break NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 241 of 1033

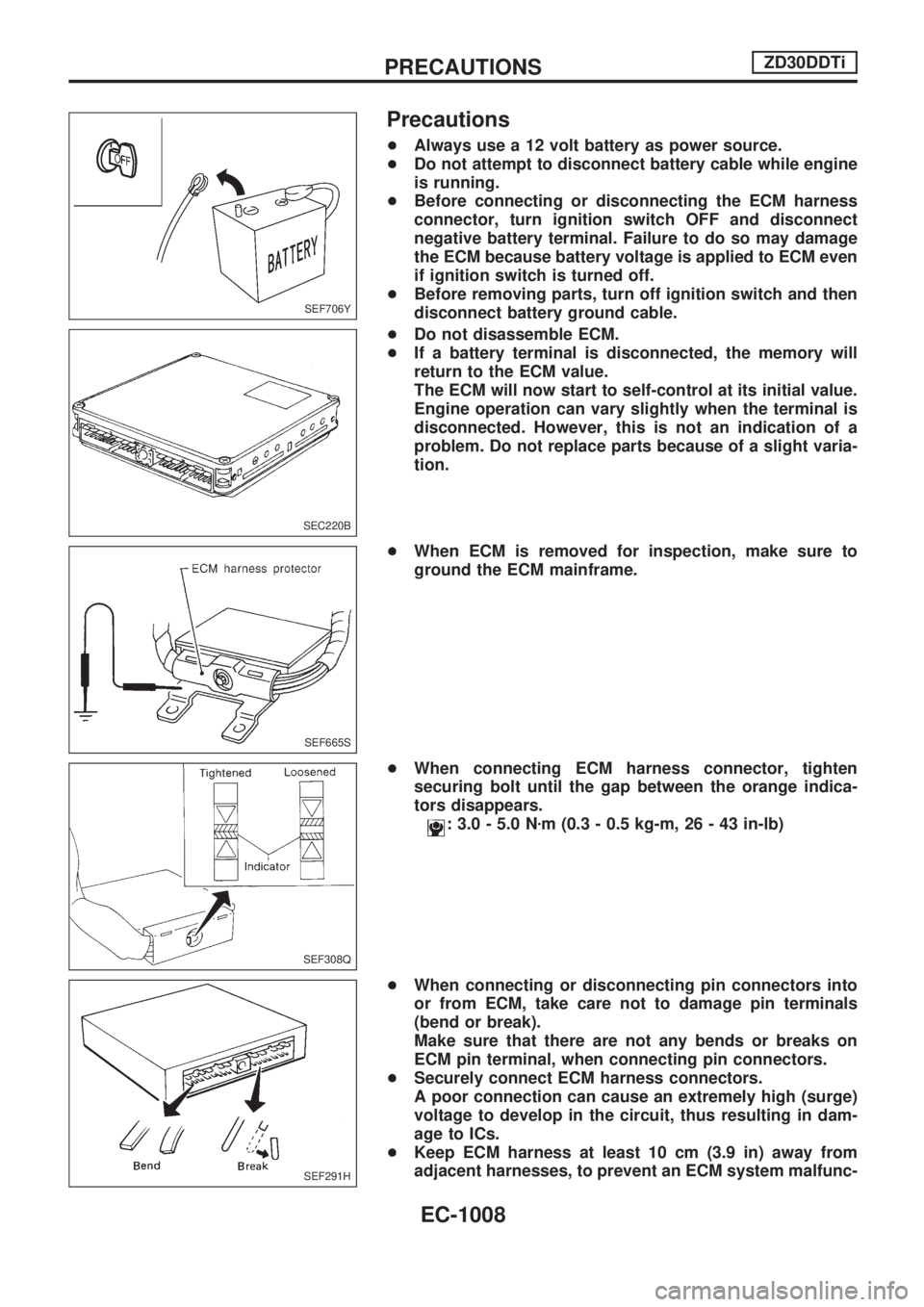

Precautions

+Always use a 12 volt battery as power source.

+Do not attempt to disconnect battery cable while engine

is running.

+Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect

negative battery terminal. Failure to do so may damage

the ECM because battery voltage is applied to ECM even

if ignition switch is turned off.

+Before removing parts, turn off ignition switch and then

disconnect battery ground cable.

+Do not disassemble ECM.

+If a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a

problem. Do not replace parts because of a slight varia-

tion.

+When ECM is removed for inspection, make sure to

ground the ECM mainframe.

+When connecting ECM harness connector, tighten

securing bolt until the gap between the orange indica-

tors disappears.

: 3.0 - 5.0 Nzm (0.3 - 0.5 kg-m, 26 - 43 in-lb)

+When connecting or disconnecting pin connectors into

or from ECM, take care not to damage pin terminals

(bend or break).

Make sure that there are not any bends or breaks on

ECM pin terminal, when connecting pin connectors.

+Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in the circuit, thus resulting in dam-

age to ICs.

+Keep ECM harness at least 10 cm (3.9 in) away from

adjacent harnesses, to prevent an ECM system malfunc-

SEF706Y

SEC220B

SEF665S

SEF308Q

SEF291H

PRECAUTIONSZD30DDTi

EC-1008

Page 286 of 1033

9 CHECK AIR CLEANER FILTER

Check air cleaner filter for clogging or breaks.

OK or NG

OKcGO TO 10.

NGcReplace air cleaner filter.

10 CHECK FUEL INJECTION NOZZLE

Check fuel injection nozzle opening pressure. Refer to ªInjection pressure testº, EC-1025.

OK or NG

OKcGO TO 11.

NGcReplace fuel injection nozzle assembly.

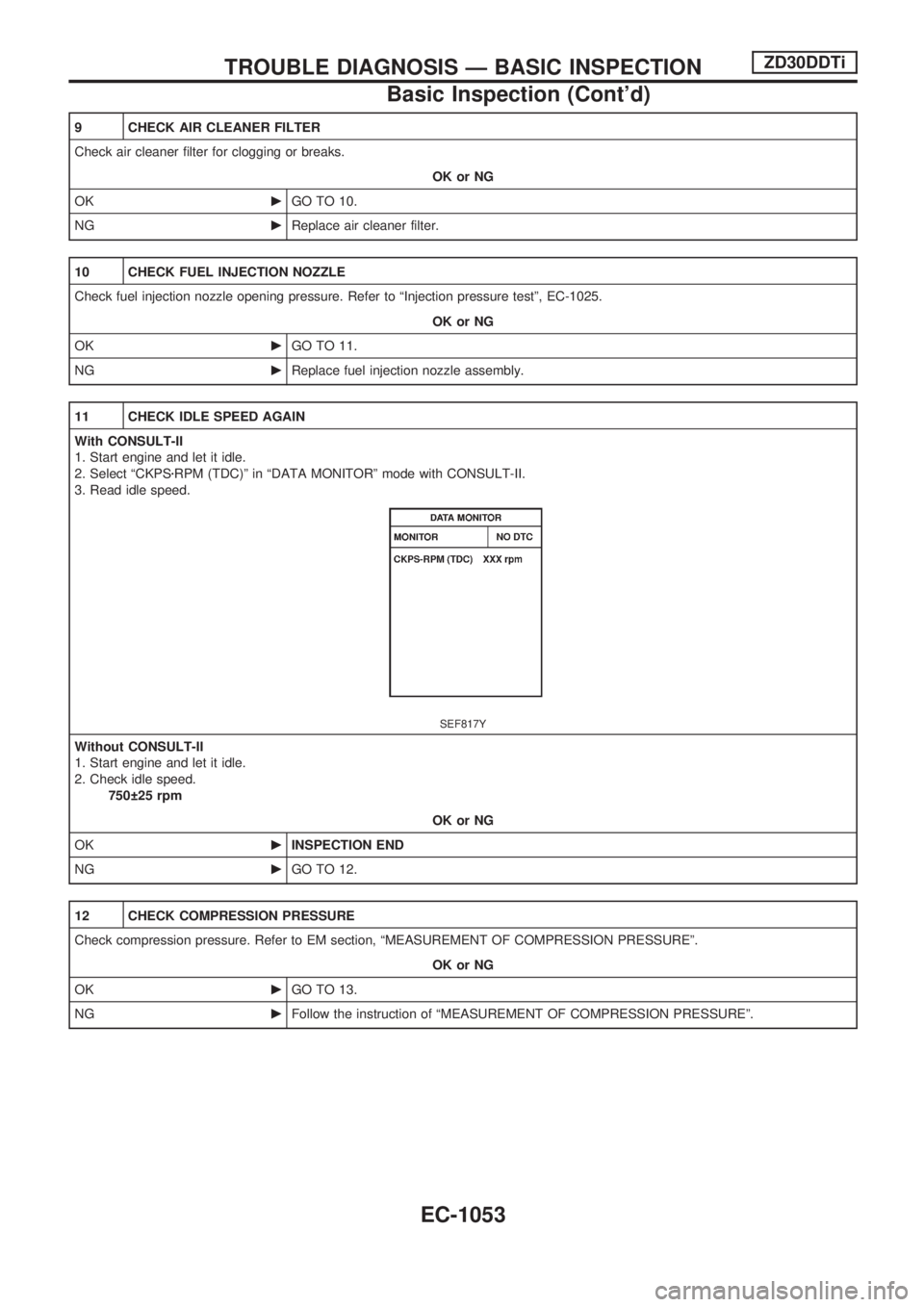

11 CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select ªCKPSzRPM (TDC)º in ªDATA MONITORº mode with CONSULT-II.

3. Read idle speed.

SEF817Y

Without CONSULT-II

1. Start engine and let it idle.

2. Check idle speed.

750 25 rpm

OK or NG

OKcINSPECTION END

NGcGO TO 12.

