parking NISSAN PATROL 2006 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 980 of 1226

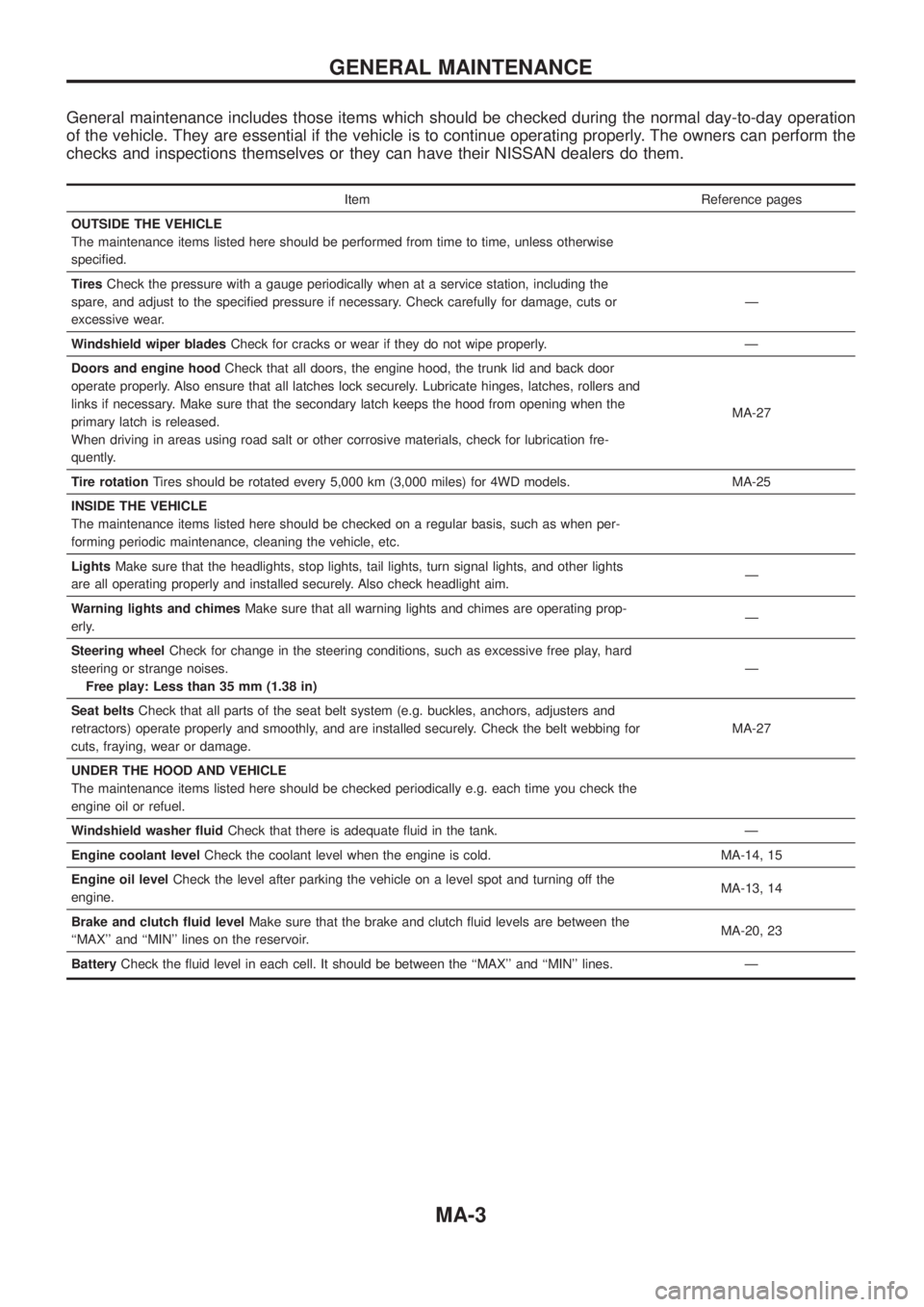

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them.

Item Reference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise

speci®ed.

TiresCheck the pressure with a gauge periodically when at a service station, including the

spare, and adjust to the speci®ed pressure if necessary. Check carefully for damage, cuts or

excessive wear.Ð

Windshield wiper bladesCheck for cracks or wear if they do not wipe properly. Ð

Doors and engine hoodCheck that all doors, the engine hood, the trunk lid and back door

operate properly. Also ensure that all latches lock securely. Lubricate hinges, latches, rollers and

links if necessary. Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication fre-

quently.MA-27

Tire rotationTires should be rotated every 5,000 km (3,000 miles) for 4WD models. MA-25

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle, etc.

