coolant temperature NISSAN PATROL 2002 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: PATROL, Model: NISSAN PATROL 2002Pages: 311, PDF Size: 12.08 MB

Page 33 of 311

Diagnostic Procedure

1 INSPECTION START

Do you have CONSULT-II?

Yes or No

YescGO TO 2.

NocGO TO 3.

2 CHECK COOLING FAN OPERATION

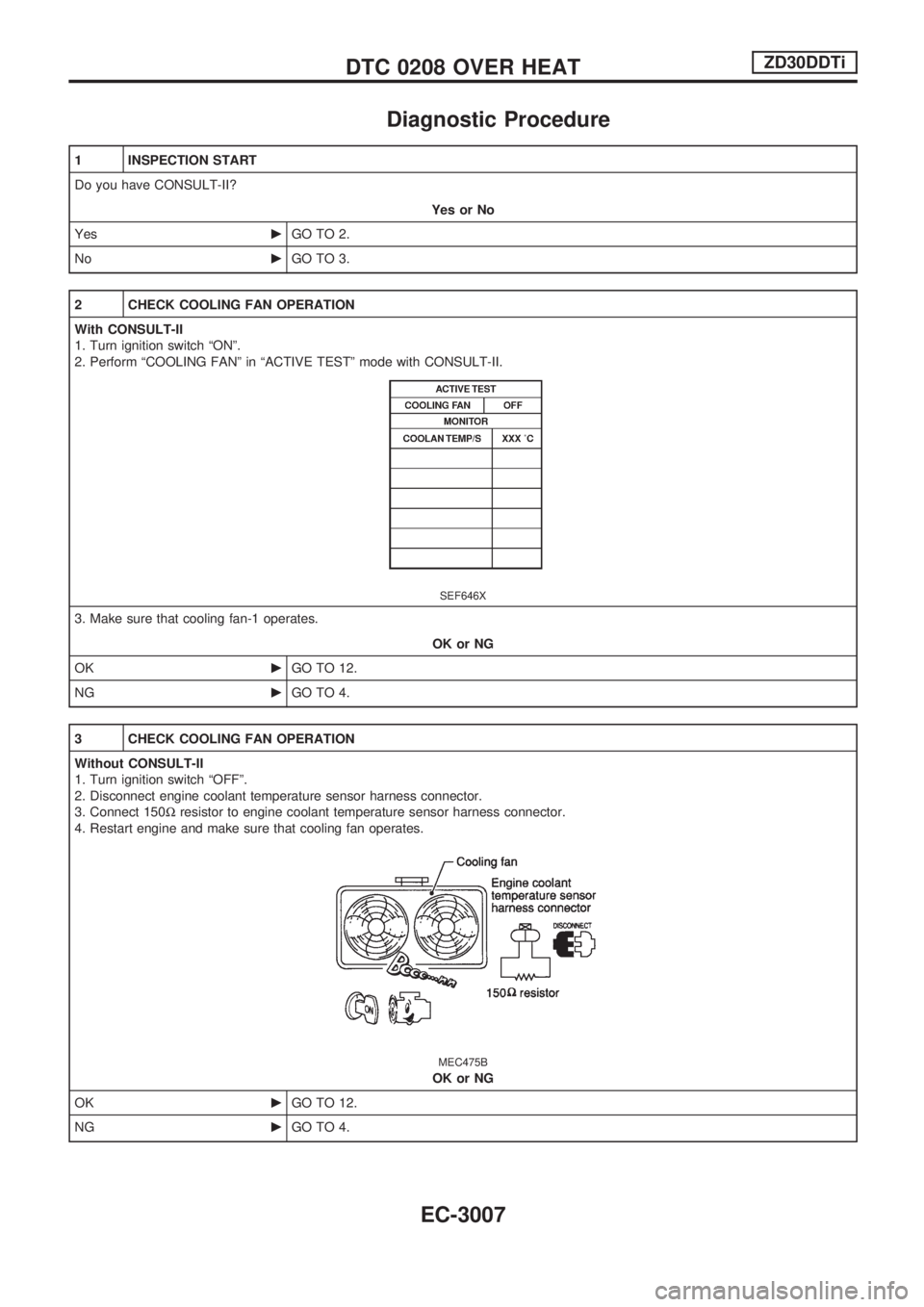

With CONSULT-II

1. Turn ignition switch ªONº.

2. Perform ªCOOLING FANº in ªACTIVE TESTº mode with CONSULT-II.

SEF646X

3. Make sure that cooling fan-1 operates.

OK or NG

OKcGO TO 12.

