brake pads NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 6 of 1226

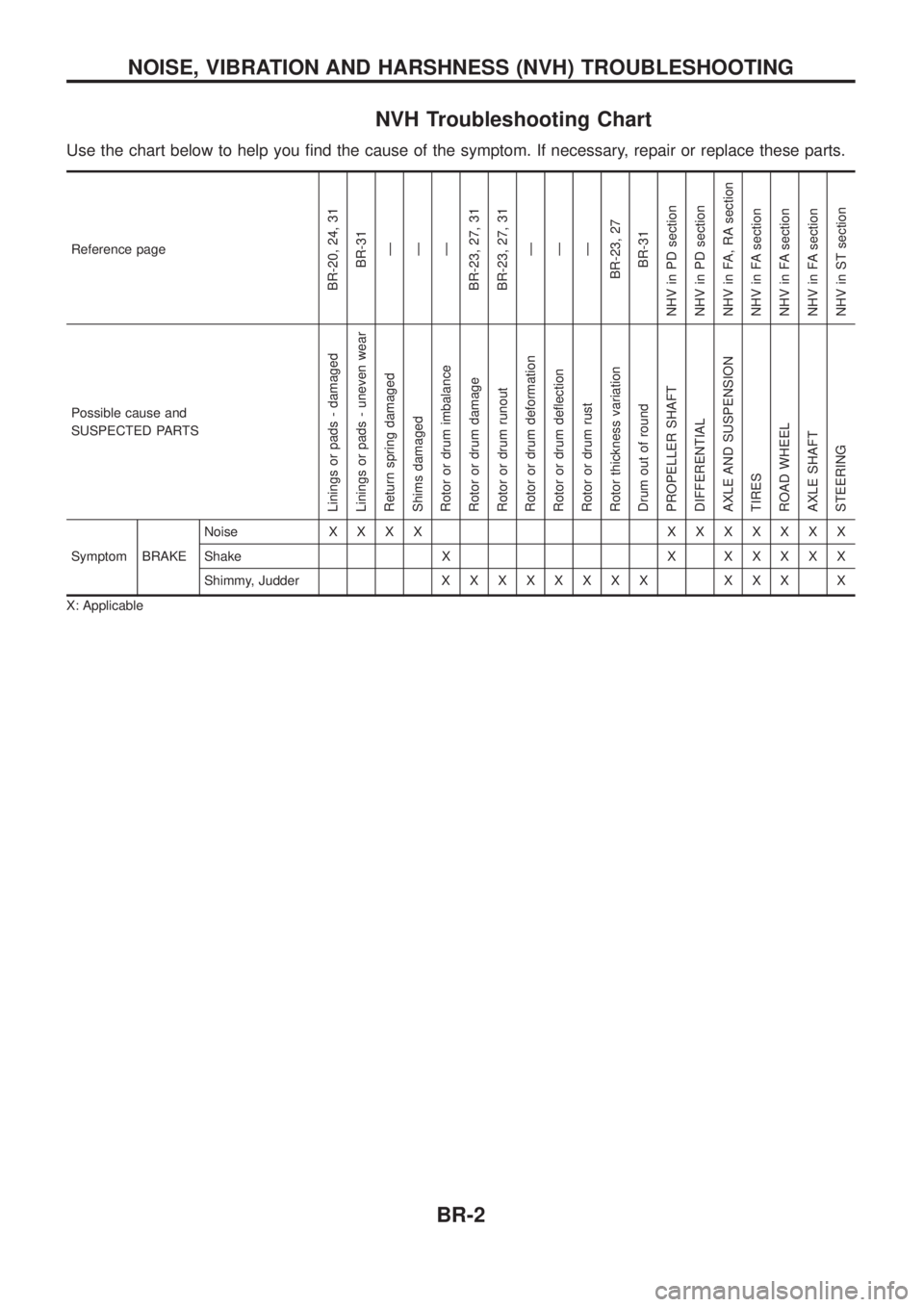

NVH Troubleshooting Chart

Use the chart below to help you ®nd the cause of the symptom. If necessary, repair or replace these parts.

