lock NISSAN PATROL 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PATROL, Model: NISSAN PATROL 2001Pages: 273, PDF Size: 9.05 MB

Page 3 of 273

AUTOMATIC TRANSMISSION

SECTION

AT

MODIFICATION NOTICE:

+Wiring diagrams have been changed.

+Service Data and Specifications (SDS) have been changed.

CONTENTS

OVERALL SYSTEM............................................ 2002

Circuit Diagram ................................................ 2002

Wiring Diagram Ð A/T Ð ................................ 2003

TROUBLE DIAGNOSES Ð A/T Shift Lock

System................................................................. 2013Wiring Diagram Ð SHIFT Ð ........................... 2013

SERVICE DATA AND SPECIFICATIONS

(SDS).................................................................... 2014

General Specifications ..................................... 2014

Specifications and Adjustment......................... 2014

AT

Page 15 of 273

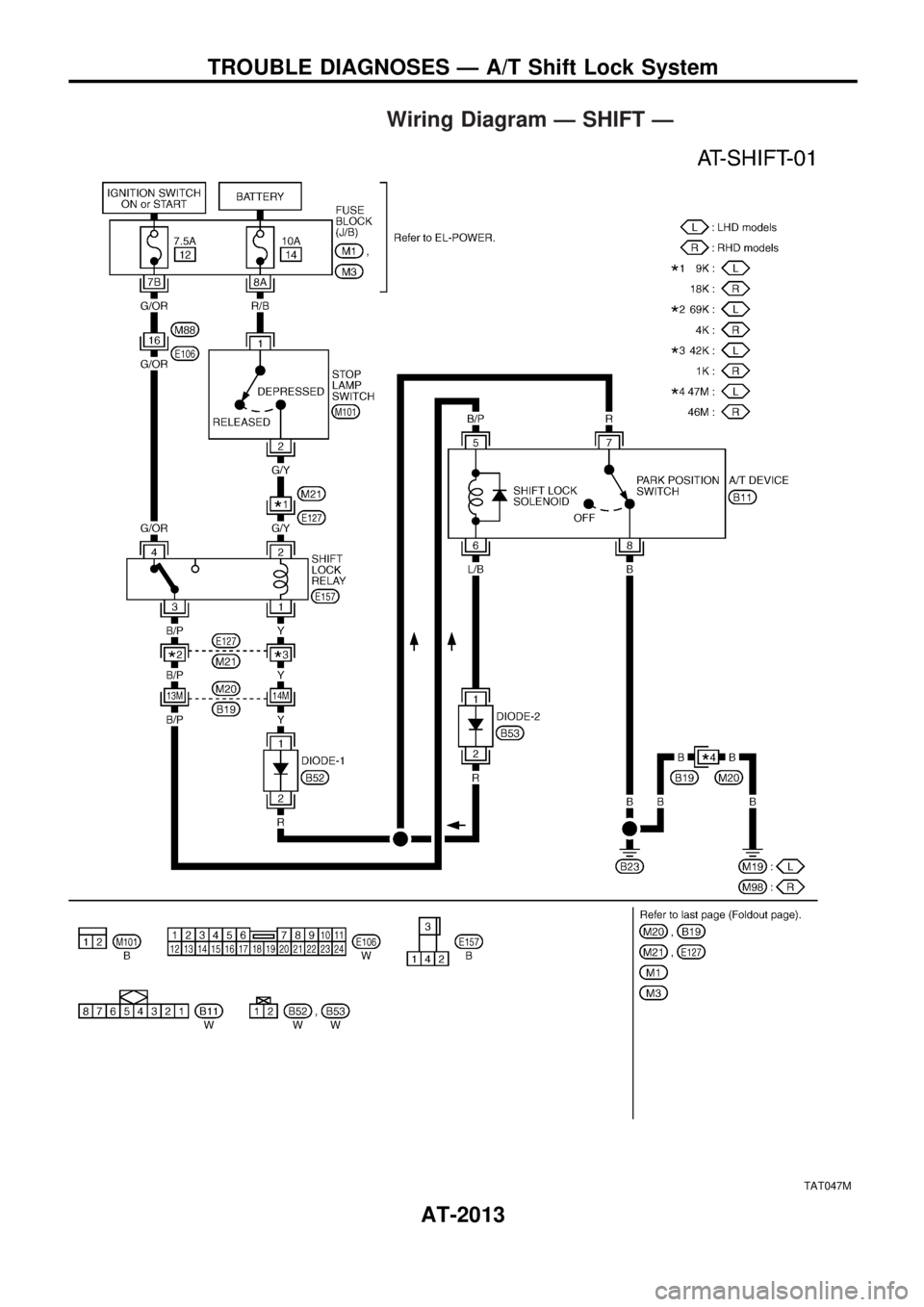

Wiring Diagram Ð SHIFT Ð

TAT047M

TROUBLE DIAGNOSES Ð A/T Shift Lock System

AT-2013

Page 27 of 273

