coil NISSAN PATROL 2006 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 760 of 1226

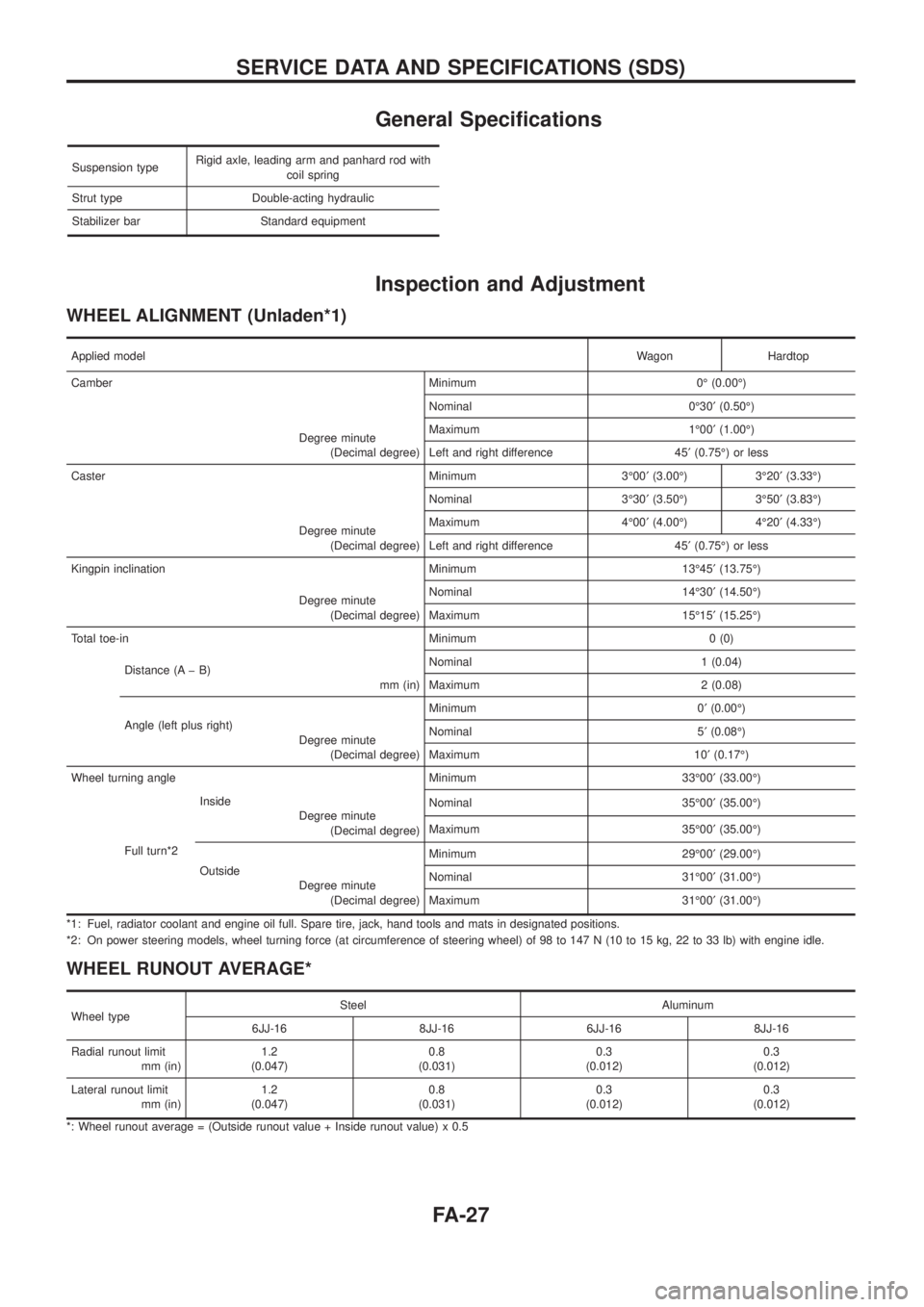

General Speci®cations

Suspension typeRigid axle, leading arm and panhard rod with

coil spring

Strut type Double-acting hydraulic

Stabilizer bar Standard equipment

Inspection and Adjustment

WHEEL ALIGNMENT (Unladen*1)

Applied modelWagon Hardtop

Camber Minimum 0É (0.00É)

Degree minute

(Decimal degree)Nominal 0É30¢(0.50É)

Maximum 1É00¢(1.00É)

Left and right difference 45¢(0.75É) or less

Caster Minimum 3É00¢(3.00É) 3É20¢(3.33É)

Degree minute

(Decimal degree)Nominal 3É30¢(3.50É) 3É50¢(3.83É)

Maximum 4É00¢(4.00É) 4É20¢(4.33É)

Left and right difference 45¢(0.75É) or less

Kingpin inclination Minimum 13É45¢(13.75É)

Degree minute

(Decimal degree)Nominal 14É30¢(14.50É)

Maximum 15É15¢(15.25É)

Total toe-in Minimum 0 (0)

Distance (A þ B)

mm (in)Nominal 1 (0.04)

Maximum 2 (0.08)

Angle (left plus right)

Degree minute

(Decimal degree)Minimum 0¢(0.00É)

Nominal 5¢(0.08É)

Maximum 10¢(0.17É)

Wheel turning angle Minimum 33É00¢(33.00É)

Full turn*2Inside

Degree minute

(Decimal degree)Nominal 35É00¢(35.00É)

Maximum 35É00¢(35.00É)

Outside

Degree minute

(Decimal degree)Minimum 29É00¢(29.00É)

Nominal 31É00¢(31.00É)

Maximum 31É00¢(31.00É)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: On power steering models, wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with engine idle.

