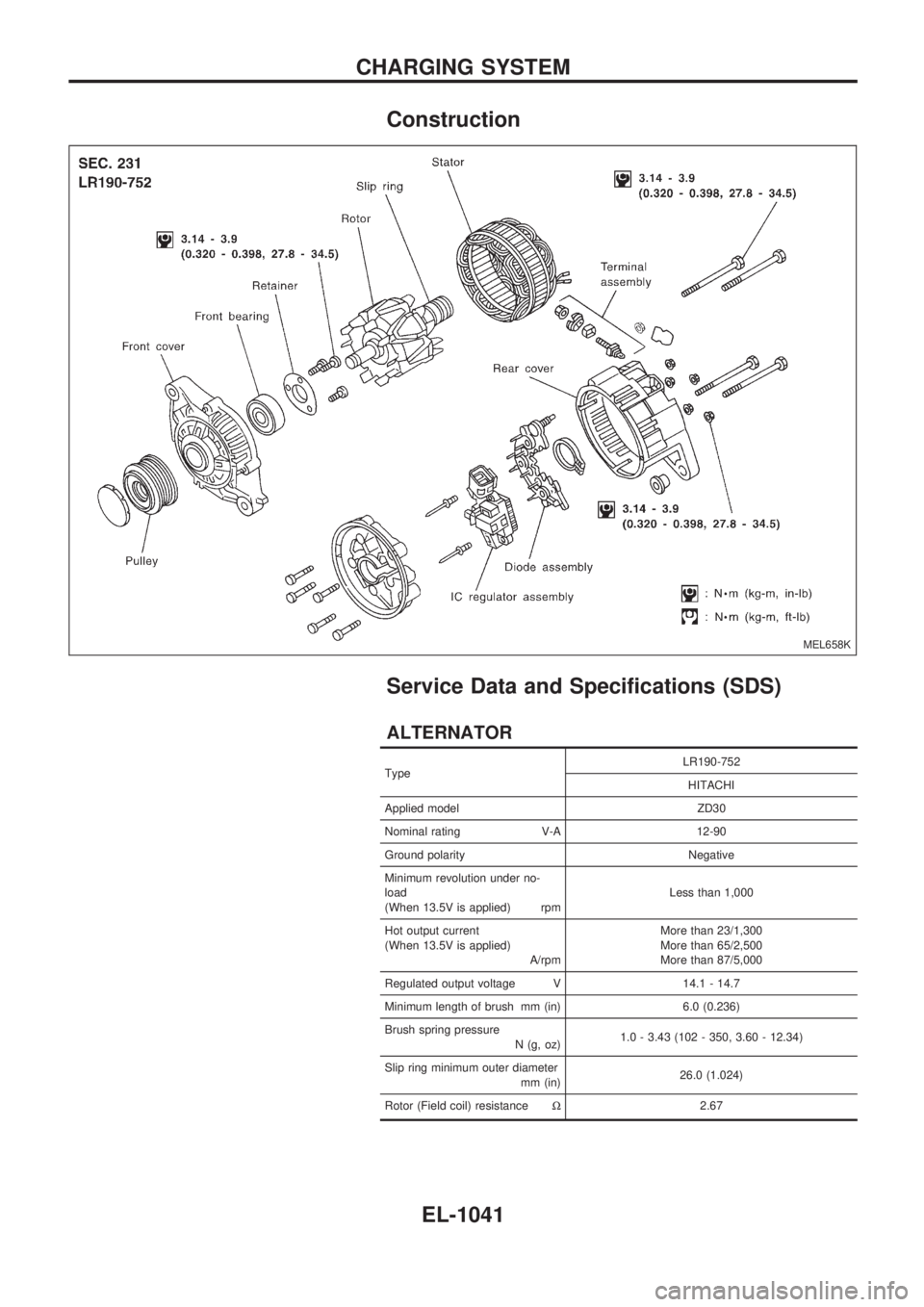

Construction

Service Data and Specifications (SDS)