12 CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM section, ªMEASUREMENT OF COMPRESSION PRESSUREº.

OK or NG

OKcGO TO 13.

NGcFollow the instruction of ªMEASUREMENT OF COMPRESSION PRESSUREº.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONZD30DDTi

Basic Inspection (Cont'd)

EC-1053

Page 632 of 1033

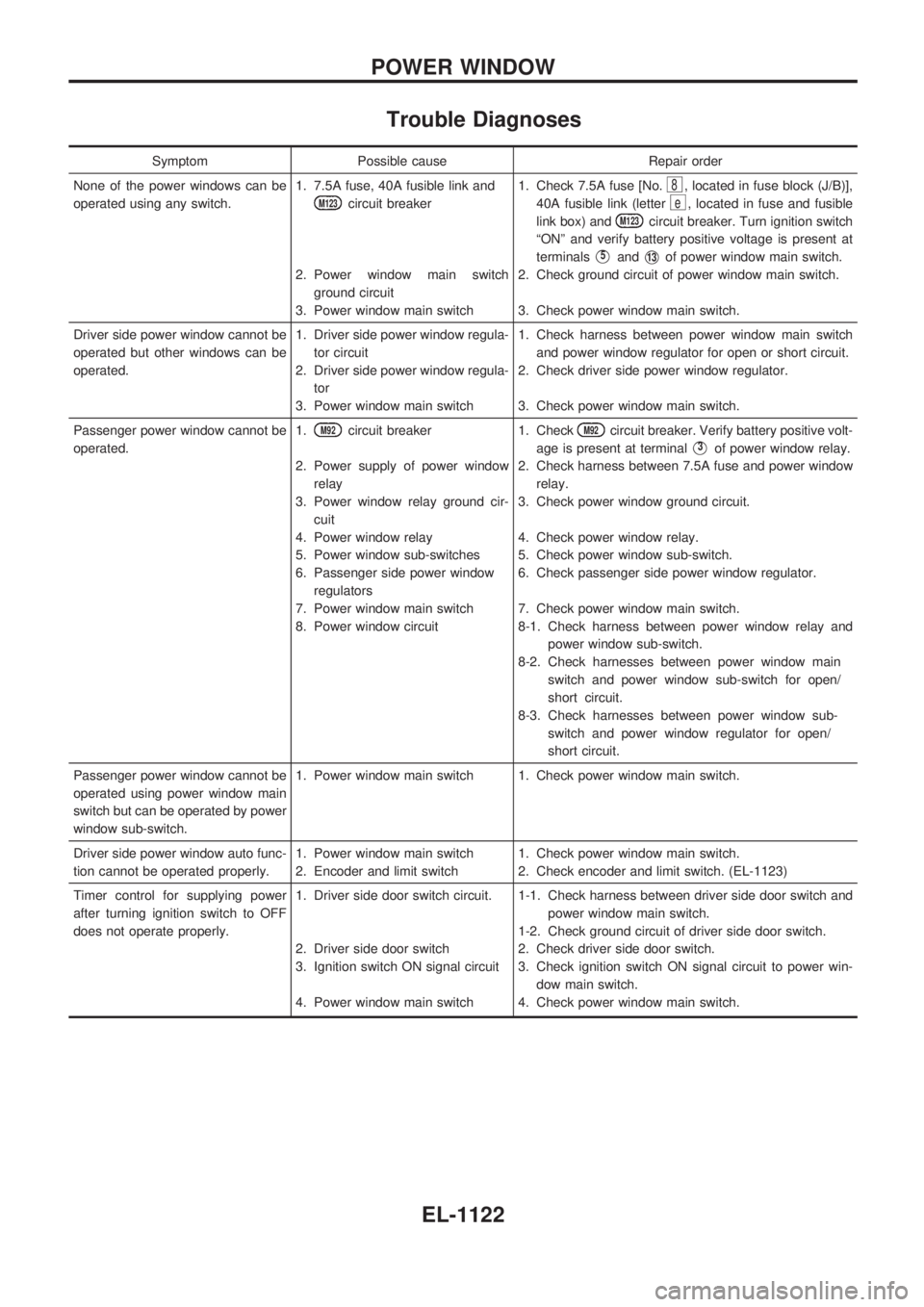

Trouble Diagnoses

Symptom Possible cause Repair order

None of the power windows can be

operated using any switch.1. 7.5A fuse, 40A fusible link and

M123circuit breaker

2. Power window main switch

ground circuit

3. Power window main switch1. Check 7.5A fuse [No.

8, located in fuse block (J/B)],

40A fusible link (letter

e, located in fuse and fusible

link box) and

M123circuit breaker. Turn ignition switch

ªONº and verify battery positive voltage is present at

terminals

V5andV13of power window main switch.