NGcGO TO 4.

3 CHECK COOLING FAN OPERATION

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

3. Connect 150Wresistor to engine coolant temperature sensor harness connector.

4. Restart engine and make sure that cooling fan operates.

MEC475B

OK or NG

OKcGO TO 12.

NGcGO TO 4.

DTC 0208 OVER HEATZD30DDTi

EC-3007

Page 38 of 311

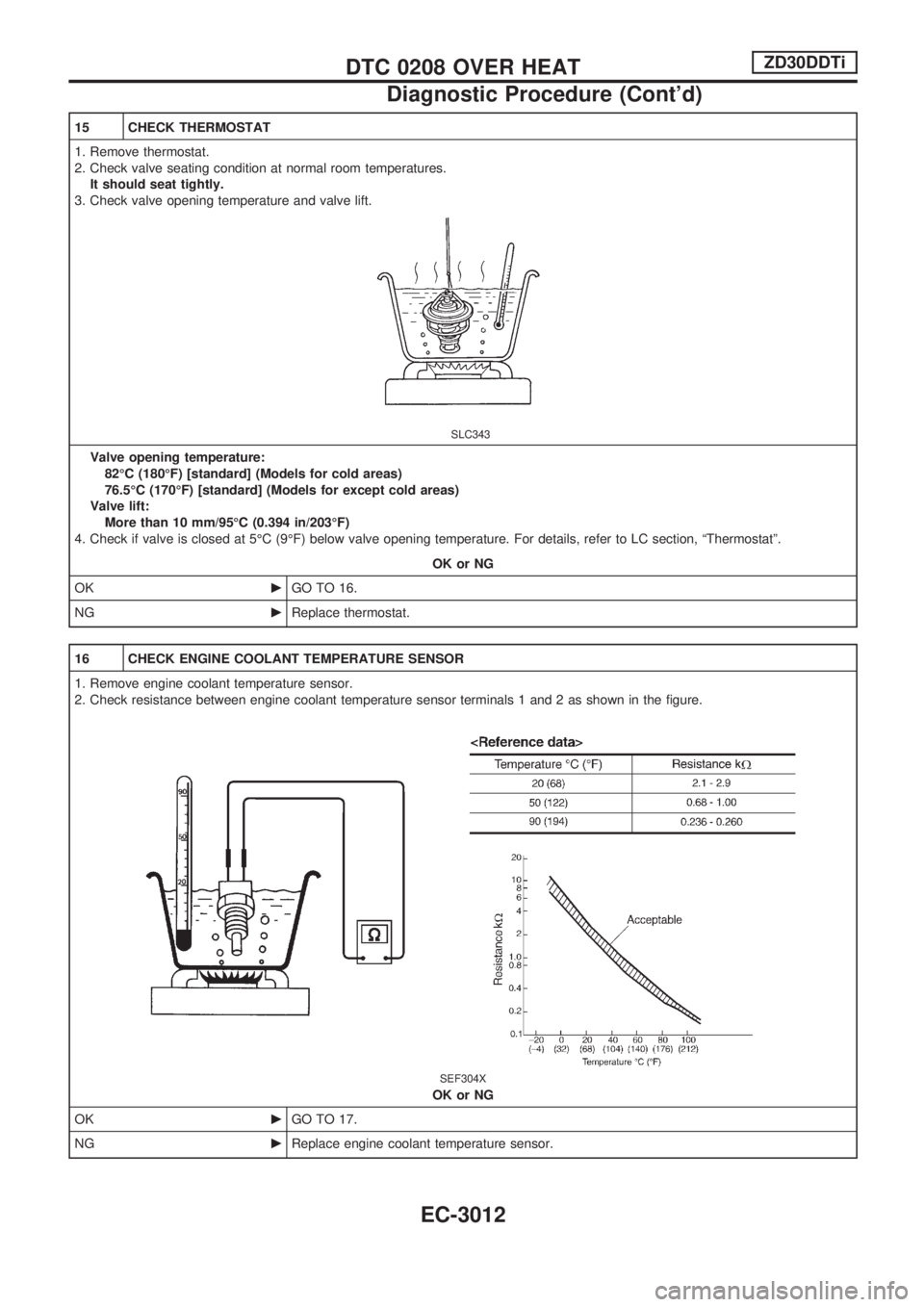

15 CHECK THERMOSTAT

1. Remove thermostat.

2. Check valve seating condition at normal room temperatures.

It should seat tightly.