Reference page

BR-20, 24, 31BR-31Ð

Ð

Ð

BR-23, 27, 31

BR-23, 27, 31 Ð

Ð

Ð

BR-23, 27 BR-31

NHV in PD section

NHV in PD section

NHV in FA, RA section

NHV in FA section

NHV in FA section

NHV in FA section

NHV in ST section

Possible cause and

SUSPECTED PARTS

Linings or pads - damaged

Linings or pads - uneven wear

Return spring damaged

Shims damaged

Rotor or drum imbalance

Rotor or drum damage

Rotor or drum runout

Rotor or drum deformation

Rotor or drum de¯ection

Rotor or drum rust

Rotor thickness variation

Drum out of round

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

AXLE SHAFT

STEERING

Symptom BRAKE Noise

XXXX XXXXXXX

Shake X X X X X X X

Shimmy, Judder X X XXXXXX XXX X

X: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

BR-2

Page 25 of 1226

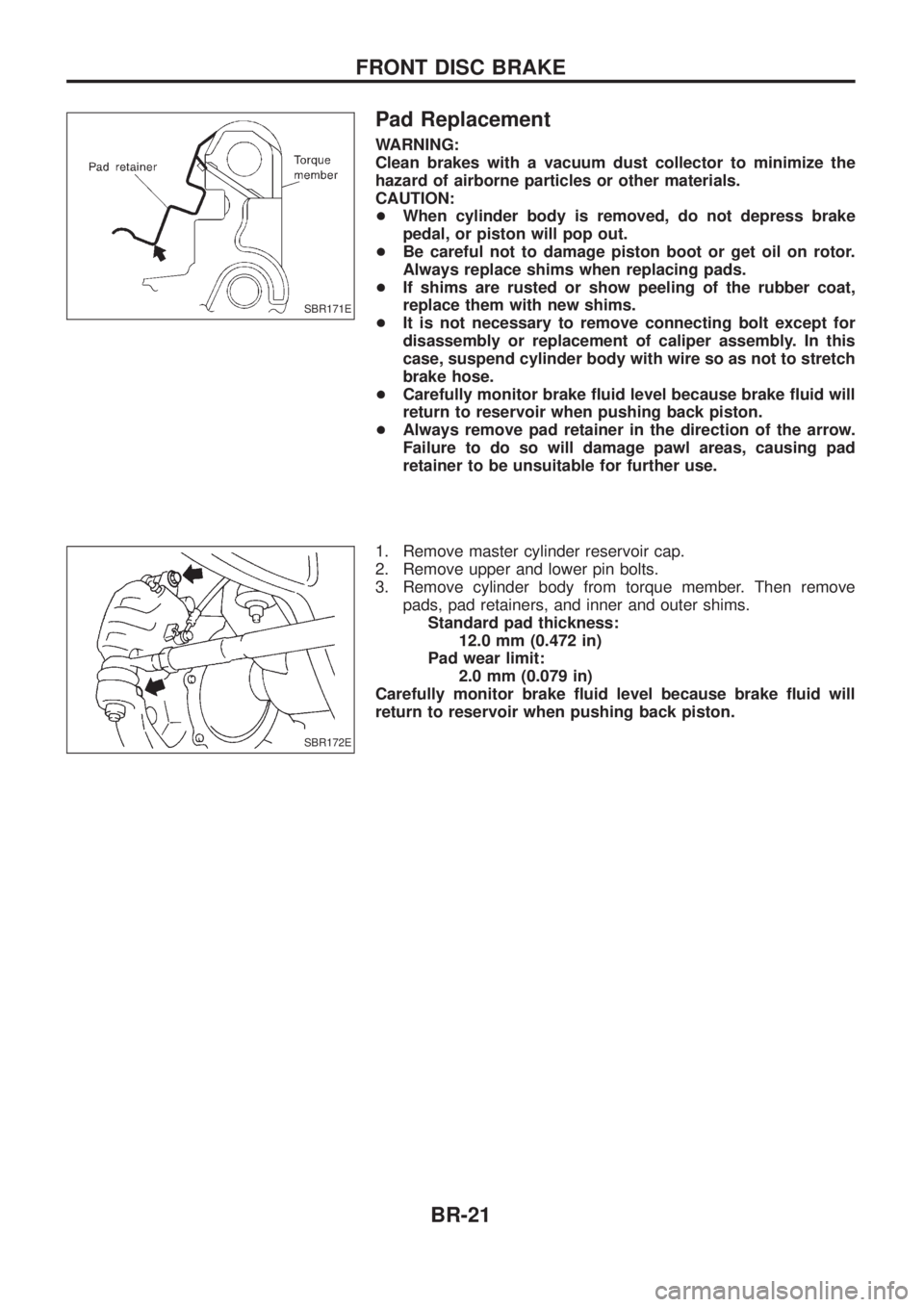

Pad Replacement

WARNING:

Clean brakes with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

CAUTION:

+When cylinder body is removed, do not depress brake

pedal, or piston will pop out.

+ Be careful not to damage piston boot or get oil on rotor.

Always replace shims when replacing pads.

+ If shims are rusted or show peeling of the rubber coat,

replace them with new shims.

+ It is not necessary to remove connecting bolt except for

disassembly or replacement of caliper assembly. In this

case, suspend cylinder body with wire so as not to stretch

brake hose.

+ Carefully monitor brake ¯uid level because brake ¯uid will

return to reservoir when pushing back piston.

+ Always remove pad retainer in the direction of the arrow.

Failure to do so will damage pawl areas, causing pad

retainer to be unsuitable for further use.

1. Remove master cylinder reservoir cap.

2. Remove upper and lower pin bolts.

3. Remove cylinder body from torque member. Then remove pads, pad retainers, and inner and outer shims.Standard pad thickness: 12.0 mm (0.472 in)

Pad wear limit: 2.0 mm (0.079 in)

Carefully monitor brake ¯uid level because brake ¯uid will

return to reservoir when pushing back piston.