LightsMake sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating properly and installed securely. Also check headlight aim.Ð

Warning lights and chimesMake sure that all warning lights and chimes are operating prop-

erly.Ð

Steering wheelCheck for change in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear or damage.MA-27

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer ¯uidCheck that there is adequate ¯uid in the tank. Ð

Engine coolant levelCheck the coolant level when the engine is cold. MA-14, 15

Engine oil levelCheck the level after parking the vehicle on a level spot and turning off the

engine.MA-13, 14

Brake and clutch ¯uid levelMake sure that the brake and clutch ¯uid levels are between the

``MAX'' and ``MIN'' lines on the reservoir.MA-20, 23

BatteryCheck the ¯uid level in each cell. It should be between the ``MAX'' and ``MIN'' lines. Ð

GENERAL MAINTENANCE

MA-3

Page 983 of 1226

![NISSAN PATROL 2006 Owners Manual Chassis and Body Services

Annual driving distance below 30,000 km (18,000 miles)

Abbreviations: R = Replace, I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

[ ]: At the spec NISSAN PATROL 2006 Owners Manual Chassis and Body Services

Annual driving distance below 30,000 km (18,000 miles)

Abbreviations: R = Replace, I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

[ ]: At the spec](/img/5/57368/w960_57368-982.png)

Chassis and Body Services

Annual driving distance below 30,000 km (18,000 miles)

Abbreviations: R = Replace, I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

[ ]: At the speci®ed mileage only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform either at number of kilometers (miles) or months,

whichever comes ®rst.km x 1,000 10 20 30 40 50 60 70 80 90

(Miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54)

Months 6 12 18 24 30 36 42 48 54

CHASSIS AND BODY Underhood and under vehicle

Brake & clutch ¯uid (For level & leaks).I I I I MA-23, 20

Brake ¯uid.R R MA-24

Brake booster vacuum hoses, connections & check valve I I MA-24

Power steering ¯uid & lines (For level & leaks) I I I I MA-26

Brake & clutch systemsI I I I MA-24, 20

Manual transmission oil (For leaks) I I I I MA-20

Manual transmission oil[R] MA-20

Transfer ¯uidI I R I MA-21

Limited slip differential (LSD) gear oil (For level & leaks).*1 I I R I MA-22

Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system.I I I I MA-26, 20 *2

Greasing points of propeller shaftLLLLMA-21

Drive shafts & steering damper.IIII *3

Body mounting bolts & nutsTTTT *4

Outside and Inside

Wheel alignment (If necessary, rotate & balance wheels) I I I I MA-25, *5

Brake pads, discs & other brake components.I I I I MA-24

Front wheel bearing grease I R I R MA-22

Axle joint in knuckle ¯angeL L MA-23

Free running hub greaseI I I I MA-23

Headlamp aimingIIII *6

Foot brake, parking brake & clutch (For free play, stroke & operation) I I I I *7

Ventilation air ®lterRRR*8

Body corrosionAnnually MA-28

Air bag systemSee NOTE (1) *9

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) Maintenance items with ``.'' should be performed more frequently according to ``Maintenance Under Severe Driv-

ing Conditions''.

*1: Including differential gear with differential lock

*2: ``Front Axle and Front Suspension Parts'' in FA section, ``Rear Axle and Rear Suspension Parts'' in RA section

*3: ``FRONT AXLE Ð Drive Shaft'' in FA section

*4: ``CAB BODY'' in BT section

*5: ``Front Wheel Alignment'' in FA section

*6: ``Aiming Adjustment'' in EL section

*7: ``Brake Pedal and Bracket'' in BR section, ``Adjusting Clutch Pedal'' in CL section

