engine control NISSAN PATROL 2004 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: PATROL, Model: NISSAN PATROL 2004Pages: 579, PDF Size: 26.61 MB

Page 442 of 579

Wiring Diagram Codes (Cell Codes)

Use the chart below to ®nd out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to ®nd

the location (Page number) of each wiring diagram.

Code Section Wiring Diagram Name

A/C, A HA Auto Air Conditioner

A/C, M HA Manual Air Conditioner

A/CCUT EC Air Conditioner Control

A/T AT A/T

ASCD EL Automatic Speed Control Device

AUDIO EL Audio

BACK/L EL Back-up Lamp

CD/CHG EL CD Auto Changer

CHIME EL Warning Chime

COMPAS EL Compass and Thermometer

COOL/B HA Cool Box

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DEICER EL Wiper Deicer

DTRL EL Headlamp Ð Daytime Light System

F/FOG EL Front Fog Lamp

FICD EC IACV-FICD Solenoid Valve

GLOW EC Quick Glow System

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

HEATUP EC Heat Up Switch

HLC EL Headlamp Washer

HORN EL Horn

HSEAT EL Heated Seat

ILL EL Illumination

LOAD EC Electrical Load Signal

MAFS EC Mass Air Flow Sensor

METER EL Meter and Gauges

MIRROR EL Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-Theft System

NAVI EL Navigation System

NONDTC AT Non-detective Items

P/ANT EL Power Antenna

PHONE EL Telephone

POWER EL Power Supply Routing

R/COOL HA Rear Cooler System

R/FOG EL Rear Fog LampCode Section Wiring Diagram Name

R/HEAT HA Rear Heater System

REMOTE EL Audio (Remote Control Switch)

ROOM/L EL Interior Room Lamp

S/LOCK EL Power Door Lock Ð Super Lock

S/TANK FE Sub Fuel Tank Control System

SRS RS Supplemental Restraint System

STAB RA Stabilizer Release Device

STOP/L EL Stop Lamp

TAIL/L EL Parking, License and Tail Lamps

THEFT EL Theft Warning System

TRQ/SG EC Engine Torque Control Signal

TURN EL Turn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

WARN EL Warning Lamps

WINDOW EL Power Window

WIP/R EL Rear Wiper and Washer

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-4347

Page 451 of 579

Removal

1. Remove the following parts.

+Undercover

+Engine oil (Drain)

+Engine coolant (Drain)

+Engine cover

+Intercooler

+Air inlet pipe

+Air cleaner case

+Throttle body

+Swirl and intake air control valve control solenoid valve and

bracket

+Vacuum tank

+Glow plate

+Rocker cover

+Spill tube

+Radiator shrouds (Rear and Lower)

+Cooling fan

+Radiator hose (Upper and Lower)

+Auxiliary belt and auto tensioner.

2. Remove the alternator.

3. Remove the A/C compressor and bracket with piping con-

nected. Move and support it at the LH side of engine bay with

a rope to avoid putting load on piping.

Refer to HA section in NISSAN Service Manual (Publication No.

SM9E-Y61CG2 or SM9E-Y61CG3).

