seats NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 748 of 1033

1. Warm up engine.

2. Turn ignition switch OFF.

3.

Using CONSULT-II, make sure no error codes are indicated for

self-diagnosis items. Refer to EC section, ªFuel Pressure

Releaseº.

+Do not disconnect CONSULT-II until the end of this opera-

tion; it will be used to check engine rpm and for error detec-

tion at the end of this operation.

4. Disconnect the negative battery terminal.

5. Remove the following parts.

+Intercooler cover

+Intercooler

+Throttle body

+Rocker cover

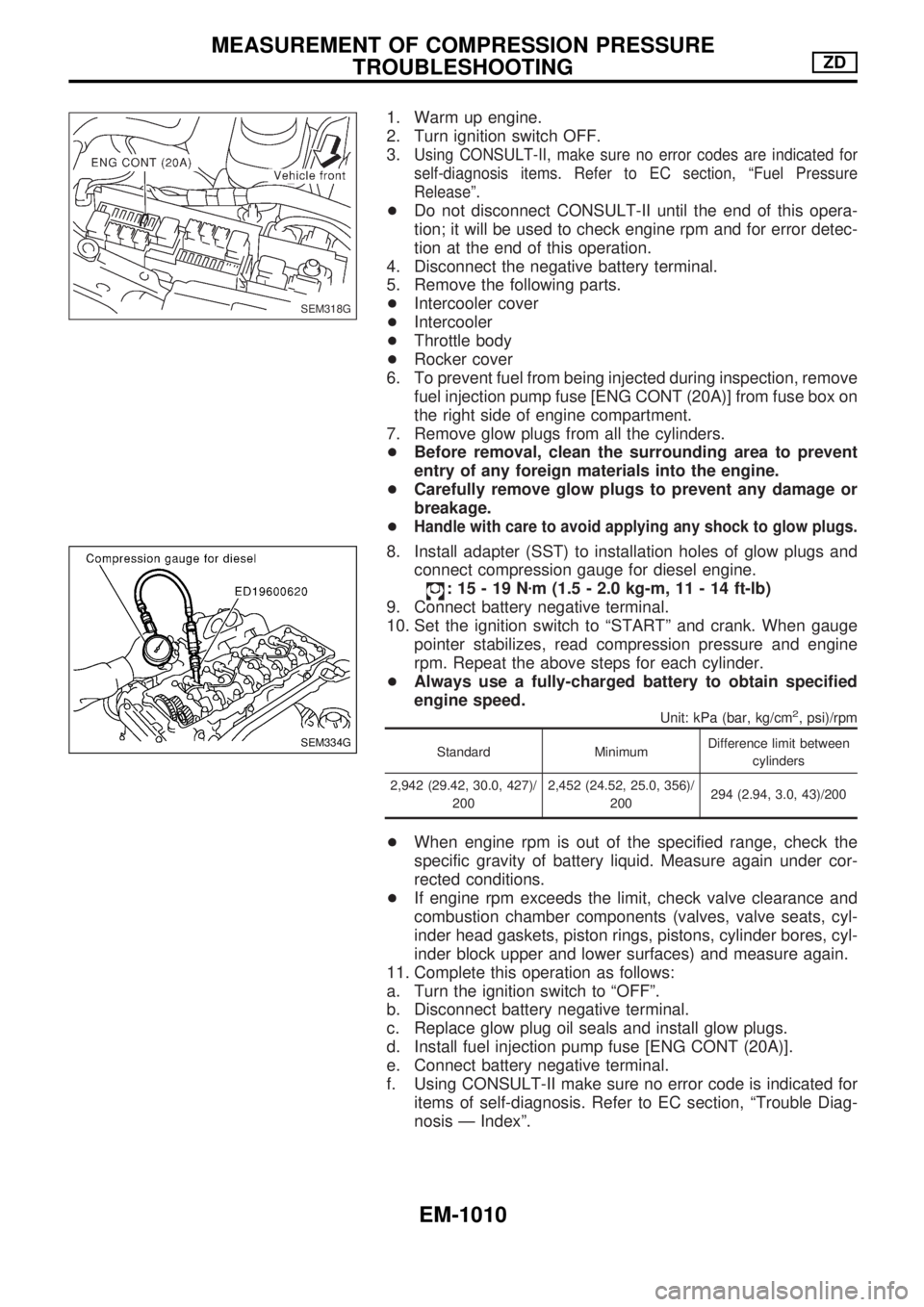

6. To prevent fuel from being injected during inspection, remove

fuel injection pump fuse [ENG CONT (20A)] from fuse box on

the right side of engine compartment.

7. Remove glow plugs from all the cylinders.

+Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

+Carefully remove glow plugs to prevent any damage or

breakage.

+

Handle with care to avoid applying any shock to glow plugs.