*8: ``Ventilation air ®lter'' in HA section

*9: ``Maintenance Items'' in RS section

PERIODIC MAINTENANCE

MA-6

Page 984 of 1226

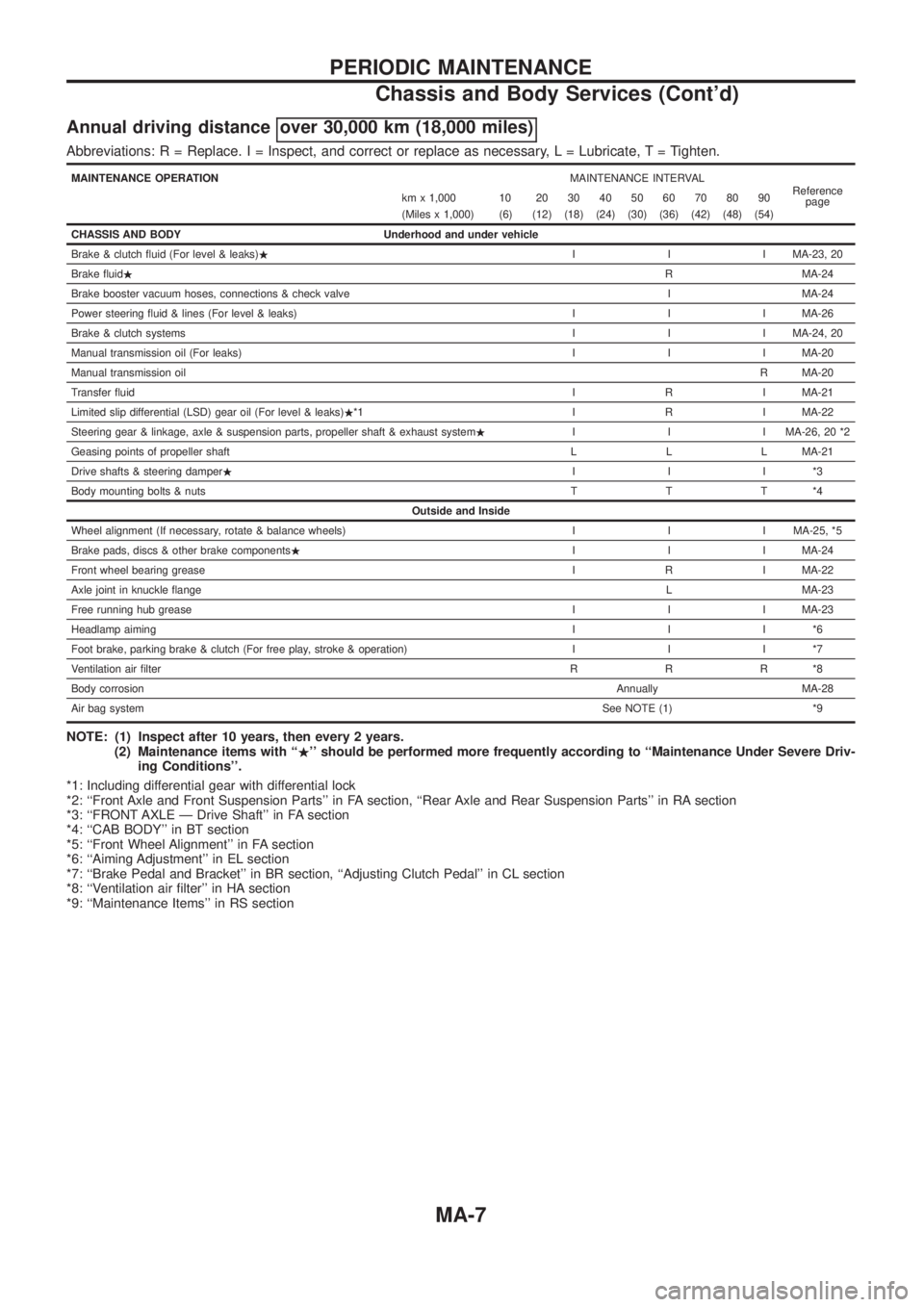

Annual driving distance over 30,000 km (18,000 miles)

Abbreviations: R = Replace. I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page km x 1,000 10 20 30 40 50 60 70 80 90

(Miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54)