3. Check valve opening temperature and valve lift.

SLC343

Valve opening temperature:

82ÉC (180ÉF) [standard] (Models for cold areas)

76.5ÉC (170ÉF) [standard] (Models for except cold areas)

Valve lift:

More than 10 mm/95ÉC (0.394 in/203ÉF)

4. Check if valve is closed at 5ÉC (9ÉF) below valve opening temperature. For details, refer to LC section, ªThermostatº.

OK or NG

OKcGO TO 16.

NGcReplace thermostat.

16 CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Remove engine coolant temperature sensor.

2. Check resistance between engine coolant temperature sensor terminals 1 and 2 as shown in the figure.

SEF304X

OK or NG

OKcGO TO 17.

NGcReplace engine coolant temperature sensor.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-3012

Page 40 of 311

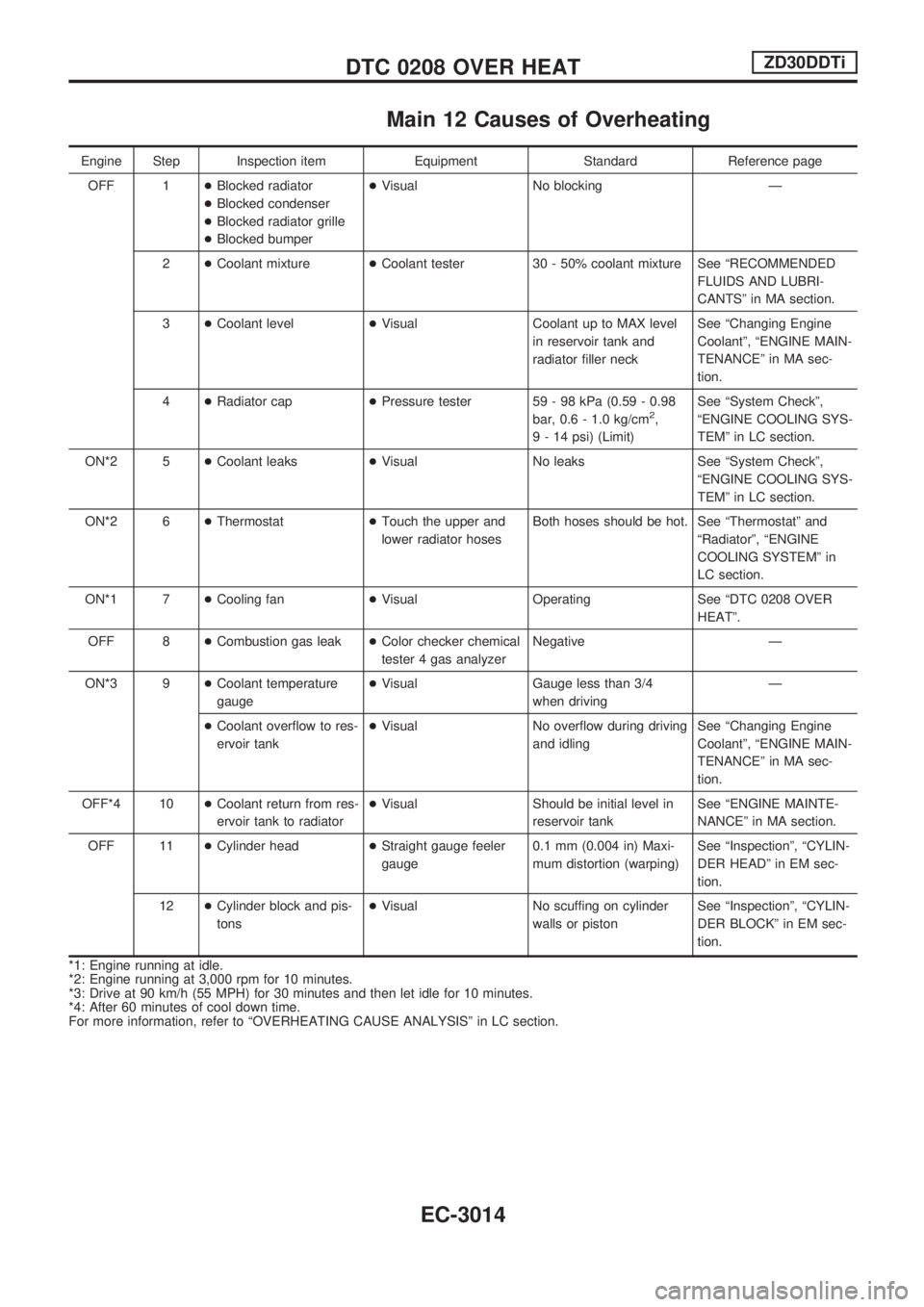

Main 12 Causes of Overheating

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 30 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

4+Radiator cap+Pressure tester 59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 5+Coolant leaks+Visual No leaks See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 6+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be hot. See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7+Cooling fan+Visual Operating See ªDTC 0208 OVER

HEATº.

OFF 8+Combustion gas leak+Color checker chemical

tester 4 gas analyzerNegative Ð

ON*3 9+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to res-

ervoir tank+Visual No overflow during driving

and idlingSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

OFF*4 10+Coolant return from res-

ervoir tank to radiator+Visual Should be initial level in

reservoir tankSee ªENGINE MAINTE-

NANCEº in MA section.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ªInspectionº, ªCYLIN-

DER HEADº in EM sec-

tion.

12+Cylinder block and pis-

tons+Visual No scuffing on cylinder

walls or pistonSee ªInspectionº, ªCYLIN-

DER BLOCKº in EM sec-

tion.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC 0208 OVER HEATZD30DDTi