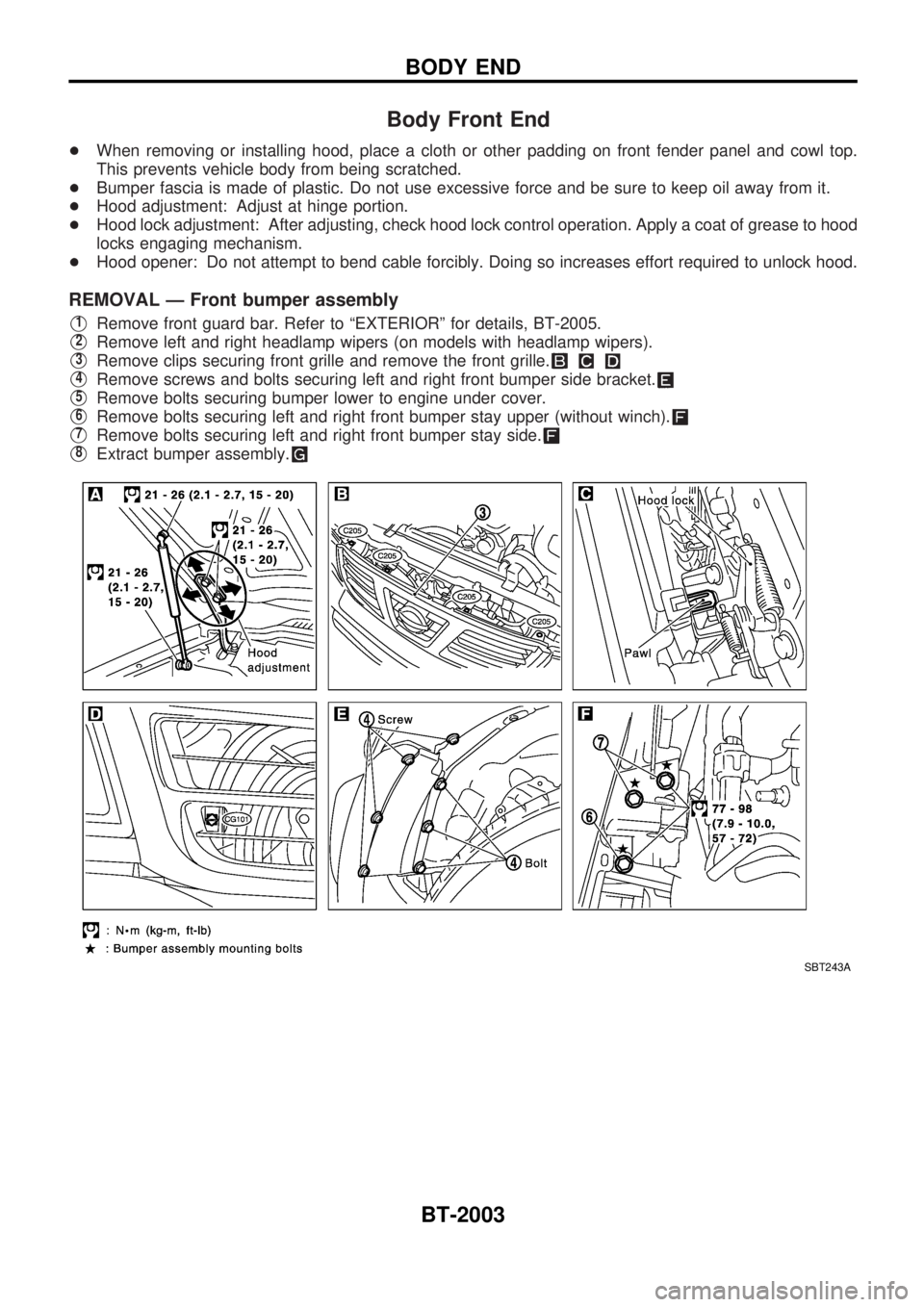

Body Front End

+When removing or installing hood, place a cloth or other padding on front fender panel and cowl top.

This prevents vehicle body from being scratched.

+Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

+Hood adjustment: Adjust at hinge portion.

+Hood lock adjustment: After adjusting, check hood lock control operation. Apply a coat of grease to hood

locks engaging mechanism.

+Hood opener: Do not attempt to bend cable forcibly. Doing so increases effort required to unlock hood.

REMOVAL Ð Front bumper assembly

V1Remove front guard bar. Refer to ªEXTERIORº for details, BT-2005.

V2Remove left and right headlamp wipers (on models with headlamp wipers).

V3Remove clips securing front grille and remove the front grille.

V4Remove screws and bolts securing left and right front bumper side bracket.

V5Remove bolts securing bumper lower to engine under cover.

V6Remove bolts securing left and right front bumper stay upper (without winch).

V7Remove bolts securing left and right front bumper stay side.

V8Extract bumper assembly.