SBR171E

SBR172E

FRONT DISC BRAKE

BR-21

Page 27 of 1226

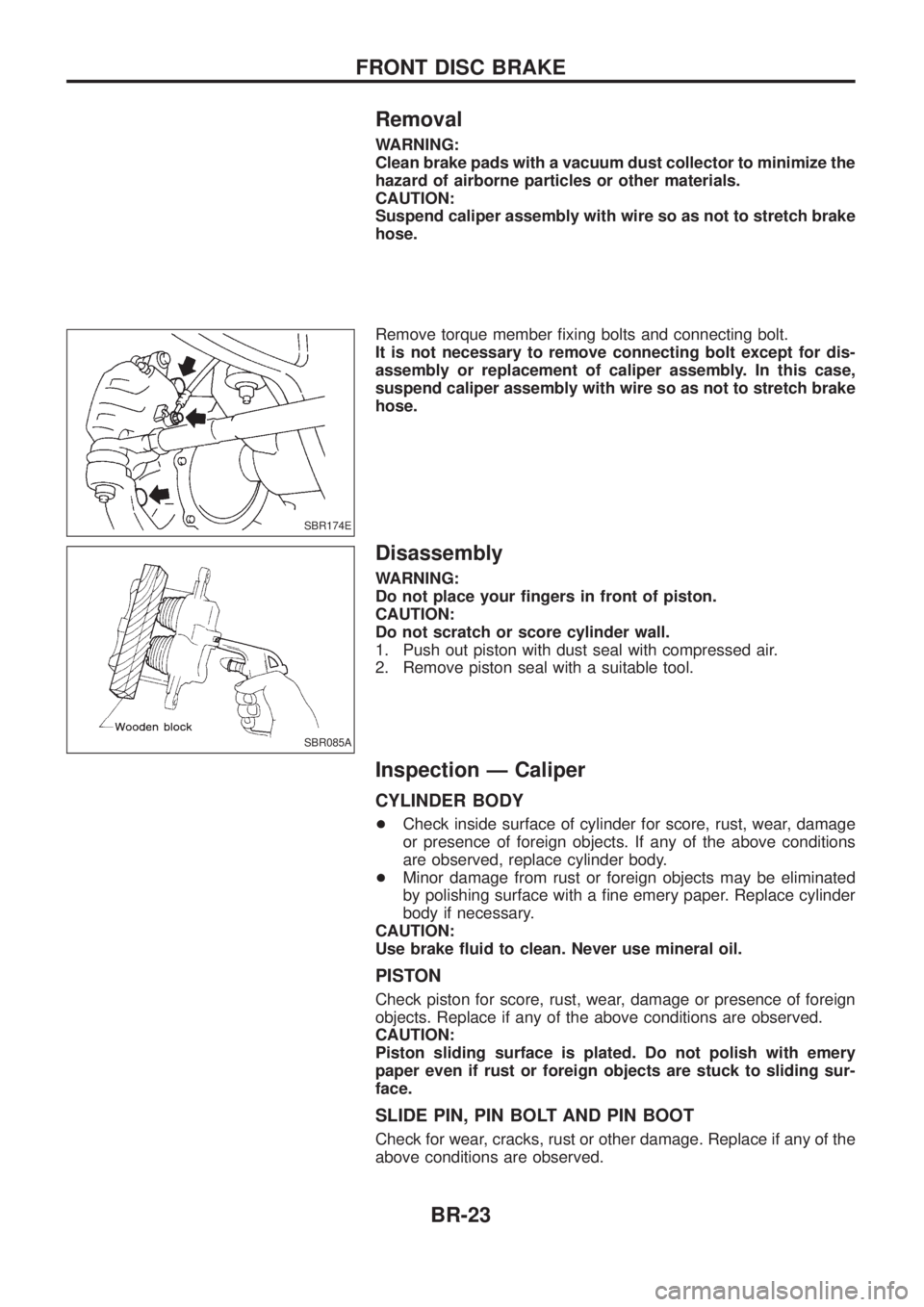

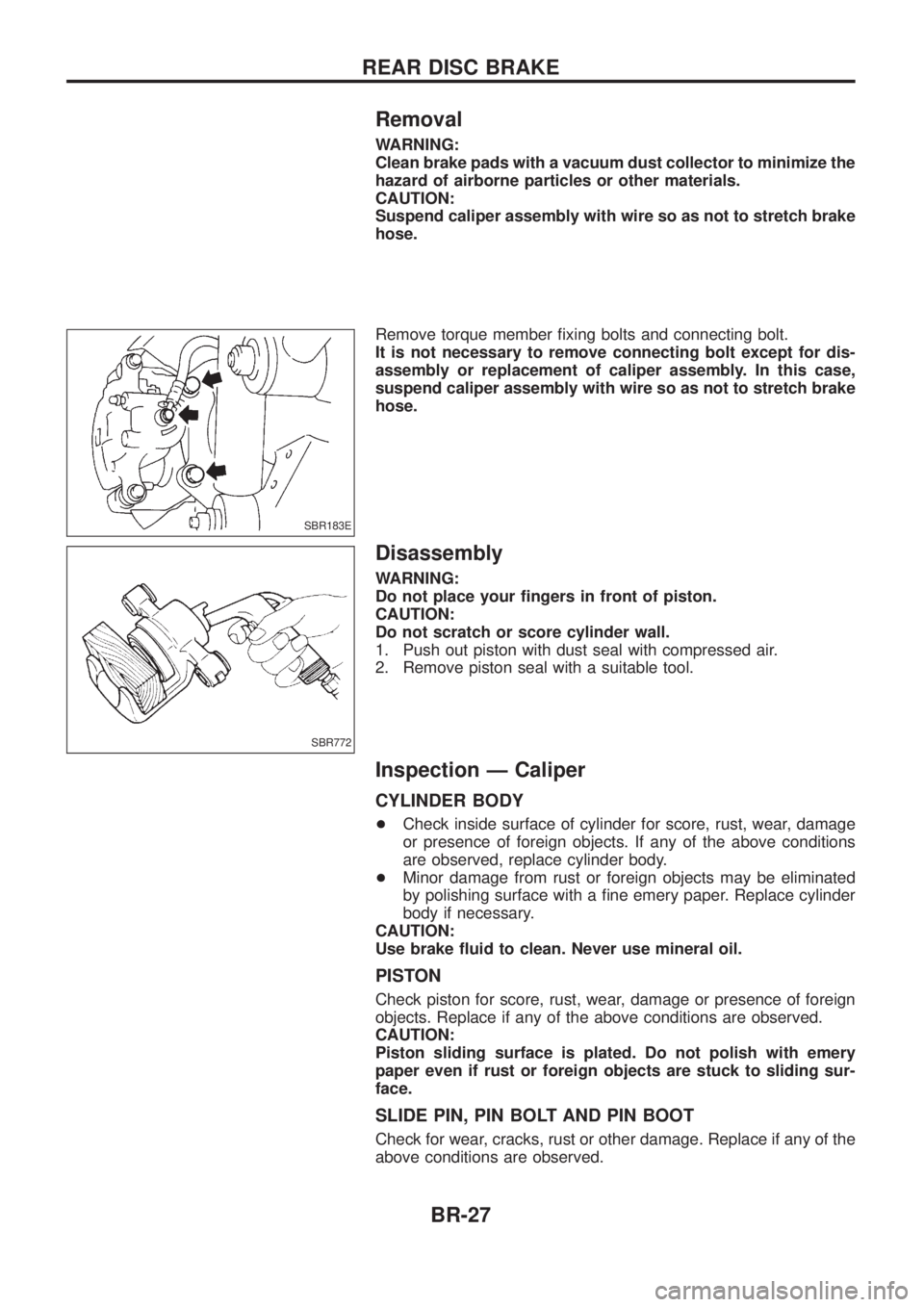

Removal

WARNING:

Clean brake pads with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

CAUTION:

Suspend caliper assembly with wire so as not to stretch brake

hose.

