clutch NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 1 of 1033

Edition: February 2000

Release: February 2000 (01)

Publication No.: SM0E-Y61AE0E

Reference No.: 7711346024GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL,

FUEL & EXHAUST SYSTEMFE

CLUTCHCL

MANUAL TRANSMISSIONMT

AUTOMATIC TRANSMISSIONAT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

PATROL GR

MODEL Y61 SERIES

NISSAN EUROPE S.A.S.

2000 NISSAN EUROPE S.A.S.

Produced in The Netherlands

Not to be reproduced in whole or in part

without the prior written permission of

Nissan Europe S.A.S., Paris, France.

QUICK REFERENCE INDEX

Page 3 of 1033

AUTOMATIC TRANSMISSION

SECTION

AT

CONTENTS

PREPARATION AND PRECAUTIONS............... 1003

Special Service Tools ...................................... 1003

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº ... 1004

Precautions ...................................................... 1004

Service Notice or Precautions ......................... 1006

OVERALL SYSTEM............................................ 1007

A/T Electrical Parts Location ........................... 1007

Circuit Diagram ................................................ 1008

Wiring Diagram Ð A/T Ð ................................ 1009

Cross-sectional View ....................................... 1022

Hydraulic Control Circuits ................................ 1023

Shift Mechanism .............................................. 1024

Control System ................................................ 1026

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION..................................................... 1028

Self-diagnosis................................................... 1028

Diagnosis by CONSULT-II ............................... 1034

TROUBLE DIAGNOSIS Ð Introduction............ 1036

Introduction ...................................................... 1036

Diagnostic Worksheet ...................................... 1037

Work Flow ........................................................ 1040

TROUBLE DIAGNOSIS Ð Basic Inspection.... 1041

A/T Fluid Check ............................................... 1041

Stall Test .......................................................... 1041

Line Pressure Test........................................... 1044

Road Test ........................................................ 1046

TROUBLE DIAGNOSIS Ð General

Description.......................................................... 1057

Symptom Chart ................................................ 1057

TCM Terminals and Reference Value ............. 1060

TROUBLE DIAGNOSIS FOR VHCL SPEED

SENzA/T................................................................ 1064Vehicle Speed SensorzA/T (Revolution