SBT243A

BODY END

BT-2003

Page 49 of 273

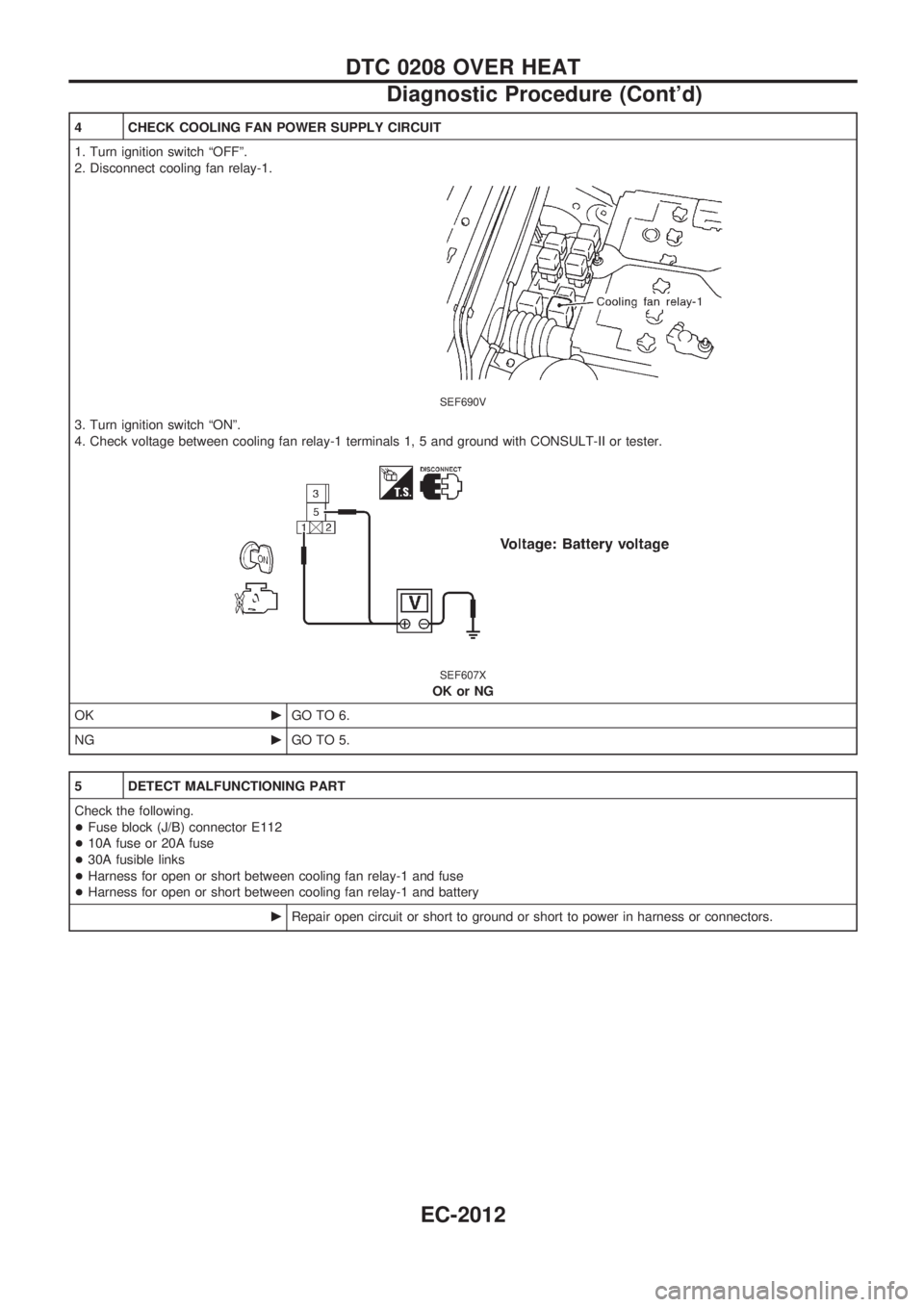

4 CHECK COOLING FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan relay-1.

SEF690V

3. Turn ignition switch ªONº.

4. Check voltage between cooling fan relay-1 terminals 1, 5 and ground with CONSULT-II or tester.

SEF607X

OK or NG

OKcGO TO 6.

NGcGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Fuse block (J/B) connector E112

+10A fuse or 20A fuse

+30A fusible links

+Harness for open or short between cooling fan relay-1 and fuse

+Harness for open or short between cooling fan relay-1 and battery

cRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0208 OVER HEAT

Diagnostic Procedure (Cont'd)