Remove torque member ®xing bolts and connecting bolt.

It is not necessary to remove connecting bolt except for dis-

assembly or replacement of caliper assembly. In this case,

suspend caliper assembly with wire so as not to stretch brake

hose.

Disassembly

WARNING:

Do not place your ®ngers in front of piston.

CAUTION:

Do not scratch or score cylinder wall.

1. Push out piston with dust seal with compressed air.

2. Remove piston seal with a suitable tool.

Inspection Ð Caliper

CYLINDER BODY

+Check inside surface of cylinder for score, rust, wear, damage

or presence of foreign objects. If any of the above conditions

are observed, replace cylinder body.

+ Minor damage from rust or foreign objects may be eliminated

by polishing surface with a ®ne emery paper. Replace cylinder

body if necessary.

CAUTION:

Use brake ¯uid to clean. Never use mineral oil.

PISTON

Check piston for score, rust, wear, damage or presence of foreign

objects. Replace if any of the above conditions are observed.

CAUTION:

Piston sliding surface is plated. Do not polish with emery

paper even if rust or foreign objects are stuck to sliding sur-

face.

SLIDE PIN, PIN BOLT AND PIN BOOT

Check for wear, cracks, rust or other damage. Replace if any of the

above conditions are observed.

SBR174E

SBR085A

FRONT DISC BRAKE

BR-23

Page 29 of 1226

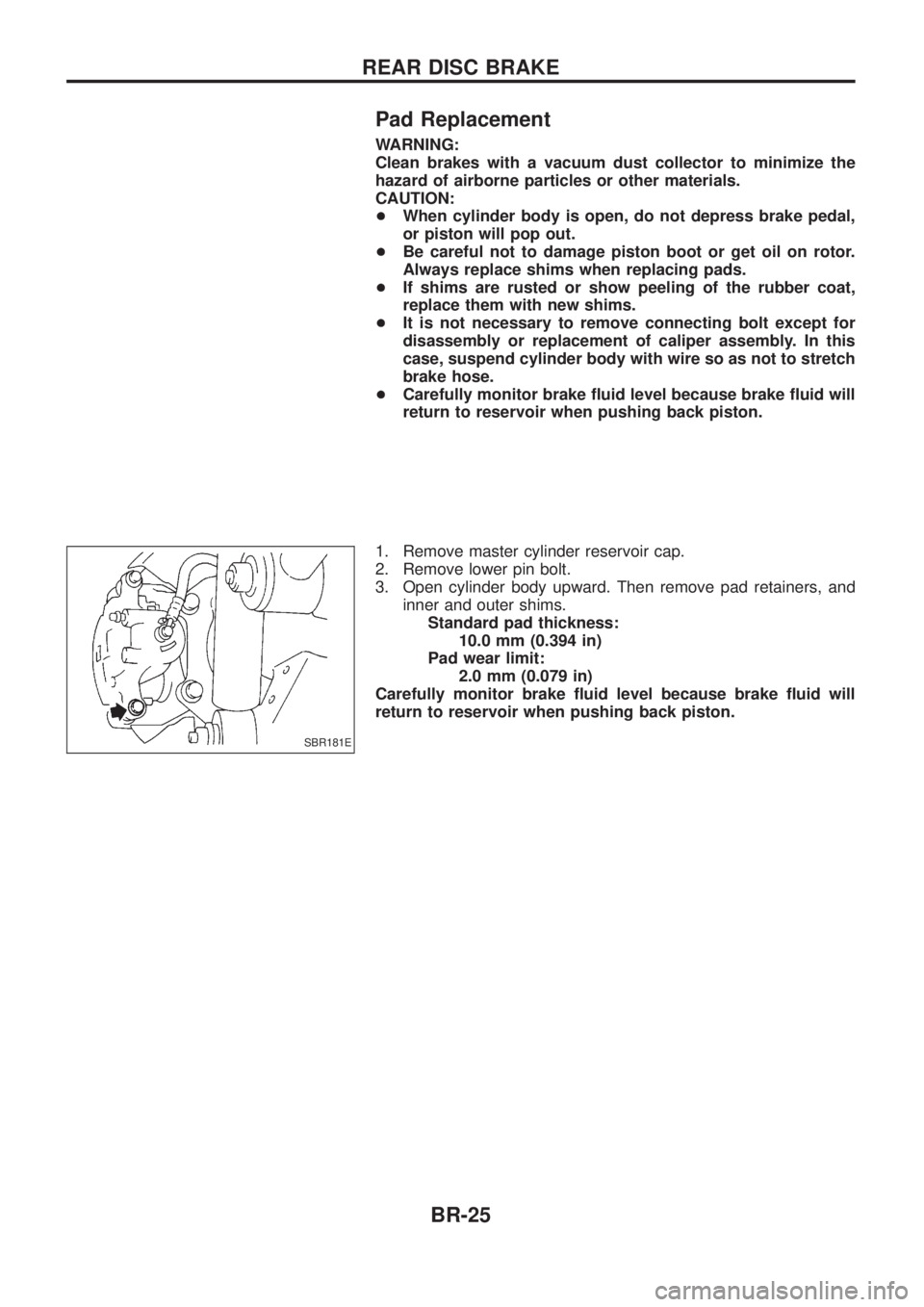

Pad Replacement

WARNING:

Clean brakes with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

CAUTION:

+When cylinder body is open, do not depress brake pedal,

or piston will pop out.