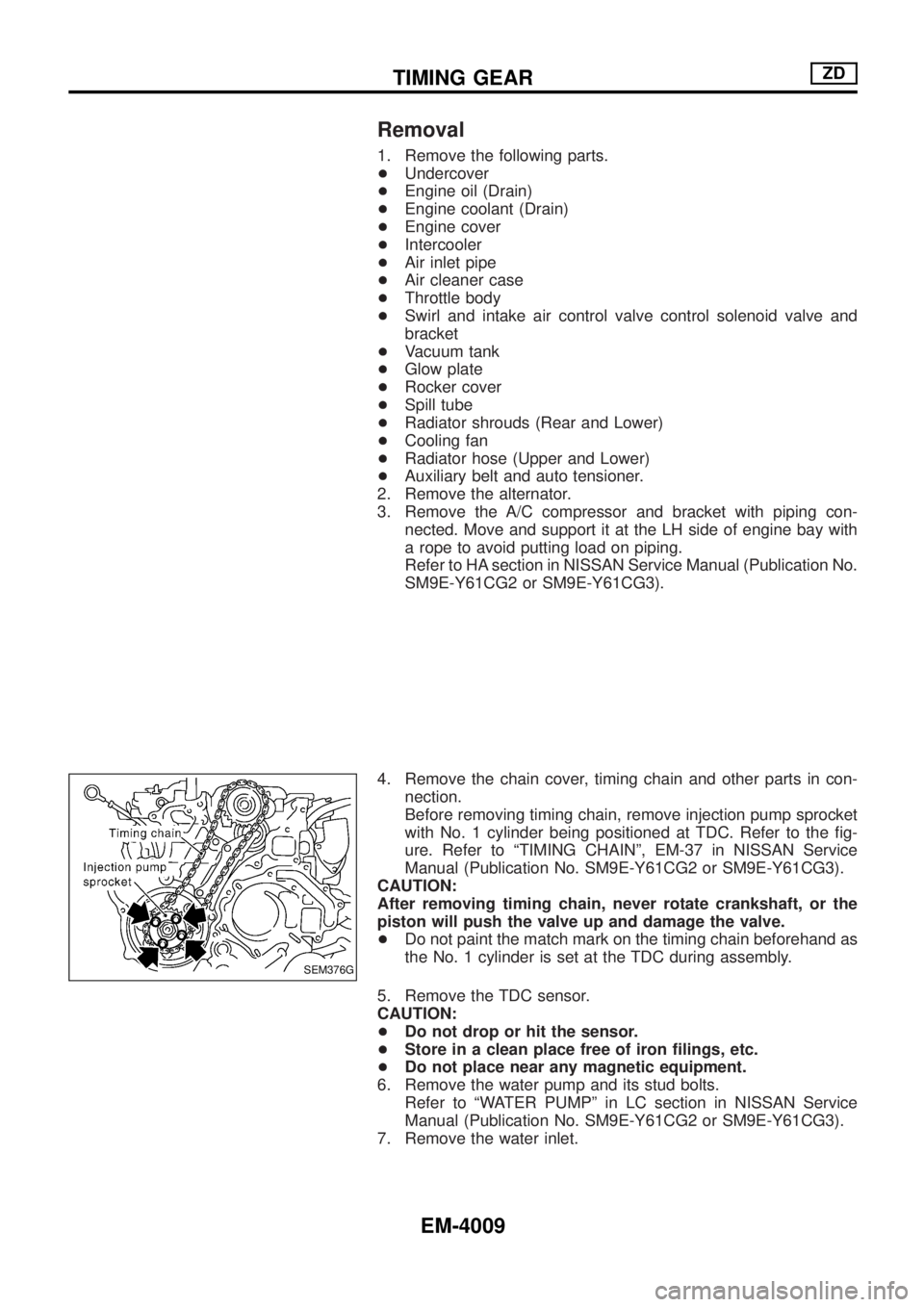

4. Remove the chain cover, timing chain and other parts in con-

nection.

Before removing timing chain, remove injection pump sprocket

with No. 1 cylinder being positioned at TDC. Refer to the ®g-

ure. Refer to ªTIMING CHAINº, EM-37 in NISSAN Service

Manual (Publication No. SM9E-Y61CG2 or SM9E-Y61CG3).

CAUTION:

After removing timing chain, never rotate crankshaft, or the

piston will push the valve up and damage the valve.

+Do not paint the match mark on the timing chain beforehand as

the No. 1 cylinder is set at the TDC during assembly.

5. Remove the TDC sensor.

CAUTION:

+Do not drop or hit the sensor.

+Store in a clean place free of iron ®lings, etc.

+Do not place near any magnetic equipment.

6. Remove the water pump and its stud bolts.

Refer to ªWATER PUMPº in LC section in NISSAN Service

Manual (Publication No. SM9E-Y61CG2 or SM9E-Y61CG3).