EC-2012

Page 54 of 273

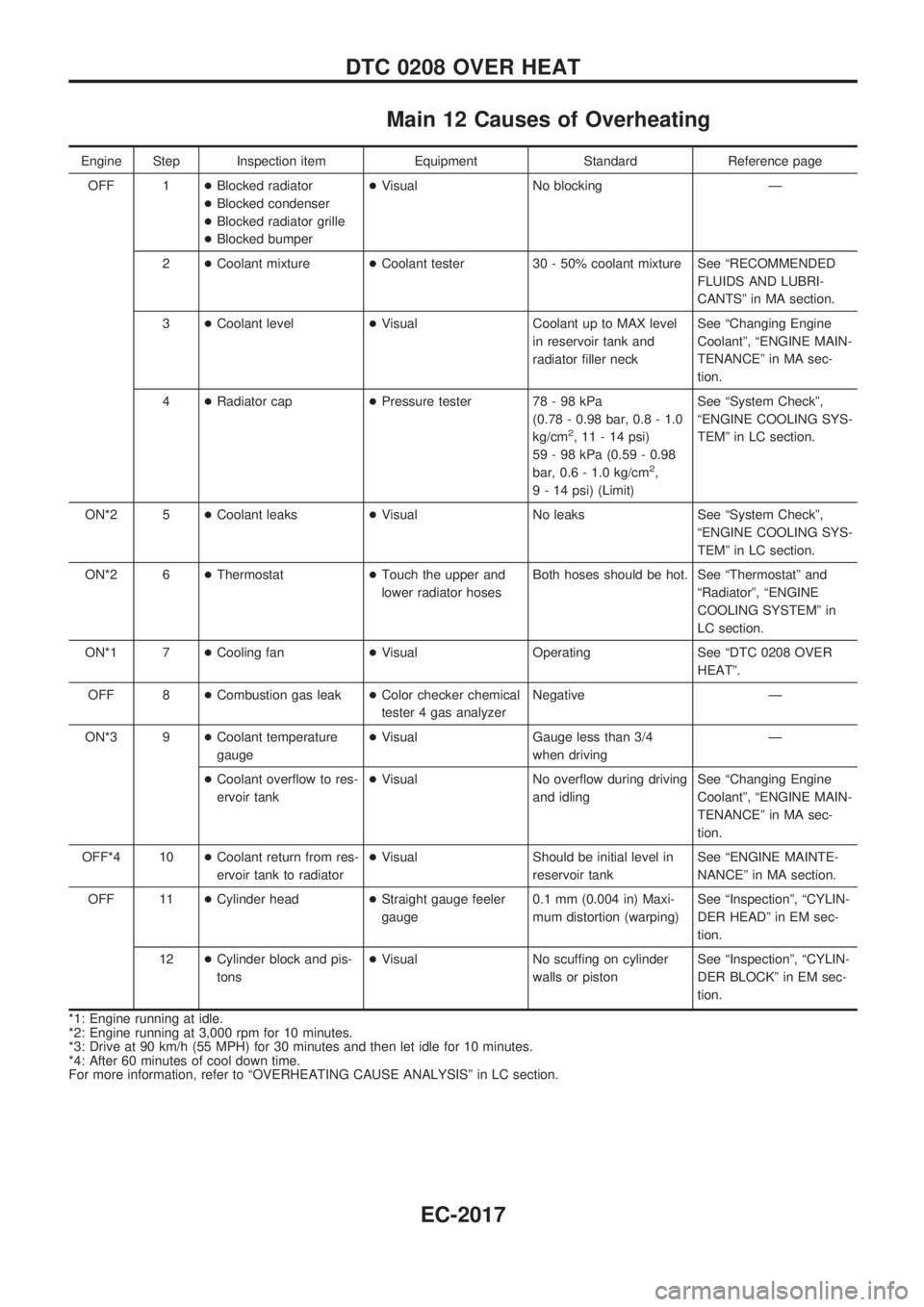

Main 12 Causes of Overheating

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 30 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

4+Radiator cap+Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 5+Coolant leaks+Visual No leaks See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 6+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be hot. See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7+Cooling fan+Visual Operating See ªDTC 0208 OVER

HEATº.

OFF 8+Combustion gas leak+Color checker chemical

tester 4 gas analyzerNegative Ð

ON*3 9+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to res-

ervoir tank+Visual No overflow during driving

and idlingSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

OFF*4 10+Coolant return from res-

ervoir tank to radiator+Visual Should be initial level in

reservoir tankSee ªENGINE MAINTE-

NANCEº in MA section.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ªInspectionº, ªCYLIN-

DER HEADº in EM sec-

tion.

