gauge NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 5 of 1033

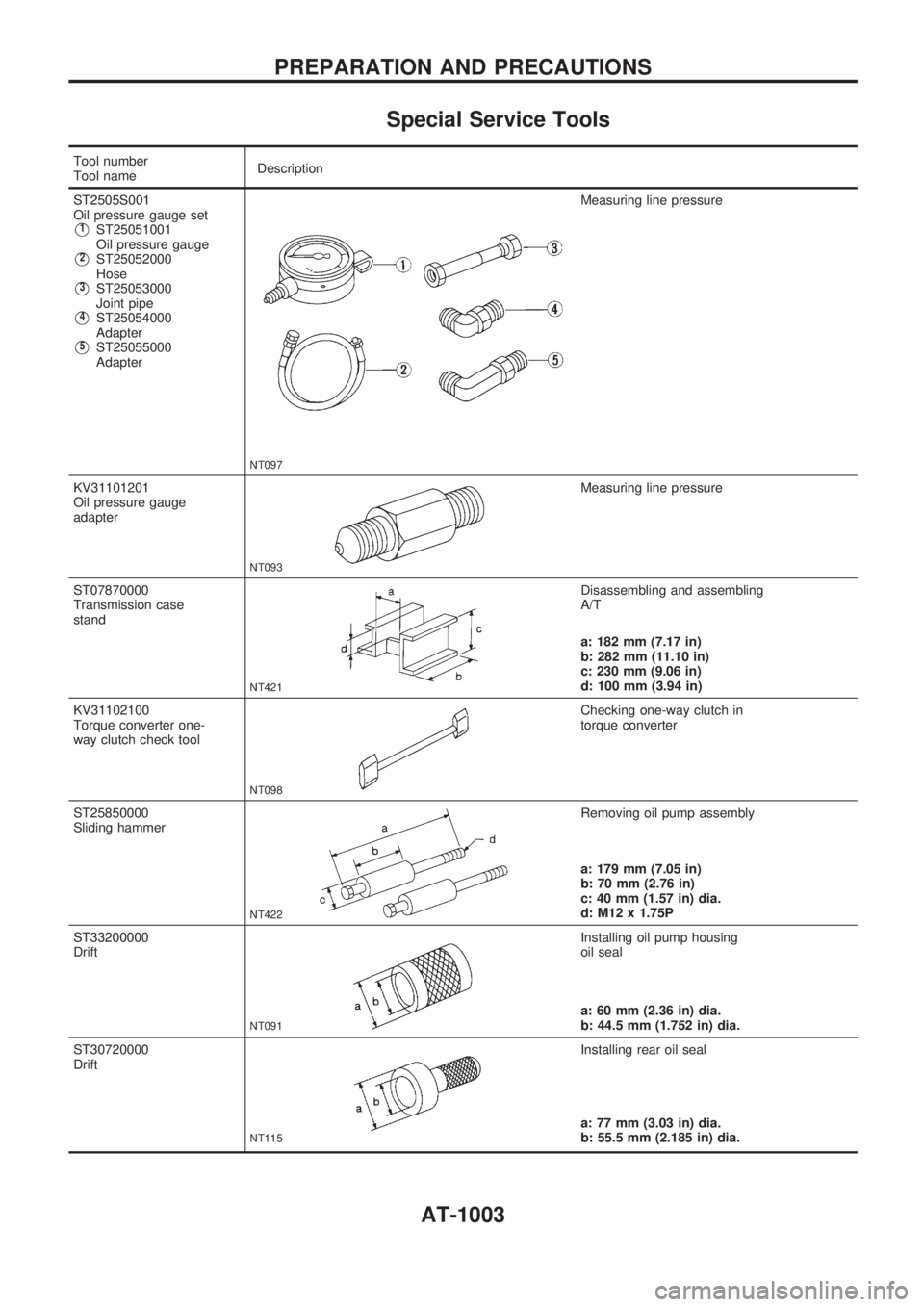

Special Service Tools

Tool number

Tool nameDescription

ST2505S001

Oil pressure gauge set

V1ST25051001

Oil pressure gauge

V2ST25052000

Hose

V3ST25053000

Joint pipe

V4ST25054000

Adapter

V5ST25055000

Adapter

NT097

Measuring line pressure

KV31101201

Oil pressure gauge

adapter

NT093

Measuring line pressure

ST07870000

Transmission case

stand

NT421

Disassembling and assembling

A/T

a: 182 mm (7.17 in)

b: 282 mm (11.10 in)

c: 230 mm (9.06 in)

d: 100 mm (3.94 in)

KV31102100

Torque converter one-

way clutch check tool

NT098

Checking one-way clutch in

torque converter

ST25850000

Sliding hammer

NT422

Removing oil pump assembly

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in) dia.