7. Remove the water inlet.

SEM376G

TIMING GEARZD

EM-4009

Page 461 of 579

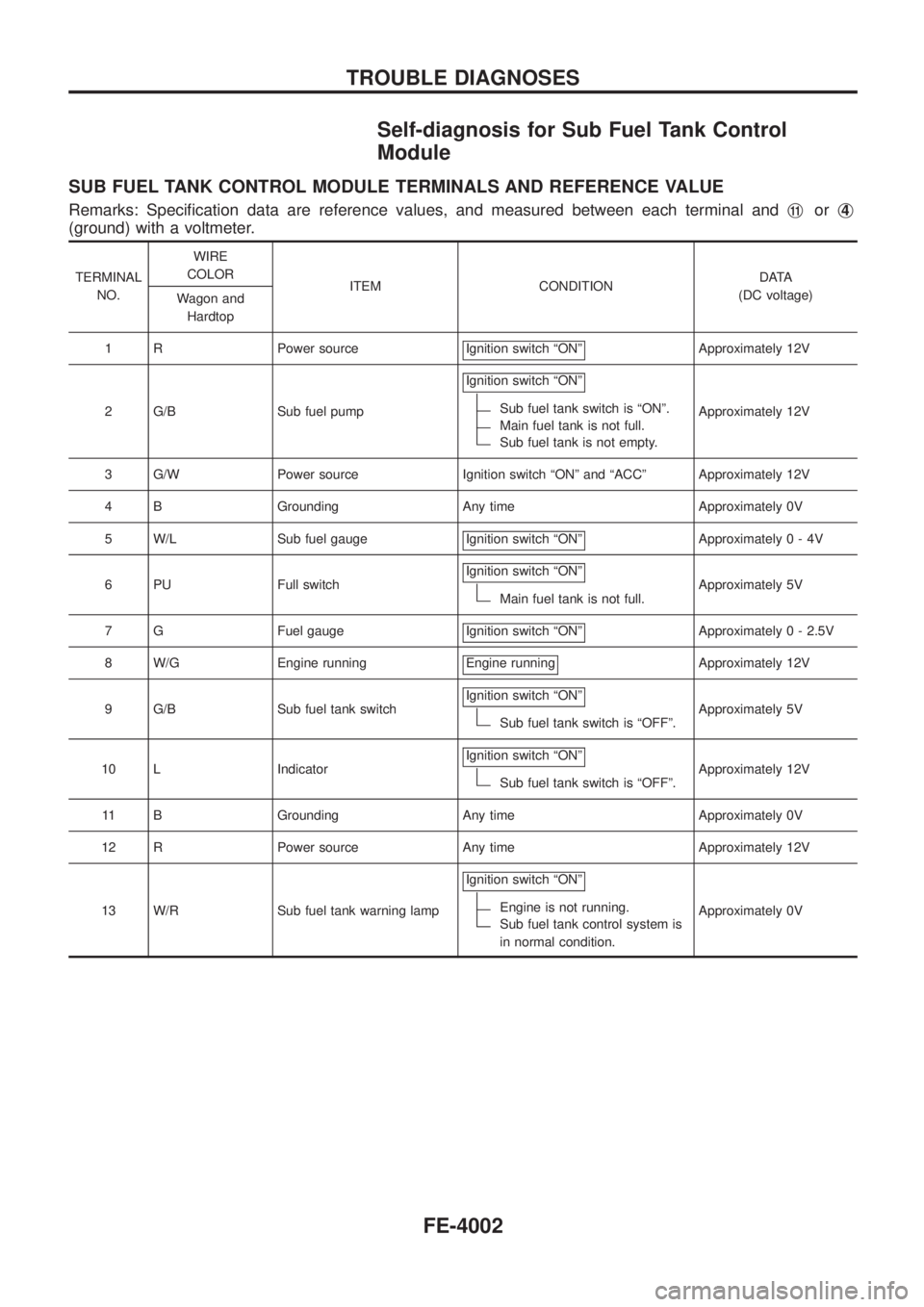

Self-diagnosis for Sub Fuel Tank Control

Module

SUB FUEL TANK CONTROL MODULE TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values, and measured between each terminal andj11orj4

(ground) with a voltmeter.

TERMINAL

NO.WIRE

COLOR

ITEM CONDITIONDATA

(DC voltage)

Wagon and

Hardtop

1 R Power source Ignition switch ªONº

Approximately 12V

2 G/B Sub fuel pumpIgnition switch ªONº

Sub fuel tank switch is ªONº.

Main fuel tank is not full.

Sub fuel tank is not empty.Approximately 12V

3 G/W Power source Ignition switch ªONº and ªACCº Approximately 12V

4 B Grounding Any time Approximately 0V

5 W/L Sub fuel gauge Ignition switch ªONº

Approximately0-4V

6 PU Full switchIgnition switch ªONº

Main fuel tank is not full.Approximately 5V

7 G Fuel gauge Ignition switch ªONº

Approximately 0 - 2.5V

8 W/G Engine running Engine running

Approximately 12V

9 G/B Sub fuel tank switchIgnition switch ªONº

Sub fuel tank switch is ªOFFº.Approximately 5V

10 L IndicatorIgnition switch ªONº

Sub fuel tank switch is ªOFFº.Approximately 12V

11 B Grounding Any time Approximately 0V

12 R Power source Any time Approximately 12V

13 W/R Sub fuel tank warning lampIgnition switch ªONº

Engine is not running.