+ Be careful not to damage piston boot or get oil on rotor.

Always replace shims when replacing pads.

+ If shims are rusted or show peeling of the rubber coat,

replace them with new shims.

+ It is not necessary to remove connecting bolt except for

disassembly or replacement of caliper assembly. In this

case, suspend cylinder body with wire so as not to stretch

brake hose.

+ Carefully monitor brake ¯uid level because brake ¯uid will

return to reservoir when pushing back piston.

1. Remove master cylinder reservoir cap.

2. Remove lower pin bolt.

3. Open cylinder body upward. Then remove pad retainers, and inner and outer shims.Standard pad thickness: 10.0 mm (0.394 in)

Pad wear limit: 2.0 mm (0.079 in)

Carefully monitor brake ¯uid level because brake ¯uid will

return to reservoir when pushing back piston.

SBR181E

REAR DISC BRAKE

BR-25

Page 31 of 1226

Removal

WARNING:

Clean brake pads with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

CAUTION:

Suspend caliper assembly with wire so as not to stretch brake

hose.

Remove torque member ®xing bolts and connecting bolt.

It is not necessary to remove connecting bolt except for dis-

assembly or replacement of caliper assembly. In this case,

suspend caliper assembly with wire so as not to stretch brake

hose.

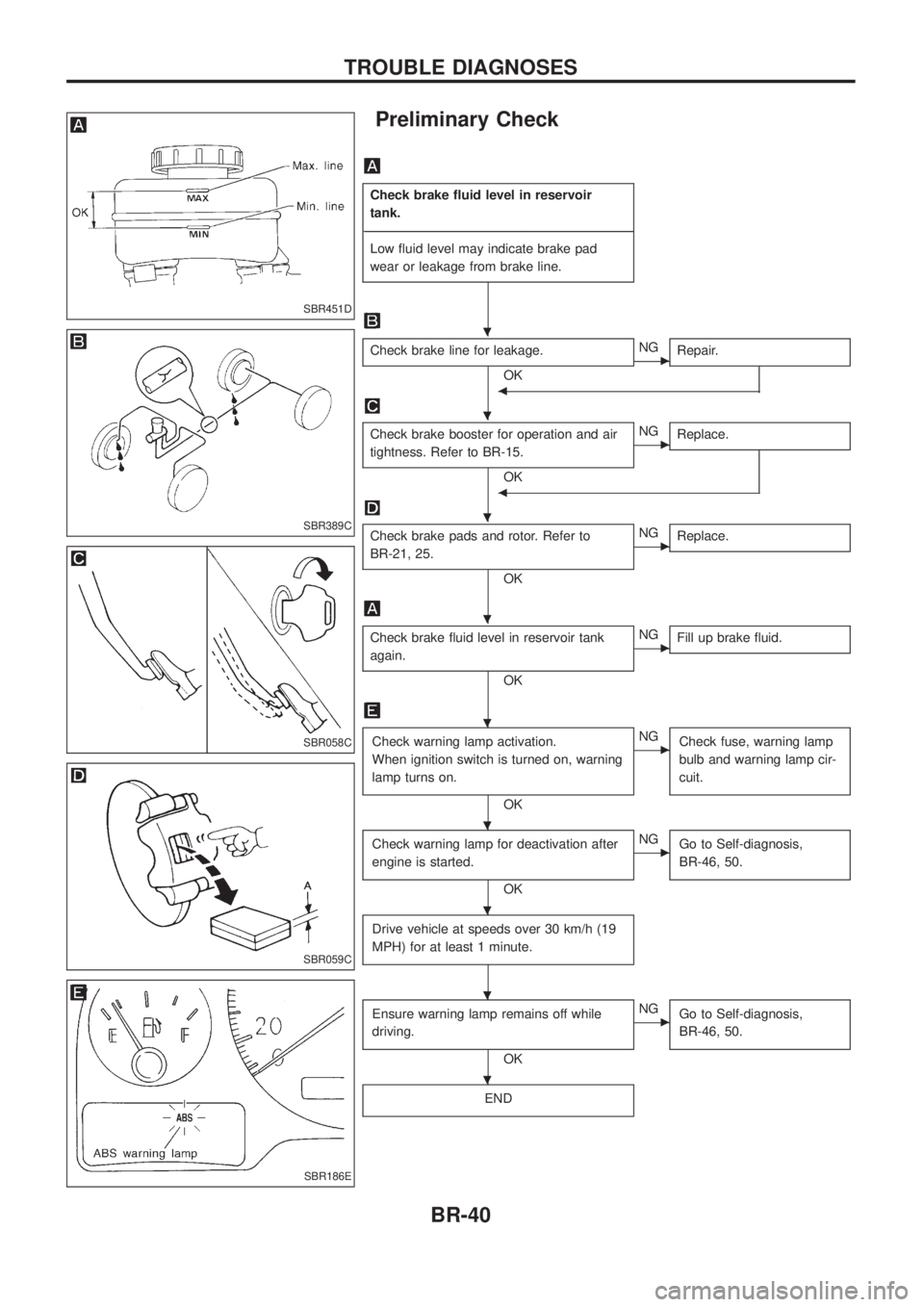

Disassembly

WARNING:

Do not place your ®ngers in front of piston.

CAUTION:

Do not scratch or score cylinder wall.