ALTERNATOR

TypeLR190-752

HITACHI

Applied model ZD30

Nominal rating V-A 12-90

Ground polarity Negative

Minimum revolution under no-

load

(When 13.5V is applied) rpmLess than 1,000

Hot output current

(When 13.5V is applied)

A/rpmMore than 23/1,300

More than 65/2,500

More than 87/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) 6.0 (0.236)

Brush spring pressure

N (g, oz)1.0 - 3.43 (102 - 350, 3.60 - 12.34)

Slip ring minimum outer diameter

mm (in)26.0 (1.024)

Rotor (Field coil) resistanceW2.67

MEL658K

CHARGING SYSTEM

EL-1041

Page 778 of 1033

Removal

1. Remove the following parts.

+Undercover

+Engine oil (Drain)

+Engine coolant (Drain)

+Engine cover

+Intercooler

+Air inlet pipe

+Air cleaner case

+Throttle body

+Swirl and intake air control valve control solenoid valve and

bracket

+Vacuum tank

+Glow plate

+Rocker cover

+Spill tube

+Radiator shrouds (Rear and Lower)

+Cooling fan

+Radiator hose (Upper and Lower)

+Auxiliary belt and auto tensioner.

2. Remove the alternator.

3. Remove the A/C compressor and bracket with piping con-

nected. Move and support it at the LH side of engine bay with

a rope to avoid putting load on piping.

Refer to HA section in Nissan Service Manual (Supplement

I: Publication No. SM0E-Y61AE0E.)