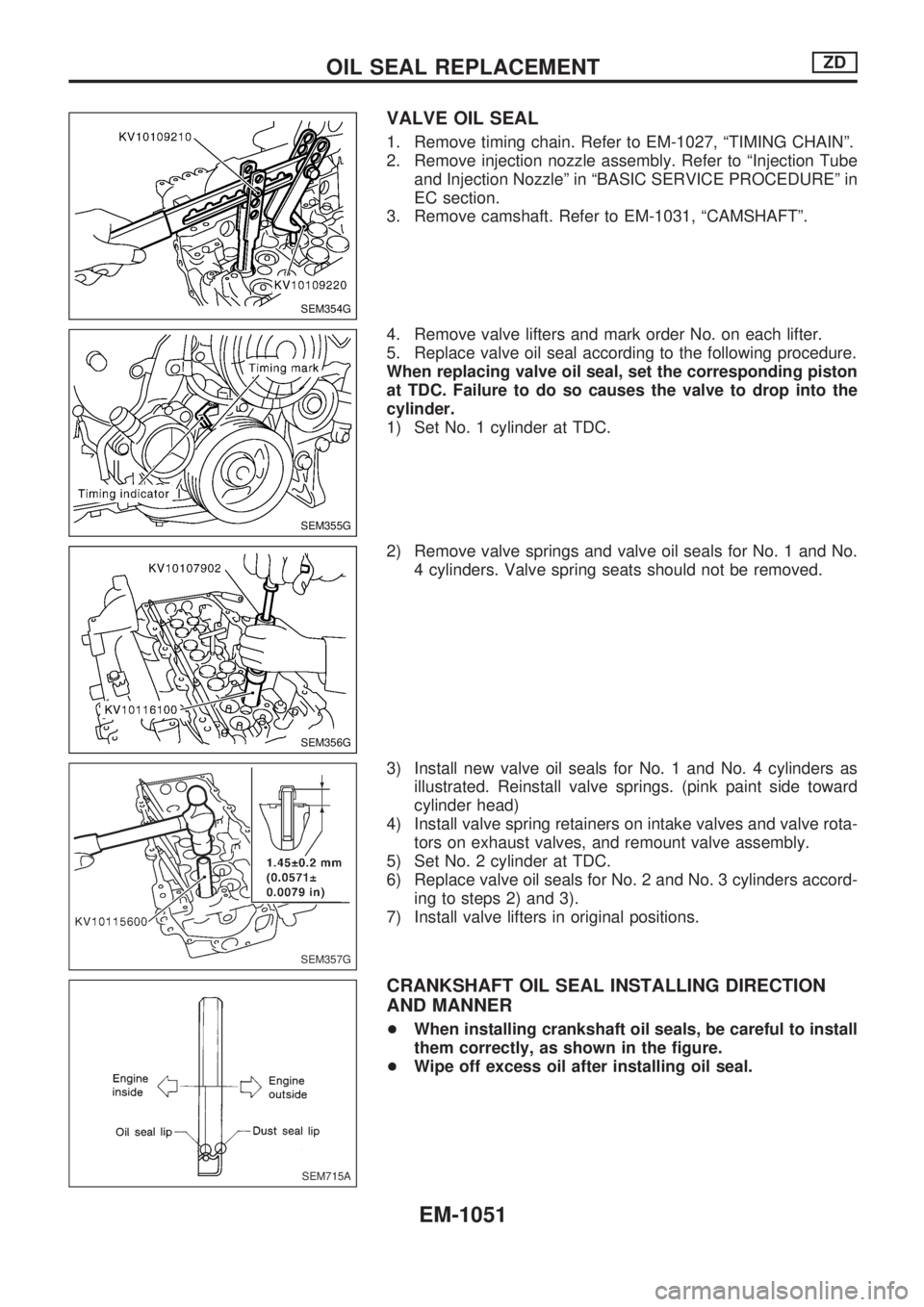

8. Install adapter (SST) to installation holes of glow plugs and

connect compression gauge for diesel engine.

:15-19Nzm (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

9. Connect battery negative terminal.

10. Set the ignition switch to ªSTARTº and crank. When gauge

pointer stabilizes, read compression pressure and engine

rpm. Repeat the above steps for each cylinder.

+Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

2,942 (29.42, 30.0, 427)/

2002,452 (24.52, 25.0, 356)/

200294 (2.94, 3.0, 43)/200

+When engine rpm is out of the specified range, check the

specific gravity of battery liquid. Measure again under cor-

rected conditions.

+If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cyl-

inder head gaskets, piston rings, pistons, cylinder bores, cyl-

inder block upper and lower surfaces) and measure again.

11. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Replace glow plug oil seals and install glow plugs.

d. Install fuel injection pump fuse [ENG CONT (20A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for

items of self-diagnosis. Refer to EC section, ªTrouble Diag-

nosis Ð Indexº.

SEM318G

SEM334G

MEASUREMENT OF COMPRESSION PRESSURE

TROUBLESHOOTINGZD

EM-1010

Page 789 of 1033

VALVE OIL SEAL

1. Remove timing chain. Refer to EM-1027, ªTIMING CHAINº.

2. Remove injection nozzle assembly. Refer to ªInjection Tube

and Injection Nozzleº in ªBASIC SERVICE PROCEDUREº in