CHASSIS AND BODY Underhood and under vehicle

Brake & clutch ¯uid (For level & leaks).I I I MA-23, 20

Brake ¯uid.R MA-24

Brake booster vacuum hoses, connections & check valve I MA-24

Power steering ¯uid & lines (For level & leaks) I I I MA-26

Brake & clutch systemsI I I MA-24, 20

Manual transmission oil (For leaks) I I I MA-20

Manual transmission oilR MA-20

Transfer ¯uidI R I MA-21

Limited slip differential (LSD) gear oil (For level & leaks).*1 I R I MA-22

Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system.I I I MA-26, 20 *2

Geasing points of propeller shaft L L L MA-21

Drive shafts & steering damper.III*3

Body mounting bolts & nutsTTT*4

Outside and Inside

Wheel alignment (If necessary, rotate & balance wheels) I I I MA-25, *5

Brake pads, discs & other brake components.I I I MA-24

Front wheel bearing greaseI R I MA-22

Axle joint in knuckle ¯angeL MA-23

Free running hub greaseI I I MA-23

Headlamp aimingIII*6

Foot brake, parking brake & clutch (For free play, stroke & operation) I I I *7

Ventilation air ®lterRRR*8

Body corrosionAnnually MA-28

Air bag systemSee NOTE (1) *9

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) Maintenance items with ``.'' should be performed more frequently according to ``Maintenance Under Severe Driv-

ing Conditions''.

*1: Including differential gear with differential lock

*2: ``Front Axle and Front Suspension Parts'' in FA section, ``Rear Axle and Rear Suspension Parts'' in RA section

*3: ``FRONT AXLE Ð Drive Shaft'' in FA section

*4: ``CAB BODY'' in BT section

*5: ``Front Wheel Alignment'' in FA section

*6: ``Aiming Adjustment'' in EL section

*7: ``Brake Pedal and Bracket'' in BR section, ``Adjusting Clutch Pedal'' in CL section

*8: ``Ventilation air ®lter'' in HA section

*9: ``Maintenance Items'' in RS section

PERIODIC MAINTENANCE

Chassis and Body Services (Cont'd)

