ignition NISSAN PATROL 2002 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: PATROL, Model: NISSAN PATROL 2002Pages: 311, PDF Size: 12.08 MB

Page 33 of 311

Diagnostic Procedure

1 INSPECTION START

Do you have CONSULT-II?

Yes or No

YescGO TO 2.

NocGO TO 3.

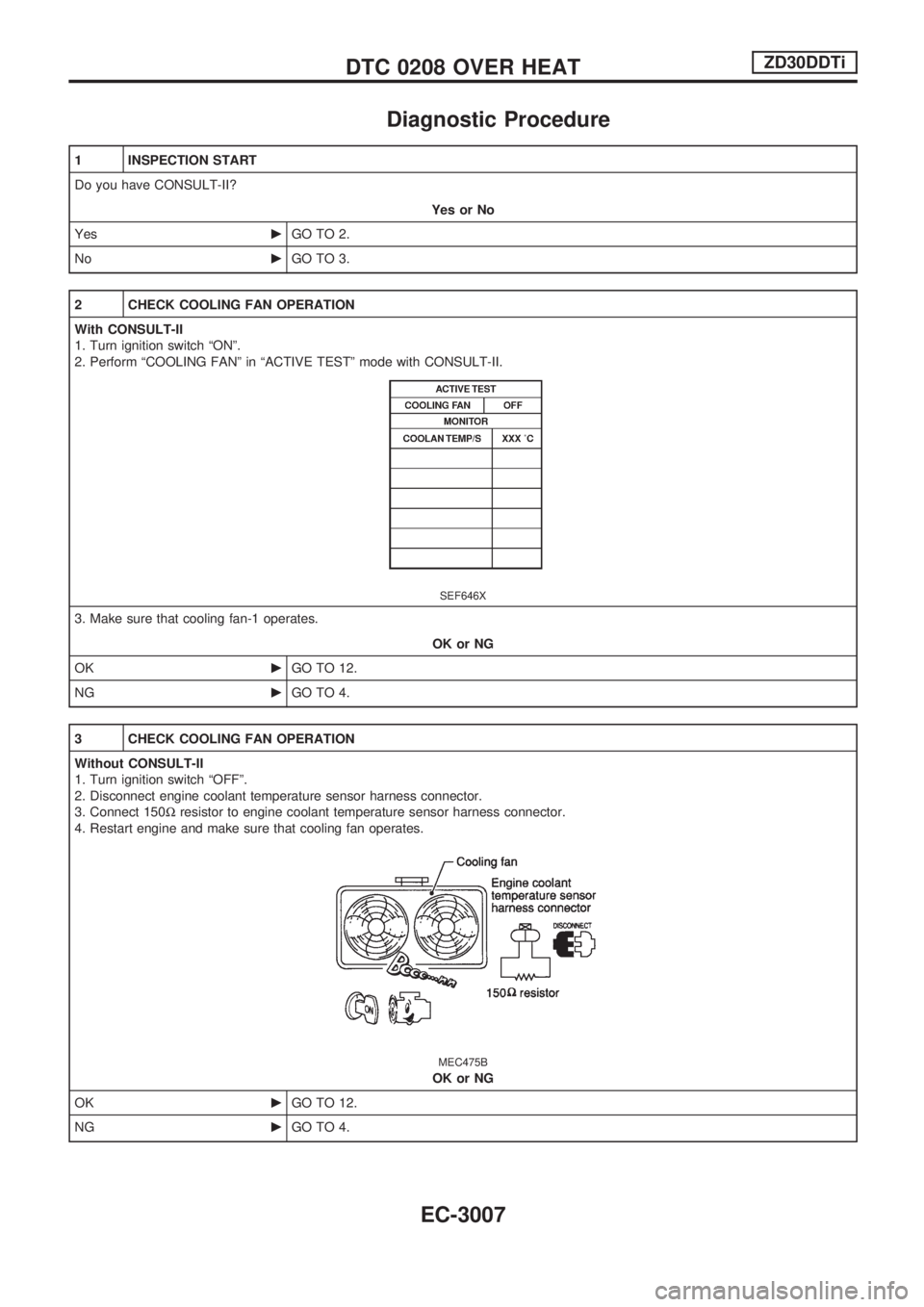

2 CHECK COOLING FAN OPERATION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Perform ªCOOLING FANº in ªACTIVE TESTº mode with CONSULT-II.

SEF646X

3. Make sure that cooling fan-1 operates.

OK or NG

OKcGO TO 12.

NGcGO TO 4.