sensor) ............................................................. 1064

TROUBLE DIAGNOSIS FOR VHCL SPEED

SENzMTR.............................................................. 1066

Vehicle Speed SensorzzMTR ............................ 1066

TROUBLE DIAGNOSIS FOR THROTTLE POSI

SEN...................................................................... 1068

Accelerator Position Sensor ............................ 1068

TROUBLE DIAGNOSIS FOR SHIFT

SOLENOID/V A.................................................... 1070

Shift Solenoid Valve A ..................................... 1070

TROUBLE DIAGNOSIS FOR SHIFT

SOLENOID/V B.................................................... 1072

Shift Solenoid Valve B ..................................... 1072

TROUBLE DIAGNOSIS FOR OVERRUN

CLUTCH S/V........................................................ 1074

Overrun Clutch Solenoid Valve ....................... 1074

TROUBLE DIAGNOSIS FOR T/C CLUTCH

SOL/V................................................................... 1076

Torque Converter Clutch Solenoid Valve ........ 1076

TROUBLE DIAGNOSIS FOR BATT/FLUID

TEMP SEN........................................................... 1079

A/T Fluid Temperature Sensor and TCM

Power Source .................................................. 1079

TROUBLE DIAGNOSIS FOR ENGINE SPEED

SIG....................................................................... 1082

Engine Speed Signal ....................................... 1082

TROUBLE DIAGNOSIS FOR LINE PRESSURE

S/V........................................................................ 1084

Line Pressure Solenoid Valve ......................... 1084

TROUBLE DIAGNOSIS FOR CONTROL UNIT

(RAM), CONTROL UNIT (ROM)......................... 1087

Description ....................................................... 1087

AT

Page 4 of 1033

Diagnostic Procedure....................................... 1088

TROUBLE DIAGNOSIS FOR CONTROL UNIT

(EFP ROM)........................................................... 1089

Description ....................................................... 1089

Diagnostic Procedure....................................... 1090

TROUBLE DIAGNOSIS FOR

NON-DETECTABLE ITEMS................................ 1091

PNP, Overdrive Control, A/T Mode or

Accelerator Position Switches ......................... 1091

DIAGNOSTIC PROCEDURES FOR

SYMPTOMS......................................................... 1097

1. SPORT Indicator Lamp Does Not

Come On.......................................................... 1097

2. SPORT Indicator Lamp Does Not

Come On.......................................................... 1098

3. O/D OFF Indicator Lamp Does Not Come

On .................................................................... 1098

4. SPORT Indicator Lamp Does Not

Come On.......................................................... 1099

5. Engine Cannot Be Started In ªPº and ªNº

Position ............................................................ 1100

6. In ªPº Position, Vehicle Moves Forward Or

Backward When Pushed ................................. 1100

7. In ªNº Position, Vehicle Moves .................... 1101

8. Large Shock. ªNº®ªRº Position ................ 1102

9. Vehicle Does Not Creep Backward In ªRº

Position ............................................................ 1103

10. Vehicle Does Not Creep Forward In ªDº,

ª2º Or ª1º Position ............................................ 1104

11. Vehicle Cannot Be Started From D

1......... 1105

12. A/T Does Not Shift: D

1®D2Or Does Not

Kickdown: D

4®D2......................................... 1106

13. A/T Does Not Shift: D

2®D3.................... 1107

14. A/T Does Not Shift: D

3®D4.................... 1108

15. A/T Does Not Perform Lock-up ................. 1109

16. A/T Does Not Hold Lock-up Condition ...... 1110

17. Lock-up Is Not Released ........................... 1110

18. Engine Speed Does Not Return To Idle

(Light Braking D

4®D3) .................................. 1111

19. Vehicle Does Not Start From D

1............... 1112

20. A/T Does Not Shift: D

2®D1When

Depressing Accelerator Pedal ......................... 1113

21. A/T Does Not Shift: D

4®D3, When

Overdrive Control Switch ªONº®ªOFFº ........ 1114

22. A/T Does Not Shift: D

3®22, When

Selector Lever ªDº®ª2º Position ................... 1114

23. A/T Does Not Shift: 2

2®11, WhenSelector Lever ª2º®ª1º Position .................... 1115

24. Vehicle Does Not Decelerate By Engine

Brake ................................................................ 1115

TROUBLE DIAGNOSES Ð A/T Shift Lock

System................................................................. 1116

Description ....................................................... 1116

Wiring Diagram Ð SHIFT Ð ........................... 1117

Diagnostic Procedure....................................... 1118

Key Interlock Cable.......................................... 1121

Component Check ........................................... 1122

ON-VEHICLE SERVICE...................................... 1124

Control Valve Assembly and Accumulators .... 1124

Revolution Sensor Replacement ..................... 1125

Rear Oil Seal Replacement ............................. 1125

Parking Pawl Components Inspection ............. 1125

PNP Switch Adjustment ................................... 1125

Manual Control Linkage Adjustment................ 1126

REMOVAL AND INSTALLATION....................... 1127

Removal ........................................................... 1127

Installation ........................................................ 1128

MAJOR OVERHAUL........................................... 1129

Oil Channel ...................................................... 1131

Locations of Needle Bearings, Thrust Washers

and Snap Rings ............................................... 1132

DISASSEMBLY.................................................... 1133

REPAIR FOR COMPONENT PARTS................. 1144

Oil Pump .......................................................... 1144

Control Valve Assembly................................... 1148

Control Valve Upper Body ............................... 1154

Control Valve Lower Body ............................... 1159

Reverse Clutch ................................................ 1161

High Clutch ...................................................... 1165

Forward and Overrun Clutches ....................... 1167

Low & Reverse Brake ...................................... 1171

Forward Clutch Drum Assembly ...................... 1175

Rear Internal Gear and Forward Clutch Hub .. 1177

Band Servo Piston Assembly .......................... 1180

Parking Pawl Components .............................. 1184

ASSEMBLY.......................................................... 1186

Assembly (1) .................................................... 1186

Adjustment ....................................................... 1190

Assembly (2) .................................................... 1195

A/T FLUID COOLER SYSTEM........................... 1205

A/T Fluid Cooler ............................................... 1205

SERVICE DATA AND SPECIFICATIONS (SDS)1206

General Specifications ..................................... 1206

Specifications and Adjustment......................... 1206

When you read wiring diagrams:

+Read GI section, ªHOW TO READ WIRING DIAGRAMSº.

+See EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSESº.