MA-7

Page 1001 of 1226

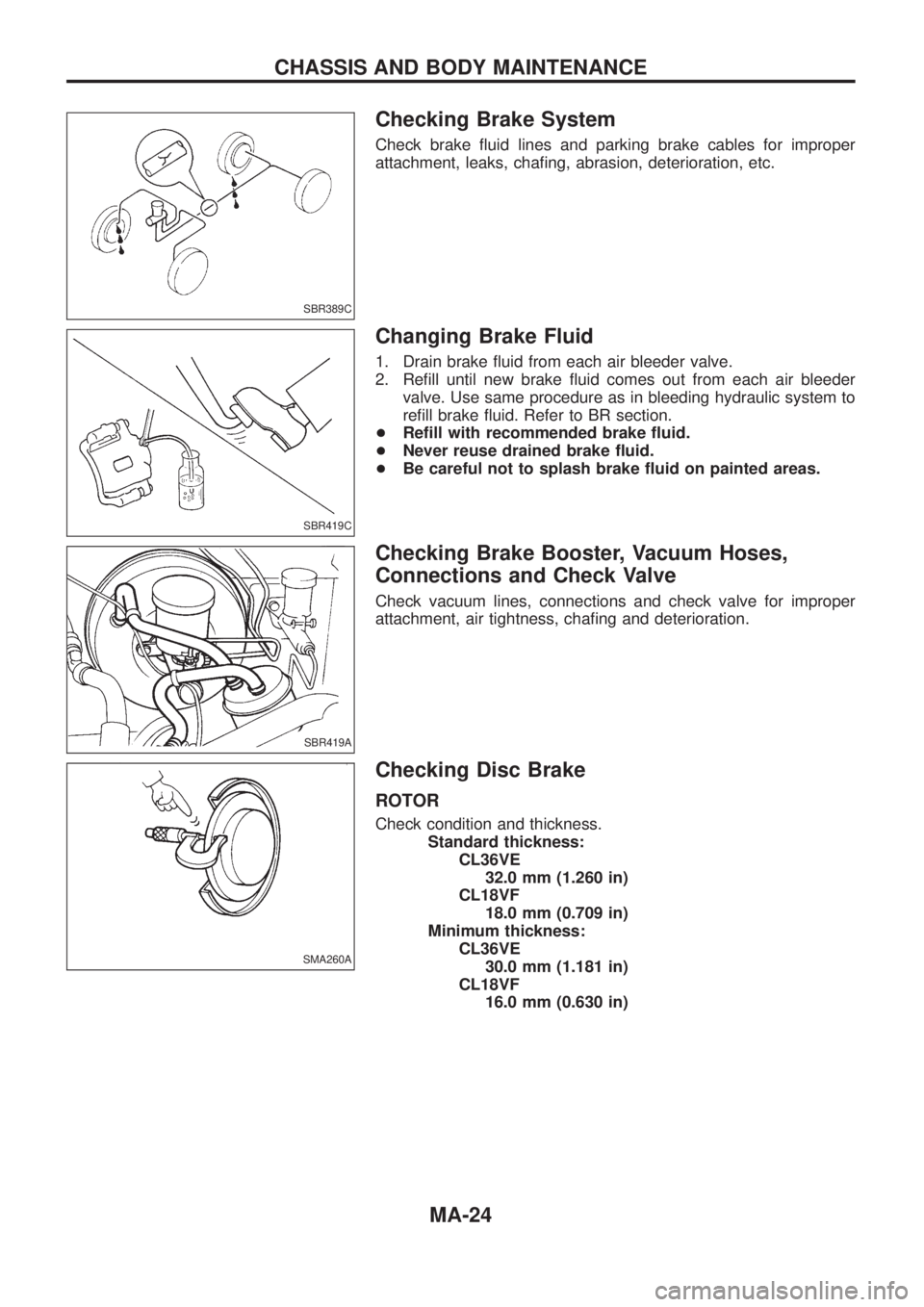

Checking Brake System

Check brake ¯uid lines and parking brake cables for improper

attachment, leaks, cha®ng, abrasion, deterioration, etc.

Changing Brake Fluid

1. Drain brake ¯uid from each air bleeder valve.

2. Re®ll until new brake ¯uid comes out from each air bleeder

valve. Use same procedure as in bleeding hydraulic system to

re®ll brake ¯uid. Refer to BR section.

+Re®ll with recommended brake ¯uid.

+Never reuse drained brake ¯uid.

+Be careful not to splash brake ¯uid on painted areas.

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve

Check vacuum lines, connections and check valve for improper

attachment, air tightness, cha®ng and deterioration.

Checking Disc Brake

ROTOR

Check condition and thickness.

Standard thickness:

CL36VE

32.0 mm (1.260 in)

CL18VF

18.0 mm (0.709 in)

Minimum thickness:

CL36VE

30.0 mm (1.181 in)

CL18VF

16.0 mm (0.630 in)