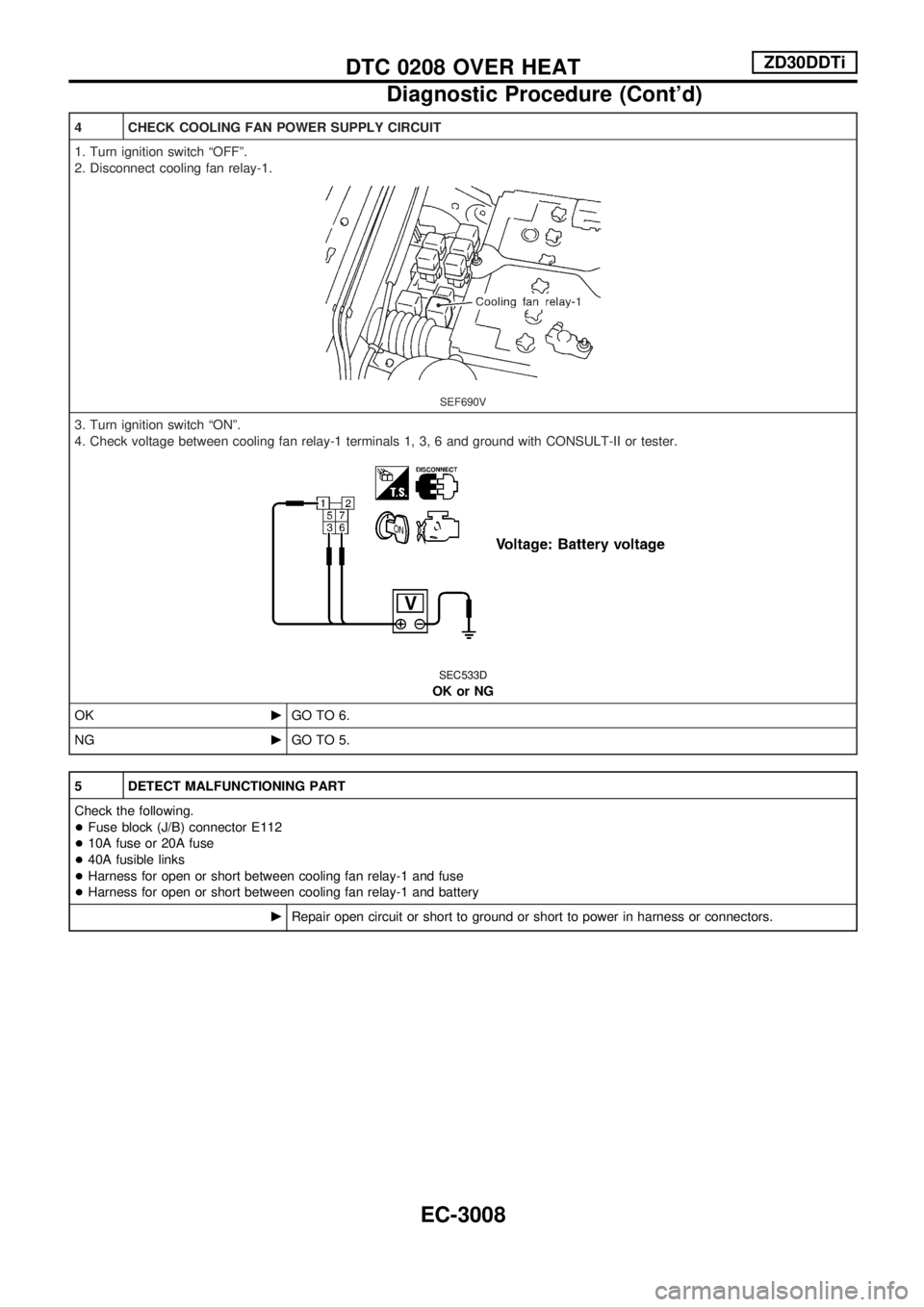

3 CHECK COOLING FAN OPERATION

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

3. Connect 150Wresistor to engine coolant temperature sensor harness connector.

4. Restart engine and make sure that cooling fan operates.

MEC475B

OK or NG

OKcGO TO 12.

NGcGO TO 4.

DTC 0208 OVER HEATZD30DDTi

EC-3007

Page 34 of 311

4 CHECK COOLING FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan relay-1.

SEF690V

3. Turn ignition switch ªONº.

4. Check voltage between cooling fan relay-1 terminals 1, 3, 6 and ground with CONSULT-II or tester.

SEC533D

OK or NG

OKcGO TO 6.

NGcGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Fuse block (J/B) connector E112