EC-3014

Page 256 of 311

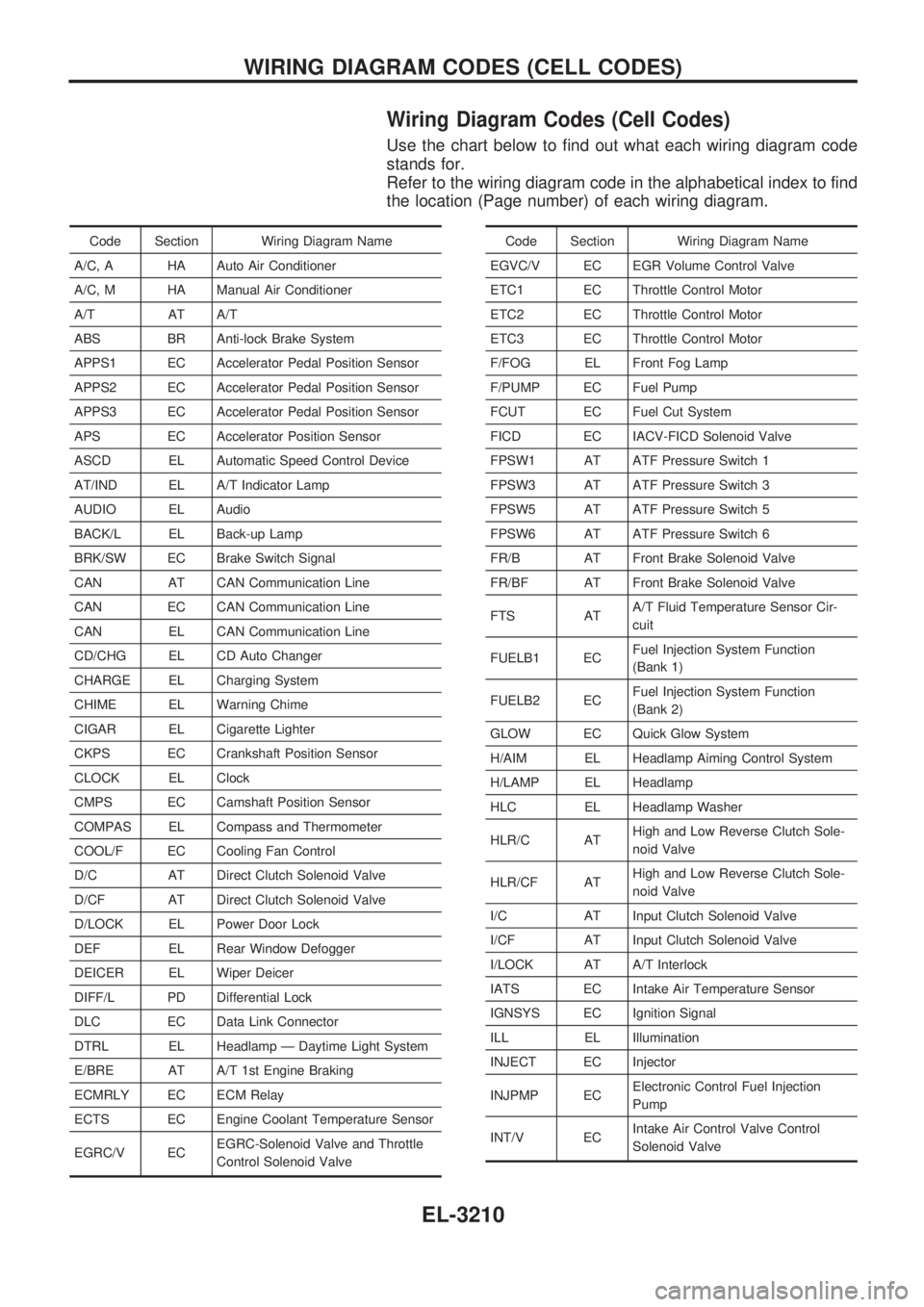

Wiring Diagram Codes (Cell Codes)

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (Page number) of each wiring diagram.

Code Section Wiring Diagram Name

A/C, A HA Auto Air Conditioner

A/C, M HA Manual Air Conditioner

A/T AT A/T

ABS BR Anti-lock Brake System

APPS1 EC Accelerator Pedal Position Sensor

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

APS EC Accelerator Position Sensor

ASCD EL Automatic Speed Control Device

AT/IND EL A/T Indicator Lamp

AUDIO EL Audio

BACK/L EL Back-up Lamp

BRK/SW EC Brake Switch Signal

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN EL CAN Communication Line

CD/CHG EL CD Auto Changer

CHARGE EL Charging System

CHIME EL Warning Chime

CIGAR EL Cigarette Lighter

CKPS EC Crankshaft Position Sensor

CLOCK EL Clock

CMPS EC Camshaft Position Sensor

COMPAS EL Compass and Thermometer

COOL/F EC Cooling Fan Control

D/C AT Direct Clutch Solenoid Valve

D/CF AT Direct Clutch Solenoid Valve

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DEICER EL Wiper Deicer

DIFF/L PD Differential Lock

DLC EC Data Link Connector

DTRL EL Headlamp Ð Daytime Light System

E/BRE AT A/T 1st Engine Braking