d: M12 x 1.75P

ST33200000

Drift

NT091

Installing oil pump housing

oil seal

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

ST30720000

Drift

NT115

Installing rear oil seal

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

PREPARATION AND PRECAUTIONS

AT-1003

Page 46 of 1033

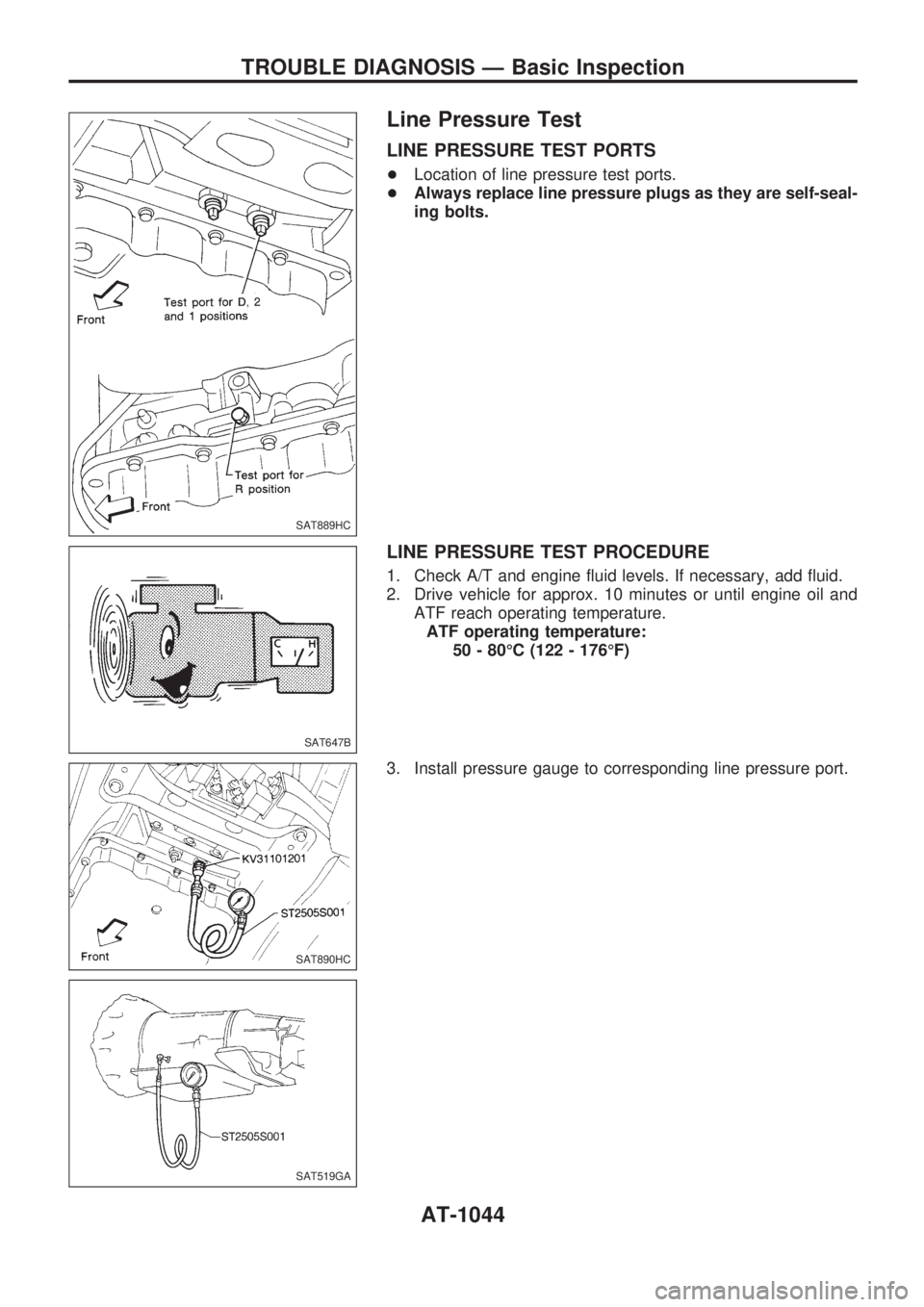

Line Pressure Test

LINE PRESSURE TEST PORTS

+Location of line pressure test ports.

+Always replace line pressure plugs as they are self-seal-

ing bolts.