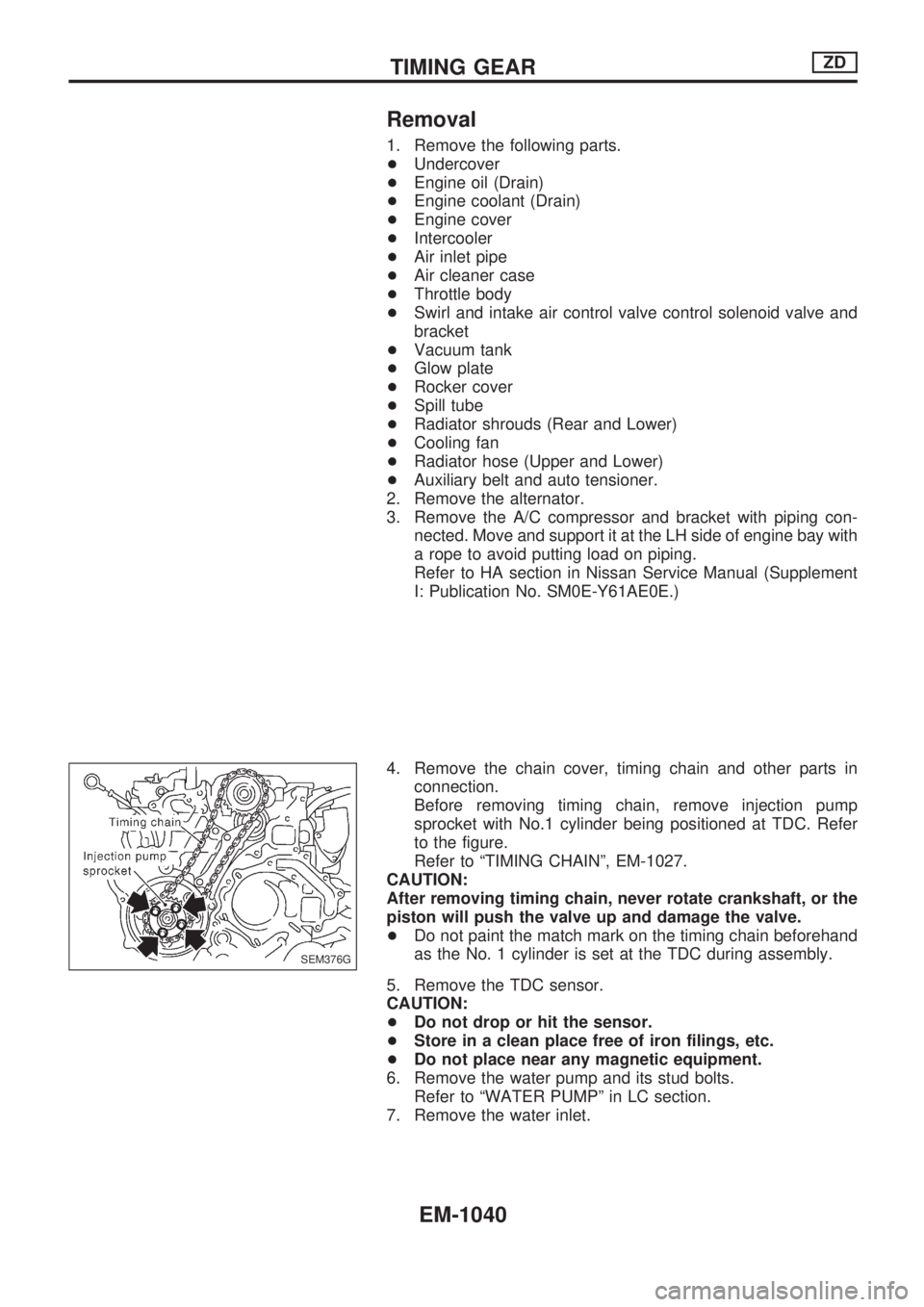

4. Remove the chain cover, timing chain and other parts in

connection.

Before removing timing chain, remove injection pump

sprocket with No.1 cylinder being positioned at TDC. Refer

to the figure.

Refer to ªTIMING CHAINº, EM-1027.

CAUTION:

After removing timing chain, never rotate crankshaft, or the

piston will push the valve up and damage the valve.

+Do not paint the match mark on the timing chain beforehand

as the No. 1 cylinder is set at the TDC during assembly.

5. Remove the TDC sensor.

CAUTION:

+Do not drop or hit the sensor.

+Store in a clean place free of iron filings, etc.

+Do not place near any magnetic equipment.

6. Remove the water pump and its stud bolts.

Refer to ªWATER PUMPº in LC section.

7. Remove the water inlet.

SEM376G

TIMING GEARZD

EM-1040

Page 803 of 1033

5. Disconnect harness connectors from alternator and air com-

pressor.

6. Remove alternator.

7. After removing refrigerant, remove pipes of air compressor

and inlet/outlet.

8. Disconnect heating hose, install blank cap to hose to prevent

coolant from leaking.

9. Remove heating pipe.

10. Remove heat insulator.

11. Remove catalytic converter.

Engine room (Right)

12. Remove power steering reservoir tank from bracket, and fix

it to the vehicle with a rope.

CAUTION:

Keep the reservoir tank level when fixing to prevent oil leak.

13. Remove fuel feed and return hoses.

CAUTION:

Install blank caps immediately to avoid fuel leakage.

14. Remove all harness connectors on the engine, and move

harnesses to the side of the vehicle.

Vehicle underfloor

15. Remove starter motor.

16. Detach A/T oil cooler pipes from oil pan. (A/T model)

17. Remove rear propeller shaft.

18. Remove mounting bolts to secure the engine to transmission.

1) Remove torque converter installation bolt. (A/T model)

2) Lift transmission bottom with transmission jack, and remove

rear mount members from the vehicle.

3) Lower transmission with the jack, and remove upper mount-

ing bolts securing the engine to transmission.

4) Lift transmission with the jack, and reinstall rear mount mem-

bers to the vehicle.

5) Position the jack to the front side of transmission.

6) Remove remaining mounting bolts securing the engine to

transmission.