WHEEL RUNOUT AVERAGE*

Wheel typeSteel Aluminum

6JJ-16 8JJ-16 6JJ-16 8JJ-16

Radial runout limit

mm (in)1.2

(0.047)0.8

(0.031)0.3

(0.012)0.3

(0.012)

Lateral runout limit

mm (in)1.2

(0.047)0.8

(0.031)0.3

(0.012)0.3

(0.012)

*: Wheel runout average = (Outside runout value + Inside runout value) x 0.5

SERVICE DATA AND SPECIFICATIONS (SDS)

FA-27

Page 832 of 1226

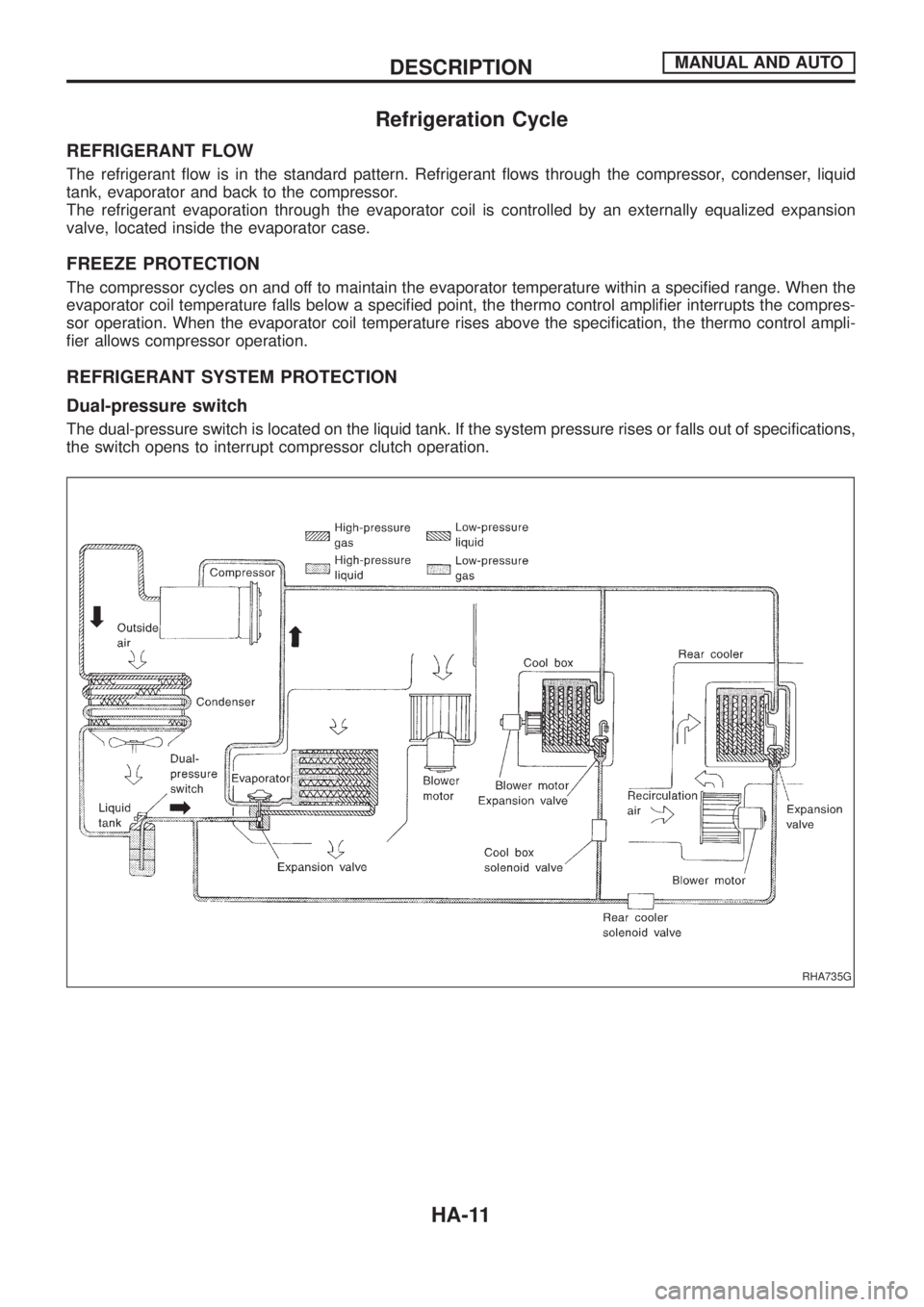

Refrigeration Cycle

REFRIGERANT FLOW

The refrigerant ¯ow is in the standard pattern. Refrigerant ¯ows through the compressor, condenser, liquid

tank, evaporator and back to the compressor.

The refrigerant evaporation through the evaporator coil is controlled by an externally equalized expansion

valve, located inside the evaporator case.

FREEZE PROTECTION

The compressor cycles on and off to maintain the evaporator temperature within a speci®ed range. When the

evaporator coil temperature falls below a speci®ed point, the thermo control ampli®er interrupts the compres-

sor operation. When the evaporator coil temperature rises above the speci®cation, the thermo control ampli-

®er allows compressor operation.

REFRIGERANT SYSTEM PROTECTION

Dual-pressure switch

The dual-pressure switch is located on the liquid tank. If the system pressure rises or falls out of specifications,

the switch opens to interrupt compressor clutch operation.