+10A fuse or 20A fuse

+40A fusible links

+Harness for open or short between cooling fan relay-1 and fuse

+Harness for open or short between cooling fan relay-1 and battery

cRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-3008

Page 35 of 311

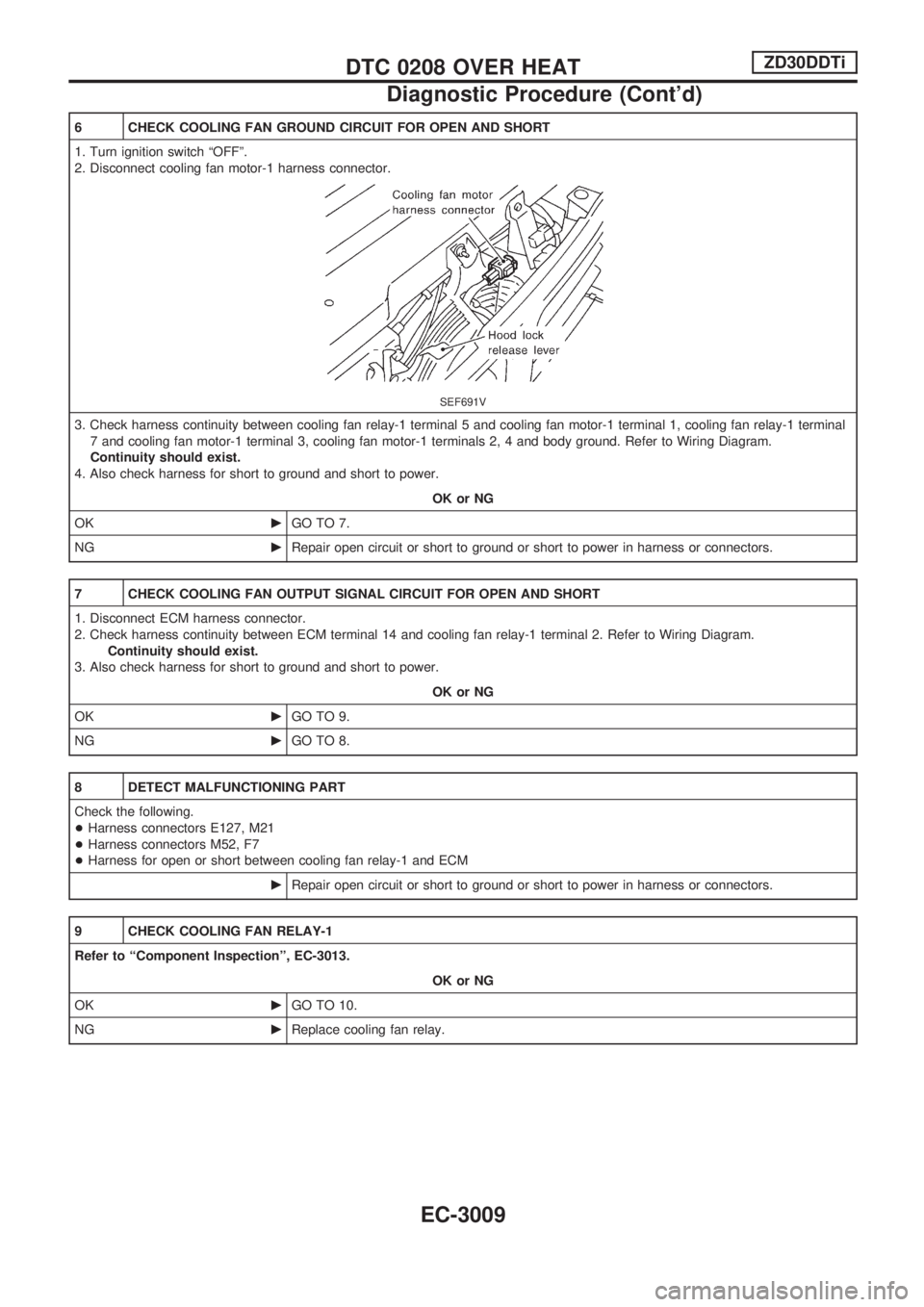

6 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan motor-1 harness connector.

SEF691V

3. Check harness continuity between cooling fan relay-1 terminal 5 and cooling fan motor-1 terminal 1, cooling fan relay-1 terminal

7 and cooling fan motor-1 terminal 3, cooling fan motor-1 terminals 2, 4 and body ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 14 and cooling fan relay-1 terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 9.

NGcGO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E127, M21

+Harness connectors M52, F7

+Harness for open or short between cooling fan relay-1 and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

9 CHECK COOLING FAN RELAY-1

Refer to ªComponent Inspectionº, EC-3013.

OK or NG

OKcGO TO 10.

NGcReplace cooling fan relay.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-3009