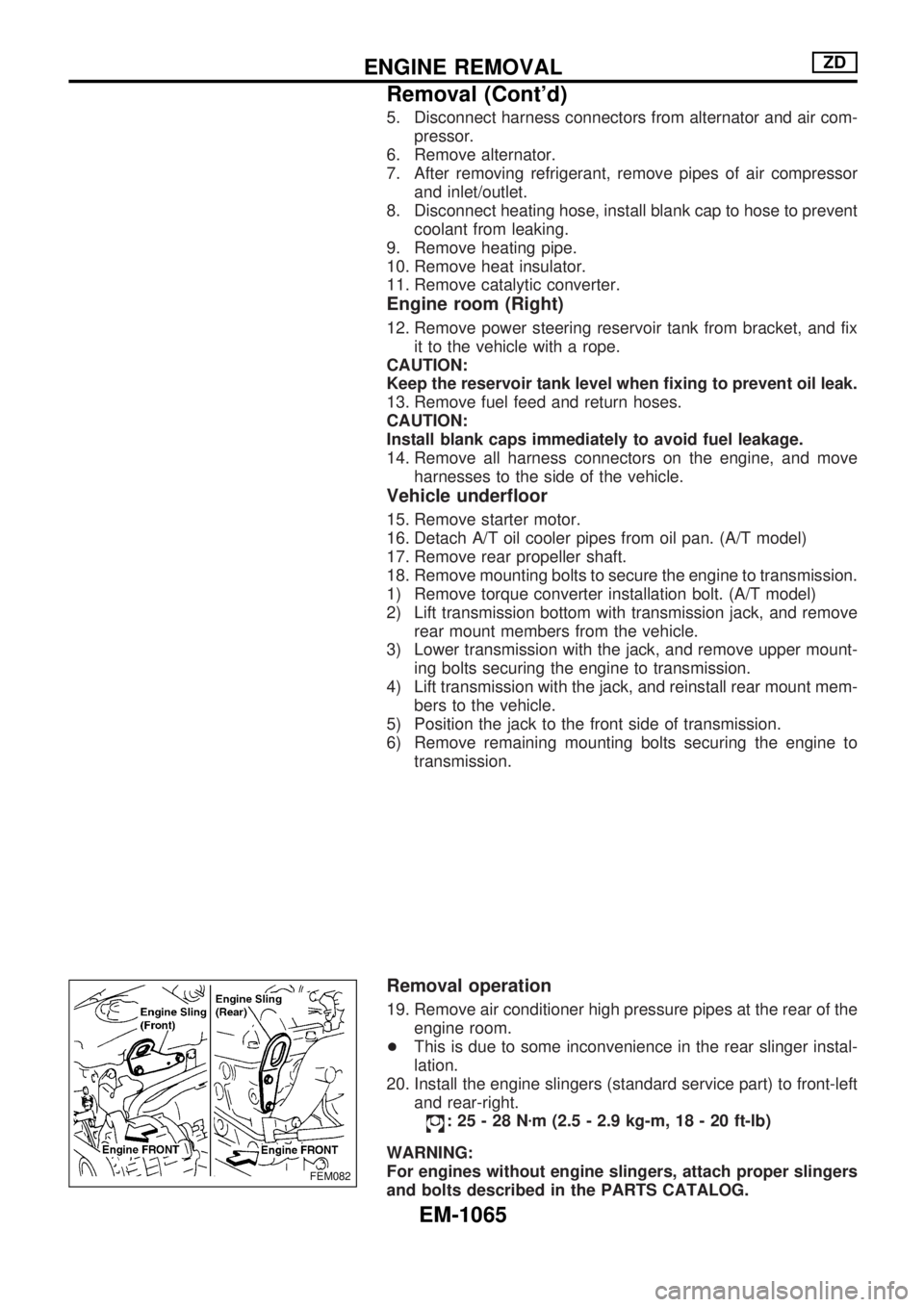

Removal operation

19. Remove air conditioner high pressure pipes at the rear of the

engine room.

+This is due to some inconvenience in the rear slinger instal-

lation.