EC section.

3. Remove camshaft. Refer to EM-1031, ªCAMSHAFTº.

4. Remove valve lifters and mark order No. on each lifter.

5. Replace valve oil seal according to the following procedure.

When replacing valve oil seal, set the corresponding piston

at TDC. Failure to do so causes the valve to drop into the

cylinder.

1) Set No. 1 cylinder at TDC.

2) Remove valve springs and valve oil seals for No. 1 and No.

4 cylinders. Valve spring seats should not be removed.

3) Install new valve oil seals for No. 1 and No. 4 cylinders as

illustrated. Reinstall valve springs. (pink paint side toward

cylinder head)

4) Install valve spring retainers on intake valves and valve rota-

tors on exhaust valves, and remount valve assembly.

5) Set No. 2 cylinder at TDC.

6) Replace valve oil seals for No. 2 and No. 3 cylinders accord-

ing to steps 2) and 3).

7) Install valve lifters in original positions.

CRANKSHAFT OIL SEAL INSTALLING DIRECTION

AND MANNER

+When installing crankshaft oil seals, be careful to install

them correctly, as shown in the figure.

+Wipe off excess oil after installing oil seal.

SEM354G

SEM355G

SEM356G

SEM357G

SEM715A

OIL SEAL REPLACEMENTZD

EM-1051

Page 797 of 1033

5. Remove valve oil seals using valve oil seal puller (SST).

6. Remove valve spring seats.

7. Before removing valve spring seats, perform valve seat con-

tact check. (Refer to EM-1061.)

8. Before removing valve guides, perform valve guide clear-

ance check. (Refer to below.)