Page 53 of 311

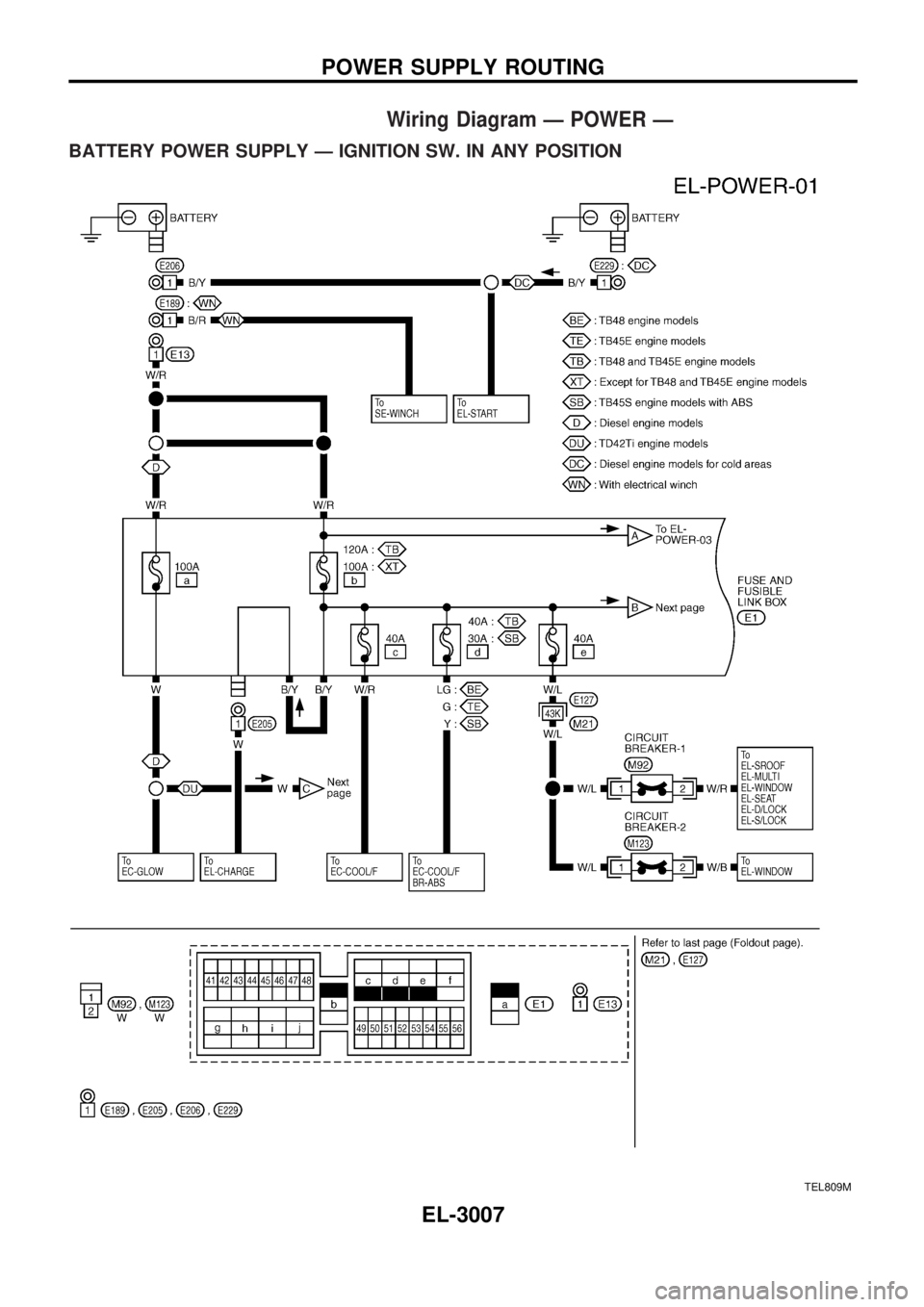

Wiring Diagram Ð POWER Ð

BATTERY POWER SUPPLY Ð IGNITION SW. IN ANY POSITION

TEL809M

POWER SUPPLY ROUTING

EL-3007

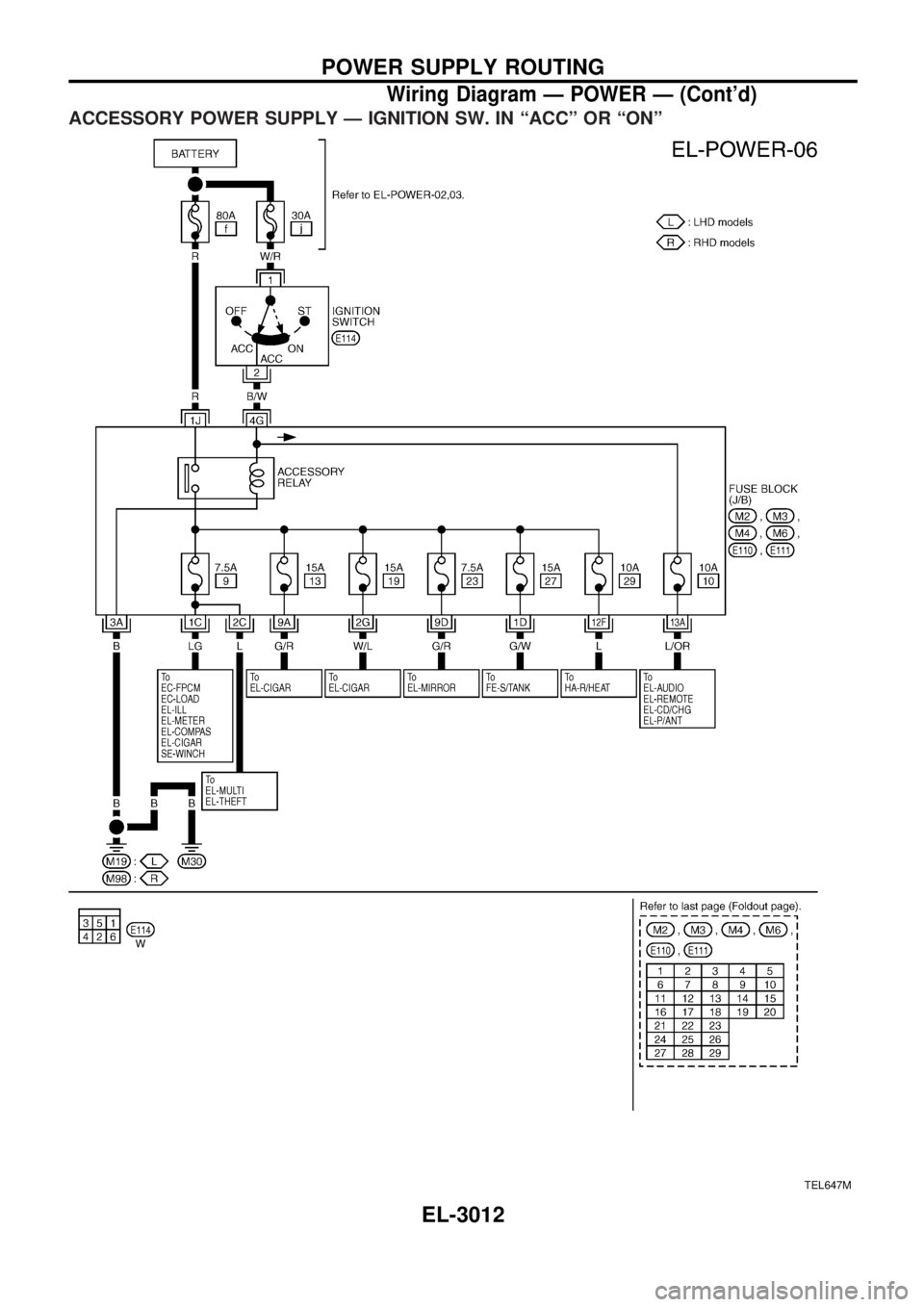

Page 58 of 311

ACCESSORY POWER SUPPLY Ð IGNITION SW. IN ªACCº OR ªONº

TEL647M

POWER SUPPLY ROUTING

Wiring Diagram Ð POWER Ð (Cont'd)