12+Cylinder block and pis-

tons+Visual No scuffing on cylinder

walls or pistonSee ªInspectionº, ªCYLIN-

DER BLOCKº in EM sec-

tion.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC 0208 OVER HEAT

EC-2017

Page 112 of 273

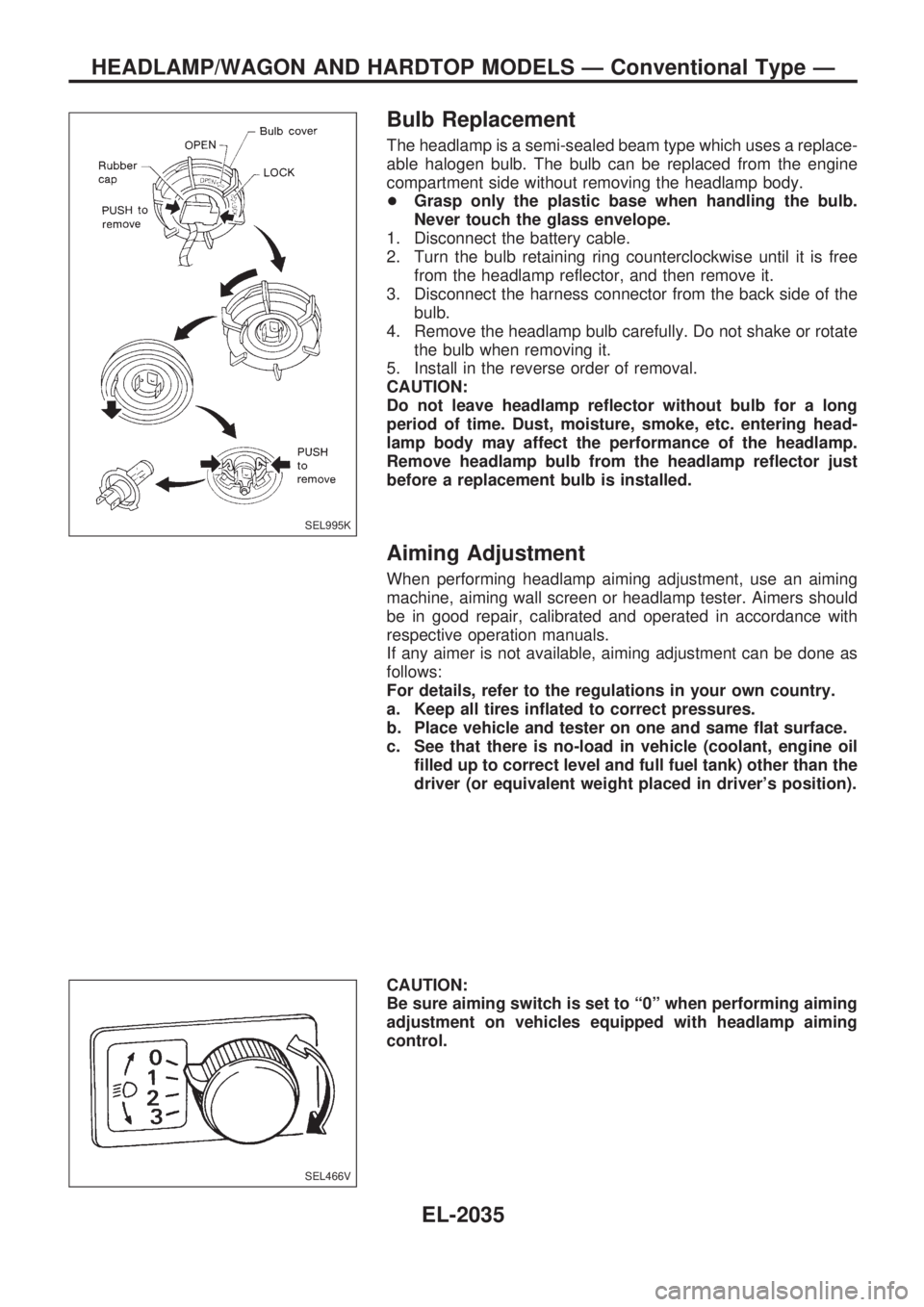

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replace-

able halogen bulb. The bulb can be replaced from the engine

compartment side without removing the headlamp body.

+Grasp only the plastic base when handling the bulb.

Never touch the glass envelope.

1. Disconnect the battery cable.

2. Turn the bulb retaining ring counterclockwise until it is free

from the headlamp reflector, and then remove it.

3. Disconnect the harness connector from the back side of the

bulb.

4. Remove the headlamp bulb carefully. Do not shake or rotate

the bulb when removing it.

5. Install in the reverse order of removal.

CAUTION:

Do not leave headlamp reflector without bulb for a long

period of time. Dust, moisture, smoke, etc. entering head-

lamp body may affect the performance of the headlamp.

Remove headlamp bulb from the headlamp reflector just

before a replacement bulb is installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. Aimers should

be in good repair, calibrated and operated in accordance with

respective operation manuals.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is no-load in vehicle (coolant, engine oil

filled up to correct level and full fuel tank) other than the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming

control.

SEL995K

SEL466V

HEADLAMP/WAGON AND HARDTOP MODELS Ð Conventional Type Ð

EL-2035

Page 155 of 273

System Description

WIPER OPERATION

The rear wiper switch is controlled by a ring built into the combination switch.

There are two wiper switch positions:

+ON (LO speed)

+INT (Intermittent)

With the ignition switch in the ON position, power is supplied

+through 10A fuse (No.

18, located in the fuse block)

+to rear wiper motor terminal

V4, and

+to rear wiper amplifier terminal

V5.

Low speed wiper operation

Ground is supplied to rear wiper switch terminalV24through body grounds.

When the rear wiper is placed in the ON position, ground is supplied

+through rear wiper switch terminal

V22

+to rear wiper relay terminalV6.

Then ground is supplied

+to rear wiper motor terminal

V1

+through rear wiper amplifier terminalsV2andV3.

With power and ground supplied, the wiper motor operates.

Auto stop operation

With the rear wiper switch turned OFF, rear wiper motor will continue to operate until wiper arm reaches

rear window base.

When wiper arm is not located at base of rear window with rear wiper switch OFF, ground is supplied

+to rear wiper motor terminal

V1

+through rear wiper amplifier terminalsV2,V7and

+through rear wiper motor terminal

V3, in order to continue rear wiper motor operation at low speed.

Ground is also supplied

+to rear wiper motor terminal

V2

+through body grounds.

When wiper arm reaches base of rear window, rear wiper motor terminals

V3andV4are connected instead

of terminals

V2andV3. Rear wiper motor will then stop wiper arm at the PARK position.

Intermittent operation

The rear wiper motor operates the wiper arm one time at low speed at an interval of approximately 7 sec-

onds.

When the rear wiper switch is placed in the INT position, ground is supplied

+to rear wiper amplifier terminal

V1

+through rear wiper switch terminalV21.

Then the rear wiper motor operates intermittently in the same manner as the low speed wiper operation.

WASHER OPERATION

With the ignition switch in the ACC or ON position, power is supplied

+through 10A fuse (No.

18, located in the fuse block)

+to rear washer motor terminal

V2.

When the ring is turned WASH position, ground is supplied

+to rear washer motor terminal

V1, and

+to rear wiper amplifier terminal

V4

+through terminalV23of rear wiper switch.