RHA735G

DESCRIPTIONMANUAL AND AUTO

HA-11

Page 865 of 1226

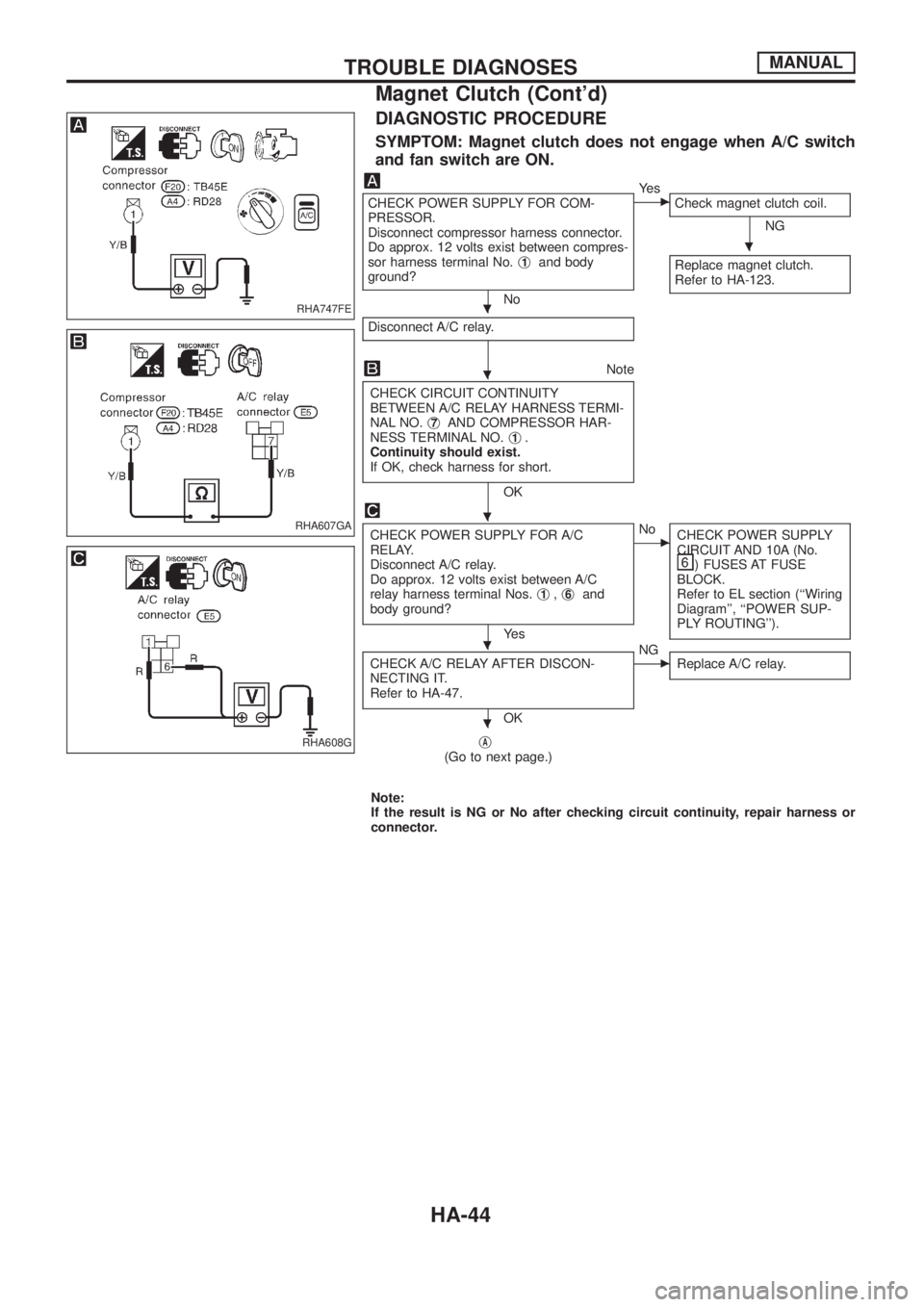

DIAGNOSTIC PROCEDURE

SYMPTOM: Magnet clutch does not engage when A/C switch

and fan switch are ON.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connector.

Do approx. 12 volts exist between compres-

sor harness terminal No.j

1and body

ground?

No

cYe s

Check magnet clutch coil.

NG

Replace magnet clutch.

Refer to HA-123.

Disconnect A/C relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS TERMI-

NAL NO.j

7AND COMPRESSOR HAR-

NESS TERMINAL NO.j1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Disconnect A/C relay.

Do approx. 12 volts exist between A/C

relay harness terminal Nos.j

1,j6and

body ground?

Ye s

cNo

CHECK POWER SUPPLY

CIRCUIT AND 10A (No.

) FUSES AT FUSE

BLOCK.

Refer to EL section (``Wiring

Diagram'', ``POWER SUP-

PLY ROUTING'').

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-47.

OK

cNG

Replace A/C relay.

jA(Go to next page.)

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA747FE

RHA607GA

RHA608G

.

.

.

.

.

.

TROUBLE DIAGNOSESMANUAL

Magnet Clutch (Cont'd)

HA-44

Page 866 of 1226

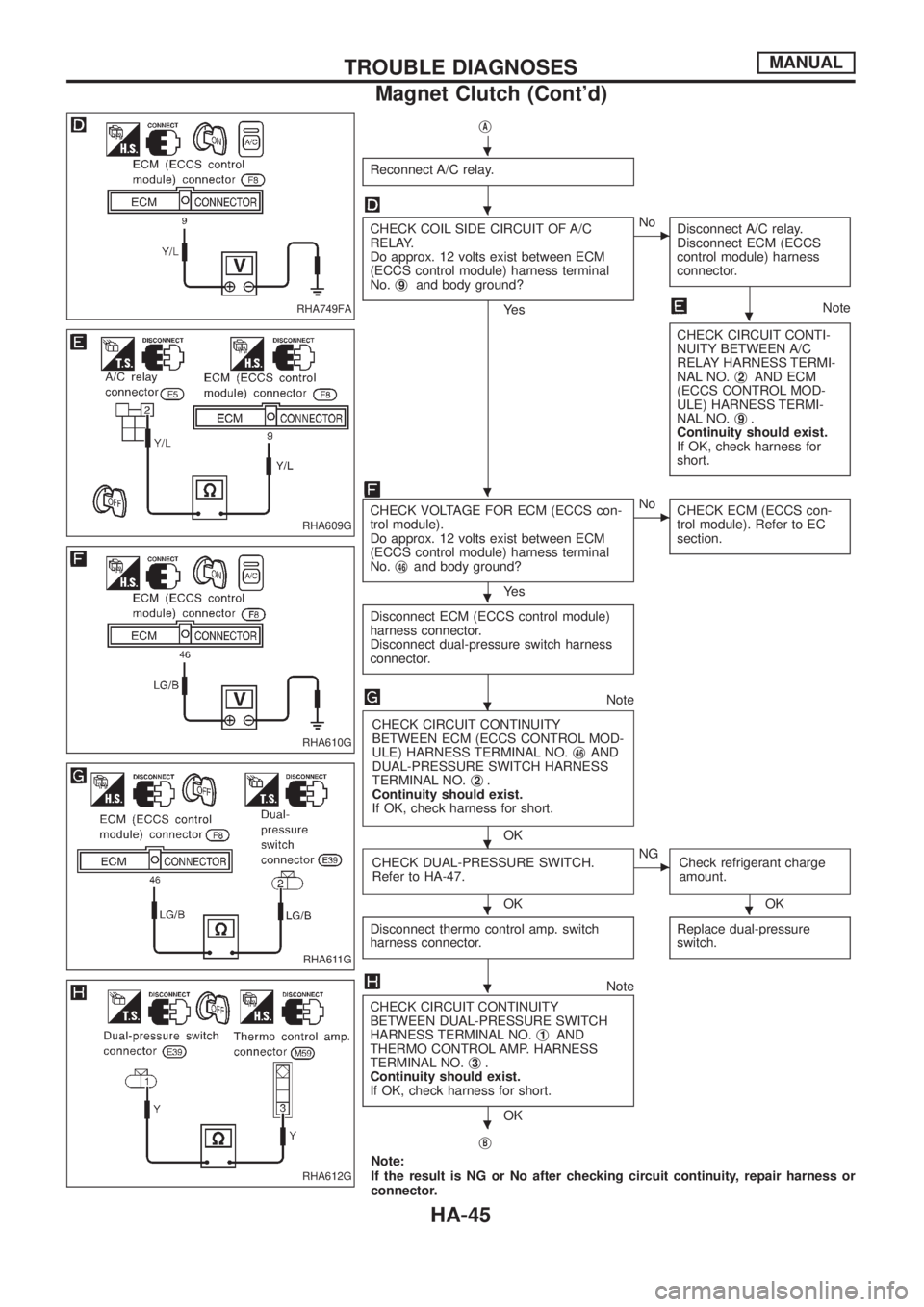

jA

Reconnect A/C relay.