Sub fuel tank control system is

in normal condition.Approximately 0V

TROUBLE DIAGNOSES

FE-4002

Page 472 of 579

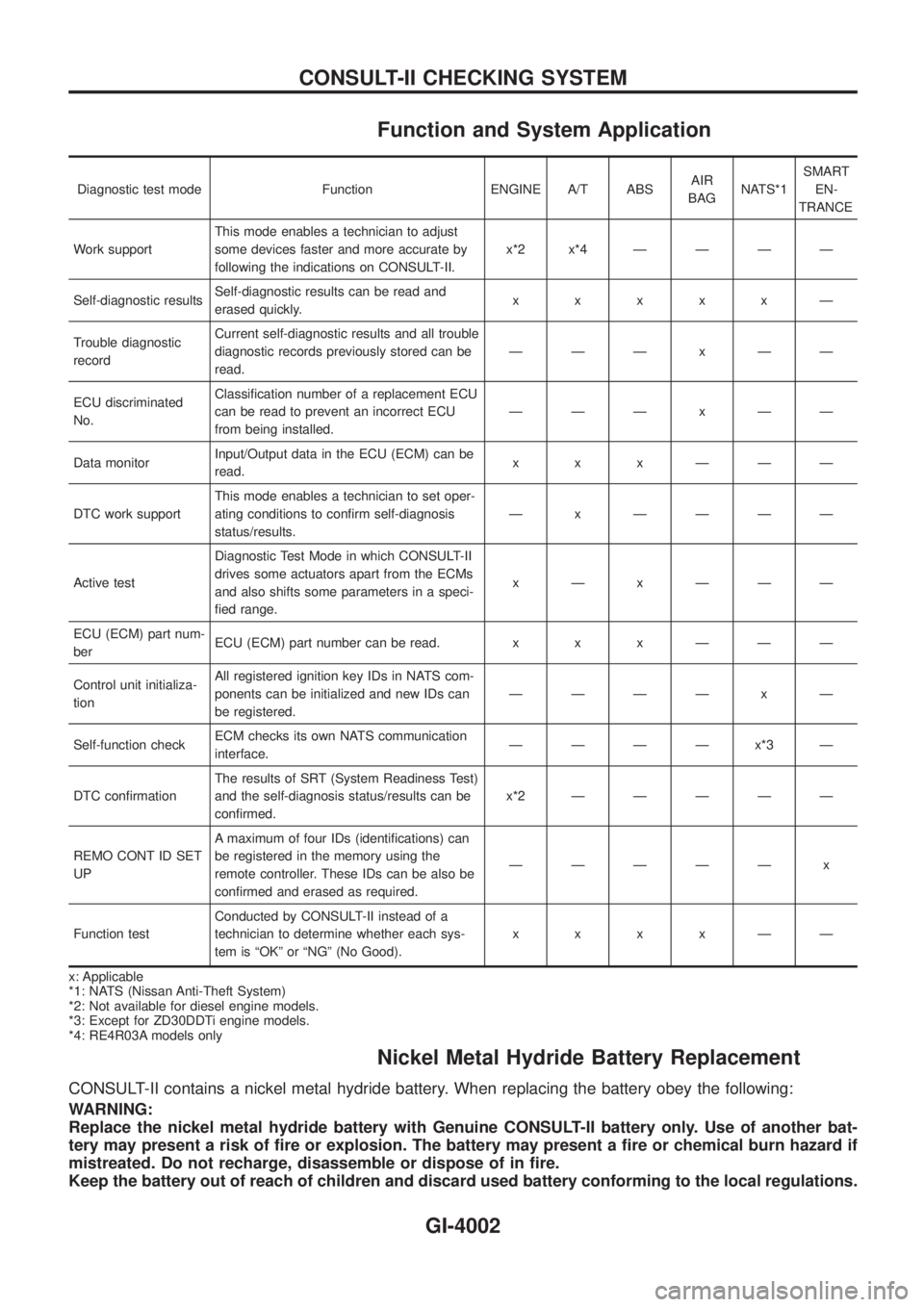

Function and System Application

Diagnostic test mode Function ENGINE A/T ABSAIR

BAGNATS*1SMART

EN-

TRANCE

Work supportThis mode enables a technician to adjust

some devices faster and more accurate by

following the indications on CONSULT-II.x*2x*4ÐÐÐÐ

Self-diagnostic resultsSelf-diagnostic results can be read and

erased quickly.xxxxxÐ

Trouble diagnostic

recordCurrent self-diagnostic results and all trouble

diagnostic records previously stored can be

read.ÐÐÐxÐÐ

ECU discriminated

No.Classi®cation number of a replacement ECU

can be read to prevent an incorrect ECU

from being installed.ÐÐÐxÐÐ

Data monitorInput/Output data in the ECU (ECM) can be

read.xxxÐÐÐ

DTC work supportThis mode enables a technician to set oper-

ating conditions to con®rm self-diagnosis

status/results.Ð x ÐÐÐÐ

Active testDiagnostic Test Mode in which CONSULT-II

drives some actuators apart from the ECMs

and also shifts some parameters in a speci-

®ed range.xÐxÐÐÐ

ECU (ECM) part num-

berECU (ECM) part number can be read. x x x Ð Ð Ð

Control unit initializa-

tionAll registered ignition key IDs in NATS com-

ponents can be initialized and new IDs can

be registered.ÐÐÐÐ x Ð

Self-function checkECM checks its own NATS communication

interface.ÐÐÐÐx*3Ð

DTC con®rmationThe results of SRT (System Readiness Test)

and the self-diagnosis status/results can be

con®rmed.x*2ÐÐÐÐÐ

REMO CONT ID SET

UPA maximum of four IDs (identi®cations) can

be registered in the memory using the

remote controller. These IDs can be also be

con®rmed and erased as required.ÐÐÐÐÐ x

Function testConducted by CONSULT-II instead of a

technician to determine whether each sys-

tem is ªOKº or ªNGº (No Good).xxxxÐÐ

x: Applicable

*1: NATS (Nissan Anti-Theft System)

*2: Not available for diesel engine models.

*3: Except for ZD30DDTi engine models.

*4: RE4R03A models only

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with Genuine CONSULT-II battery only. Use of another bat-

tery may present a risk of ®re or explosion. The battery may present a ®re or chemical burn hazard if

mistreated. Do not recharge, disassemble or dispose of in ®re.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