LINE PRESSURE TEST PROCEDURE

1. Check A/T and engine fluid levels. If necessary, add fluid.

2. Drive vehicle for approx. 10 minutes or until engine oil and

ATF reach operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

3. Install pressure gauge to corresponding line pressure port.

SAT889HC

SAT647B

SAT890HC

SAT519GA

TROUBLE DIAGNOSIS Ð Basic Inspection

AT-1044

Page 69 of 1033

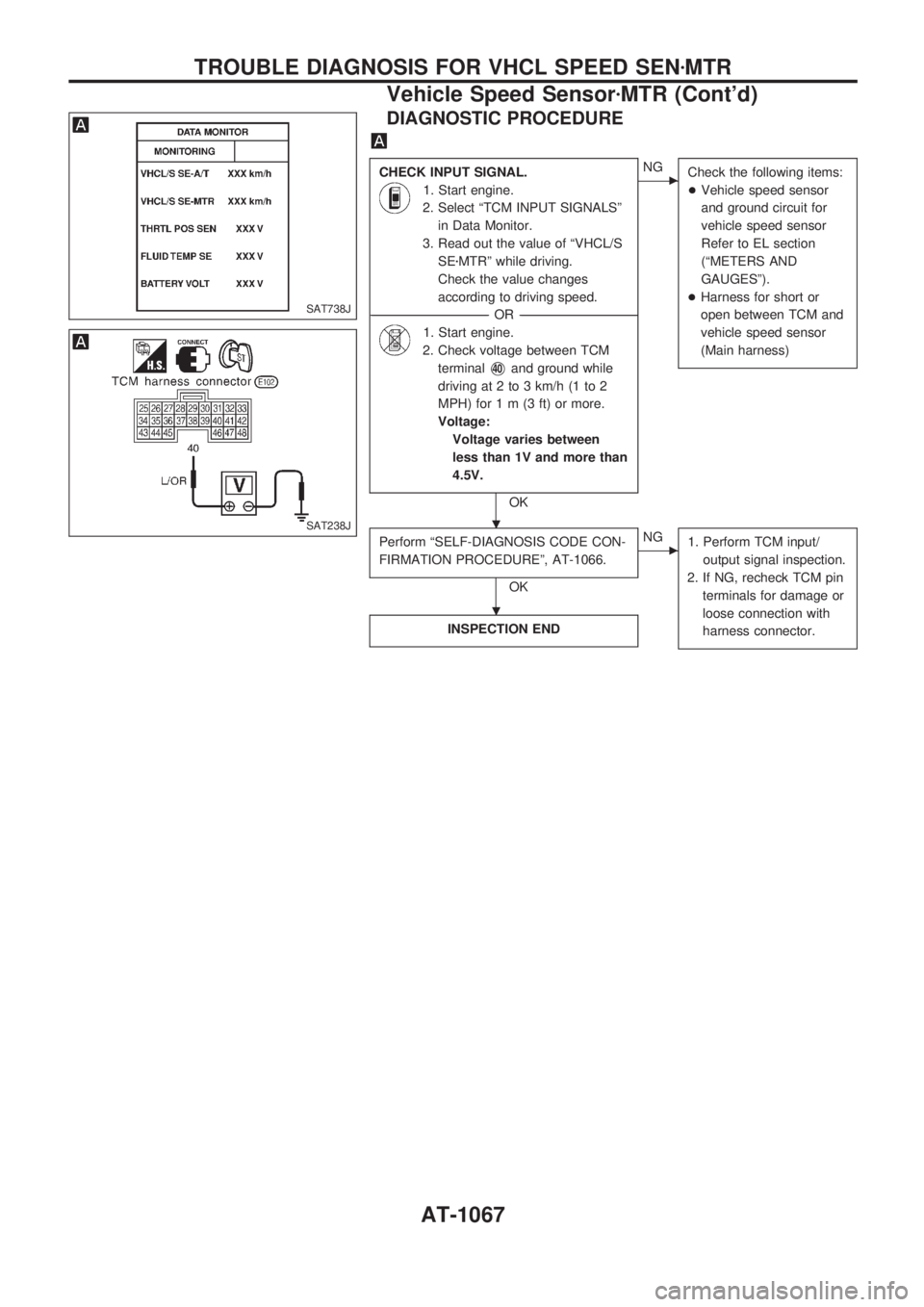

DIAGNOSTIC PROCEDURE

CHECK INPUT SIGNAL.

1. Start engine.

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªVHCL/S

SEzMTRº while driving.

Check the value changes

according to driving speed.

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM

terminal

V40and ground while

driving at 2 to 3 km/h (1 to 2

MPH) for1m(3ft)ormore.

Voltage:

Voltage varies between

less than 1V and more than

4.5V.

OK

cNG

Check the following items:

+Vehicle speed sensor

and ground circuit for

vehicle speed sensor

Refer to EL section

(ªMETERS AND

GAUGESº).

+Harness for short or

open between TCM and

vehicle speed sensor

(Main harness)

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1066.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT738J

SAT238J.

.

TROUBLE DIAGNOSIS FOR VHCL SPEED SENzMTR

Vehicle Speed SensorzMTR (Cont'd)

AT-1067

Page 258 of 1033

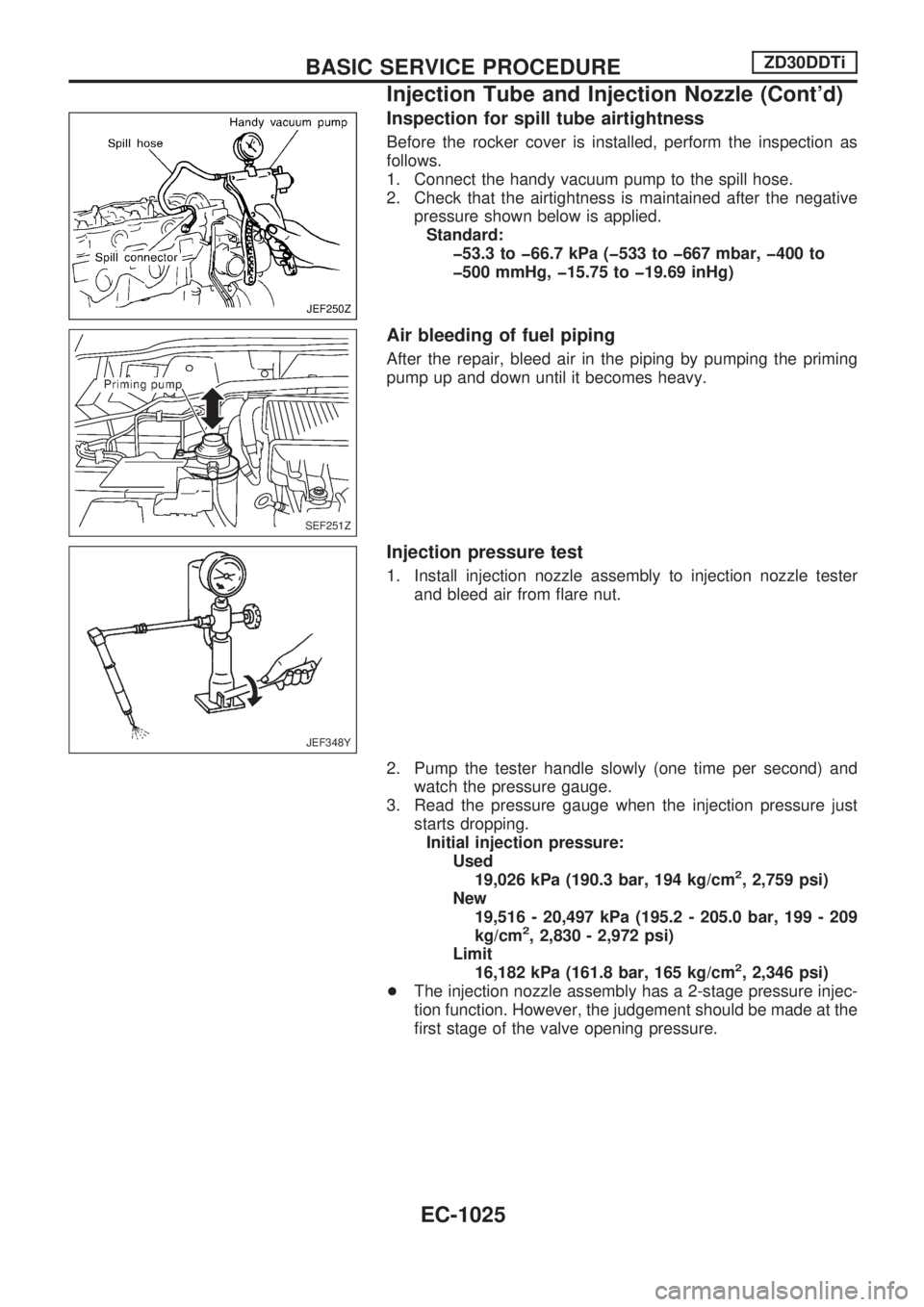

Inspection for spill tube airtightness

Before the rocker cover is installed, perform the inspection as

follows.