AT-1002

Page 5 of 1033

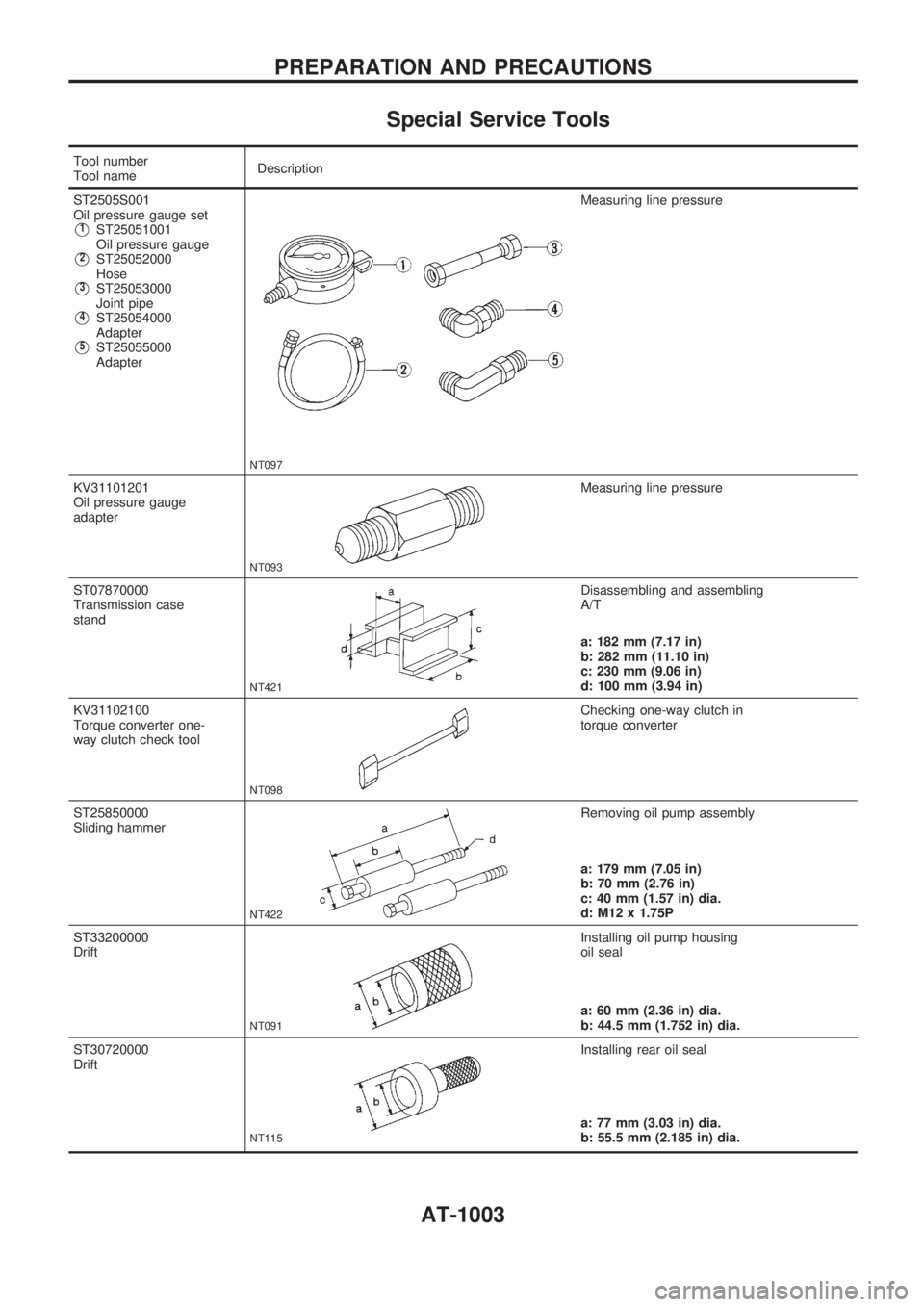

Special Service Tools

Tool number

Tool nameDescription

ST2505S001

Oil pressure gauge set

V1ST25051001

Oil pressure gauge

V2ST25052000

Hose

V3ST25053000

Joint pipe

V4ST25054000

Adapter

V5ST25055000

Adapter

NT097

Measuring line pressure

KV31101201

Oil pressure gauge

adapter

NT093

Measuring line pressure

ST07870000

Transmission case

stand

NT421

Disassembling and assembling

A/T

a: 182 mm (7.17 in)

b: 282 mm (11.10 in)

c: 230 mm (9.06 in)

d: 100 mm (3.94 in)

KV31102100

Torque converter one-

way clutch check tool

NT098

Checking one-way clutch in

torque converter

ST25850000

Sliding hammer

NT422

Removing oil pump assembly

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in) dia.