CONSULT-II CHECKING SYSTEM

GI-4002

Page 474 of 579

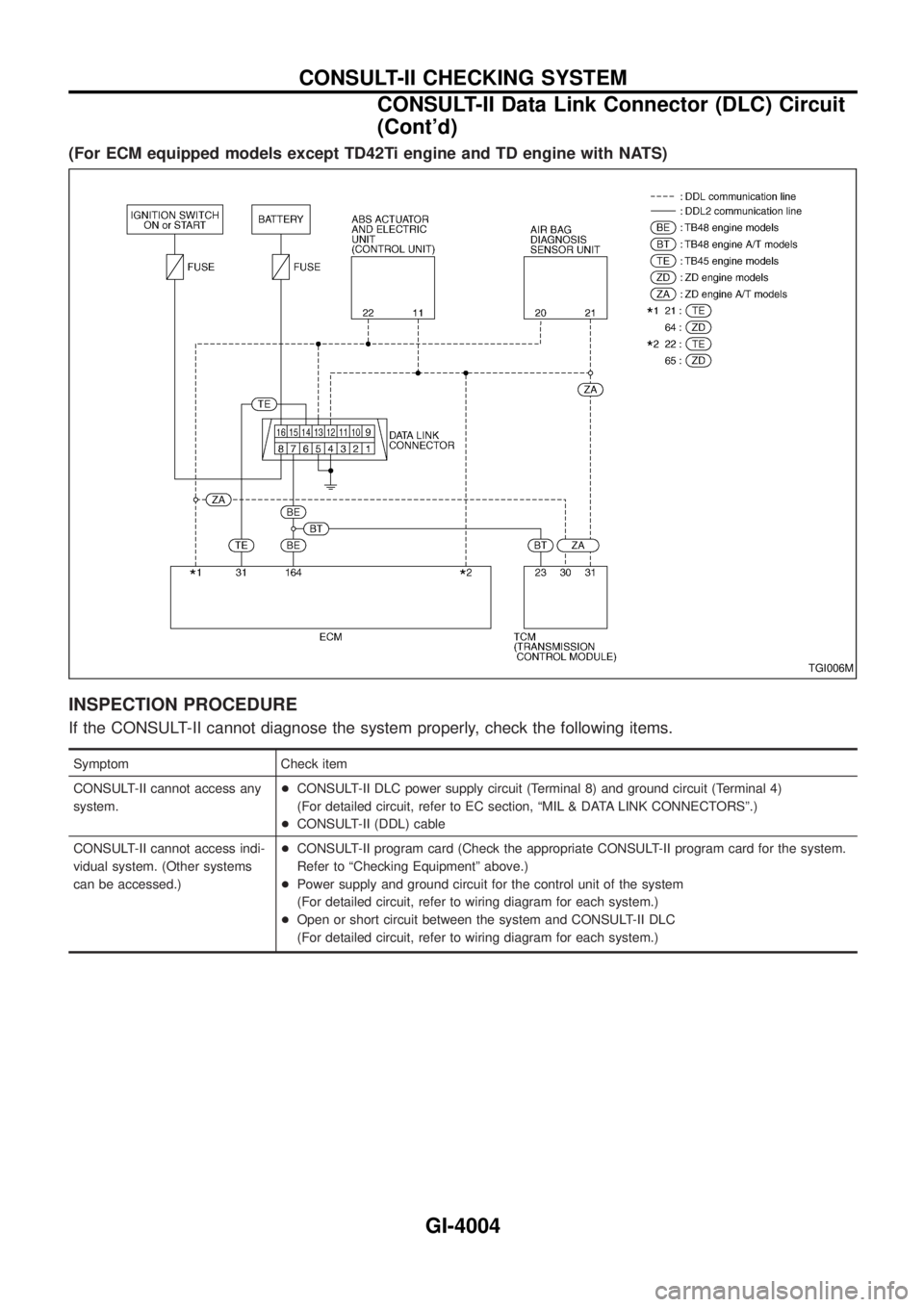

(For ECM equipped models except TD42Ti engine and TD engine with NATS)

INSPECTION PROCEDURE

If the CONSULT-II cannot diagnose the system properly, check the following items.

Symptom Check item

CONSULT-II cannot access any

system.+CONSULT-II DLC power supply circuit (Terminal 8) and ground circuit (Terminal 4)

(For detailed circuit, refer to EC section, ªMIL & DATA LINK CONNECTORSº.)

+CONSULT-II (DDL) cable

CONSULT-II cannot access indi-

vidual system. (Other systems

can be accessed.)+CONSULT-II program card (Check the appropriate CONSULT-II program card for the system.

Refer to ªChecking Equipmentº above.)

+Power supply and ground circuit for the control unit of the system

(For detailed circuit, refer to wiring diagram for each system.)

+Open or short circuit between the system and CONSULT-II DLC

(For detailed circuit, refer to wiring diagram for each system.)

TGI006M

CONSULT-II CHECKING SYSTEM

CONSULT-II Data Link Connector (DLC) Circuit

(Cont'd)

GI-4004

Page 480 of 579

HEATER&

AIR CONDITIONER

SECTION

HA

MODIFICATION NOTICE:

+ Wiring diagram has been changed.

+ Automatic A/C controller has been changed.

+ Front thermo amp. for auto A/C has been eliminated.

CONTENTS

AUTO

DESCRIPTION ...........................................................4002

Features (TB48 Engine Models) ...........................4002

REAR HEATER

TROUBLE DIAGNOSES ...........................................4003

Wiring Diagram Ð R/HEAT Ð/LHD Models .........4003

Wiring Diagram Ð R/HEAT Ð/RHD Models .........4004

MANUAL

TROUBLE DIAGNOSES ...........................................4005

Wiring Diagram Ð A/C, M Ð/Wagon and

Hardtop Models with ZD Engine ...........................4005

AUTO

DESCRIPTION...........................................................4007

Control Operation ..................................................4007

TROUBLE DIAGNOSES ...........................................4008

Circuit Diagram Ð A/C, A Ð/TB48 Engine ...........4008

Wiring Diagram Ð A/C, A Ð/TB48 Engine ...........4009

Circuit Diagram Ð A/C, A Ð/TB45 Engine ...........4013

Wiring Diagram Ð A/C, A Ð/TB45 Engine ...........4014

Circuit Diagram Ð A/C, A Ð/TD Engine ...............4017

Wiring Diagram Ð A/C, A Ð/TD Engine ...............4018

Circuit Diagram Ð A/C, A Ð/ZD Engine ...............4021

Wiring Diagram Ð A/C, A Ð/ZD Engine ...............4022

Self-diagnosis ........................................................4025

Operational Check .................................................4032

A/C System ............................................................4034 Mode Door Motor...................................................4035

Air Mix Door Motor ................................................4036

Intake Door Motor ..................................................4037

Blower Motor..........................................................4038

Magnet Clutch........................................................4039

Insufficient Cooling ................................................4052

Insufficient Heating ................................................4053

Self-diagnosis ........................................................4054

REAR COOLER

TROUBLE DIAGNOSES ...........................................4055

Wiring Diagram Ð R/COOL Ð/LHD Models with

Front Auto A/C .......................................................4055

Wiring Diagram Ð R/COOL Ð/LHD Models with

Front Manual A/C Except for TB45E Engine ........4057

Wiring Diagram Ð R/COOL Ð/LHD Models with

Front Manual A/C for TB45E Engine.....................4059

Wiring Diagram Ð R/COOL Ð/RHD Models with

Front Auto A/C .......................................................4061

Wiring Diagram Ð R/COOL Ð/RHD Models with

Front Manual A/C...................................................4063

COOL BOX

TROUBLE DIAGNOSES ...........................................4065

Wiring Diagram Ð COOL/B Ð/All Engines

Except TB48 and TB45E Wagon Models for the

Middle East ............................................................4065

Wiring Diagram Ð COOL/B Ð/TB48 and TB45E

Engine Wagon Models for the Middle East...........4066

HA-4001

Page 481 of 579

Features (TB48 Engine Models)