1. Connect the handy vacuum pump to the spill hose.

2. Check that the airtightness is maintained after the negative

pressure shown below is applied.

Standard:

þ53.3 to þ66.7 kPa (þ533 to þ667 mbar, þ400 to

þ500 mmHg, þ15.75 to þ19.69 inHg)

Air bleeding of fuel piping

After the repair, bleed air in the piping by pumping the priming

pump up and down until it becomes heavy.

Injection pressure test

1. Install injection nozzle assembly to injection nozzle tester

and bleed air from flare nut.

2. Pump the tester handle slowly (one time per second) and

watch the pressure gauge.

3. Read the pressure gauge when the injection pressure just

starts dropping.

Initial injection pressure:

Used

19,026 kPa (190.3 bar, 194 kg/cm

2, 2,759 psi)

New

19,516 - 20,497 kPa (195.2 - 205.0 bar, 199 - 209

kg/cm

2, 2,830 - 2,972 psi)

Limit

16,182 kPa (161.8 bar, 165 kg/cm

2, 2,346 psi)

+The injection nozzle assembly has a 2-stage pressure injec-

tion function. However, the judgement should be made at the

first stage of the valve opening pressure.

JEF250Z

SEF251Z

JEF348Y

BASIC SERVICE PROCEDUREZD30DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-1025

Page 260 of 1033

REMOVAL

1. Remove the following:

+Engine coolant draining

+Charge air cooler

+Air inlet pipe

+Throttle body

+Rocker cover

+Oil level gauge guide

+EGR guide tube

+EGR volume control solenoid valve

+Fuel hose

+Injection tube

+Radiator upper hose

+Radiator shroud

+Cooling fan

+Drive belt

+Vacuum pipe

+Vacuum pump

2. Move the power steering pump.

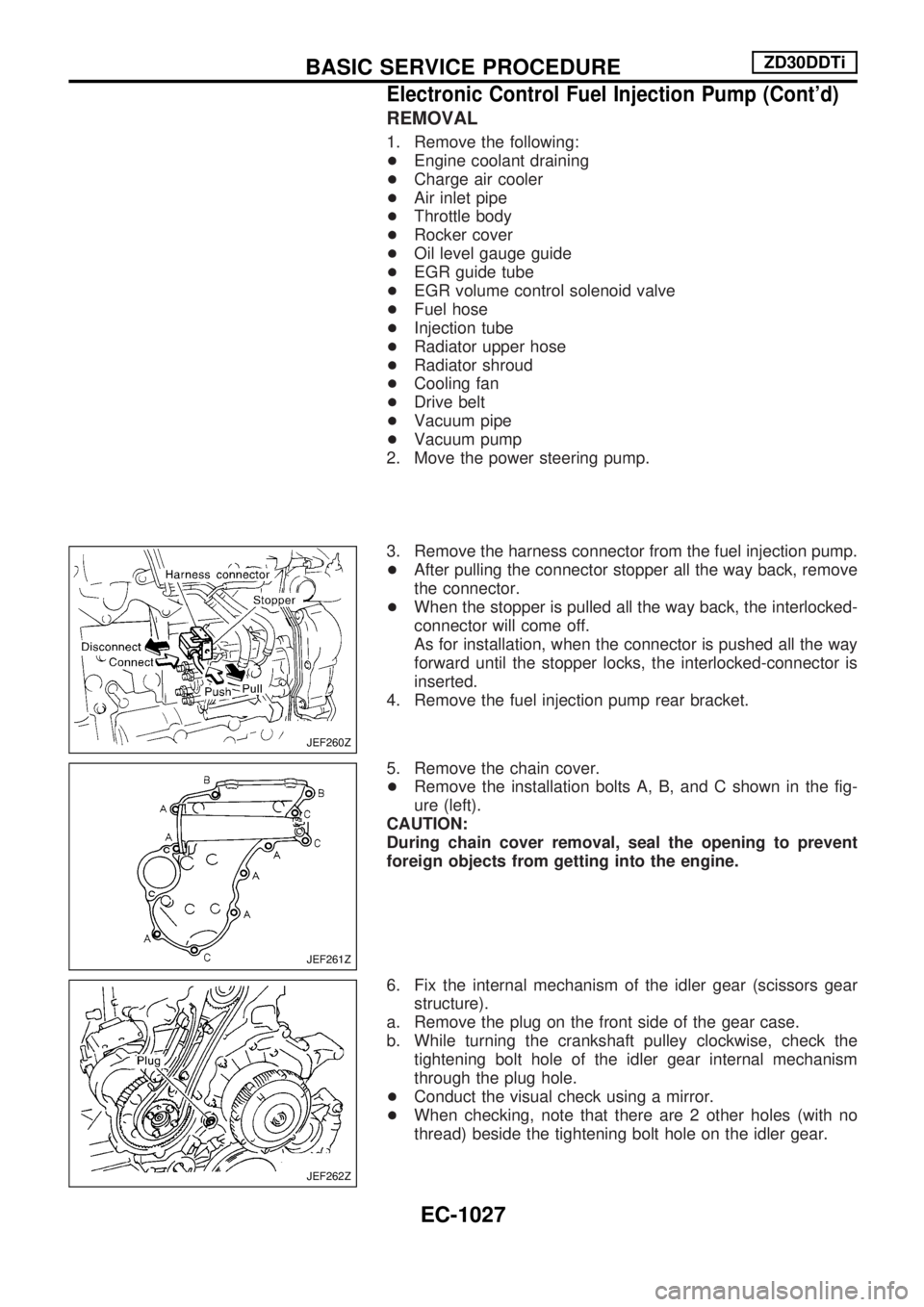

3. Remove the harness connector from the fuel injection pump.

+After pulling the connector stopper all the way back, remove

the connector.

+When the stopper is pulled all the way back, the interlocked-

connector will come off.

As for installation, when the connector is pushed all the way

forward until the stopper locks, the interlocked-connector is

inserted.

4. Remove the fuel injection pump rear bracket.

5. Remove the chain cover.

+Remove the installation bolts A, B, and C shown in the fig-

ure (left).