d: M12 x 1.75P

ST33200000

Drift

NT091

Installing oil pump housing

oil seal

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

ST30720000

Drift

NT115

Installing rear oil seal

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

PREPARATION AND PRECAUTIONS

AT-1003

Page 6 of 1033

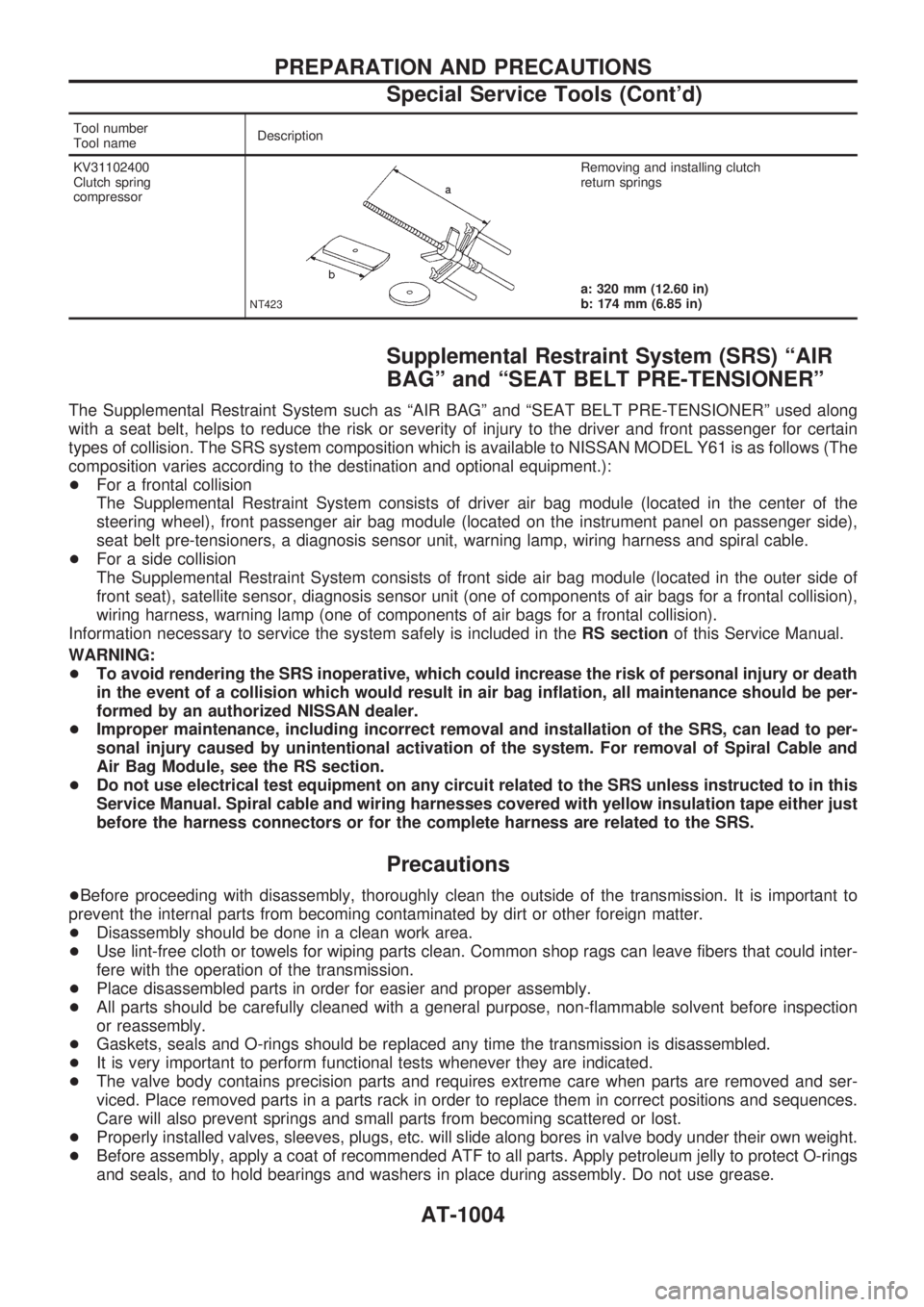

Tool number

Tool nameDescription

KV31102400

Clutch spring

compressor

NT423

Removing and installing clutch

return springs

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions

+Before proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

+Disassembly should be done in a clean work area.

+Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

+Place disassembled parts in order for easier and proper assembly.

+All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection

or reassembly.

+Gaskets, seals and O-rings should be replaced any time the transmission is disassembled.

+It is very important to perform functional tests whenever they are indicated.

+The valve body contains precision parts and requires extreme care when parts are removed and ser-

viced. Place removed parts in a parts rack in order to replace them in correct positions and sequences.

Care will also prevent springs and small parts from becoming scattered or lost.

+Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

+Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, and to hold bearings and washers in place during assembly. Do not use grease.

PREPARATION AND PRECAUTIONS

Special Service Tools (Cont'd)