With power and ground is supplied, the rear washer motor operates.

The rear wiper motor operates when the ring is turned to WASH position for one second or more and for

approximately 3 seconds after the ring is released. This feature is controlled by the rear wiper amplifier in

the same manner as the low speed wiper operation.

REAR WIPER AND WASHER/WAGON AND HARDTOP MODELS

EL-2078

Page 209 of 273

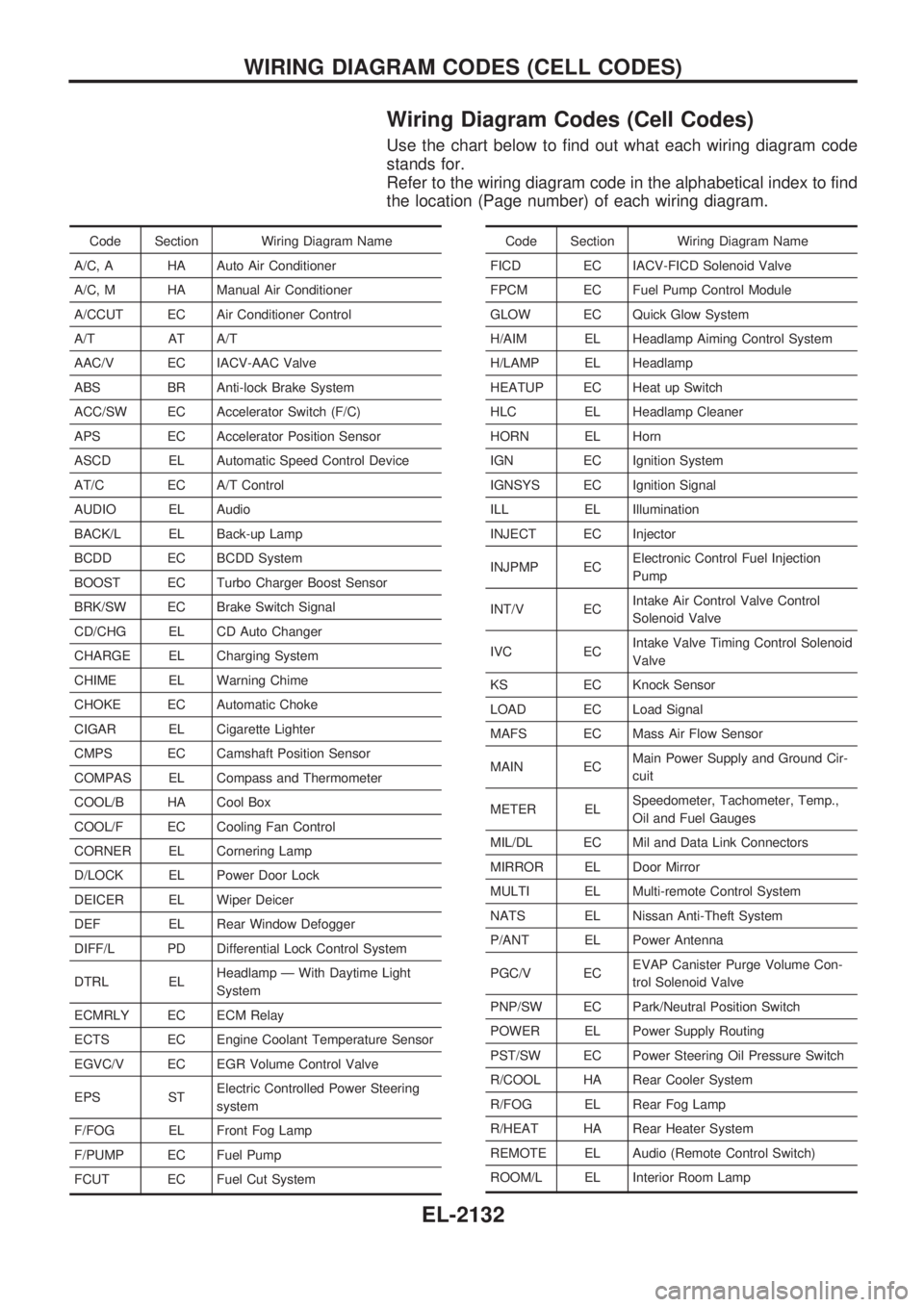

Wiring Diagram Codes (Cell Codes)

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (Page number) of each wiring diagram.

Code Section Wiring Diagram Name

A/C, A HA Auto Air Conditioner

A/C, M HA Manual Air Conditioner

A/CCUT EC Air Conditioner Control

A/T AT A/T

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

ACC/SW EC Accelerator Switch (F/C)

APS EC Accelerator Position Sensor

ASCD EL Automatic Speed Control Device

AT/C EC A/T Control

AUDIO EL Audio

BACK/L EL Back-up Lamp

BCDD EC BCDD System

BOOST EC Turbo Charger Boost Sensor

BRK/SW EC Brake Switch Signal

CD/CHG EL CD Auto Changer

CHARGE EL Charging System

CHIME EL Warning Chime

CHOKE EC Automatic Choke

CIGAR EL Cigarette Lighter

CMPS EC Camshaft Position Sensor

COMPAS EL Compass and Thermometer

COOL/B HA Cool Box

COOL/F EC Cooling Fan Control

CORNER EL Cornering Lamp

D/LOCK EL Power Door Lock

DEICER EL Wiper Deicer

DEF EL Rear Window Defogger

DIFF/L PD Differential Lock Control System

DTRL ELHeadlamp Ð With Daytime Light

System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGVC/V EC EGR Volume Control Valve