2. Check ground circuit of power window main switch.

3. Check power window main switch.

Driver side power window cannot be

operated but other windows can be

operated.1. Driver side power window regula-

tor circuit

2. Driver side power window regula-

tor

3. Power window main switch1. Check harness between power window main switch

and power window regulator for open or short circuit.

2. Check driver side power window regulator.

3. Check power window main switch.

Passenger power window cannot be

operated.1.

M92circuit breaker

2. Power supply of power window

relay

3. Power window relay ground cir-

cuit

4. Power window relay

5. Power window sub-switches

6. Passenger side power window

regulators

7. Power window main switch

8. Power window circuit1. CheckM92circuit breaker. Verify battery positive volt-

age is present at terminal

V3of power window relay.

2. Check harness between 7.5A fuse and power window

relay.

3. Check power window ground circuit.

4. Check power window relay.

5. Check power window sub-switch.

6. Check passenger side power window regulator.

7. Check power window main switch.

8-1. Check harness between power window relay and

power window sub-switch.

8-2. Check harnesses between power window main

switch and power window sub-switch for open/

short circuit.

8-3. Check harnesses between power window sub-

switch and power window regulator for open/

short circuit.

Passenger power window cannot be

operated using power window main

switch but can be operated by power

window sub-switch.1. Power window main switch 1. Check power window main switch.

Driver side power window auto func-

tion cannot be operated properly.1. Power window main switch

2. Encoder and limit switch1. Check power window main switch.

2. Check encoder and limit switch. (EL-1123)

Timer control for supplying power

after turning ignition switch to OFF

does not operate properly.1. Driver side door switch circuit.

2. Driver side door switch

3. Ignition switch ON signal circuit

4. Power window main switch1-1. Check harness between driver side door switch and

power window main switch.

1-2. Check ground circuit of driver side door switch.

2. Check driver side door switch.

3. Check ignition switch ON signal circuit to power win-

dow main switch.