EL-3012

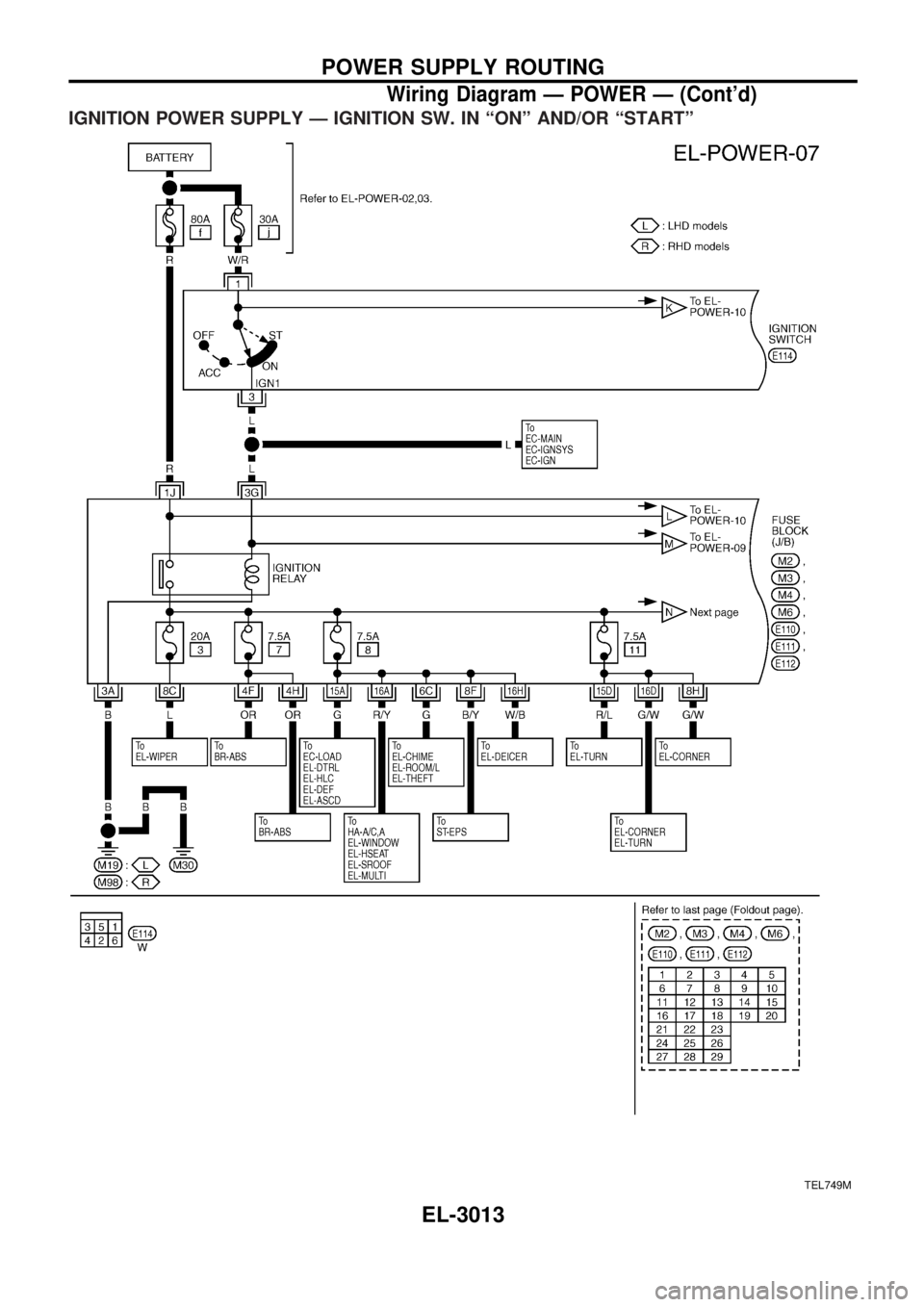

Page 59 of 311

IGNITION POWER SUPPLY Ð IGNITION SW. IN ªONº AND/OR ªSTARTº

TEL749M

POWER SUPPLY ROUTING

Wiring Diagram Ð POWER Ð (Cont'd)