AT-1004

Page 26 of 1033

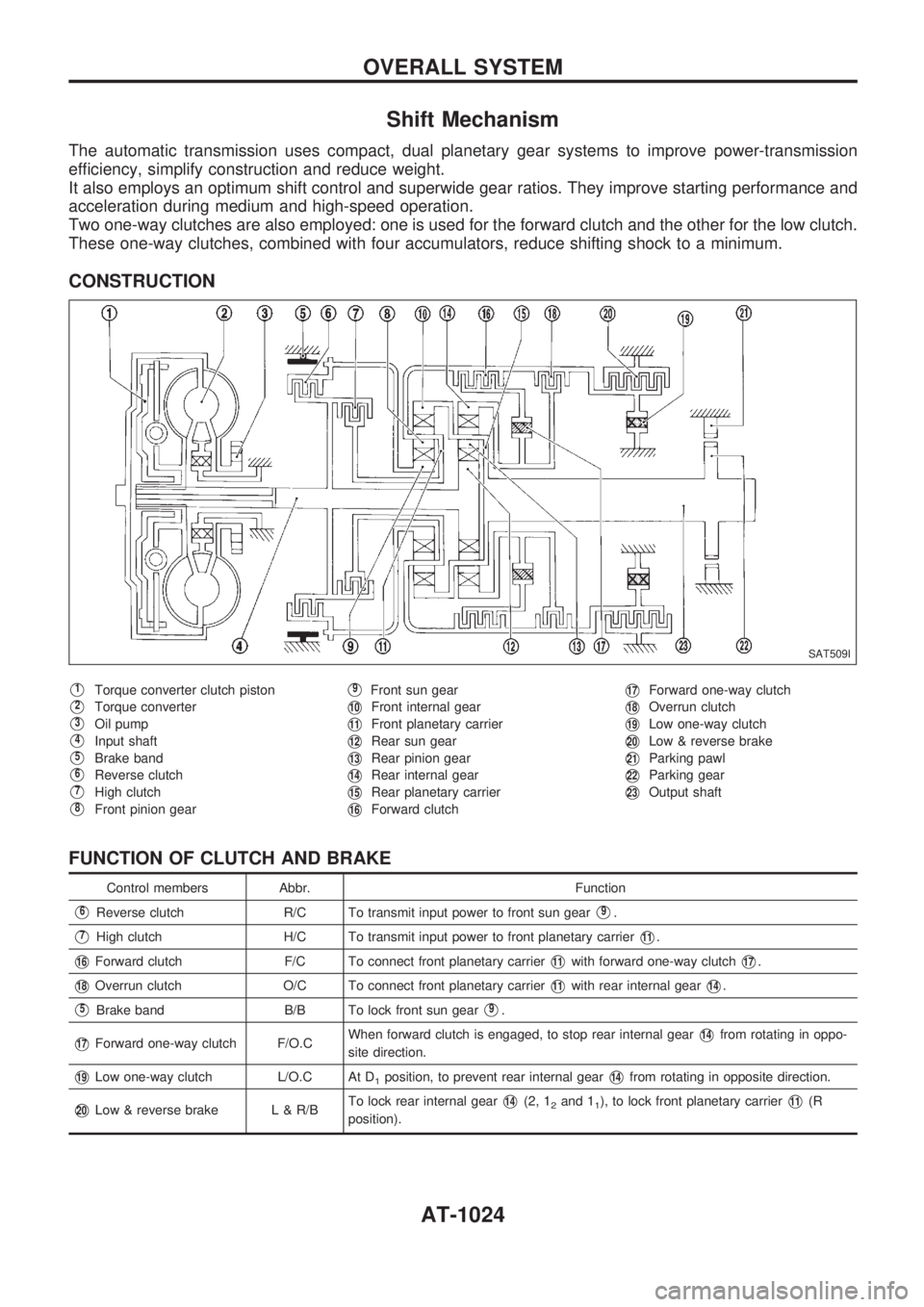

Shift Mechanism

The automatic transmission uses compact, dual planetary gear systems to improve power-transmission

efficiency, simplify construction and reduce weight.

It also employs an optimum shift control and superwide gear ratios. They improve starting performance and

acceleration during medium and high-speed operation.

Two one-way clutches are also employed: one is used for the forward clutch and the other for the low clutch.

These one-way clutches, combined with four accumulators, reduce shifting shock to a minimum.

CONSTRUCTION

V1Torque converter clutch piston

V2Torque converter

V3Oil pump

V4Input shaft

V5Brake band

V6Reverse clutch

V7High clutch

V8Front pinion gear

V9Front sun gear

V10Front internal gear

V11Front planetary carrier

V12Rear sun gear

V13Rear pinion gear

V14Rear internal gear

V15Rear planetary carrier

V16Forward clutch

V17Forward one-way clutch

V18Overrun clutch

V19Low one-way clutch

V20Low & reverse brake

V21Parking pawl

V22Parking gear

V23Output shaft

FUNCTION OF CLUTCH AND BRAKE

Control members Abbr. Function

V6Reverse clutch R/C To transmit input power to front sun gearV9.

V7High clutch H/C To transmit input power to front planetary carrierV11.

V16Forward clutch F/C To connect front planetary carrierV11with forward one-way clutchV17.

V18Overrun clutch O/C To connect front planetary carrierV11with rear internal gearV14.

V5Brake band B/B To lock front sun gearV9.

V17Forward one-way clutch F/O.CWhen forward clutch is engaged, to stop rear internal gearV14from rotating in oppo-

site direction.

V19Low one-way clutch L/O.C At D1position, to prevent rear internal gearV14from rotating in opposite direction.

V20Low & reverse brake L & R/BTo lock rear internal gearV14(2, 12and 11), to lock front planetary carrierV11(R

position).