4. Check power window main switch.

POWER WINDOW

EL-1122

Page 748 of 1033

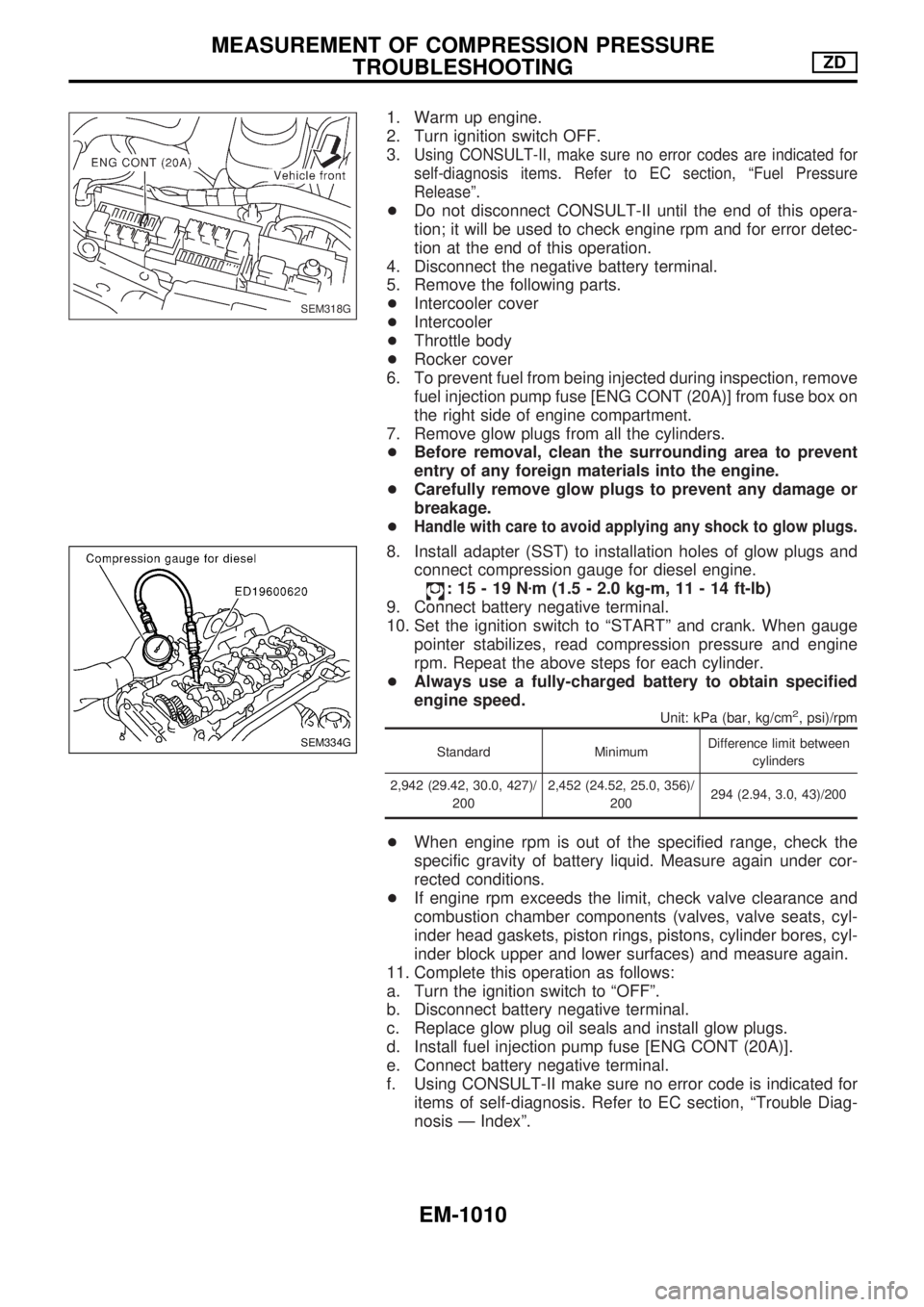

1. Warm up engine.

2. Turn ignition switch OFF.

3.

Using CONSULT-II, make sure no error codes are indicated for

self-diagnosis items. Refer to EC section, ªFuel Pressure

Releaseº.

+Do not disconnect CONSULT-II until the end of this opera-

tion; it will be used to check engine rpm and for error detec-

tion at the end of this operation.

4. Disconnect the negative battery terminal.

5. Remove the following parts.

+Intercooler cover

+Intercooler

+Throttle body

+Rocker cover

6. To prevent fuel from being injected during inspection, remove

fuel injection pump fuse [ENG CONT (20A)] from fuse box on

the right side of engine compartment.

7. Remove glow plugs from all the cylinders.

+Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

+Carefully remove glow plugs to prevent any damage or

breakage.

+

Handle with care to avoid applying any shock to glow plugs.

8. Install adapter (SST) to installation holes of glow plugs and

connect compression gauge for diesel engine.

:15-19Nzm (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

9. Connect battery negative terminal.

10. Set the ignition switch to ªSTARTº and crank. When gauge

pointer stabilizes, read compression pressure and engine

rpm. Repeat the above steps for each cylinder.

+Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

2,942 (29.42, 30.0, 427)/

2002,452 (24.52, 25.0, 356)/

200294 (2.94, 3.0, 43)/200

+When engine rpm is out of the specified range, check the

specific gravity of battery liquid. Measure again under cor-

rected conditions.

+If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cyl-

inder head gaskets, piston rings, pistons, cylinder bores, cyl-

inder block upper and lower surfaces) and measure again.

11. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Replace glow plug oil seals and install glow plugs.

d. Install fuel injection pump fuse [ENG CONT (20A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for

items of self-diagnosis. Refer to EC section, ªTrouble Diag-

nosis Ð Indexº.