20. Install the engine slingers (standard service part) to front-left

and rear-right.

:25-28Nzm (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

WARNING:

For engines without engine slingers, attach proper slingers

and bolts described in the PARTS CATALOG.

FEM082

ENGINE REMOVALZD

Removal (Cont'd)

EM-1065

Page 880 of 1033

A

A/T - Wiring diagram ............................. AT-1009

A/T control ............................................. EC-1148

A/T fluid temperature sensor ................. AT-1081

A/T mode switch .................................... AT-1095

A/T self-diagnoses ................................. AT-1028

A/T shift lock system - Wiring

diagram .............................................. AT-1117

A/T shift lock system ............................. AT-1116

A/T trouble diagnoses ........................... AT-1036

APS - Wiring diagram ........................... EC-1125

ASCD (automatic speed control

device) ............................................... EL-1110

ASCD - Wiring diagram ......................... EL-1111

AT/C - Wiring diagram .......................... EC-1150

Accelerator control system .................... FE-1007

Accelerator position sensor .................. EC-1125

Air bag disposal .................................... RS-1015

Air bag precautions ................................ GI-1002

Air bag ................................................... RS-1003

Air cleaner filter replacement ............... MA-1019

Air conditioner cut control ..................... EC-1021

Air flow meter - See Mass air flow

sensor ................................................ EC-1086

Alternator ............................................... EL-1041

Angular tightening application .............. EM-1003

Anti-lock brake system - Wiring

diagram ............................................. BR-1002

Audio ...................................................... EL-1108

Automatic speed control system - See

ASCD ................................................. EL-1110

Automatic transmission fluid

replacement ...................................... MA-1021

B

BACK/L - Wiring diagram ...................... EL-1051

BOOST - Wiring diagram ...................... EC-1204

Back-up lamp ......................................... EL-1051

Basic inspection .................................... EC-1049

Battery ................................................... EL-1035

Boring/horning cylinder block ............... EM-1075

C

CHARGE - Wiring diagram ................... EL-1040

CKPS - Wiring diagram ........................ EC-1140

CONSULT for engine ............................ EC-1038

CONSULT general information .............. GI-1003

COOL/F - Wiring diagram ..................... EC-1105

CORNER - Wiring diagram ................... EL-1054

Camshaft inspection ............................. EM-1032

Charging system .................................... EL-1040

Chassis and body maintenance ........... MA-1020

Clutch operating cylinder ....................... CL-1003

Collision diagnosis ................................ RS-1052

Combination meter ................................ EL-1073Combination switch ............................... EL-1042