1. Push out piston with dust seal with compressed air.

2. Remove piston seal with a suitable tool.

Inspection Ð Caliper

CYLINDER BODY

+Check inside surface of cylinder for score, rust, wear, damage

or presence of foreign objects. If any of the above conditions

are observed, replace cylinder body.

+ Minor damage from rust or foreign objects may be eliminated

by polishing surface with a ®ne emery paper. Replace cylinder

body if necessary.

CAUTION:

Use brake ¯uid to clean. Never use mineral oil.

PISTON

Check piston for score, rust, wear, damage or presence of foreign

objects. Replace if any of the above conditions are observed.

CAUTION:

Piston sliding surface is plated. Do not polish with emery

paper even if rust or foreign objects are stuck to sliding sur-

face.

SLIDE PIN, PIN BOLT AND PIN BOOT

Check for wear, cracks, rust or other damage. Replace if any of the

above conditions are observed.

SBR183E

SBR772

REAR DISC BRAKE

BR-27

Page 44 of 1226

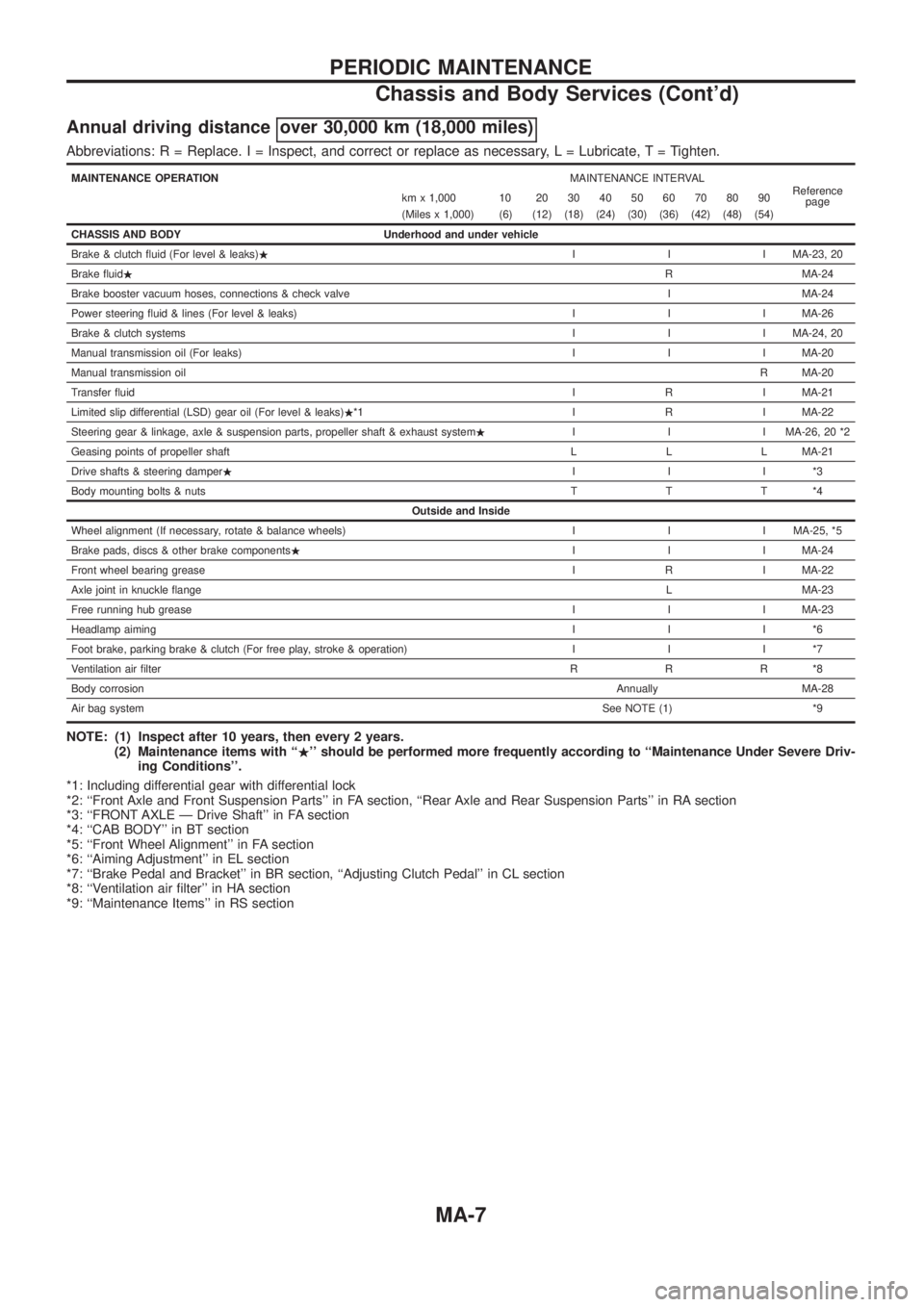

Preliminary Check

Check brake ¯uid level in reservoir

tank.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Low ¯uid level may indicate brake pad

wear or leakage from brake line.

Check brake line for leakage.

OKcNG Repair.

b

Check brake booster for operation and air

tightness. Refer to BR-15.

OK

cNGReplace.

b

Check brake pads and rotor. Refer to

BR-21, 25.

OK

cNGReplace.

Check brake ¯uid level in reservoir tank

again.

OK

cNGFill up brake ¯uid.

Check warning lamp activation.

When ignition switch is turned on, warning

lamp turns on.

OK

cNG

Check fuse, warning lamp

bulb and warning lamp cir-

cuit.

Check warning lamp for deactivation after

engine is started.

OK

cNGGo to Self-diagnosis,

BR-46, 50.

Drive vehicle at speeds over 30 km/h (19

MPH) for at least 1 minute.