EL-3013

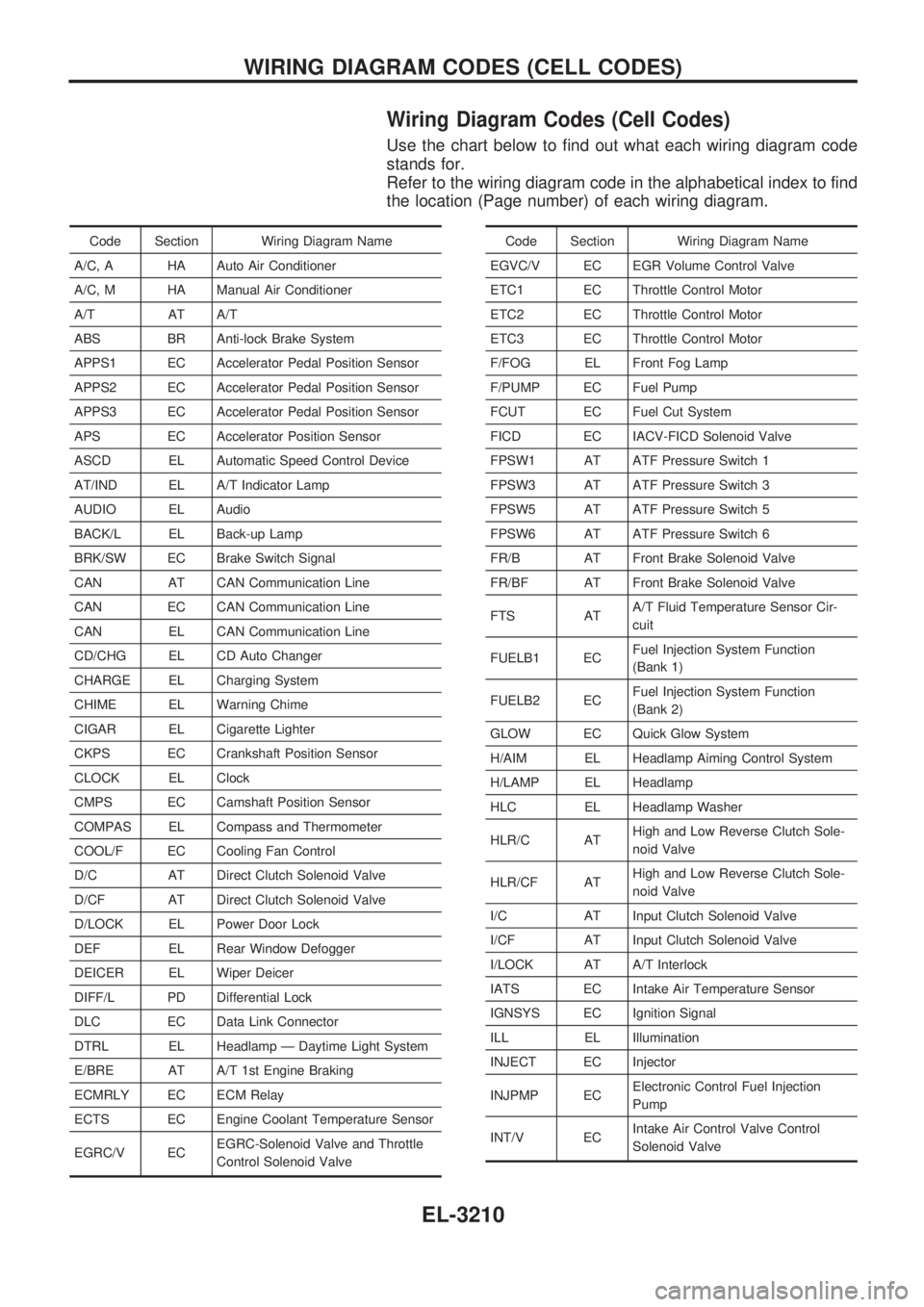

Page 256 of 311

Wiring Diagram Codes (Cell Codes)

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (Page number) of each wiring diagram.

Code Section Wiring Diagram Name

A/C, A HA Auto Air Conditioner

A/C, M HA Manual Air Conditioner

A/T AT A/T

ABS BR Anti-lock Brake System

APPS1 EC Accelerator Pedal Position Sensor

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

APS EC Accelerator Position Sensor

ASCD EL Automatic Speed Control Device

AT/IND EL A/T Indicator Lamp

AUDIO EL Audio

BACK/L EL Back-up Lamp

BRK/SW EC Brake Switch Signal

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN EL CAN Communication Line

CD/CHG EL CD Auto Changer

CHARGE EL Charging System

CHIME EL Warning Chime

CIGAR EL Cigarette Lighter

CKPS EC Crankshaft Position Sensor

CLOCK EL Clock

CMPS EC Camshaft Position Sensor

COMPAS EL Compass and Thermometer

COOL/F EC Cooling Fan Control

D/C AT Direct Clutch Solenoid Valve

D/CF AT Direct Clutch Solenoid Valve

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DEICER EL Wiper Deicer

DIFF/L PD Differential Lock

DLC EC Data Link Connector

DTRL EL Headlamp Ð Daytime Light System

E/BRE AT A/T 1st Engine Braking

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGRC/V ECEGRC-Solenoid Valve and Throttle

Control Solenoid ValveCode Section Wiring Diagram Name

EGVC/V EC EGR Volume Control Valve

ETC1 EC Throttle Control Motor

ETC2 EC Throttle Control Motor

ETC3 EC Throttle Control Motor

F/FOG EL Front Fog Lamp

F/PUMP EC Fuel Pump

FCUT EC Fuel Cut System

FICD EC IACV-FICD Solenoid Valve

FPSW1 AT ATF Pressure Switch 1

FPSW3 AT ATF Pressure Switch 3

FPSW5 AT ATF Pressure Switch 5

FPSW6 AT ATF Pressure Switch 6

FR/B AT Front Brake Solenoid Valve

FR/BF AT Front Brake Solenoid Valve

FTS ATA/T Fluid Temperature Sensor Cir-

cuit

FUELB1 ECFuel Injection System Function

(Bank 1)

FUELB2 ECFuel Injection System Function

(Bank 2)

GLOW EC Quick Glow System

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

HLC EL Headlamp Washer

HLR/C ATHigh and Low Reverse Clutch Sole-

noid Valve

HLR/CF ATHigh and Low Reverse Clutch Sole-

noid Valve

I/C AT Input Clutch Solenoid Valve

I/CF AT Input Clutch Solenoid Valve

I/LOCK AT A/T Interlock

IATS EC Intake Air Temperature Sensor

IGNSYS EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INJPMP ECElectronic Control Fuel Injection

Pump

INT/V ECIntake Air Control Valve Control

Solenoid Valve

WIRING DIAGRAM CODES (CELL CODES)