CAUTION:

During chain cover removal, seal the opening to prevent

foreign objects from getting into the engine.

6. Fix the internal mechanism of the idler gear (scissors gear

structure).

a. Remove the plug on the front side of the gear case.

b. While turning the crankshaft pulley clockwise, check the

tightening bolt hole of the idler gear internal mechanism

through the plug hole.

+Conduct the visual check using a mirror.

+When checking, note that there are 2 other holes (with no

thread) beside the tightening bolt hole on the idler gear.

JEF260Z

JEF261Z

JEF262Z

BASIC SERVICE PROCEDUREZD30DDTi

Electronic Control Fuel Injection Pump (Cont'd)

EC-1027

Page 349 of 1033

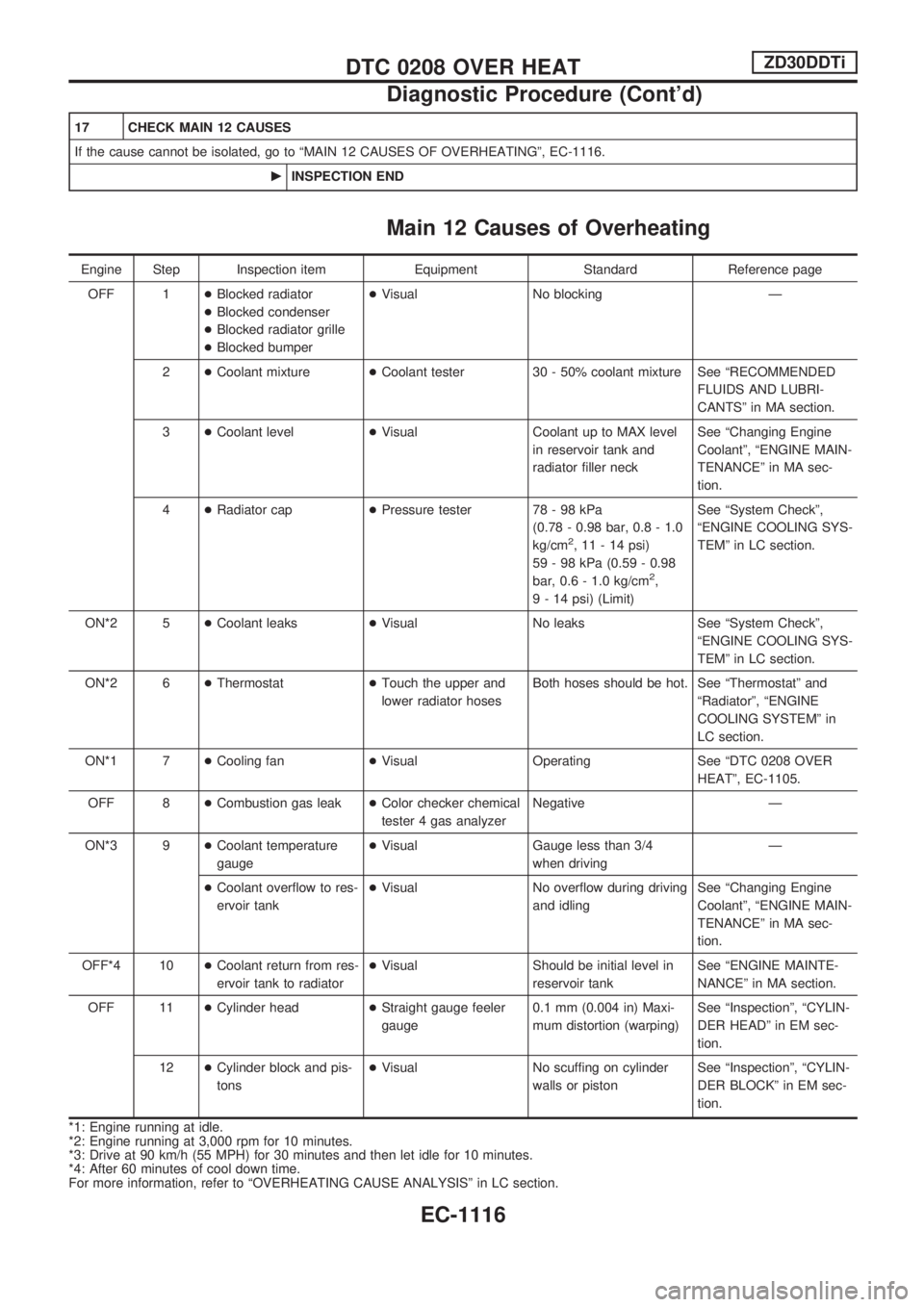

17 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-1116.

cINSPECTION END

Main 12 Causes of Overheating

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 30 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

4+Radiator cap+Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 5+Coolant leaks+Visual No leaks See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 6+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be hot. See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7+Cooling fan+Visual Operating See ªDTC 0208 OVER

HEATº, EC-1105.

OFF 8+Combustion gas leak+Color checker chemical

tester 4 gas analyzerNegative Ð

ON*3 9+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to res-

ervoir tank+Visual No overflow during driving

and idlingSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

OFF*4 10+Coolant return from res-

ervoir tank to radiator+Visual Should be initial level in

reservoir tankSee ªENGINE MAINTE-

NANCEº in MA section.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ªInspectionº, ªCYLIN-

DER HEADº in EM sec-

tion.