SEM318G

SEM334G

MEASUREMENT OF COMPRESSION PRESSURE

TROUBLESHOOTINGZD

EM-1010

Page 792 of 1033

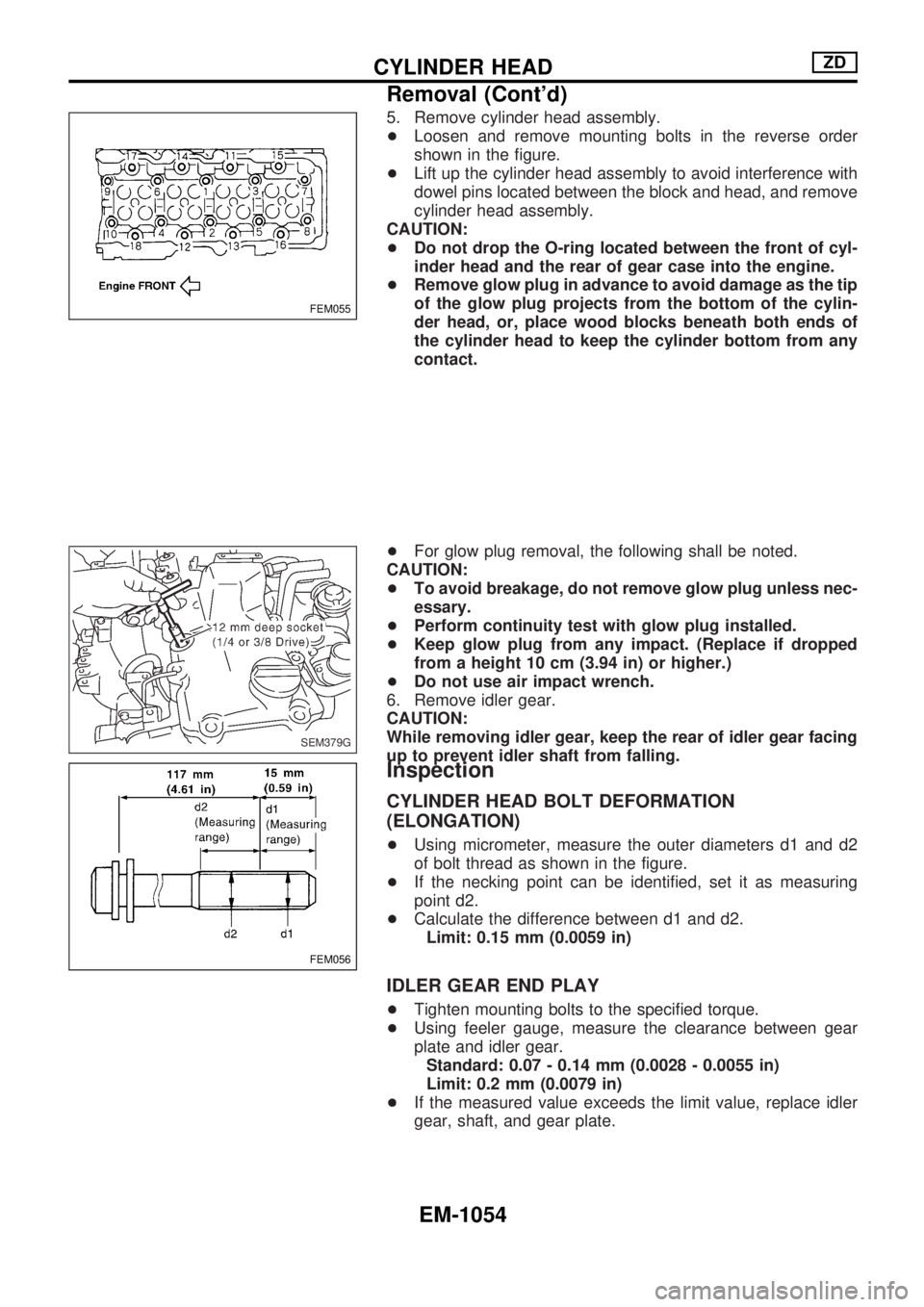

5. Remove cylinder head assembly.

+Loosen and remove mounting bolts in the reverse order

shown in the figure.

+Lift up the cylinder head assembly to avoid interference with

dowel pins located between the block and head, and remove

cylinder head assembly.

CAUTION:

+Do not drop the O-ring located between the front of cyl-

inder head and the rear of gear case into the engine.

+Remove glow plug in advance to avoid damage as the tip

of the glow plug projects from the bottom of the cylin-

der head, or, place wood blocks beneath both ends of

the cylinder head to keep the cylinder bottom from any

contact.

+For glow plug removal, the following shall be noted.

CAUTION:

+To avoid breakage, do not remove glow plug unless nec-

essary.

+Perform continuity test with glow plug installed.

+Keep glow plug from any impact. (Replace if dropped

from a height 10 cm (3.94 in) or higher.)

+Do not use air impact wrench.

6. Remove idler gear.

CAUTION:

While removing idler gear, keep the rear of idler gear facing

up to prevent idler shaft from falling.

Inspection

CYLINDER HEAD BOLT DEFORMATION

(ELONGATION)

+Using micrometer, measure the outer diameters d1 and d2

of bolt thread as shown in the figure.

+If the necking point can be identified, set it as measuring

point d2.

+Calculate the difference between d1 and d2.

Limit: 0.15 mm (0.0059 in)

IDLER GEAR END PLAY

+Tighten mounting bolts to the specified torque.

+Using feeler gauge, measure the clearance between gear

plate and idler gear.

Standard: 0.07 - 0.14 mm (0.0028 - 0.0055 in)

Limit: 0.2 mm (0.0079 in)

+If the measured value exceeds the limit value, replace idler

gear, shaft, and gear plate.

FEM055

SEM379G

FEM056

CYLINDER HEADZD

Removal (Cont'd)