EL-3210

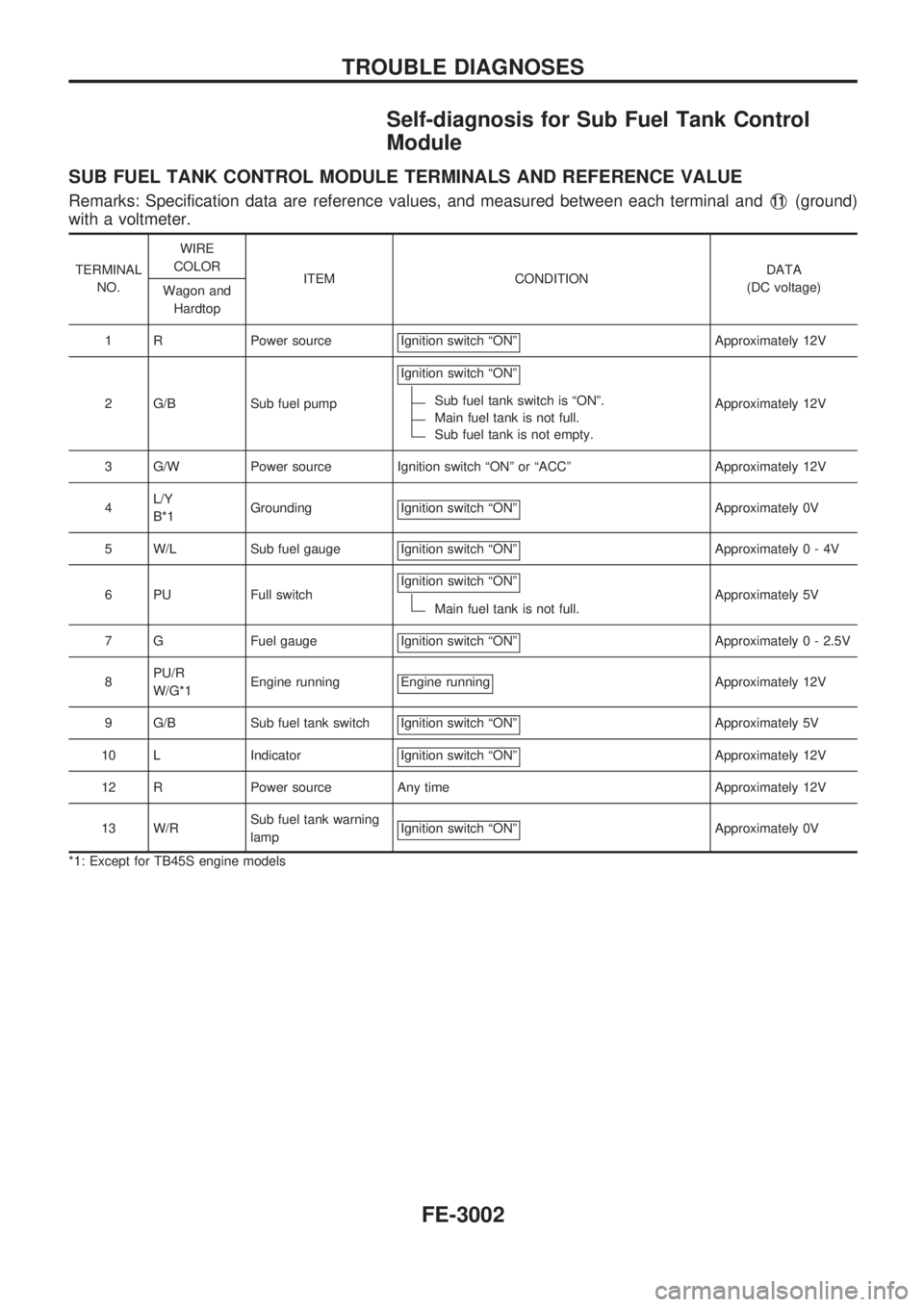

Page 260 of 311

Self-diagnosis for Sub Fuel Tank Control

Module

SUB FUEL TANK CONTROL MODULE TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values, and measured between each terminal andV11(ground)

with a voltmeter.

TERMINAL

NO.WIRE

COLOR

ITEM CONDITIONDATA

(DC voltage)

Wagon and

Hardtop

1 R Power source Ignition switch ªONº

Approximately 12V

2 G/B Sub fuel pumpIgnition switch ªONº

Sub fuel tank switch is ªONº.

Main fuel tank is not full.