Compression pressure ......................... EM-1010

Compressor mounting ........................... HA-1023

Connecting rod bearing clearance ....... EM-1078

Connecting rod bushing clearance ....... EM-1074

Connecting rod ..................................... EM-1074

Control valve (A/T) ................................ AT-1148

Converter housing installation ............... AT-1128

Coolant mixture ratio ............................ MA-1010

Coolant replacement ............................ MA-1014

Cooling fan control ................................ EC-1105

Cornering lamp ...................................... EL-1054

Crankcase emission control system -

See Positive crankcase ventilation ... EC-1022

Crankcase ventilation system - See

Positive crankcase ventilation ........... EC-1022

Crankshaft position sensor (TDC) ........ EC-1140

Crankshaft ............................................ EM-1077

Cruise control - See ASCD ................... EL-1110

Cylinder block boring ............................ EM-1020

Cylinder block ....................................... EM-1067

Cylinder head bolt tightening ................ EM-1034

Cylinder head ....................................... EM-1053

D

DEF - Wiring diagram ............................ EL-1102

DTRL - Wiring diagram ......................... EL-1044

Data link connector for Consult ............ EC-1038

Daytime light system ............................. EL-1044

Diagnosis sensor unit ........................... RS-1008

Diagnostic trouble code (DTC) for

OBD system ...................................... EC-1032

Dome light - See Interior lamp .............. EL-1067

Door mirror ............................................ BT-1007

Door trim ................................................ BT-1004

Drive belt inspection ............................. MA-1011

Drive plate runout ................................. EM-1095

Dropping resistor (A/T) .......................... AT-1086

E

ECCS-D control module .. EC-1068, 1117, 1189,

1191, 1196, 1200

ECM input/output signal ........................ EC-1068

ECTS - Wiring diagram ......................... EC-1092

EGR - Wiring diagram .......................... EC-1209

EGR volume control valve .................... EC-1207

Electrical unit ......................................... EL-1231

Electrical units location .......................... EL-1185

Electronic fuel injection pump .... EC-1119, 1153,

1159, 1165, 1171, 1177, 1180, 1215

Engine control circuit diagram .............. EC-1015

Engine control component parts

location .............................................. EC-1011

Engine control system diagram and

chart .................................................. EC-1016

ALPHABETICAL INDEX

IDX-1002

Page 909 of 1033

Checking Tightening Torque

Checking should be performed while engine is cold.

MANIFOLD BOLTS AND NUTS

Intake and exhaust manifolds:

Intake

:25-28Nzm (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

Exhaust

:40-49Nzm (4.0 - 4.5 kg-m, 29 - 36 ft-lb)

Adjusting Intake and Exhaust Valve

Clearance

Refer to EM section.