12+Cylinder block and pis-

tons+Visual No scuffing on cylinder

walls or pistonSee ªInspectionº, ªCYLIN-

DER BLOCKº in EM sec-

tion.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1116

Page 439 of 1033

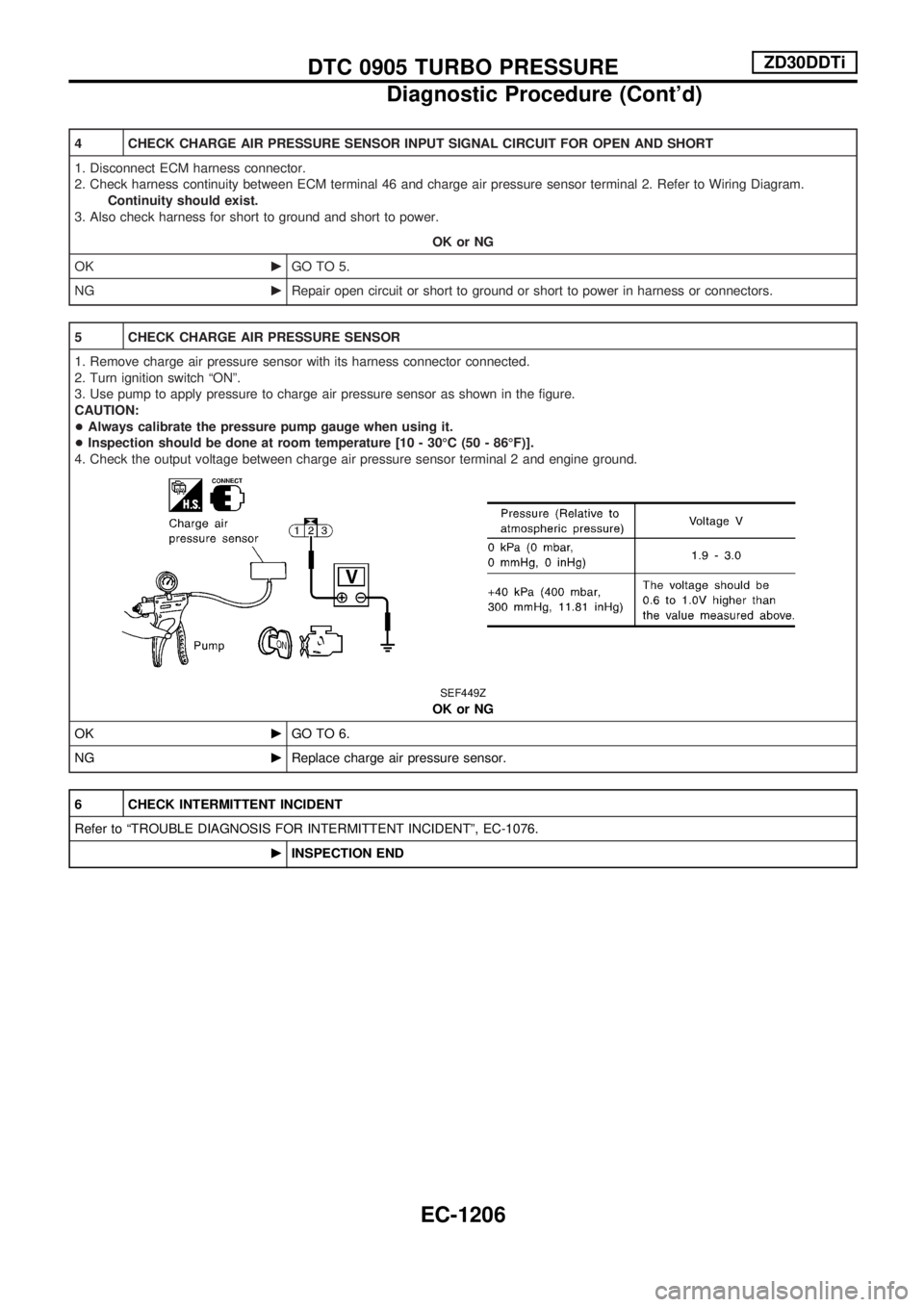

4 CHECK CHARGE AIR PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 46 and charge air pressure sensor terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 5.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK CHARGE AIR PRESSURE SENSOR

1. Remove charge air pressure sensor with its harness connector connected.

2. Turn ignition switch ªONº.

3. Use pump to apply pressure to charge air pressure sensor as shown in the figure.

CAUTION:

+Always calibrate the pressure pump gauge when using it.

+Inspection should be done at room temperature [10 - 30ÉC (50 - 86ÉF)].

4. Check the output voltage between charge air pressure sensor terminal 2 and engine ground.

SEF449Z

OK or NG

OKcGO TO 6.

NGcReplace charge air pressure sensor.

6 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

DTC 0905 TURBO PRESSUREZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1206