SAT509I

OVERALL SYSTEM

AT-1024

Page 27 of 1033

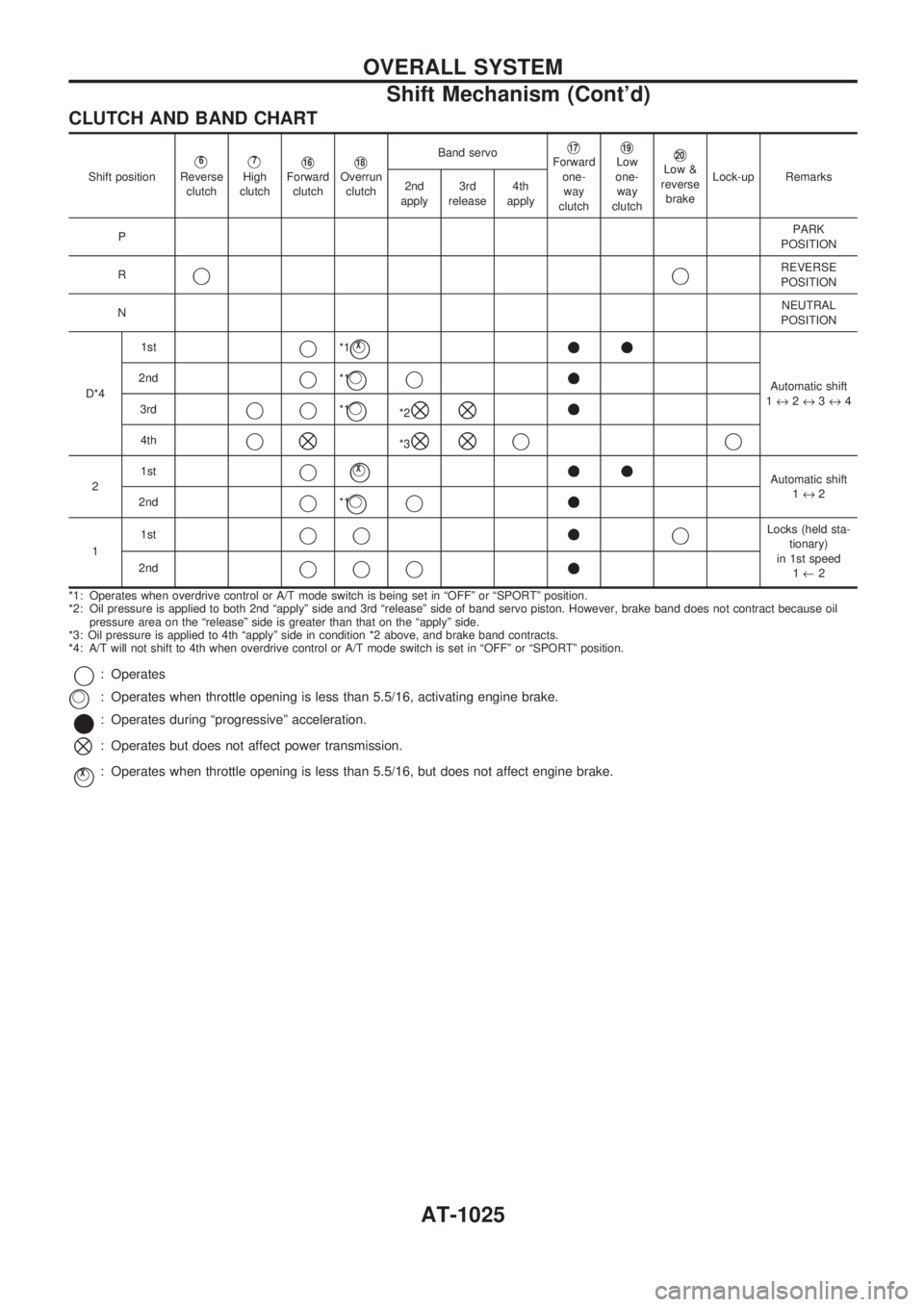

CLUTCH AND BAND CHART

Shift positionV6

Reverse

clutchV7

High

clutchV16Forward

clutchV18Overrun

clutchBand servo

V17Forward

one-

way

clutchV19Low

one-

way

clutchV20Low &

reverse

brakeLock-up Remarks

2nd

apply3rd

release4th

apply

PPARK

POSITION

R

jjREVERSE

POSITION

NNEUTRAL

POSITION

D*41st

j*1jVX++

Automatic shift

1«2«3«4 2ndj*1jVj+

3rdjj*1jV*2^^+

4thj^*3^^jj

21stjjVX++Automatic shift

1«2

2nd

j*1jVj+

11stjj+jLocks (held sta-

tionary)

in 1st speed

1¬2 2nd

jjj+

*1: Operates when overdrive control or A/T mode switch is being set in ªOFFº or ªSPORTº position.

*2: Oil pressure is applied to both 2nd ªapplyº side and 3rd ªreleaseº side of band servo piston. However, brake band does not contract because oil

pressure area on the ªreleaseº side is greater than that on the ªapplyº side.

*3: Oil pressure is applied to 4th ªapplyº side in condition *2 above, and brake band contracts.

*4: A/T will not shift to 4th when overdrive control or A/T mode switch is set in ªOFFº or ªSPORTº position.

j: Operates

: Operates when throttle opening is less than 5.5/16, activating engine brake.

*: Operates during ªprogressiveº acceleration.