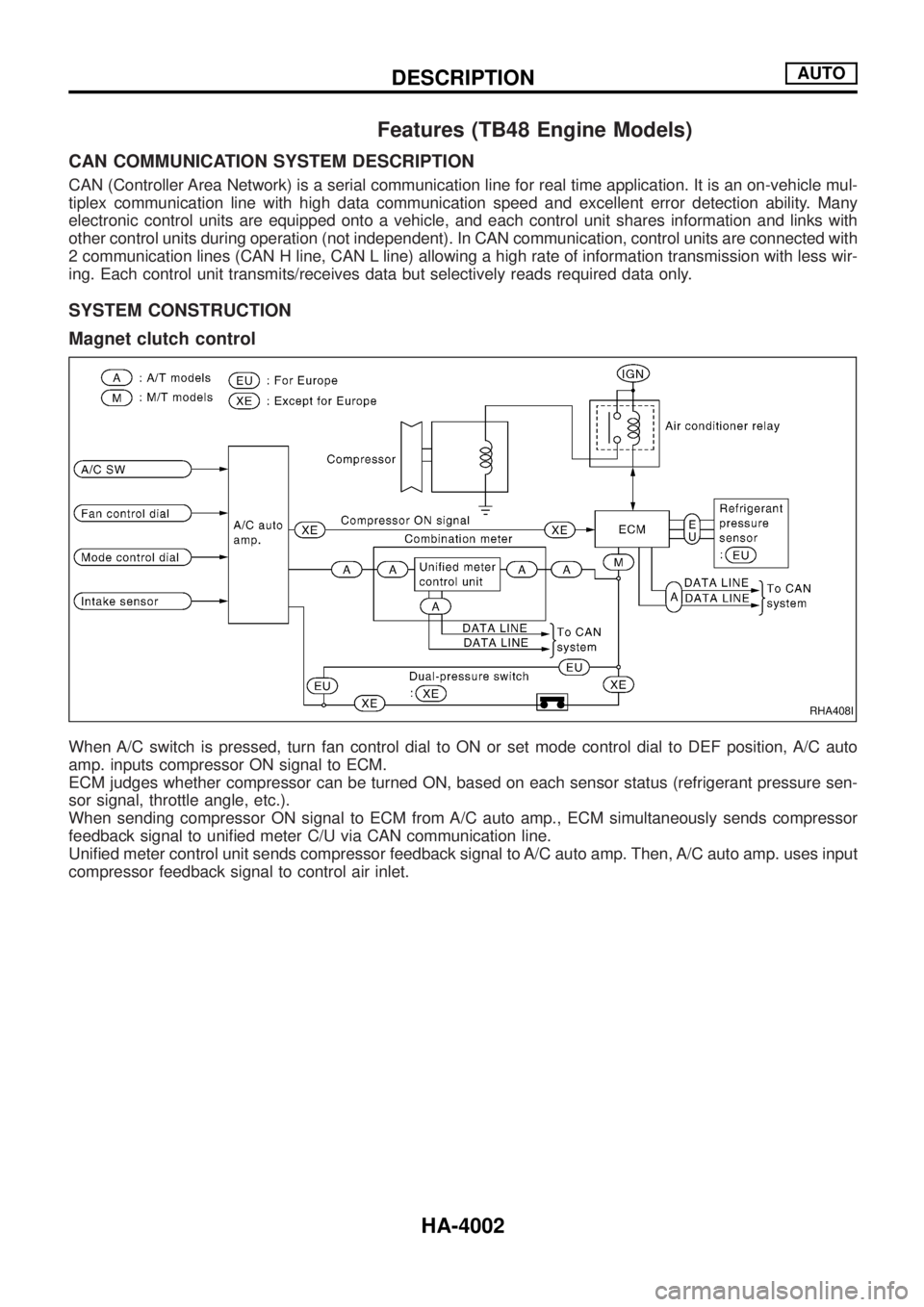

CAN COMMUNICATION SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many

electronic control units are equipped onto a vehicle, and each control unit shares information and links with

other control units during operation (not independent). In CAN communication, control units are connected with

2 communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wir-

ing. Each control unit transmits/receives data but selectively reads required data only.

SYSTEM CONSTRUCTION

Magnet clutch control

When A/C switch is pressed, turn fan control dial to ON or set mode control dial to DEF position, A/C auto

amp. inputs compressor ON signal to ECM.

ECM judges whether compressor can be turned ON, based on each sensor status (refrigerant pressure sen-

sor signal, throttle angle, etc.).

When sending compressor ON signal to ECM from A/C auto amp., ECM simultaneously sends compressor

feedback signal to uni®ed meter C/U via CAN communication line.

Uni®ed meter control unit sends compressor feedback signal to A/C auto amp. Then, A/C auto amp. uses input

compressor feedback signal to control air inlet.

RHA408I

DESCRIPTIONAUTO

HA-4002

Page 504 of 579

Self-diagnosis

INTRODUCTION AND GENERAL DESCRIPTION

The self-diagnostic system diagnoses sensors, door motors, blower motor, etc. by system line.

Self-diagnosis is step-1 to 7. There are two ways of changing method during self-diagnosis.

+Switching to self-diagnosis step-1 to 4.