CHECK COIL SIDE CIRCUIT OF A/C

RELAY.

Do approx. 12 volts exist between ECM

(ECCS control module) harness terminal

No.j

9and body ground?

Ye s

cNo

Disconnect A/C relay.

Disconnect ECM (ECCS

control module) harness

connector.

Note

CHECK CIRCUIT CONTI-

NUITY BETWEEN A/C

RELAY HARNESS TERMI-

NAL NO.j

2AND ECM

(ECCS CONTROL MOD-

ULE) HARNESS TERMI-

NAL NO.j

9.

Continuity should exist.

If OK, check harness for

short.

CHECK VOLTAGE FOR ECM (ECCS con-

trol module).

Do approx. 12 volts exist between ECM

(ECCS control module) harness terminal

No.j

46and body ground?

Ye s

cNo

CHECK ECM (ECCS con-

trol module). Refer to EC

section.

Disconnect ECM (ECCS control module)

harness connector.

Disconnect dual-pressure switch harness

connector.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN ECM (ECCS CONTROL MOD-

ULE) HARNESS TERMINAL NO.j

46AND

DUAL-PRESSURE SWITCH HARNESS

TERMINAL NO.j

2.

Continuity should exist.

If OK, check harness for short.

OK

CHECK DUAL-PRESSURE SWITCH.

Refer to HA-47.

OK

cNG

Check refrigerant charge

amount.

OK

Disconnect thermo control amp. switch

harness connector.

Replace dual-pressure

switch.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN DUAL-PRESSURE SWITCH

HARNESS TERMINAL NO.j

1AND

THERMO CONTROL AMP. HARNESS

TERMINAL NO.j

3.

Continuity should exist.

If OK, check harness for short.

OK

j

B

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA749FA

RHA609G

RHA610G

RHA611G

RHA612G

.

.

.

.

.

.

.

..

.

.

TROUBLE DIAGNOSESMANUAL

Magnet Clutch (Cont'd)

HA-45

Page 915 of 1226

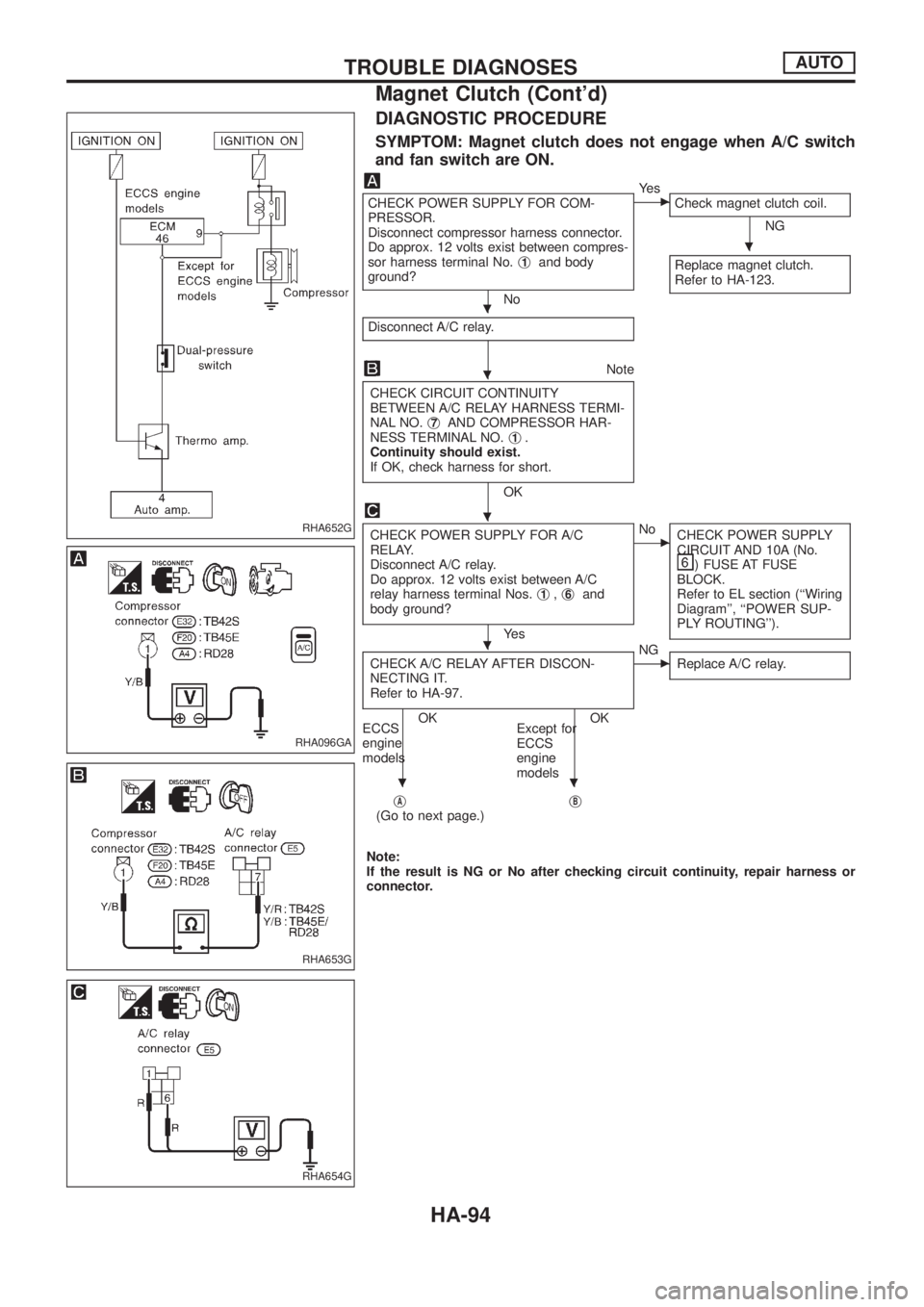

DIAGNOSTIC PROCEDURE

SYMPTOM: Magnet clutch does not engage when A/C switch

and fan switch are ON.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connector.

Do approx. 12 volts exist between compres-

sor harness terminal No.j

1and body

ground?

No

cYe s

Check magnet clutch coil.

NG

Replace magnet clutch.

Refer to HA-123.