Ensure warning lamp remains off while

driving.

OK

cNGGo to Self-diagnosis,

BR-46, 50.

END

SBR451D

SBR389C

SBR058C

SBR059C

SBR186E

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSES

BR-40

Page 983 of 1226

![NISSAN PATROL 2006 Service Manual Chassis and Body Services

Annual driving distance below 30,000 km (18,000 miles)

Abbreviations: R = Replace, I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

[ ]: At the spec NISSAN PATROL 2006 Service Manual Chassis and Body Services

Annual driving distance below 30,000 km (18,000 miles)

Abbreviations: R = Replace, I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

[ ]: At the spec](/img/5/57368/w960_57368-982.png)

Chassis and Body Services

Annual driving distance below 30,000 km (18,000 miles)

Abbreviations: R = Replace, I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

[ ]: At the speci®ed mileage only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform either at number of kilometers (miles) or months,

whichever comes ®rst.km x 1,000 10 20 30 40 50 60 70 80 90

(Miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54)

Months 6 12 18 24 30 36 42 48 54

CHASSIS AND BODY Underhood and under vehicle

Brake & clutch ¯uid (For level & leaks).I I I I MA-23, 20

Brake ¯uid.R R MA-24

Brake booster vacuum hoses, connections & check valve I I MA-24

Power steering ¯uid & lines (For level & leaks) I I I I MA-26

Brake & clutch systemsI I I I MA-24, 20

Manual transmission oil (For leaks) I I I I MA-20

Manual transmission oil[R] MA-20

Transfer ¯uidI I R I MA-21

Limited slip differential (LSD) gear oil (For level & leaks).*1 I I R I MA-22

Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system.I I I I MA-26, 20 *2

Greasing points of propeller shaftLLLLMA-21

Drive shafts & steering damper.IIII *3

Body mounting bolts & nutsTTTT *4

Outside and Inside

Wheel alignment (If necessary, rotate & balance wheels) I I I I MA-25, *5

Brake pads, discs & other brake components.I I I I MA-24

Front wheel bearing grease I R I R MA-22

Axle joint in knuckle ¯angeL L MA-23

Free running hub greaseI I I I MA-23

Headlamp aimingIIII *6

Foot brake, parking brake & clutch (For free play, stroke & operation) I I I I *7

Ventilation air ®lterRRR*8

Body corrosionAnnually MA-28

Air bag systemSee NOTE (1) *9

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) Maintenance items with ``.'' should be performed more frequently according to ``Maintenance Under Severe Driv-

ing Conditions''.

*1: Including differential gear with differential lock

*2: ``Front Axle and Front Suspension Parts'' in FA section, ``Rear Axle and Rear Suspension Parts'' in RA section

*3: ``FRONT AXLE Ð Drive Shaft'' in FA section

*4: ``CAB BODY'' in BT section

*5: ``Front Wheel Alignment'' in FA section

*6: ``Aiming Adjustment'' in EL section

*7: ``Brake Pedal and Bracket'' in BR section, ``Adjusting Clutch Pedal'' in CL section