EPS STElectric Controlled Power Steering

system

F/FOG EL Front Fog Lamp

F/PUMP EC Fuel Pump

FCUT EC Fuel Cut SystemCode Section Wiring Diagram Name

FICD EC IACV-FICD Solenoid Valve

FPCM EC Fuel Pump Control Module

GLOW EC Quick Glow System

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

HEATUP EC Heat up Switch

HLC EL Headlamp Cleaner

HORN EL Horn

IGN EC Ignition System

IGNSYS EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INJPMP ECElectronic Control Fuel Injection

Pump

INT/V ECIntake Air Control Valve Control

Solenoid Valve

IVC ECIntake Valve Timing Control Solenoid

Valve

KS EC Knock Sensor

LOAD EC Load Signal

MAFS EC Mass Air Flow Sensor

MAIN ECMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.,

Oil and Fuel Gauges

MIL/DL EC Mil and Data Link Connectors

MIRROR EL Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-Theft System

P/ANT EL Power Antenna

PGC/V ECEVAP Canister Purge Volume Con-

trol Solenoid Valve

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

PST/SW EC Power Steering Oil Pressure Switch

R/COOL HA Rear Cooler System

R/FOG EL Rear Fog Lamp

R/HEAT HA Rear Heater System

REMOTE EL Audio (Remote Control Switch)

ROOM/L EL Interior Room Lamp

WIRING DIAGRAM CODES (CELL CODES)