Disconnect A/C relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS TERMI-

NAL NO.j

7AND COMPRESSOR HAR-

NESS TERMINAL NO.j1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Disconnect A/C relay.

Do approx. 12 volts exist between A/C

relay harness terminal Nos.j

1,j6and

body ground?

Ye s

cNo

CHECK POWER SUPPLY

CIRCUIT AND 10A (No.

) FUSE AT FUSE

BLOCK.

Refer to EL section (``Wiring

Diagram'', ``POWER SUP-

PLY ROUTING'').

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-97.

OK OK

ECCS

engine

modelsExcept for

ECCS

engine

models

cNG

Replace A/C relay.

jA(Go to next page.)jB

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA652G

RHA096GA

RHA653G

RHA654G

.

.

.

.

.

..

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-94

Page 916 of 1226

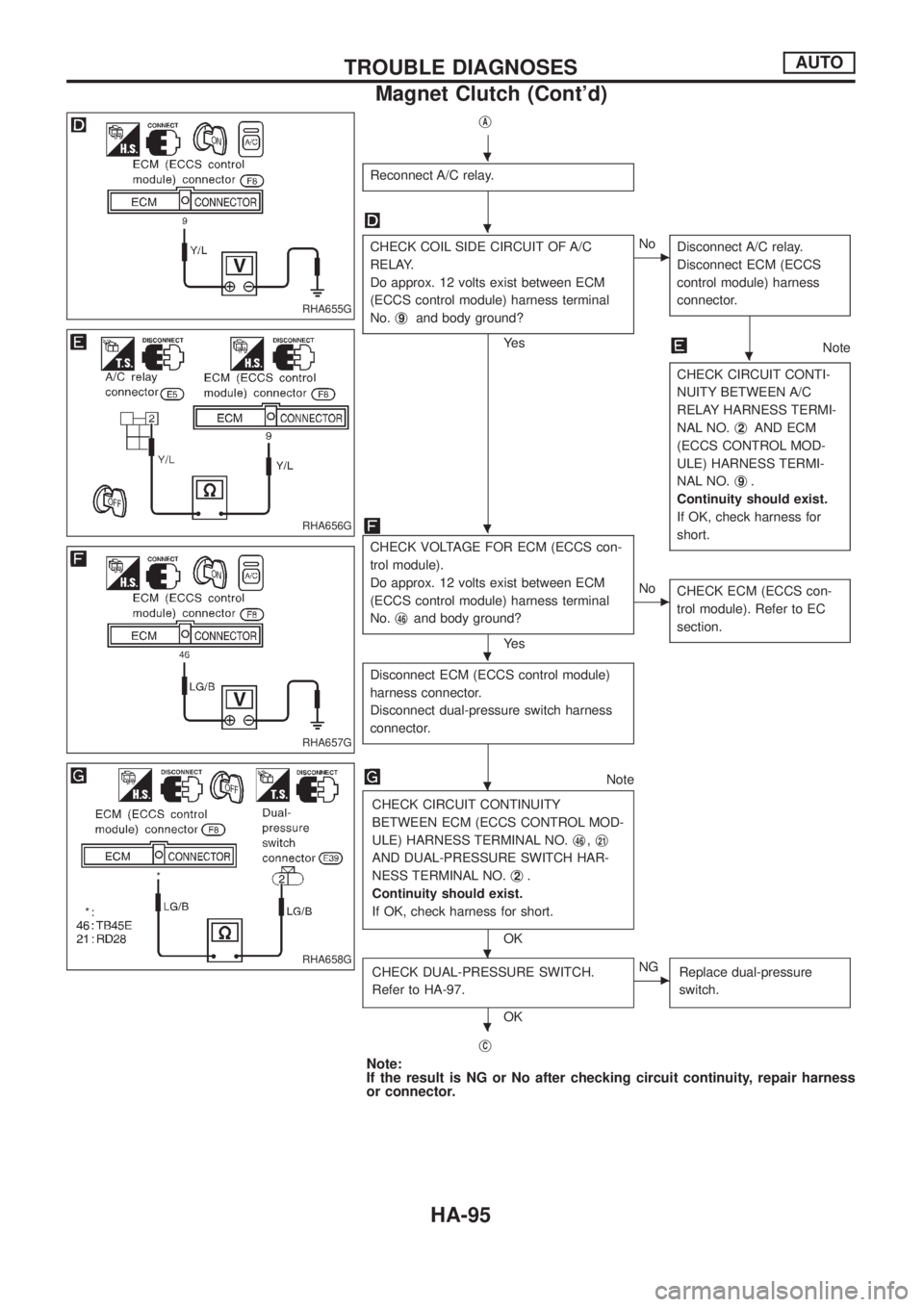

jA

Reconnect A/C relay.

CHECK COIL SIDE CIRCUIT OF A/C

RELAY.

Do approx. 12 volts exist between ECM

(ECCS control module) harness terminal

No.j

9and body ground?

Ye s

cNo

Disconnect A/C relay.

Disconnect ECM (ECCS

control module) harness

connector.

Note

CHECK CIRCUIT CONTI-

NUITY BETWEEN A/C

RELAY HARNESS TERMI-

NAL NO.j

2AND ECM

(ECCS CONTROL MOD-

ULE) HARNESS TERMI-

NAL NO.j

9.

Continuity should exist.

If OK, check harness for

short.

CHECK VOLTAGE FOR ECM (ECCS con-

trol module).

Do approx. 12 volts exist between ECM

(ECCS control module) harness terminal

No.j

46and body ground?

Ye s

cNo

CHECK ECM (ECCS con-

trol module). Refer to EC

section.

Disconnect ECM (ECCS control module)

harness connector.

Disconnect dual-pressure switch harness

connector.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN ECM (ECCS CONTROL MOD-

ULE) HARNESS TERMINAL NO.j

46,j21

AND DUAL-PRESSURE SWITCH HAR-

NESS TERMINAL NO.j

2.

Continuity should exist.

If OK, check harness for short.

OK

CHECK DUAL-PRESSURE SWITCH.

Refer to HA-97.

OK

cNG

Replace dual-pressure

switch.

jC

Note:

If the result is NG or No after checking circuit continuity, repair harness

or connector.