Inspection

CYLINDER HEAD DISTORTION

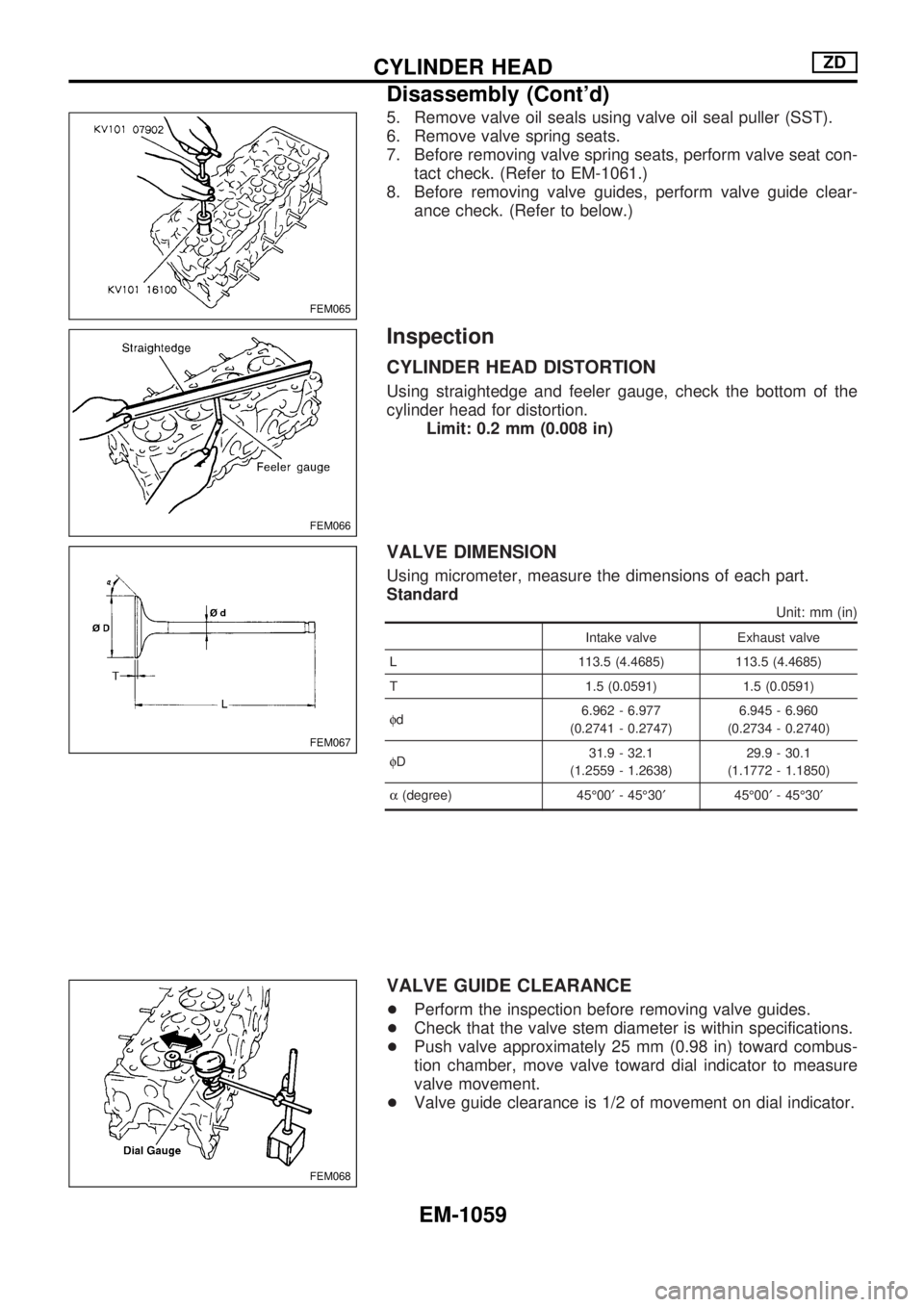

Using straightedge and feeler gauge, check the bottom of the

cylinder head for distortion.

Limit: 0.2 mm (0.008 in)

VALVE DIMENSION

Using micrometer, measure the dimensions of each part.