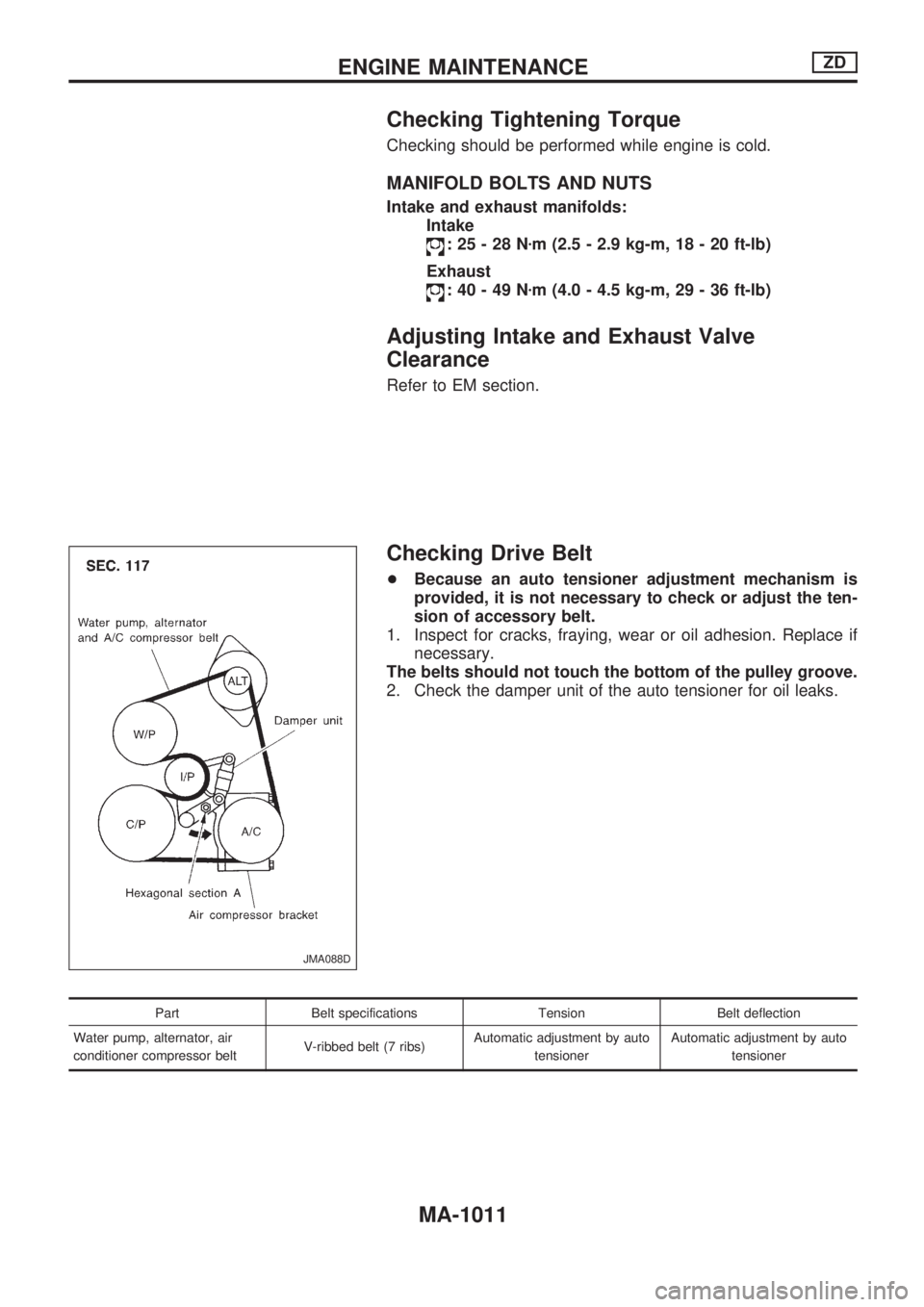

Checking Drive Belt

+Because an auto tensioner adjustment mechanism is

provided, it is not necessary to check or adjust the ten-

sion of accessory belt.

1. Inspect for cracks, fraying, wear or oil adhesion. Replace if

necessary.

The belts should not touch the bottom of the pulley groove.

2. Check the damper unit of the auto tensioner for oil leaks.

Part Belt specifications Tension Belt deflection

Water pump, alternator, air

conditioner compressor beltV-ribbed belt (7 ribs)Automatic adjustment by auto

tensionerAutomatic adjustment by auto

tensioner

JMA088D

ENGINE MAINTENANCEZD

MA-1011

Page 910 of 1033

Removal

WATER PUMP, ALTERNATOR AND AIR

CONDITIONER BELT

1. Remove radiator shroud.

2. Contract and hold the auto tensioner using the following pro-

cedure.

a. Securely hold the 19 mm (0.75 in) hexagonal portion A of

auto tensioner with a closed wrench.

+Preferably use a tool with a handhold of 500 mm (19.69 in)

or more in length.

+No bolts or nuts are required to be loosened during the

operation.

b. Turn the hexagonal portion A in the direction shown by the

arrow to contract the damper unit of the auto tensioner.

CAUTION:

+Because the tensioner has a high tension, it shall be

securely held and turned with a closed wrench.

+Because the hexagonal portion A of the tensioner is

made of aluminum and may be damaged by sudden

input, turn it slowly according to the contraction of the

damper unit.

3. Remove the belt from the alternator pulley first, and then

remove it from the other pulleys.

+If the tensioner is not held firmly, your finger may get caught

between the belt and the pulleys. Confirm the holding of the

tensioner, and then hold the belt side in the place away from

the pulleys to attach or remove the belt, paying attention to

prevent your finger from being caught.

CAUTION:

+When handling the belt, pay attention to prevent the oil

or coolant from adhering to the belt.

+Do not distort or bend the belt intensively.

Installation

+Install the belt in the reverse order of removal.

+After installation of the belt, confirm that the belt engages the

pulleys securely.

+Depending on the engagement between the belt and the idler

pulley, noise (belt noise) may be heard when the engine is

started just after installation. This noise will stop with time.