RHA655G

RHA656G

RHA657G

RHA658G

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-95

Page 945 of 1226

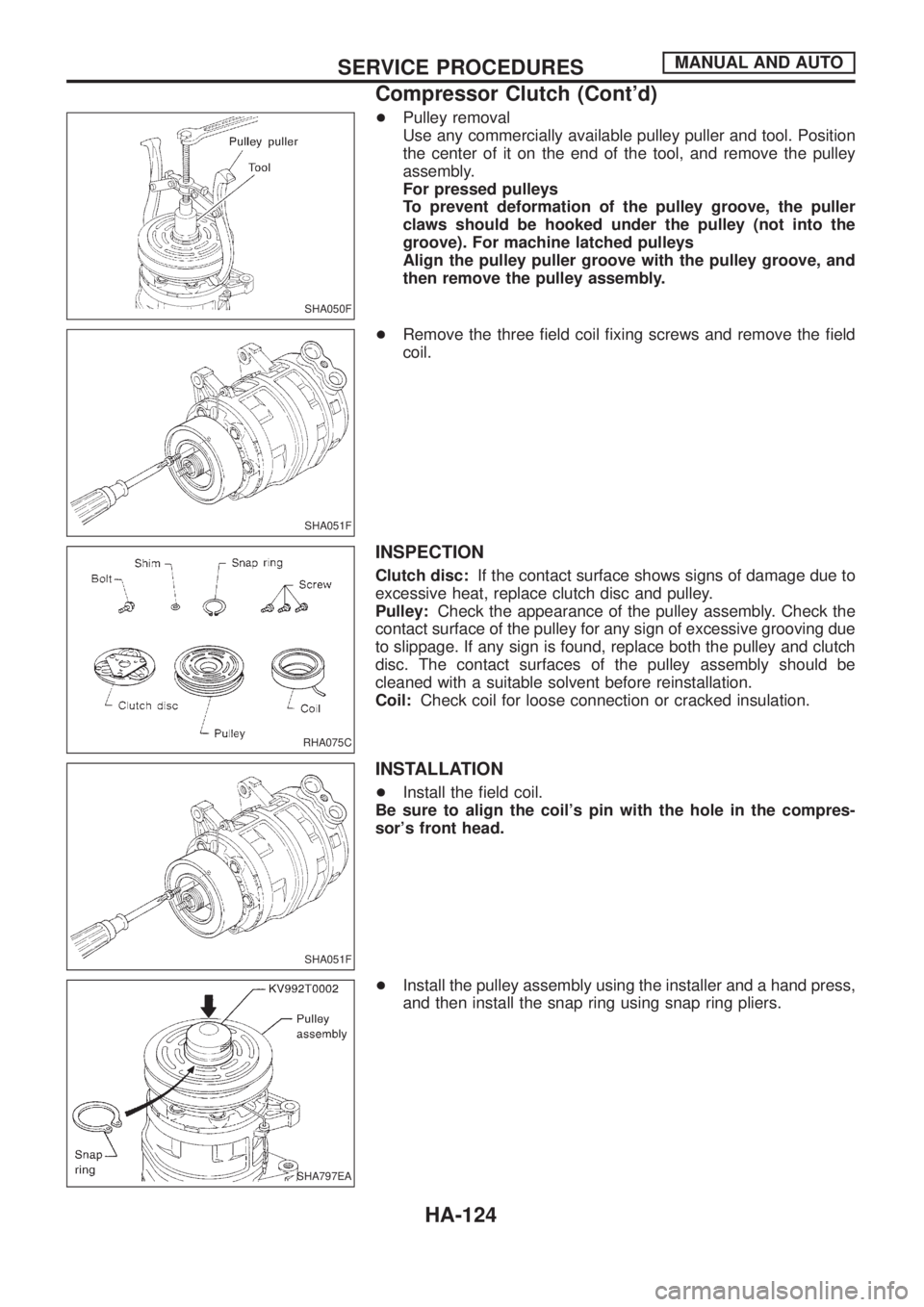

+Pulley removal

Use any commercially available pulley puller and tool. Position

the center of it on the end of the tool, and remove the pulley

assembly.

For pressed pulleys

To prevent deformation of the pulley groove, the puller

claws should be hooked under the pulley (not into the

groove). For machine latched pulleys

Align the pulley puller groove with the pulley groove, and

then remove the pulley assembly.

+Remove the three ®eld coil ®xing screws and remove the ®eld

coil.

INSPECTION

Clutch disc:If the contact surface shows signs of damage due to

excessive heat, replace clutch disc and pulley.

Pulley:Check the appearance of the pulley assembly. Check the

contact surface of the pulley for any sign of excessive grooving due

to slippage. If any sign is found, replace both the pulley and clutch

disc. The contact surfaces of the pulley assembly should be

cleaned with a suitable solvent before reinstallation.

Coil:Check coil for loose connection or cracked insulation.

INSTALLATION

+Install the ®eld coil.

Be sure to align the coil's pin with the hole in the compres-

sor's front head.

+Install the pulley assembly using the installer and a hand press,

and then install the snap ring using snap ring pliers.

SHA050F

SHA051F

RHA075C

SHA051F

SHA797EA

SERVICE PROCEDURESMANUAL AND AUTO

Compressor Clutch (Cont'd)

HA-124

Page 949 of 1226

A

A/C HFC134a (R134a) system service

procedure ..................................................HA-112

A/C HFC134a system service equip-

ment precaution ............................................HA-9

A/C air ¯ow .....................................................HA-13

A/C component layout ....................................HA-12

A/C compressor precaution..............................HA-6

A/C compressor special service tool ...........HA-6, 7

A/C control linkage adjustment (auto

A/C).............................................................HA-77

A/C control operation (manual A/C) ...............HA-16

A/C harness layout (manual A/C) ..................HA-17

A/C lubricant (R134a) ...................................HA-114

A/C relay.........................................................HA-97

A/C self-diagnoses (auto A/C)........................HA-63

A/CCUT - Wiring diagram ............................EC-186

A/T control ....................................................EC-174

ABS sensor rotor ............................................FA-15

ACC/SW - Wiring diagram ...........................EC-105

ACL/SW - Wiring diagram ............................EC-164

ADJRES - Wiring diagram .............................EC-91

APS - Wiring diagram ..................................EC-138

AT/C - Wiring diagram..................................EC-174

AUDIO - Wiring diagram ...............................EL-168

Accelerator position sensor ..........................EC-138

Accelerator position switch...........................EC-164

Accelerator switch (F/C) ...............................EC-105

Adjustment resistor.........................................EC-91

Air bag disposal..............................................RS-17

Air bag ..............................................................RS-8

Air bleeding (hydraulic clutch) ..........................CL-6

Air bleeding for brake system ..........................BR-4

Air cleaner ®lter replacement .........................MA-18

Air conditioner cut control ..............................EC-19

Air ¯ow meter - See Mass air ¯ow

sensor .........................................................EC-73

Air mix door control linkage

adjustment ................................................HA-81

Alternator.........................................................EL-56

Antenna - See Power antenna .....................EL-181

Audio and A/C control removal and

installation - See Instrument panel .............BT-11

Audio .............................................................EL-168

Auto lock free running hub .............................FA-13

Automatic ampli®er .........................................HA-61

Axle housing (rear) ...........................................RA-9

B

BACK/L - Wiring diagram................................EL-78

Back door opener - See Back door ..................BT-6

Back door trim.................................................BT-24

Back door window...........................................BT-45

Back door ..........................................................BT-6Back-up lamp switch (M/T) ..............................MT-4