Shifting from usual control to the self-diagnostic system is accomplished by starting the engine (turning

the ignition switch from OFF to ON) and pressing A/C switch for at least 5 seconds. The A/C switch must

be pressed within 10 seconds after starting the engine (ignition switch is turned ON). This system will be

canceled by either pressing intake switch or turning the ignition switch OFF. Shifting from one step to

another is accomplished be means of turning fan control dial, as required.

+Switching to self-diagnosis step-5 to 7 (Auxiliary mechanism).

Shifting from usual control to the self-diagnostic system is accomplished by starting the engine (turning

the ignition switch from OFF to ON) and pressing intake switch for at least 5 seconds. The intake switch

must be pressed within 10 seconds after starting the engine (ignition switch is turned ON). This system

will be canceled by either pressing A/C switch or turning the ignition switch OFF. Shifting from one step

to another is accomplished by means of turning fan control dial, as required.

TROUBLE DIAGNOSESAUTO

HA-4025

Page 506 of 579

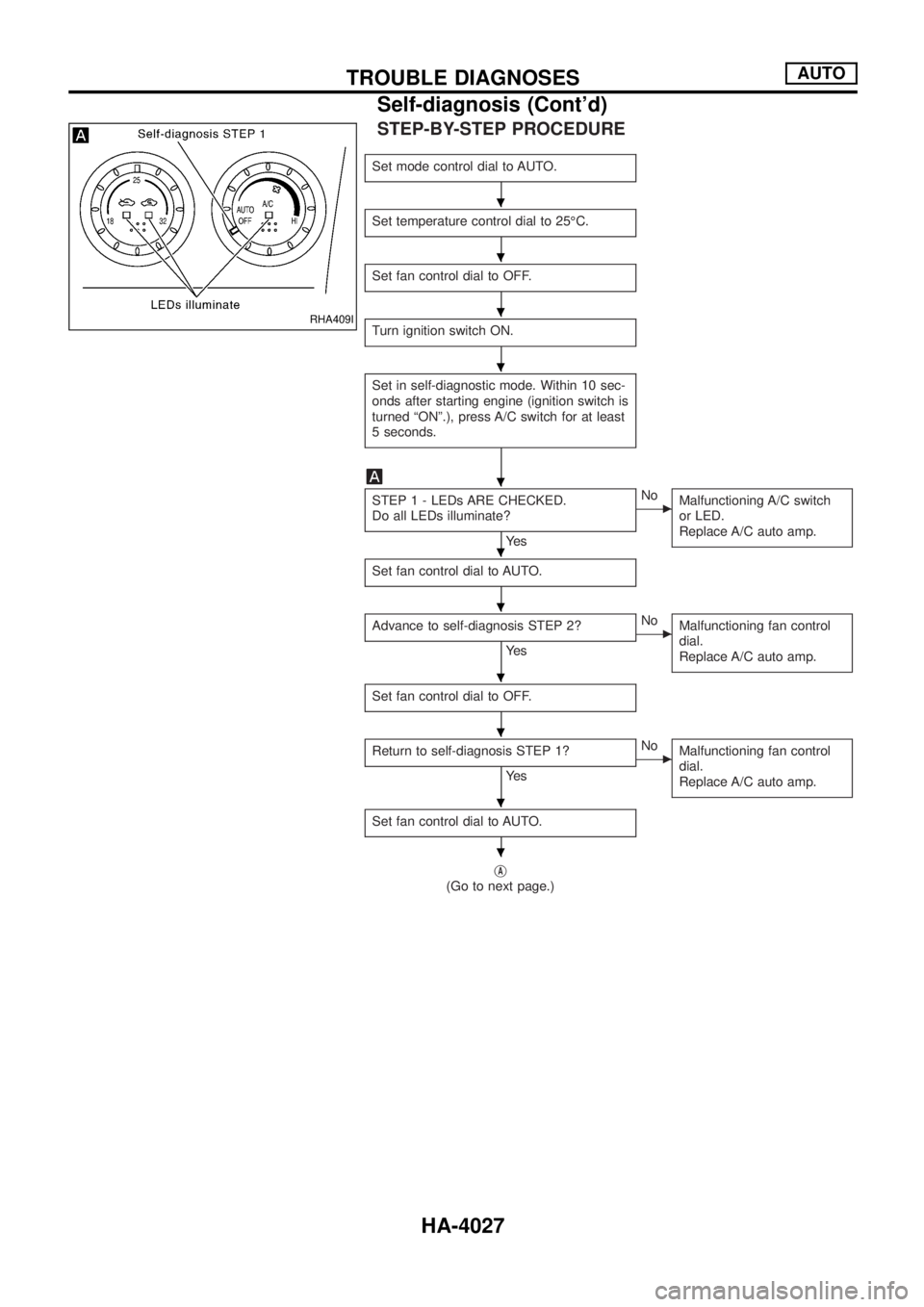

STEP-BY-STEP PROCEDURE

Set mode control dial to AUTO.

Set temperature control dial to 25ÉC.

Set fan control dial to OFF.

Turn ignition switch ON.

Set in self-diagnostic mode. Within 10 sec-

onds after starting engine (ignition switch is

turned ªONº.), press A/C switch for at least

5 seconds.

STEP 1 - LEDs ARE CHECKED.

Do all LEDs illuminate?

Ye s

cNo

Malfunctioning A/C switch

or LED.

Replace A/C auto amp.

Set fan control dial to AUTO.

Advance to self-diagnosis STEP 2?