EM-1054

Page 889 of 1033

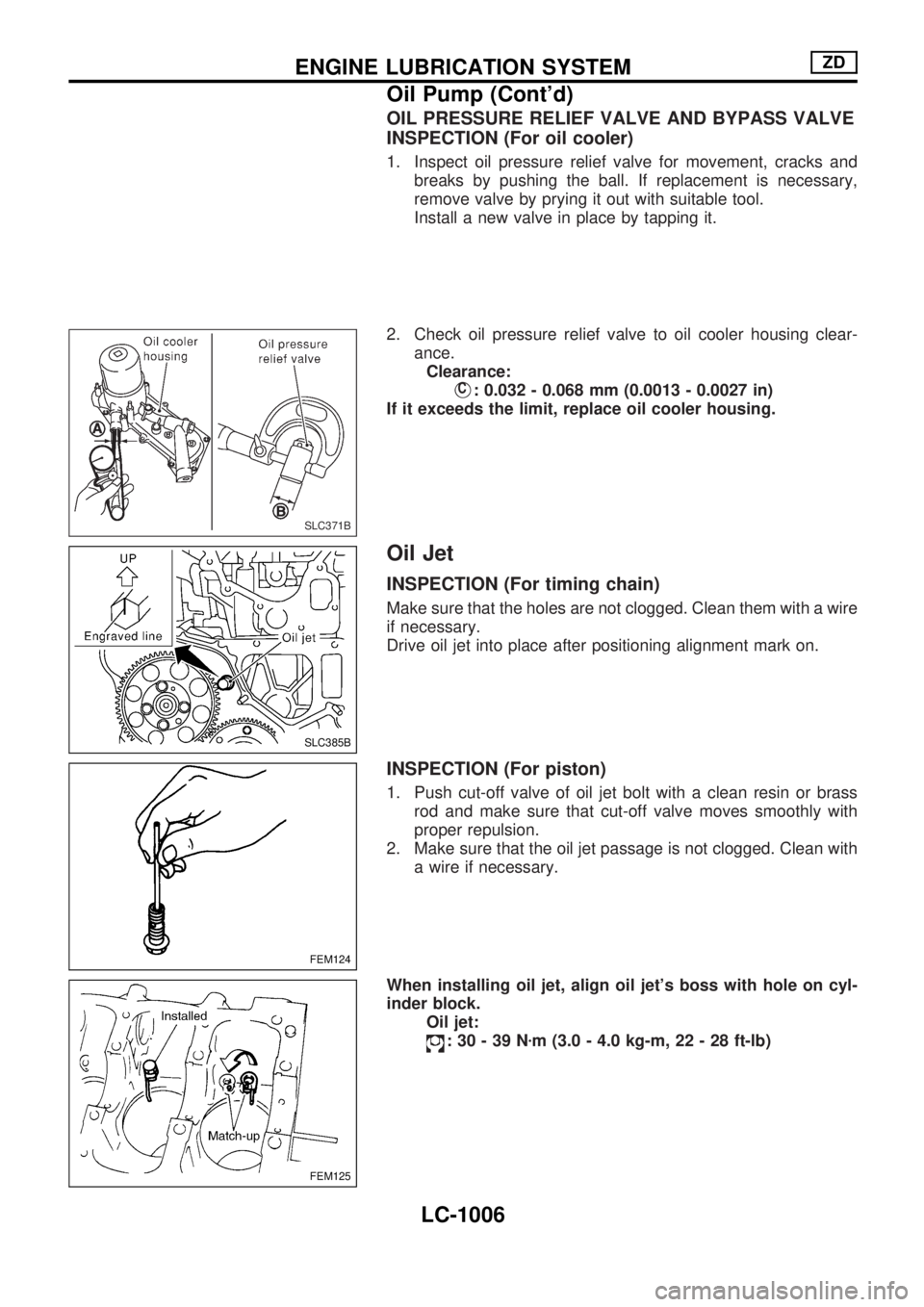

OIL PRESSURE RELIEF VALVE AND BYPASS VALVE

INSPECTION (For oil cooler)

1. Inspect oil pressure relief valve for movement, cracks and

breaks by pushing the ball. If replacement is necessary,

remove valve by prying it out with suitable tool.

Install a new valve in place by tapping it.

2. Check oil pressure relief valve to oil cooler housing clear-

ance.

Clearance:

VC: 0.032 - 0.068 mm (0.0013 - 0.0027 in)

If it exceeds the limit, replace oil cooler housing.

Oil Jet

INSPECTION (For timing chain)

Make sure that the holes are not clogged. Clean them with a wire

if necessary.

Drive oil jet into place after positioning alignment mark on.

INSPECTION (For piston)

1. Push cut-off valve of oil jet bolt with a clean resin or brass

rod and make sure that cut-off valve moves smoothly with

proper repulsion.

2. Make sure that the oil jet passage is not clogged. Clean with

a wire if necessary.

When installing oil jet, align oil jet's boss with hole on cyl-

inder block.