Back-up lamp ..................................................EL-78

Battery .............................................................EL-37

Baulk ring (M/T)..............................................MT-10

Body alignment ...............................................BT-49

Body mounting ................................................BT-48

Brake booster .................................................BR-15

Brake ¯uid change ...........................................BR-3

Brake ¯uid level and line check .......................BR-3

Brake ¯uid level .............................................MA-23

Brake hydraulic line ..........................................BR-5

Brake inspection ............................................MA-24

Brake master cylinder ....................................BR-12

Brake pedal ....................................................BR-10

Bulb speci®cations ........................................EL-314

Bumper, front ................................................... BT-4

Bumper, rear .....................................................BT-6

C

CD/CHG - Wiring diagram ............................EL-176

CHIME - Wiring diagram...............................EL-136

CIGAR - Wiring diagram ...............................EL-156

CKPS - Wiring diagram ................................EC-143

CLOCK - Wiring diagram ..............................EL-157

CMPS - Wiring diagram .................................EC-68

COMPAS - Wiring diagram ...........................EL-117

CONSULT for ECCS ......................................EC-36

CONSULT general information ........................GI-33

COOL/F - Wiring diagram ............................EC-112

CSPS - Wiring diagram ..................................EC-86

Cab body.........................................................BT-47

Camshaft inspection ......................................EM-36

Camshaft position sensor (PUMP).................EC-68

Center case (Transfer) ....................................TF-10

Charge air cooler fan control .......................EC-177

Charge air temperature sensor ....................EC-121

Chassis and body maintenance ....................MA-20

Cigarette lighter.............................................EL-156

Circuit breaker.................................................EL-14

Clock .............................................................EL-157

Clutch booster...................................................CL-9

Clutch cover ....................................................CL-14

Clutch damper ..................................................CL-7

Clutch disc ......................................................CL-13

Clutch ¯uid level.............................................MA-20

Clutch master cylinder ......................................CL-7

Clutch operating cylinder ..................................CL-8

Clutch pedal ......................................................CL-5

Clutch release bearing ....................................CL-11

Clutch release mechanism .............................CL-11

Clutch withdrawal lever ...................................CL-11

Coil spring (front) ............................................FA-25

Coil spring (rear) ............................................RA-14

Collision diagnosis..........................................RS-45

Combination meter removal and instal-

lation - See Instrument panel ......................BT-11

ALPHABETICAL INDEX

IDX-2

Page 1096 of 1226

REAR AXLE &

REAR SUSPENSION

SECTION

RA

CONTENTS

PRECAUTIONS AND PREPARATION............................1

Precautions ..................................................................1

Special Service Tools ..................................................1

Commercial Service Tools ...........................................2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................3

NVH Troubleshooting Chart.........................................3

REAR AXLE AND REAR SUSPENSION........................4

ON-VEHICLE SERVICE..................................................5

Rear Axle and Rear Suspension Parts .......................5

Rear Wheel Bearing ....................................................5

REAR AXLE.....................................................................6

Components.................................................................6

Removal .......................................................................7

Inspection.....................................................................9Installation ....................................................................9