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGRC/V ECEGRC-Solenoid Valve and Throttle

Control Solenoid ValveCode Section Wiring Diagram Name

EGVC/V EC EGR Volume Control Valve

ETC1 EC Throttle Control Motor

ETC2 EC Throttle Control Motor

ETC3 EC Throttle Control Motor

F/FOG EL Front Fog Lamp

F/PUMP EC Fuel Pump

FCUT EC Fuel Cut System

FICD EC IACV-FICD Solenoid Valve

FPSW1 AT ATF Pressure Switch 1

FPSW3 AT ATF Pressure Switch 3

FPSW5 AT ATF Pressure Switch 5

FPSW6 AT ATF Pressure Switch 6

FR/B AT Front Brake Solenoid Valve

FR/BF AT Front Brake Solenoid Valve

FTS ATA/T Fluid Temperature Sensor Cir-

cuit

FUELB1 ECFuel Injection System Function

(Bank 1)

FUELB2 ECFuel Injection System Function

(Bank 2)

GLOW EC Quick Glow System

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

HLC EL Headlamp Washer

HLR/C ATHigh and Low Reverse Clutch Sole-

noid Valve

HLR/CF ATHigh and Low Reverse Clutch Sole-

noid Valve

I/C AT Input Clutch Solenoid Valve

I/CF AT Input Clutch Solenoid Valve

I/LOCK AT A/T Interlock

IATS EC Intake Air Temperature Sensor

IGNSYS EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INJPMP ECElectronic Control Fuel Injection

Pump

INT/V ECIntake Air Control Valve Control

Solenoid Valve

WIRING DIAGRAM CODES (CELL CODES)

EL-3210