^: Operates but does not affect power transmission.

jVX: Operates when throttle opening is less than 5.5/16, but does not affect engine brake.

jV

OVERALL SYSTEM

Shift Mechanism (Cont'd)

AT-1025

Page 28 of 1033

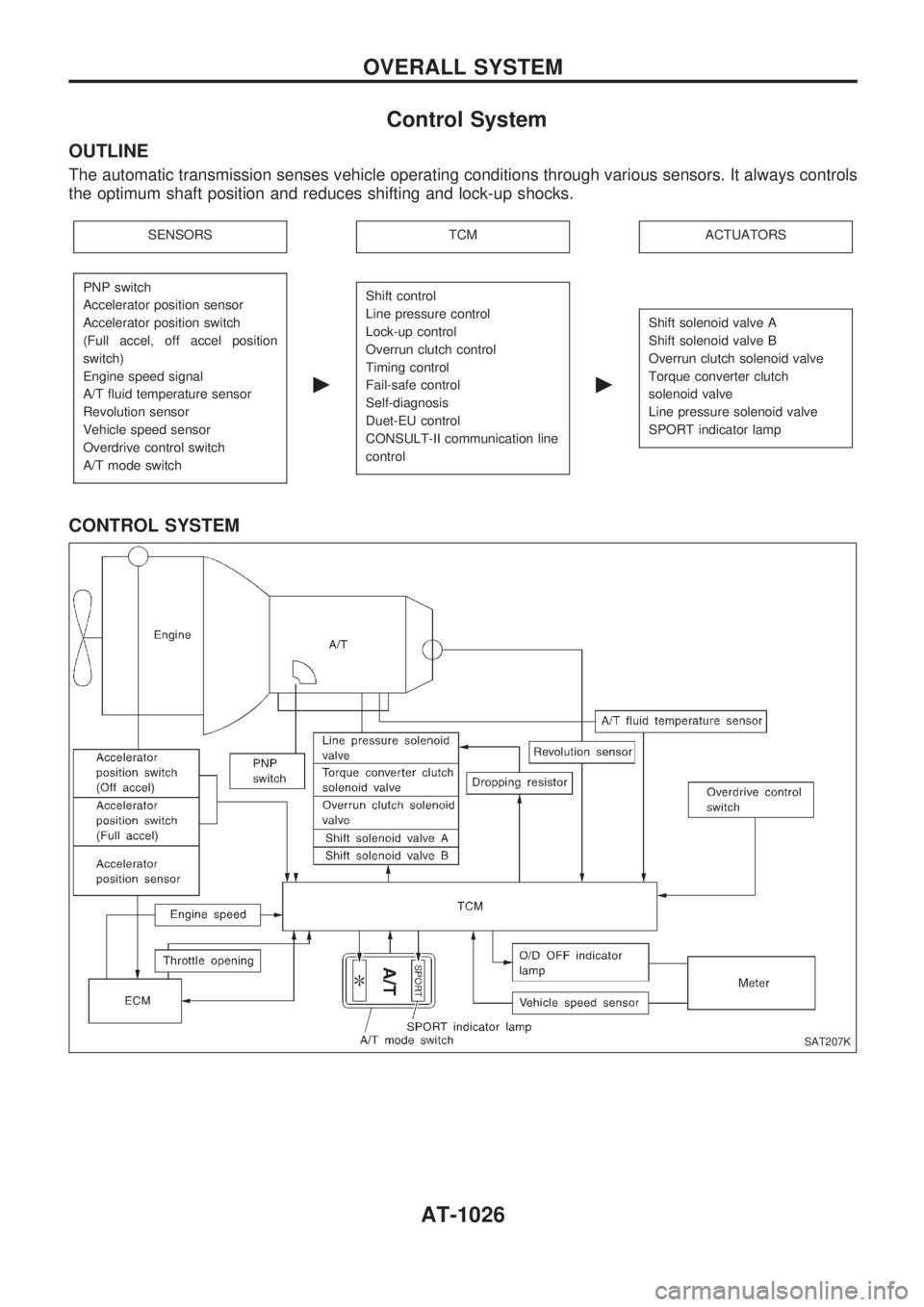

Control System

OUTLINE

The automatic transmission senses vehicle operating conditions through various sensors. It always controls

the optimum shaft position and reduces shifting and lock-up shocks.

SENSORSTCMACTUATORS

PNP switch

Accelerator position sensor

Accelerator position switch

(Full accel, off accel position

switch)

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed sensor

Overdrive control switch

A/T mode switch

c

Shift control

Line pressure control

Lock-up control

Overrun clutch control

Timing control

Fail-safe control

Self-diagnosis

Duet-EU control

CONSULT-II communication line

control

c

Shift solenoid valve A

Shift solenoid valve B

Overrun clutch solenoid valve

Torque converter clutch

solenoid valve

Line pressure solenoid valve

SPORT indicator lamp

CONTROL SYSTEM

SAT207K

OVERALL SYSTEM

AT-1026

Page 29 of 1033

TCM FUNCTION

The function of the TCM is to:

+Receive input signals sent from various switches and sensors.

+Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

+Send required output signals to the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCM

Sensors and solenoid valves Function

InputPNP switch Detects select lever position and sends a signal to TCM.

Accelerator position sensor Detects throttle valve position and sends a signal to TCM.

Accelerator position switch

(Off accel)Detects throttle valve's fully-closed position and sends a signal to TCM.

Accelerator position switch

(Full accel)Detects a throttle valve position of greater than 1/2 of full throttle and sends a

signal to TCM.

Engine speed signal From ECM.

A/T fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

Revolution sensor Detects output shaft rpm and sends a signal to TCM.

Vehicle speed sensorUsed as an auxiliary vehicle speed sensor. Sends a signal when revolution sen-

sor (installed on transmission) malfunctions.

Overdrive control switch

A/T mode switchSends a signal, which prohibits a shift to ªD

4º (overdrive) position, to the TCM.

OutputShift solenoid valve A/BSelects shifting point suited to driving conditions in relation to a signal sent from

TCM.

Line pressure solenoid valveRegulates (or decreases) line pressure suited to driving conditions in relation to

a signal sent from TCM.

Torque converter clutch solenoid valveRegulates (or decreases) lock-up pressure suited to driving conditions in relation

to a signal sent from TCM.

Overrun clutch solenoid valveControls an ªengine brakeº effect suited to driving conditions in relation to a sig-

nal sent from TCM.

O/D OFF indicator lamp

SPORT indicator lampShows TCM faults, when A/T control components malfunction.

OVERALL SYSTEM

Control System (Cont'd)

AT-1027

Page 30 of 1033

Self-diagnosis

After performing this procedure, place check marks for results on

the ªDIAGNOSTIC WORKSHEETº, AT-1038. Reference pages

are provided following the items.

SELF-DIAGNOSTIC PROCEDURE (With

CONSULT-II)

1. Turn on CONSULT-II and touch ªA/Tº.

If A/T is not displayed, check TCM power supply and ground

circuit. Refer to AT-1060. If result is NG, refer to EL section

(ªPOWER SUPPLY ROUTINGº).

2. Touch ªSELF-DIAG RESULTSº.

Display shows malfunction experienced since the last eras-

ing operation.

CONSULT-II performs REAL-TIME SELF-DIAGNOSIS.

Also, any malfunction detected while in this mode will be

displayed at real time.

Item Display Description Remarks

No failure

****NO FAILURE

****+No failure has been detected.

Initial start

*INITIAL START

*+This is NOT a malfunction message.

Whenever shutting off a power supply to the

TCM, this message appears on the screen.

[]

Vehicle speed sensorzA/T

(Revolution sensor)VHCL SPEED SENzA/T+No signal input from vehicle speed sensorzA/T

(revolution sensor) during traveling due to

disconnection, or input of abnormal signal.

Vehicle speed sensorzMTR

(Meter)VHCL SPEED SENzMTR+No signal input from vehicle speed sensorzMTR

during traveling due to disconnection, or input of

abnormal signal.

Accelerator position sensor THROTTLE POSI SEN+Accelerator position sensor signal voltage is abnor-

mally high.

+Throttle (accelerator) position sensor signal voltage

is abnormally low with closed throttle position

switch ªOFFº or wide open throttle position switch

ªONº.

Shift solenoid valve A SHIFT SOLENOID/V A+Specified voltage is not applied to solenoid valve

due to disconnection or shortcircuit.

Shift solenoid valve B SHIFT SOLENOID/V B+Specified voltage is not applied to solenoid valve

due to disconnection or shortcircuit.

Overrun clutch solenoid

valveOVERRUN CLUTCH S/V+Specified voltage is not applied to solenoid valve

due to disconnection or shortcircuit.

T/C clutch solenoid valve T/C CLUTCH SOL/V+Specified voltage is not applied to solenoid valve

due to disconnection or shortcircuit.

A/T fluid temperature

sensor/TCM power sourceBATT/FLUID TEMP SEN+Supply voltage to TCM is abnormally low during

traveling.

+Fluid temperature signal voltage is abnormally high

(fluid temperature is low) during traveling.To be dis-

played in case

of abnormality

and no record-

ing is made

Engine speed signal ENGINE SPEED SIG+Engine RPM is abnormally low during traveling.

Line pressure solenoid

valveLINE PRESSURE S/V+Specified voltage is not applied to solenoid valve

due to disconnection or shortcircuit.

TCM (ROM) CONTROL UNIT (ROM)+TCM memory (ROM) is malfunctioning.

TCM (RAM) CONTROL UNIT (RAM)+TCM memory (RAM) is malfunctioning.

TCM (EEP ROM) CONTROL UNIT (EEP ROM)+TCM memory (EEP ROM) is malfunctioning.

SAT014K

SAT987J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-1028