Sub fuel tank is not empty.Approximately 12V

3 G/W Power source Ignition switch ªONº or ªACCº Approximately 12V

4L/Y

B*1Grounding Ignition switch ªONº

Approximately 0V

5 W/L Sub fuel gauge Ignition switch ªONº

Approximately0-4V

6 PU Full switchIgnition switch ªONº

Main fuel tank is not full.Approximately 5V

7 G Fuel gauge Ignition switch ªONº

Approximately 0 - 2.5V

8PU/R

W/G*1Engine running Engine running

Approximately 12V

9 G/B Sub fuel tank switch Ignition switch ªONº

Approximately 5V

10 L Indicator Ignition switch ªONº

Approximately 12V

12 R Power source Any time Approximately 12V

13 W/RSub fuel tank warning

lampIgnition switch ªONº

Approximately 0V

*1: Except for TB45S engine models

TROUBLE DIAGNOSES

FE-3002

Page 270 of 311

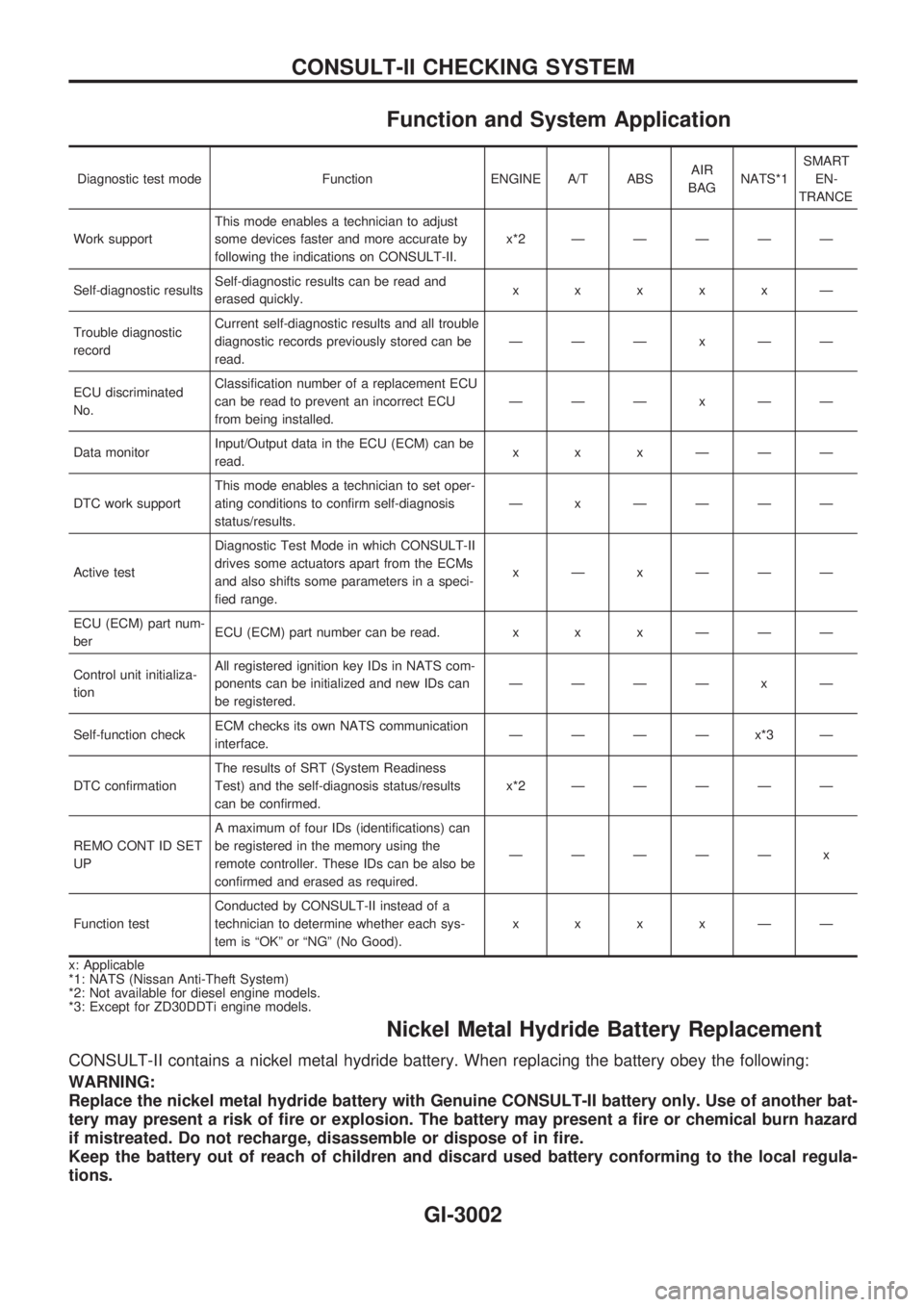

Function and System Application

Diagnostic test mode Function ENGINE A/T ABSAIR

BAGNATS*1SMART

EN-

TRANCE

Work supportThis mode enables a technician to adjust

some devices faster and more accurate by

following the indications on CONSULT-II.x*2ÐÐÐÐÐ

Self-diagnostic resultsSelf-diagnostic results can be read and

erased quickly.xxxxxÐ

Trouble diagnostic

recordCurrent self-diagnostic results and all trouble

diagnostic records previously stored can be

read.ÐÐÐxÐÐ

ECU discriminated

No.Classification number of a replacement ECU

can be read to prevent an incorrect ECU

from being installed.ÐÐÐxÐÐ

Data monitorInput/Output data in the ECU (ECM) can be

read.xxxÐÐÐ

DTC work supportThis mode enables a technician to set oper-

ating conditions to confirm self-diagnosis

status/results.Ð x ÐÐÐÐ

Active testDiagnostic Test Mode in which CONSULT-II

drives some actuators apart from the ECMs

and also shifts some parameters in a speci-

fied range.xÐxÐÐÐ

ECU (ECM) part num-

berECU (ECM) part number can be read. x x x Ð Ð Ð

Control unit initializa-

tionAll registered ignition key IDs in NATS com-

ponents can be initialized and new IDs can

be registered.ÐÐÐÐ x Ð

Self-function checkECM checks its own NATS communication

interface.ÐÐÐÐx*3Ð

DTC confirmationThe results of SRT (System Readiness

Test) and the self-diagnosis status/results

can be confirmed.x*2ÐÐÐÐÐ

REMO CONT ID SET

UPA maximum of four IDs (identifications) can

be registered in the memory using the

remote controller. These IDs can be also be

confirmed and erased as required.ÐÐÐÐÐ x

Function testConducted by CONSULT-II instead of a

technician to determine whether each sys-

tem is ªOKº or ªNGº (No Good).xxxxÐÐ

x: Applicable

*1: NATS (Nissan Anti-Theft System)

*2: Not available for diesel engine models.

*3: Except for ZD30DDTi engine models.

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with Genuine CONSULT-II battery only. Use of another bat-

tery may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard

if mistreated. Do not recharge, disassemble or dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regula-

tions.

CONSULT-II CHECKING SYSTEM

GI-3002