REAR SUSPENSION.....................................................12

Removal and Installation ...........................................13

Coil Spring and Shock Absorber ...............................14

Upper Link, Lower Link and Panhard Rod ................14

Stabilizer Bar .............................................................15

STABILIZER RELEASE DEVICE..................................16

System Components .................................................16

System Description ....................................................16

Removal and Installation ...........................................17

Wiring Diagram ..........................................................18

Trouble Diagnoses.....................................................20

SERVICE DATA AND SPECIFICATIONS (SDS)..........25

General Speci®cations ...............................................25

Inspection and Adjustment ........................................25

RA

Page 1110 of 1226

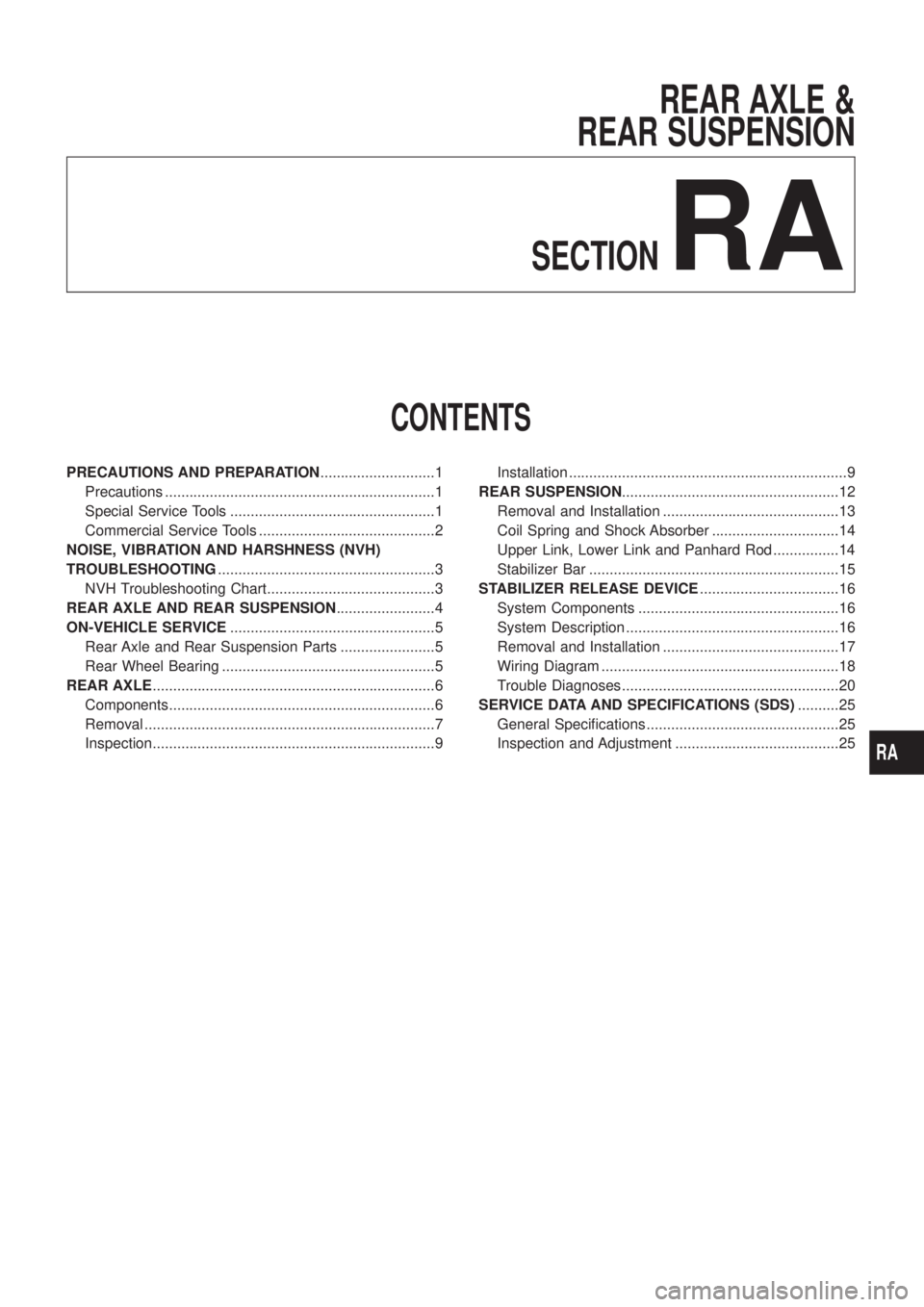

Final tightening for rubber parts requires to be carried out

under unladen condition with tires on ground.

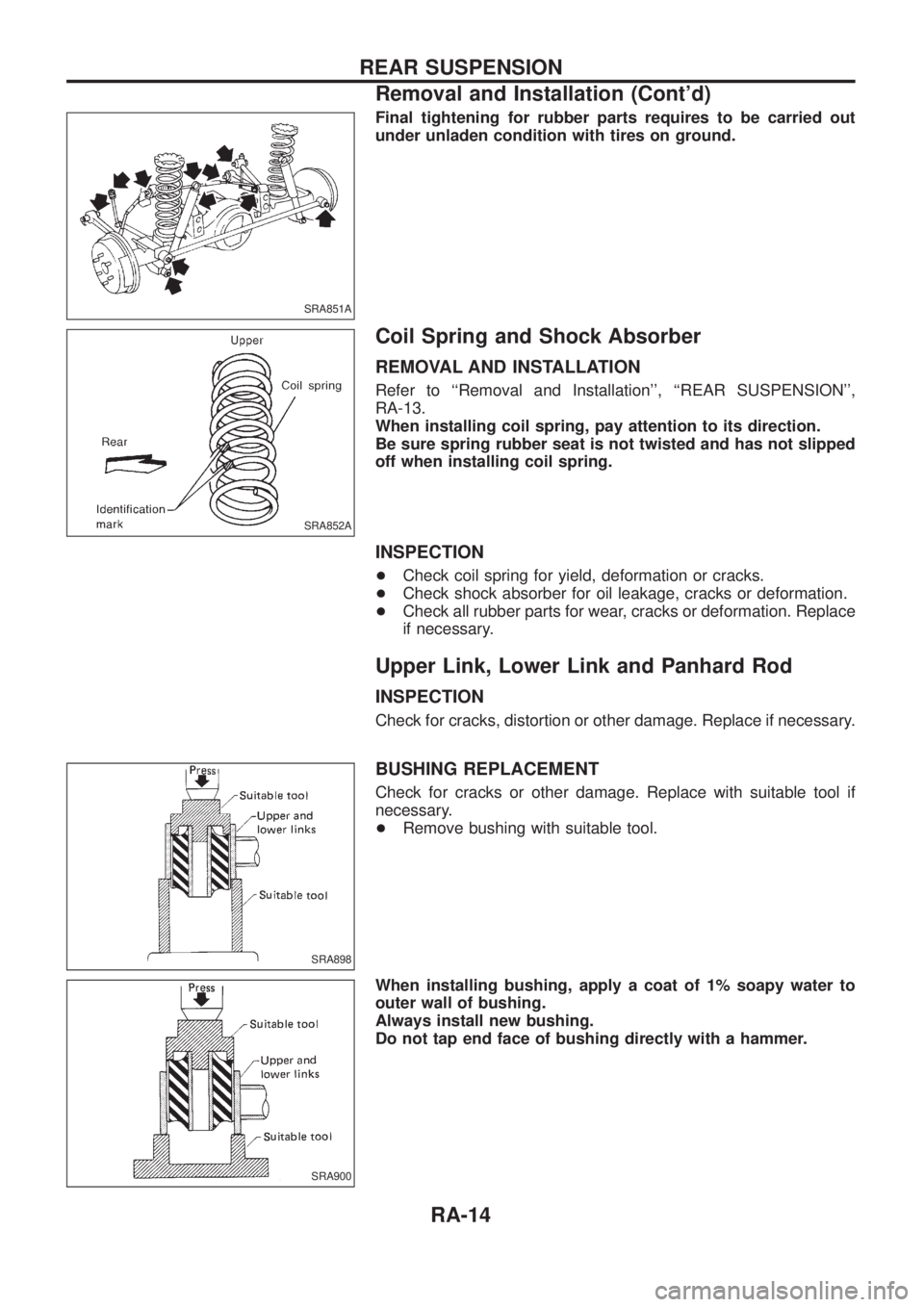

Coil Spring and Shock Absorber

REMOVAL AND INSTALLATION

Refer to ``Removal and Installation'', ``REAR SUSPENSION'',

RA-13.

When installing coil spring, pay attention to its direction.

Be sure spring rubber seat is not twisted and has not slipped

off when installing coil spring.

INSPECTION

+Check coil spring for yield, deformation or cracks.

+Check shock absorber for oil leakage, cracks or deformation.

+Check all rubber parts for wear, cracks or deformation. Replace

if necessary.

Upper Link, Lower Link and Panhard Rod

INSPECTION

Check for cracks, distortion or other damage. Replace if necessary.

BUSHING REPLACEMENT

Check for cracks or other damage. Replace with suitable tool if

necessary.

+Remove bushing with suitable tool.

When installing bushing, apply a coat of 1% soapy water to

outer wall of bushing.

Always install new bushing.

Do not tap end face of bushing directly with a hammer.

SRA851A

SRA852A

SRA898

SRA900

REAR SUSPENSION

Removal and Installation (Cont'd)

RA-14