EL-2132

Page 210 of 273

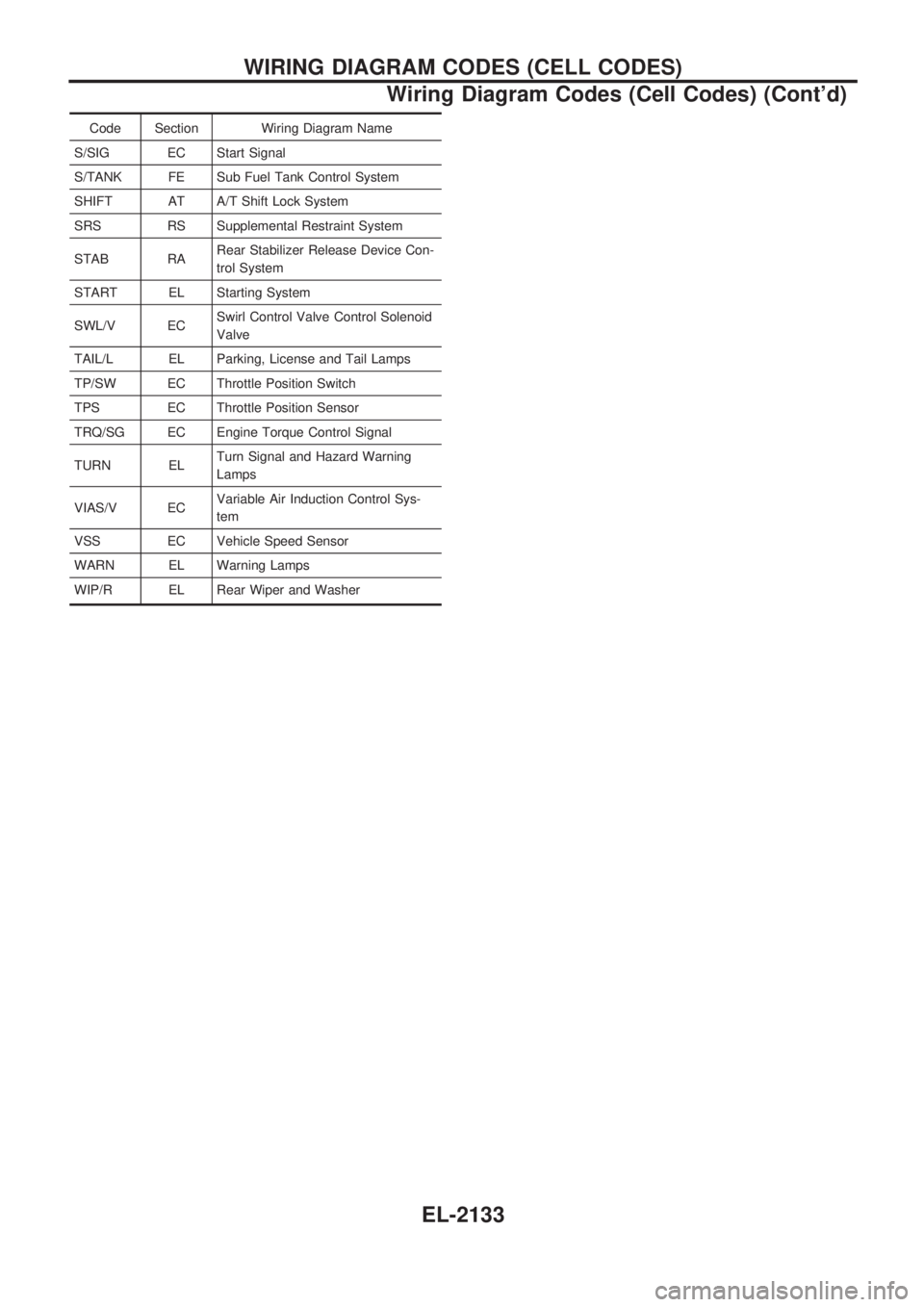

Code Section Wiring Diagram Name

S/SIG EC Start Signal

S/TANK FE Sub Fuel Tank Control System

SHIFT AT A/T Shift Lock System

SRS RS Supplemental Restraint System

STAB RARear Stabilizer Release Device Con-

trol System

START EL Starting System

SWL/V ECSwirl Control Valve Control Solenoid

Valve

TAIL/L EL Parking, License and Tail Lamps

TP/SW EC Throttle Position Switch

TPS EC Throttle Position Sensor

TRQ/SG EC Engine Torque Control Signal

TURN ELTurn Signal and Hazard Warning

Lamps

VIAS/V ECVariable Air Induction Control Sys-

tem

VSS EC Vehicle Speed Sensor

WARN EL Warning Lamps

WIP/R EL Rear Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

Wiring Diagram Codes (Cell Codes) (Cont'd)

EL-2133

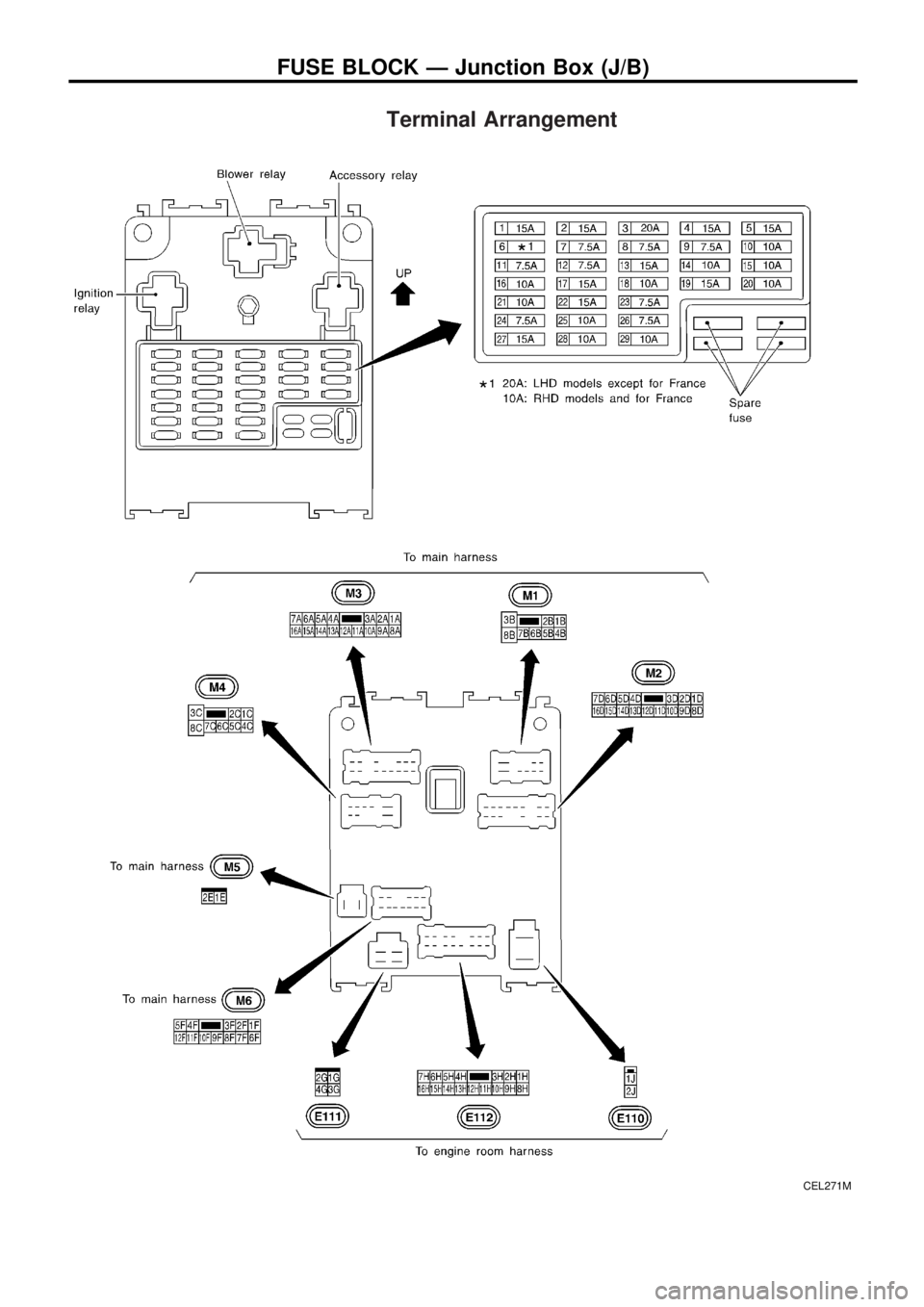

Page 211 of 273

Terminal Arrangement

CEL271M

FUSE BLOCK Ð Junction Box (J/B)