SBR389C

SBR419C

SBR419A

SMA260A

CHASSIS AND BODY MAINTENANCE

MA-24

Page 1103 of 1226

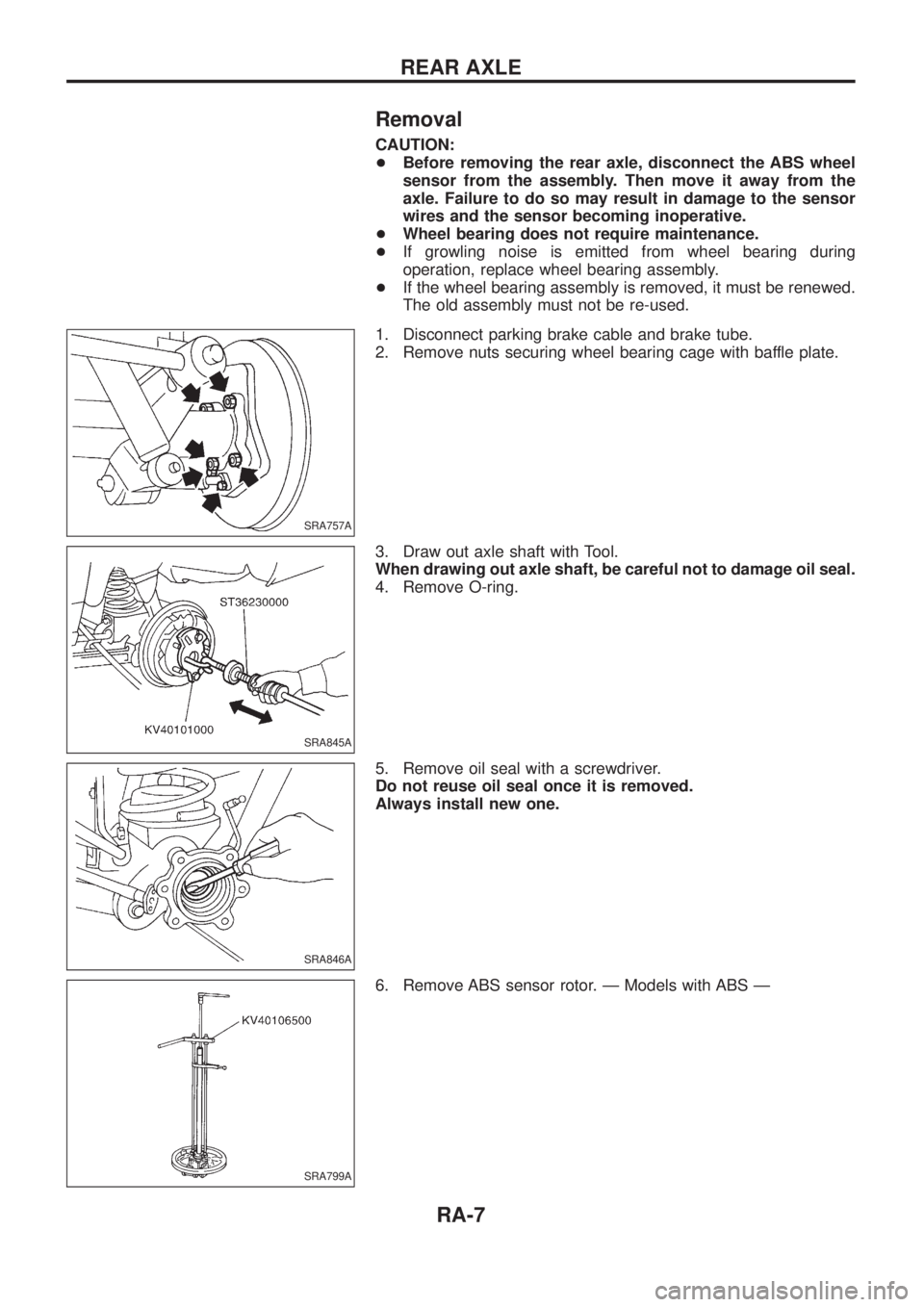

Removal

CAUTION:

+Before removing the rear axle, disconnect the ABS wheel

sensor from the assembly. Then move it away from the

axle. Failure to do so may result in damage to the sensor

wires and the sensor becoming inoperative.

+Wheel bearing does not require maintenance.

+If growling noise is emitted from wheel bearing during

operation, replace wheel bearing assembly.

+If the wheel bearing assembly is removed, it must be renewed.

The old assembly must not be re-used.

1. Disconnect parking brake cable and brake tube.

2. Remove nuts securing wheel bearing cage with baffle plate.

3. Draw out axle shaft with Tool.

When drawing out axle shaft, be careful not to damage oil seal.

4. Remove O-ring.

5. Remove oil seal with a screwdriver.

Do not reuse oil seal once it is removed.

Always install new one.