Page 459 of 1033

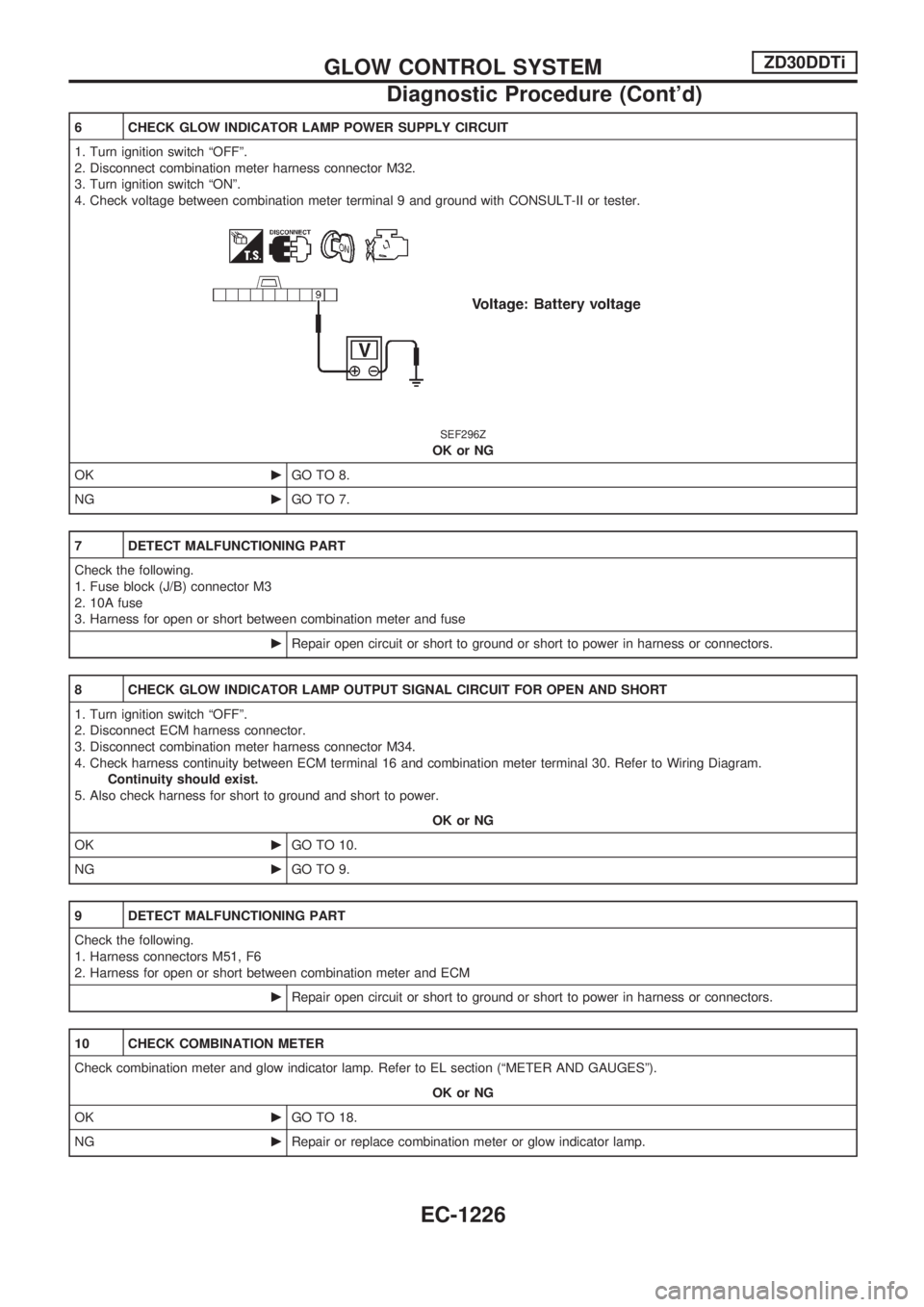

6 CHECK GLOW INDICATOR LAMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect combination meter harness connector M32.

3. Turn ignition switch ªONº.

4. Check voltage between combination meter terminal 9 and ground with CONSULT-II or tester.

SEF296Z

OK or NG

OKcGO TO 8.

NGcGO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

1. Fuse block (J/B) connector M3

2. 10A fuse

3. Harness for open or short between combination meter and fuse

cRepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK GLOW INDICATOR LAMP OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Disconnect combination meter harness connector M34.

4. Check harness continuity between ECM terminal 16 and combination meter terminal 30. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

1. Harness connectors M51, F6

2. Harness for open or short between combination meter and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

10 CHECK COMBINATION METER

Check combination meter and glow indicator lamp. Refer to EL section (ªMETER AND GAUGESº).

OK or NG

OKcGO TO 18.

NGcRepair or replace combination meter or glow indicator lamp.