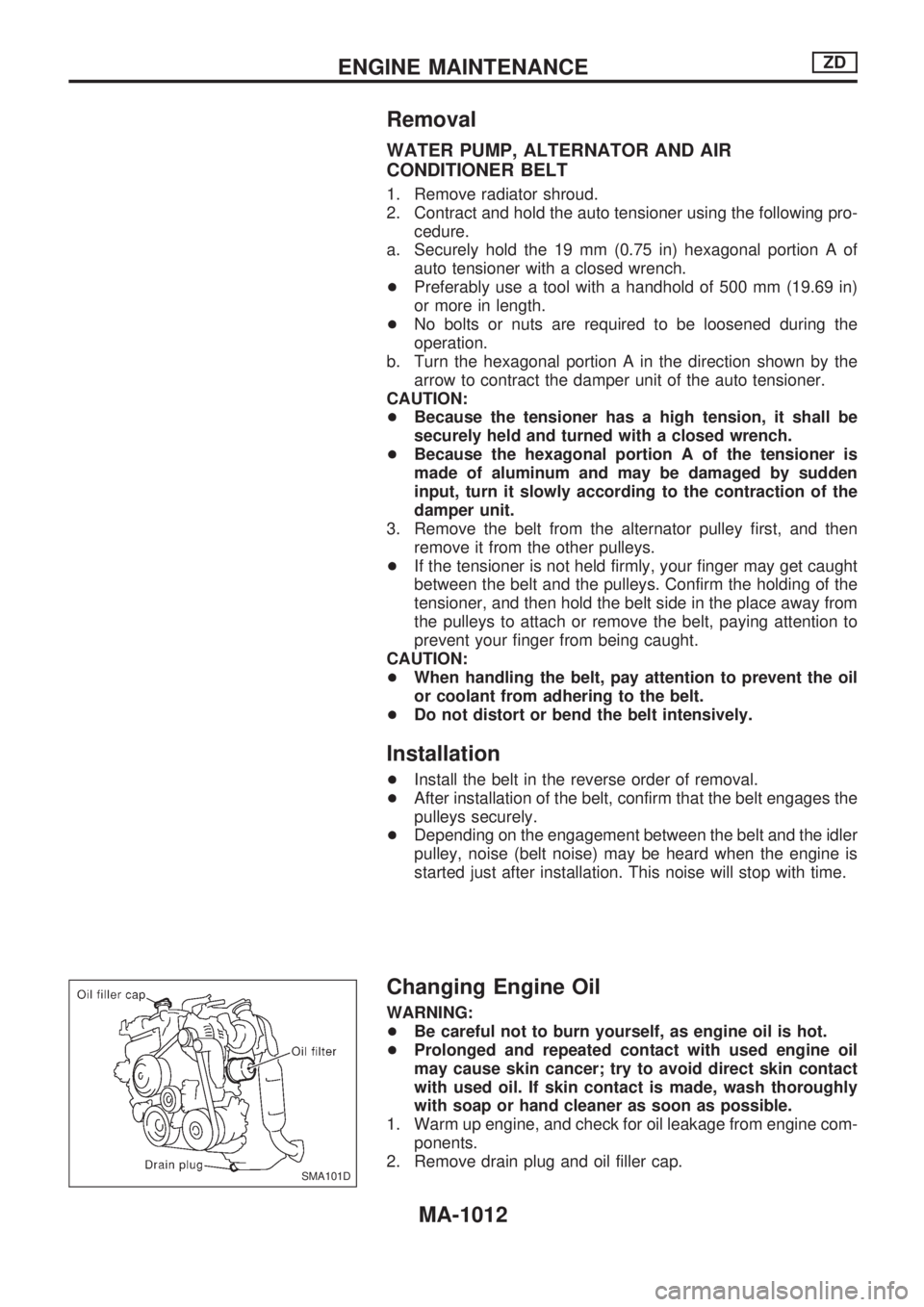

Changing Engine Oil

WARNING:

+Be careful not to burn yourself, as engine oil is hot.

+Prolonged and repeated contact with used engine oil

may cause skin cancer; try to avoid direct skin contact

with used oil. If skin contact is made, wash thoroughly

with soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Remove drain plug and oil filler cap.

SMA101D

ENGINE MAINTENANCEZD

MA-1012