6. Remove ABS sensor rotor. Ð Models with ABS Ð

SRA757A

SRA845A

SRA846A

SRA799A

REAR AXLE

RA-7

Page 1109 of 1226

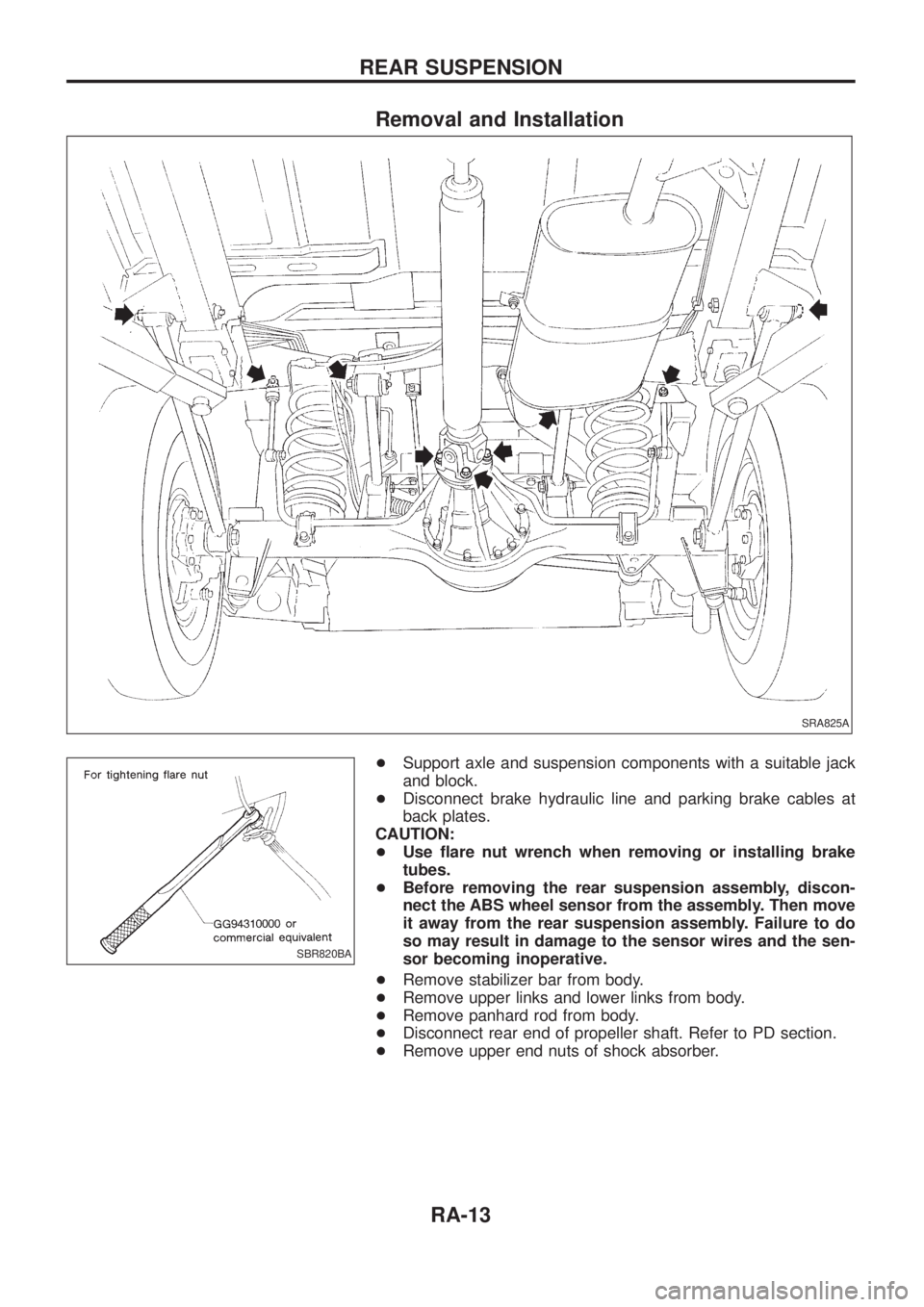

Removal and Installation

+Support axle and suspension components with a suitable jack

and block.

+Disconnect brake hydraulic line and parking brake cables at

back plates.

CAUTION:

+Use ¯are nut wrench when removing or installing brake

tubes.

+Before removing the rear suspension assembly, discon-

nect the ABS wheel sensor from the assembly. Then move

it away from the rear suspension assembly. Failure to do

so may result in damage to the sensor wires and the sen-

sor becoming inoperative.

+Remove stabilizer bar from body.

+Remove upper links and lower links from body.

+Remove panhard rod from body.

+Disconnect rear end of propeller shaft. Refer to PD section.

+Remove upper end nuts of shock absorber.

SRA825A

SBR820BA

REAR SUSPENSION

RA-13

Page 1175 of 1226

Bleeding Hydraulic System

1. Raise front end of vehicle until wheels are clear of the ground.

2. Add ¯uid into oil tank to speci®ed level. Then, quickly turn steer-

ing wheel fully to right and left and lightly touch steering stop-

pers.

Repeat steering wheel operation until ¯uid level no longer

decreases.

3. Start engine.

Repeat step 2 above.

+Incomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

a. Air bubbles in reservoir tank

b. Clicking noise in oil pump

c. Excessive buzzing in oil pump

Fluid noise may occur in the valve or oil pump. This is common

when the vehicle is stationary or while turning steering wheel

slowly. This does not affect performance or durability of the system.