Ye s

cNo

Malfunctioning fan control

dial.

Replace A/C auto amp.

Set fan control dial to OFF.

Return to self-diagnosis STEP 1?

Ye s

cNo

Malfunctioning fan control

dial.

Replace A/C auto amp.

Set fan control dial to AUTO.

jA

(Go to next page.)

RHA409I

.

.

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-4027

Page 509 of 579

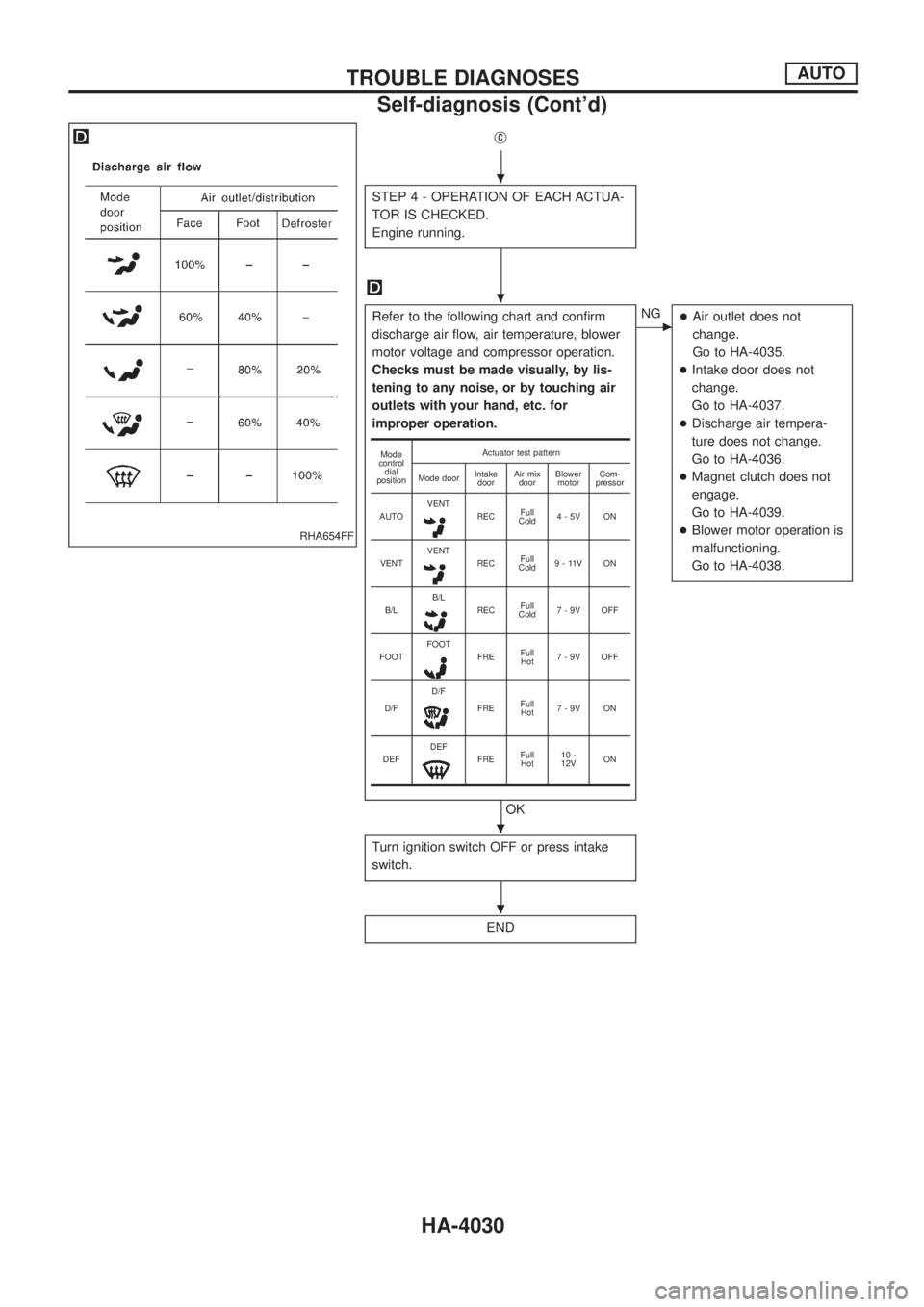

jC

STEP 4 - OPERATION OF EACH ACTUA-

TOR IS CHECKED.

Engine running.

Refer to the following chart and con®rm

discharge air ¯ow, air temperature, blower

motor voltage and compressor operation.

Checks must be made visually, by lis-

tening to any noise, or by touching air

outlets with your hand, etc. for

improper operation.

OK

cNG

+Air outlet does not

change.

Go to HA-4035.

+Intake door does not

change.

Go to HA-4037.

+Discharge air tempera-

ture does not change.

Go to HA-4036.

+Magnet clutch does not

engage.

Go to HA-4039.

+Blower motor operation is

malfunctioning.

Go to HA-4038.

Turn ignition switch OFF or press intake

switch.

END

Mode

control

dial

positionActuator test pattern

Mode doorIntake

doorAir mix

doorBlower

motorCom-

pressor

AUTOVENT

RECFull

Cold4-5V ON

VENTVENT

RECFull

Cold9 - 11V ON

B/LB/L

RECFull

Cold7-9V OFF

FOOTFOOT

FREFull

Hot7-9V OFF

D/FD/F

FREFull

Hot7-9V ON

DEFDEF

FREFull

Hot10 -

12VON

RHA654FF

.

.

.

.

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-4030