Standard

Unit: mm (in)

Intake valve Exhaust valve

L 113.5 (4.4685) 113.5 (4.4685)

T 1.5 (0.0591) 1.5 (0.0591)

fd6.962 - 6.977

(0.2741 - 0.2747)6.945 - 6.960

(0.2734 - 0.2740)

fD31.9 - 32.1

(1.2559 - 1.2638)29.9 - 30.1

(1.1772 - 1.1850)

a(degree) 45É00¢- 45É30¢45É00¢- 45É30¢

VALVE GUIDE CLEARANCE

+Perform the inspection before removing valve guides.

+Check that the valve stem diameter is within specifications.

+Push valve approximately 25 mm (0.98 in) toward combus-

tion chamber, move valve toward dial indicator to measure

valve movement.

+Valve guide clearance is 1/2 of movement on dial indicator.

FEM065

FEM066

FEM067

FEM068

CYLINDER HEADZD

Disassembly (Cont'd)

EM-1059

Page 799 of 1033

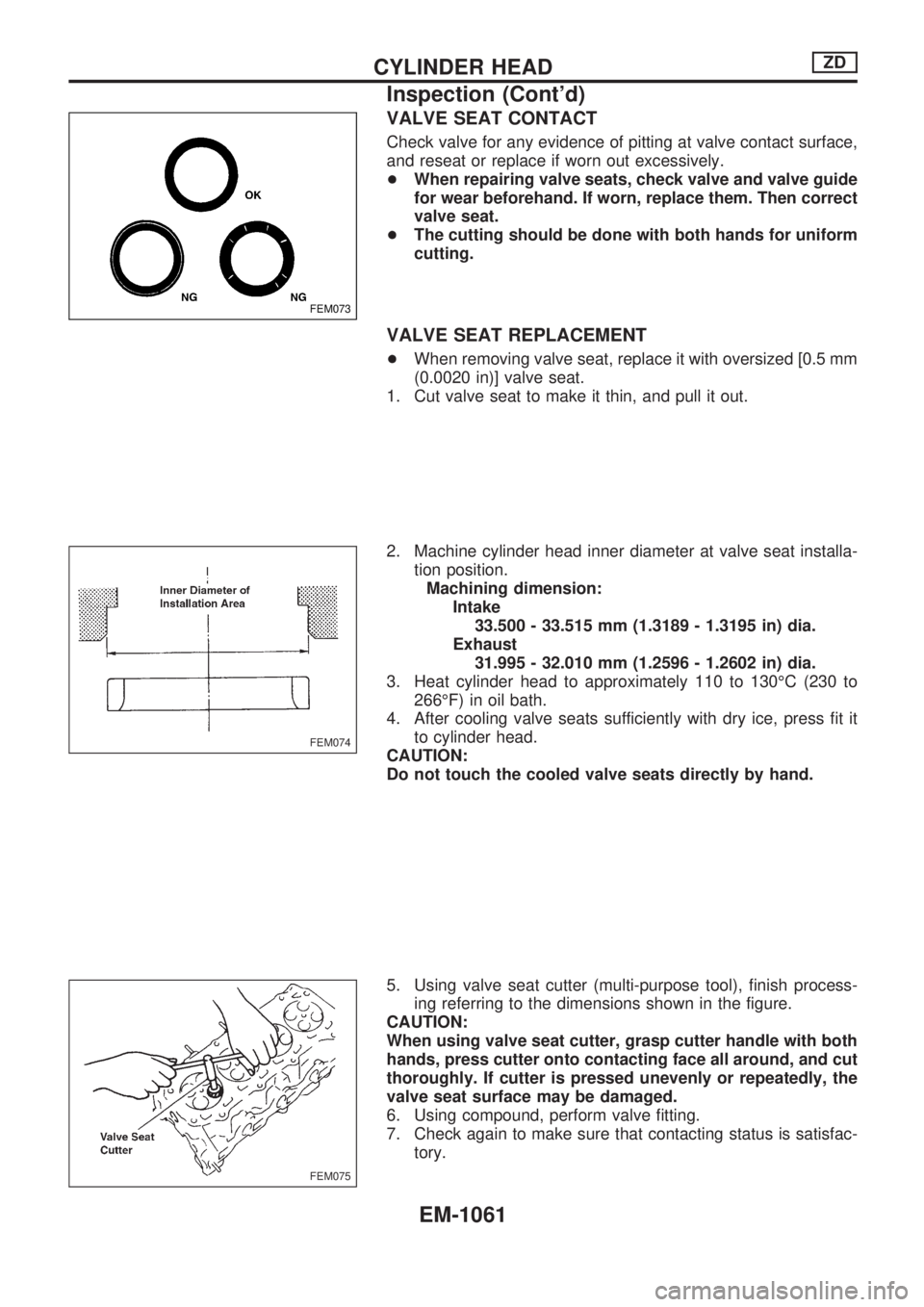

VALVE SEAT CONTACT

Check valve for any evidence of pitting at valve contact surface,

and reseat or replace if worn out excessively.

+When repairing valve seats, check valve and valve guide

for wear beforehand. If worn, replace them. Then correct

valve seat.

+The cutting should be done with both hands for uniform

cutting.

VALVE SEAT REPLACEMENT

+When removing valve seat, replace it with oversized [0.5 mm

(0.0020 in)] valve seat.

1. Cut valve seat to make it thin, and pull it out.

2. Machine cylinder head inner diameter at valve seat installa-

tion position.

Machining dimension:

Intake

33.500 - 33.515 mm (1.3189 - 1.3195 in) dia.

Exhaust

31.995 - 32.010 mm (1.2596 - 1.2602 in) dia.

3. Heat cylinder head to approximately 110 to 130ÉC (230 to

266ÉF) in oil bath.

4. After cooling valve seats sufficiently with dry ice, press fit it

to cylinder head.

CAUTION:

Do not touch the cooled valve seats directly by hand.

5. Using valve seat cutter (multi-purpose tool), finish process-

ing referring to the dimensions shown in the figure.

CAUTION:

When using valve seat cutter, grasp cutter handle with both

hands, press cutter onto contacting face all around, and cut

thoroughly. If cutter is pressed unevenly or repeatedly, the

valve seat surface may be damaged.

6. Using compound, perform valve fitting.

7. Check again to make sure that contacting status is satisfac-

tory.

FEM073

FEM074

FEM075

CYLINDER HEADZD

Inspection (Cont'd)