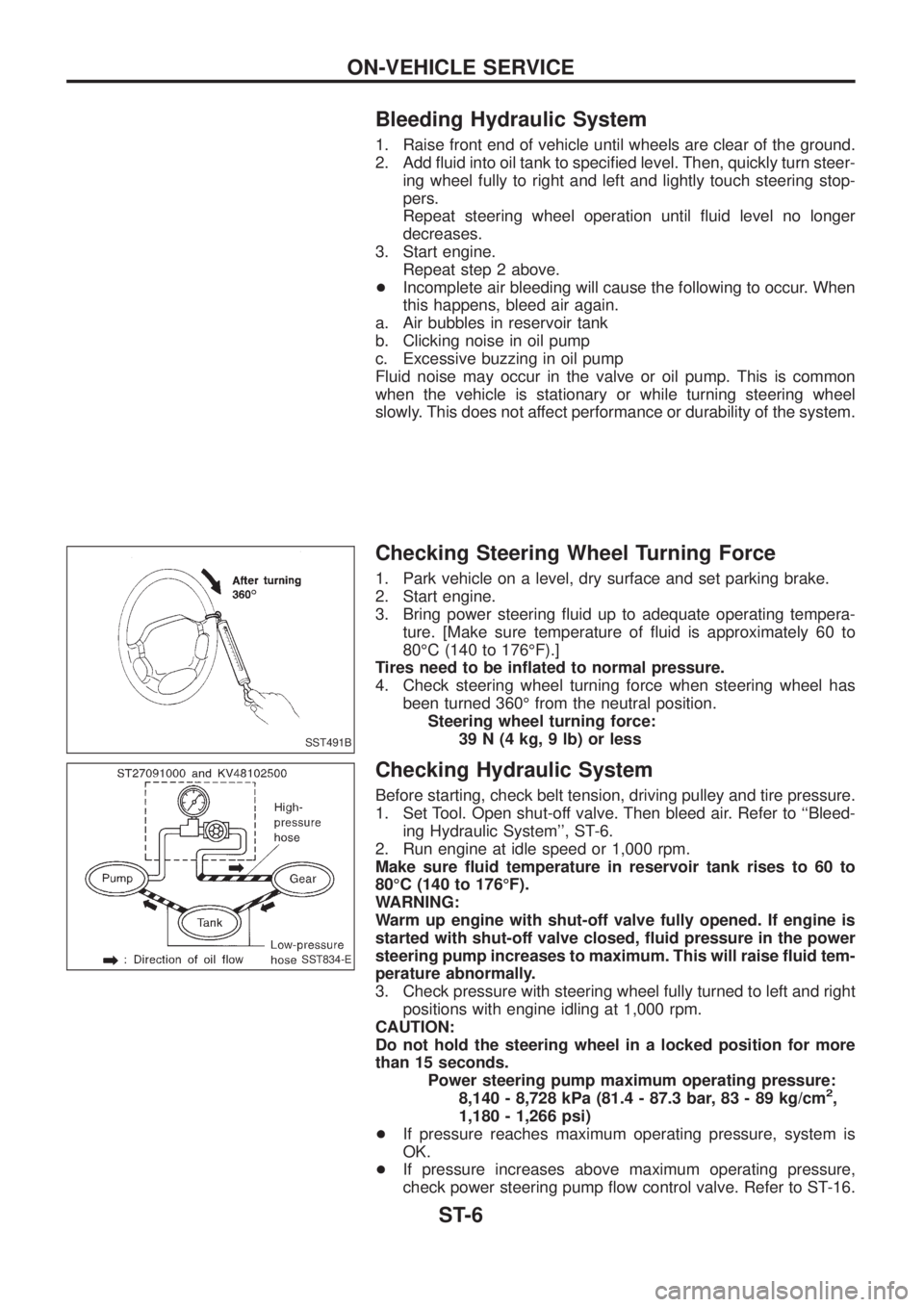

Checking Steering Wheel Turning Force

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering ¯uid up to adequate operating tempera-

ture. [Make sure temperature of ¯uid is approximately 60 to

80ÉC (140 to 176ÉF).]

Tires need to be in¯ated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360É from the neutral position.

Steering wheel turning force:

39 N (4 kg, 9 lb) or less

Checking Hydraulic System

Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve. Then bleed air. Refer to ``Bleed-

ing Hydraulic System'', ST-6.

2. Run engine at idle speed or 1,000 rpm.

Make sure ¯uid temperature in reservoir tank rises to 60 to

80ÉC (140 to 176ÉF).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, ¯uid pressure in the power

steering pump increases to maximum. This will raise ¯uid tem-

perature abnormally.

3. Check pressure with steering wheel fully turned to left and right

positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

Power steering pump maximum operating pressure:

8,140 - 8,728 kPa (81.4 - 87.3 bar, 83 - 89 kg/cm

2,

1,180 - 1,266 psi)

+If pressure reaches maximum operating pressure, system is

OK.

+If pressure increases above maximum operating pressure,

check power steering pump ¯ow control valve. Refer to ST-16.

SST491B

SST834-E

ON-VEHICLE SERVICE

ST-6