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1226

Page 512 of 1033

TURN SIGNAL AND HAZARD WARNING

LAMPS................................................................. 1058

Wiring Diagram Ð TURN Ð ........................... 1058

ILLUMINATION .................................................... 1060

Schematic ........................................................ 1060

Wiring Diagram Ð ILL Ð ................................ 1061

INTERIOR ROOM LAMP ..................................... 1067

System Description .......................................... 1067

Wiring Diagram Ð ROOM/L Ð/LHD Models .. 1068

Wiring Diagram Ð ROOM/L Ð/RHD Models.. 1070

Trouble Diagnoses ........................................... 1072

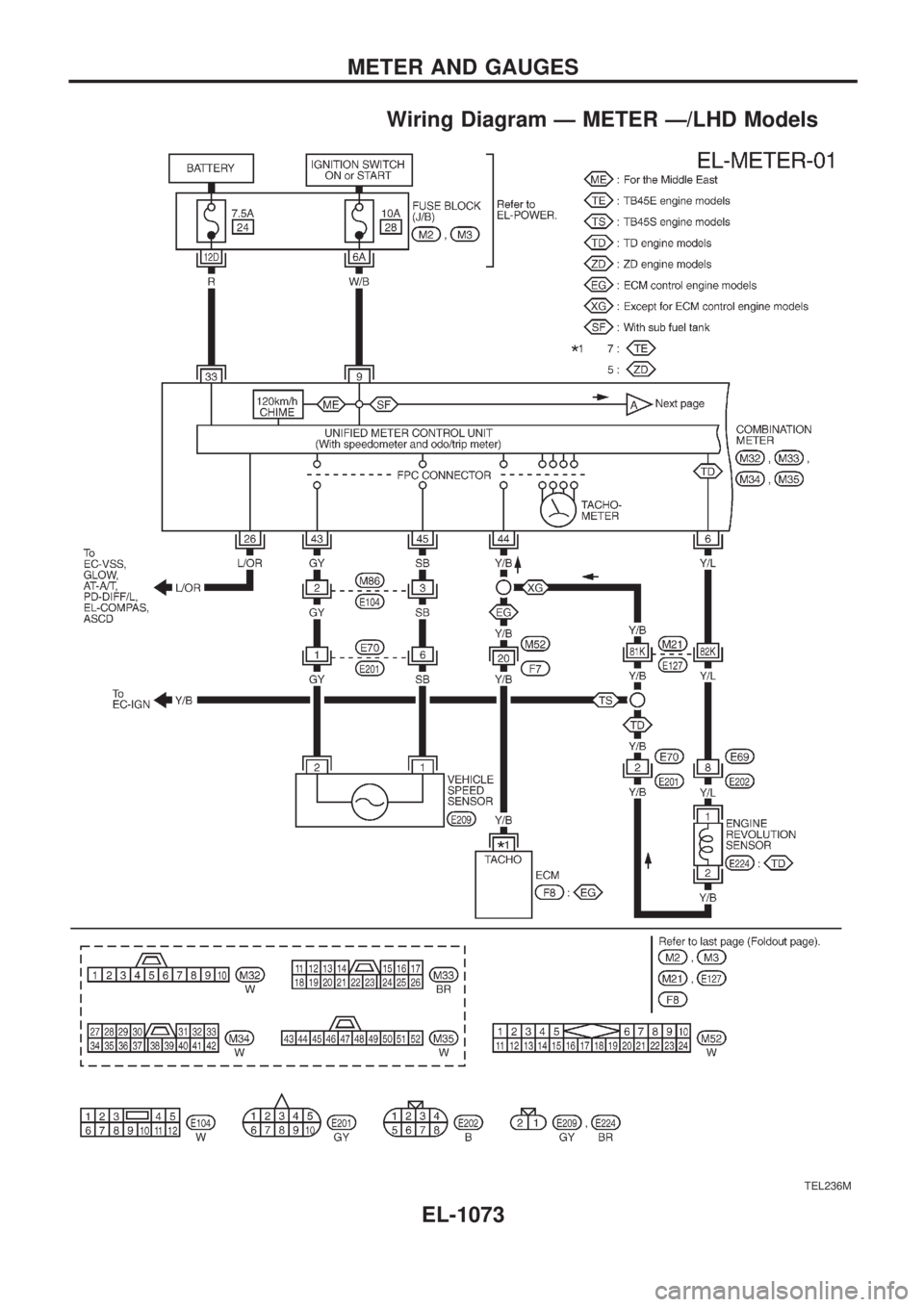

METER AND GAUGES ....................................... 1073

Wiring Diagram Ð METER Ð/LHD Models .... 1073

Wiring Diagram Ð METER Ð/RHD Models ... 1075

WARNING LAMPS .............................................. 1078

Schematic ........................................................ 1078

Wiring Diagram Ð WARN Ð .......................... 1080

WARNING CHIME ............................................... 1091

System Description .......................................... 1091

Wiring Diagram Ð CHIME Ð/LHD Models ..... 1092

Wiring Diagram Ð CHIME Ð/RHD Models .... 1093

Trouble Diagnoses ........................................... 1094

Electrical Components Inspection ................... 1097

FRONT WIPER AND WASHER .......................... 1098

Wiring Diagram Ð WIPER Ð.......................... 1098

HEADLAMP WIPER AND WASHER .................. 1099

Wiring Diagram Ð HLC Ð .............................. 1099

HORN ................................................................... 1100

Wiring Diagram Ð HORN Ð ........................... 1100

REAR WINDOW DEFOGGER ............................. 1101

System Description .......................................... 1101

Wiring Diagram Ð DEF Ð/LHD Models ......... 1102

Wiring Diagram Ð DEF Ð/RHD Models......... 1104

Trouble Diagnoses ........................................... 1106

Electrical Components Inspection ................... 1107

AUDIO .................................................................. 1108

Wiring Diagram Ð REMOTE Ð ...................... 1108

AUDIO ANTENNA ............................................... 1109

Wiring Diagram Ð P/ANT Ð/RHD Models ..... 1109

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ................................................................. 1110

Schematic ........................................................ 1110

Wiring Diagram Ð ASCD Ð ........................... 1111

POWER WINDOW ............................................... 1115

System Description .......................................... 1115

Schematic ........................................................ 1116

Wiring Diagram Ð WINDOW Ð...................... 1117

Trouble Diagnoses ........................................... 1122

POWER DOOR LOCK Ð Super Lock Ð .......... 1124

Component Parts and Harness Connector

Location............................................................ 1124

System Description .......................................... 1125

Schematic ........................................................ 1127

Wiring Diagram Ð S/LOCK Ð/LHD Models ... 1128 Wiring Diagram Ð S/LOCK Ð/RHD Models... 1133

Trouble Diagnoses ........................................... 1138

MULTI-REMOTE CONTROL SYSTEM ............... 1149

System Description .......................................... 1149

Wiring Diagram Ð MULTI Ð/LHD Models...... 1150

Wiring Diagram Ð MULTI Ð/RHD Models ..... 1152

Trouble Diagnoses ........................................... 1154

ID Code Entry Procedure ................................ 1156

Remote Controller Battery Replacement ......... 1157

SUPER LOCK CONTROL UNIT ......................... 1159

Description ....................................................... 1159

Schematic ........................................................ 1160

Input/Output Operation Signal ......................... 1162

NATS (Nissan Anti-Theft System) .................... 1163

Component Parts and Harness Connector

Location............................................................ 1163

System Description .......................................... 1164

System Composition ........................................ 1165

Wiring Diagram Ð NATS Ð ............................ 1166

Wiring Diagram Ð NATS Ð/LHD Models ....... 1167

Wiring Diagram Ð NATS Ð/RHD Models ...... 1168

CONSULT-II ..................................................... 1169

Trouble Diagnoses ........................................... 1172

How to Replace NATS IMMU .......................... 1183

LOCATION OF ELECTRICAL UNITS ................. 1185

Engine Compartment ....................................... 1185

Passenger Compartment Ð LHD Models ....... 1186

Passenger Compartment Ð RHD Models ...... 1188

HARNESS LAYOUT ............................................ 1191

How to Read Harness Layout ......................... 1191

Main Harness/LHD Models .............................. 1192

Main Harness/RHD Models ............................. 1196

Engine Room Harness/LHD Models................ 1200

Engine Room Harness/RHD Models ............... 1204

Engine Harness ............................................... 1208

Engine Control Harness................................... 1209

Body Harness/LHD Models ............................. 1210

Body Harness/RHD Models ............................. 1214

Body No. 2 Harness/LHD Models ................... 1218

Body No. 2 Harness/RHD Models ................... 1220

Chassis Harness .............................................. 1222

Room Lamp Harness ....................................... 1223

Front Door Harness (Driver side) .................... 1224

Front Door Harness (Passenger side)............. 1225

Back Door Harness and Rear Window

Defogger Harness ............................................ 1226

WIRING DIAGRAM CODES (CELL CODES) ..... 1227

Wiring Diagram Codes (Cell Codes) ............... 1227

ELECTRICAL SYSTEM

Page 583 of 1033

Wiring Diagram Ð METER Ð/LHD Models

TEL236M

METER AND GAUGES

EL-1073