EM-1061

Page 800 of 1033

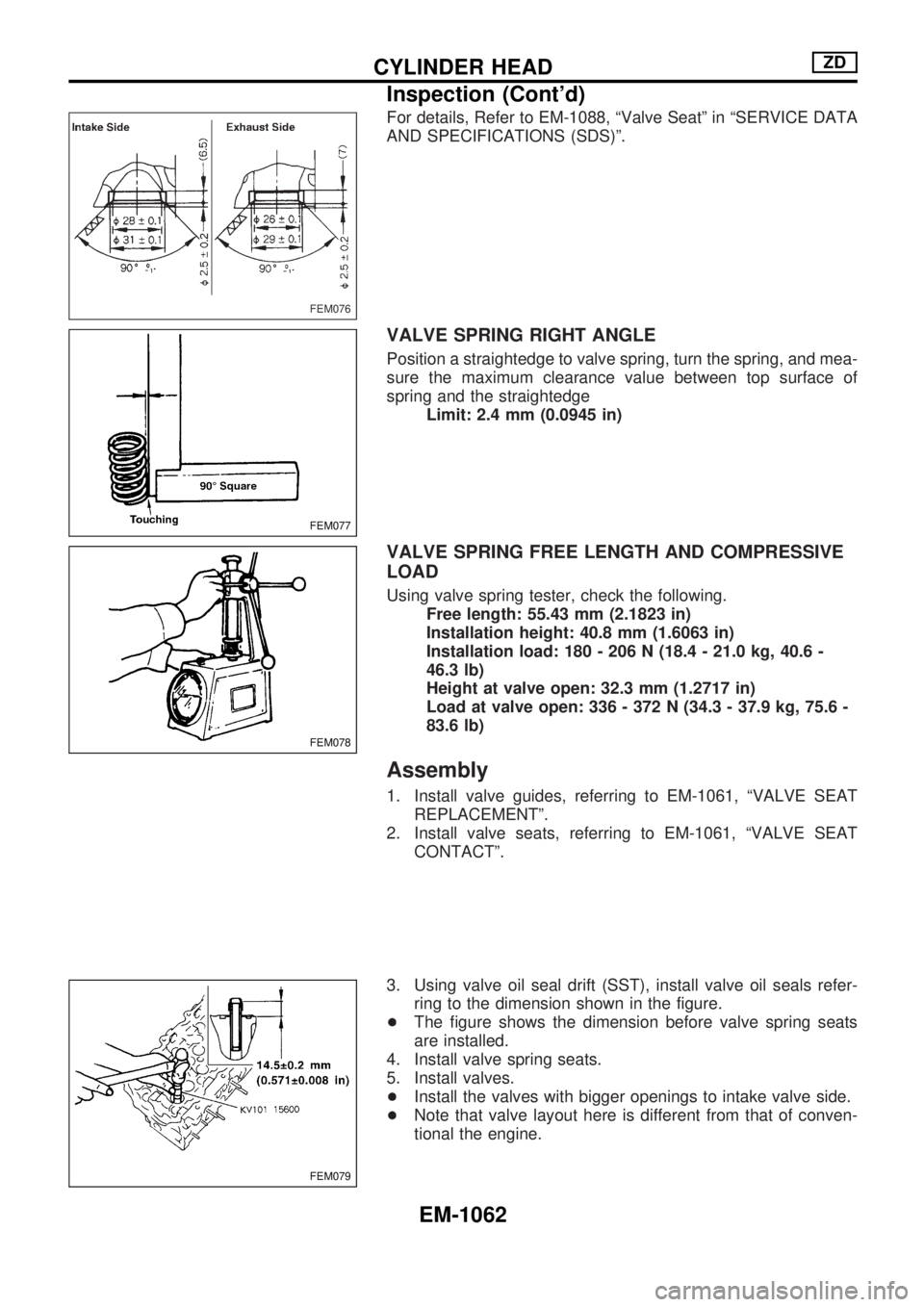

For details, Refer to EM-1088, ªValve Seatº in ªSERVICE DATA

AND SPECIFICATIONS (SDS)º.

VALVE SPRING RIGHT ANGLE

Position a straightedge to valve spring, turn the spring, and mea-

sure the maximum clearance value between top surface of

spring and the straightedge

Limit: 2.4 mm (0.0945 in)

VALVE SPRING FREE LENGTH AND COMPRESSIVE

LOAD

Using valve spring tester, check the following.

Free length: 55.43 mm (2.1823 in)

Installation height: 40.8 mm (1.6063 in)

Installation load: 180 - 206 N (18.4 - 21.0 kg, 40.6 -

46.3 lb)

Height at valve open: 32.3 mm (1.2717 in)

Load at valve open: 336 - 372 N (34.3 - 37.9 kg, 75.6 -

83.6 lb)

Assembly

1. Install valve guides, referring to EM-1061, ªVALVE SEAT

REPLACEMENTº.

2. Install valve seats, referring to EM-1061, ªVALVE SEAT

CONTACTº.

3. Using valve oil seal drift (SST), install valve oil seals refer-

ring to the dimension shown in the figure.

+The figure shows the dimension before valve spring seats

are installed.

4. Install valve spring seats.

5. Install valves.

+Install the valves with bigger openings to intake valve side.

+Note that valve layout here is different from that of conven-

tional the engine.

FEM076

FEM077

FEM078

FEM079

CYLINDER HEADZD

Inspection (Cont'd)

EM-1062