Oil jet:

:30-39Nzm (3.0 - 4.0 kg-m, 22 - 28 ft-lb)

SLC371B

SLC385B

FEM124

FEM125

ENGINE LUBRICATION SYSTEMZD

Oil Pump (Cont'd)

LC-1006

Page 977 of 1033

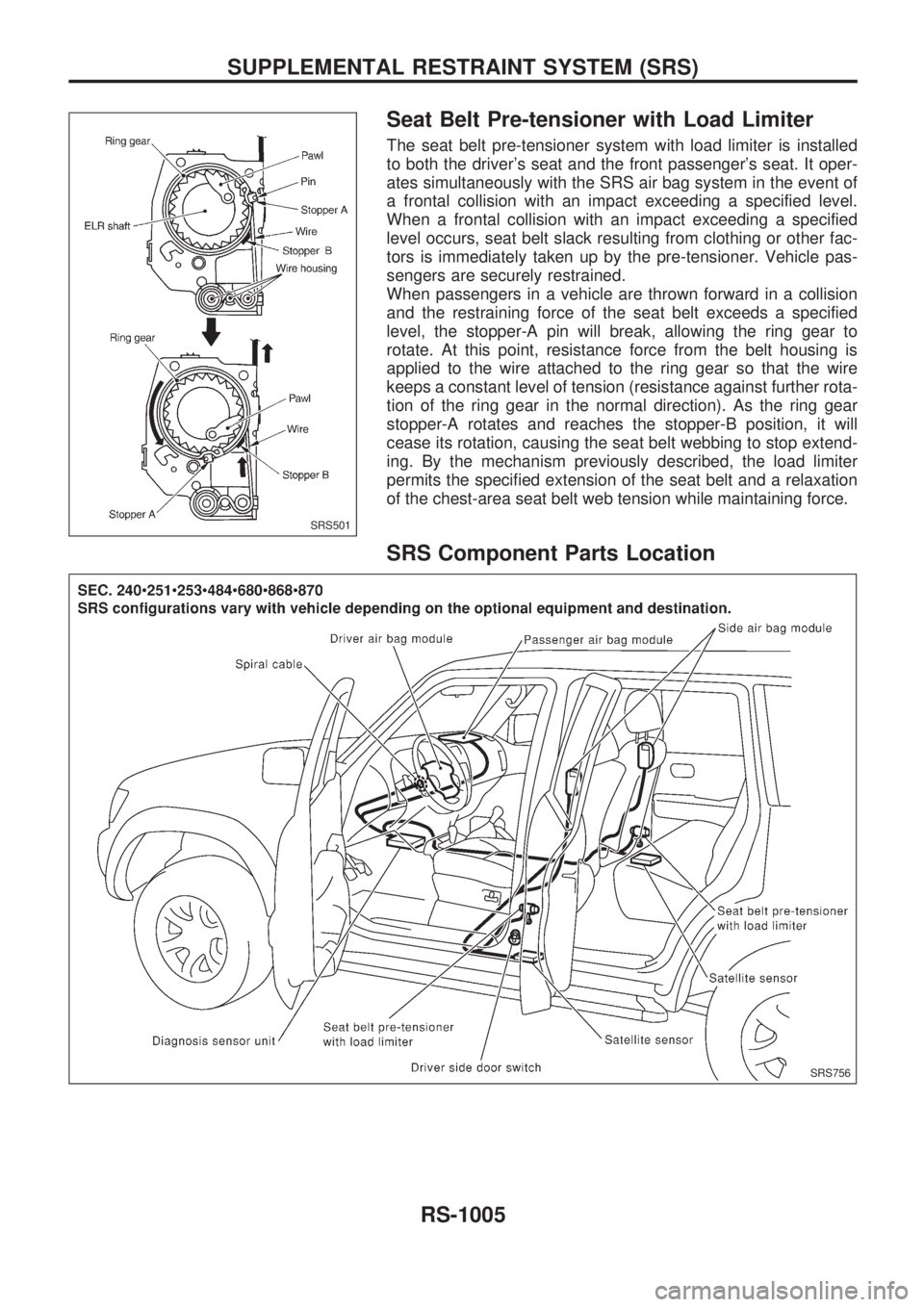

Seat Belt Pre-tensioner with Load Limiter

The seat belt pre-tensioner system with load limiter is installed

to both the driver's seat and the front passenger's seat. It oper-

ates simultaneously with the SRS air bag system in the event of

a frontal collision with an impact exceeding a specified level.

When a frontal collision with an impact exceeding a specified

level occurs, seat belt slack resulting from clothing or other fac-

tors is immediately taken up by the pre-tensioner. Vehicle pas-

sengers are securely restrained.

When passengers in a vehicle are thrown forward in a collision

and the restraining force of the seat belt exceeds a specified

level, the stopper-A pin will break, allowing the ring gear to

rotate. At this point, resistance force from the belt housing is

applied to the wire attached to the ring gear so that the wire

keeps a constant level of tension (resistance against further rota-

tion of the ring gear in the normal direction). As the ring gear

stopper-A rotates and reaches the stopper-B position, it will

cease its rotation, causing the seat belt webbing to stop extend-

ing. By the mechanism previously described, the load limiter

permits the specified extension of the seat belt and a relaxation

of the chest-area seat belt web tension while maintaining force.

SRS Component Parts Location

SRS501

SRS756

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-1005