*8: ``Ventilation air ®lter'' in HA section

*9: ``Maintenance Items'' in RS section

PERIODIC MAINTENANCE

MA-6

Page 984 of 1226

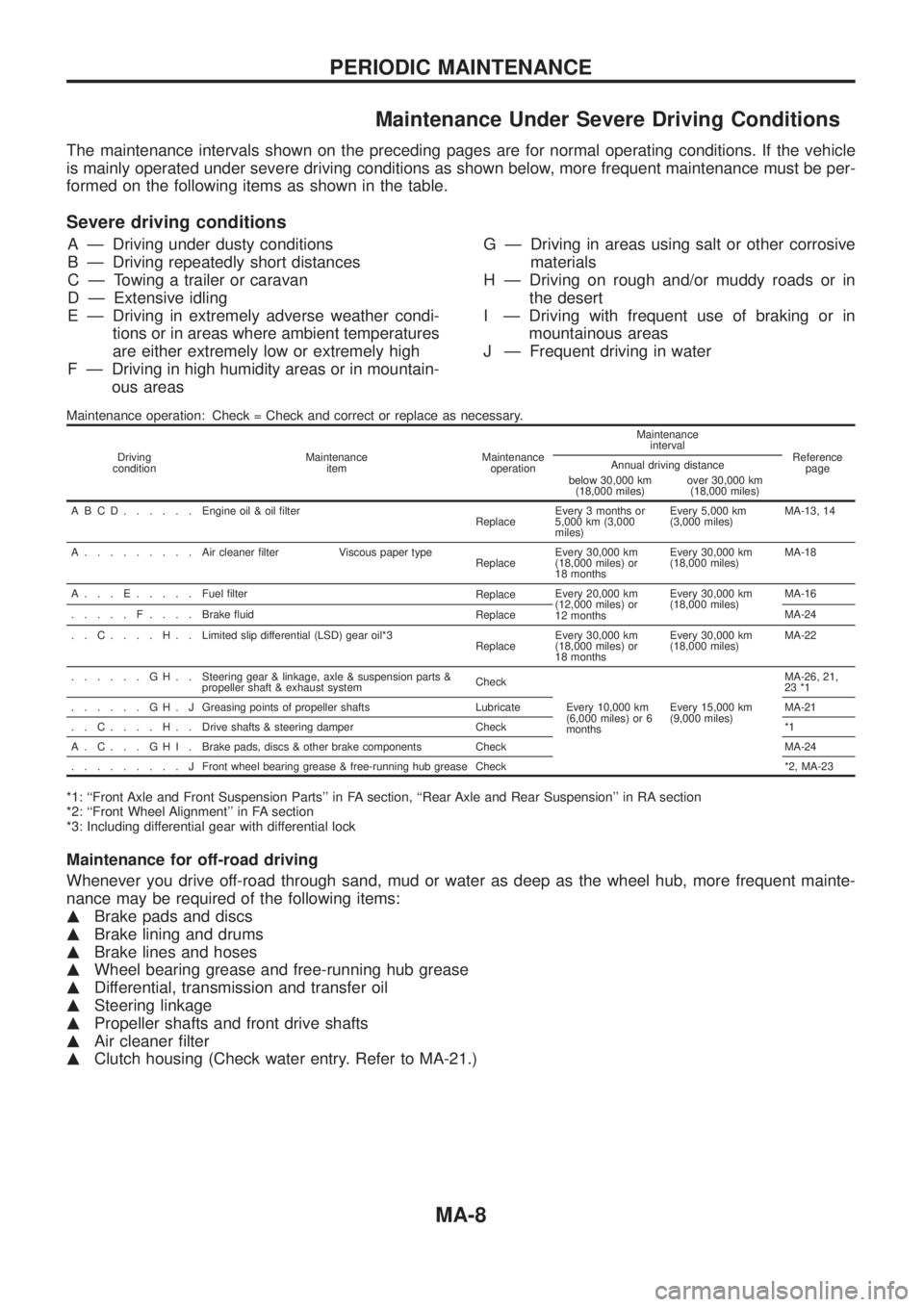

Annual driving distance over 30,000 km (18,000 miles)

Abbreviations: R = Replace. I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page km x 1,000 10 20 30 40 50 60 70 80 90

(Miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54)

CHASSIS AND BODY Underhood and under vehicle

Brake & clutch ¯uid (For level & leaks).I I I MA-23, 20

Brake ¯uid.R MA-24

Brake booster vacuum hoses, connections & check valve I MA-24

Power steering ¯uid & lines (For level & leaks) I I I MA-26

Brake & clutch systemsI I I MA-24, 20

Manual transmission oil (For leaks) I I I MA-20

Manual transmission oilR MA-20

Transfer ¯uidI R I MA-21

Limited slip differential (LSD) gear oil (For level & leaks).*1 I R I MA-22

Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system.I I I MA-26, 20 *2

Geasing points of propeller shaft L L L MA-21

Drive shafts & steering damper.III*3

Body mounting bolts & nutsTTT*4

Outside and Inside

Wheel alignment (If necessary, rotate & balance wheels) I I I MA-25, *5

Brake pads, discs & other brake components.I I I MA-24

Front wheel bearing greaseI R I MA-22

Axle joint in knuckle ¯angeL MA-23

Free running hub greaseI I I MA-23

Headlamp aimingIII*6

Foot brake, parking brake & clutch (For free play, stroke & operation) I I I *7

Ventilation air ®lterRRR*8

Body corrosionAnnually MA-28

Air bag systemSee NOTE (1) *9

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) Maintenance items with ``.'' should be performed more frequently according to ``Maintenance Under Severe Driv-

ing Conditions''.

*1: Including differential gear with differential lock

*2: ``Front Axle and Front Suspension Parts'' in FA section, ``Rear Axle and Rear Suspension Parts'' in RA section

*3: ``FRONT AXLE Ð Drive Shaft'' in FA section

*4: ``CAB BODY'' in BT section

*5: ``Front Wheel Alignment'' in FA section

*6: ``Aiming Adjustment'' in EL section

*7: ``Brake Pedal and Bracket'' in BR section, ``Adjusting Clutch Pedal'' in CL section

*8: ``Ventilation air ®lter'' in HA section

*9: ``Maintenance Items'' in RS section

PERIODIC MAINTENANCE

Chassis and Body Services (Cont'd)

MA-7

Page 985 of 1226

Maintenance Under Severe Driving Conditions

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather condi-

tions or in areas where ambient temperatures

are either extremely low or extremely high

F Ð Driving in high humidity areas or in mountain-

ous areasG Ð Driving in areas using salt or other corrosive

materials

H Ð Driving on rough and/or muddy roads or in

the desert

I Ð Driving with frequent use of braking or in

mountainous areas

J Ð Frequent driving in water

Maintenance operation: Check = Check and correct or replace as necessary.

Driving

conditionMaintenance

itemMaintenance

operationMaintenance

interval

Reference

page Annual driving distance

below 30,000 km

(18,000 miles)over 30,000 km

(18,000 miles)

ABCD......Engine oil & oil ®lter

ReplaceEvery 3 months or

5,000 km (3,000

miles)Every 5,000 km

(3,000 miles)MA-13, 14

A.........Aircleaner ®lter Viscous paper type

ReplaceEvery 30,000 km

(18,000 miles) or

18 monthsEvery 30,000 km

(18,000 miles)MA-18

A...E.....Fuel ®lter

ReplaceEvery 20,000 km

(12,000 miles) or

12 monthsEvery 30,000 km

(18,000 miles)MA-16

.....F....Brake ¯uid

ReplaceMA-24

..C....H..Limited slip differential (LSD) gear oil*3

ReplaceEvery 30,000 km

(18,000 miles) or

18 monthsEvery 30,000 km

(18,000 miles)MA-22

......GH..Steering gear & linkage, axle & suspension parts &

propeller shaft & exhaust systemCheck

Every 10,000 km

(6,000 miles) or 6

monthsEvery 15,000 km

(9,000 miles)MA-26, 21,

23 *1

......GH.JGreasing points of propeller shafts Lubricate MA-21

..C....H..Drive shafts & steering damper Check *1

A.C...GHI.Brake pads, discs & other brake components Check MA-24

.........JFront wheel bearing grease & free-running hub grease Check *2, MA-23

*1: ``Front Axle and Front Suspension Parts'' in FA section, ``Rear Axle and Rear Suspension'' in RA section

*2: ``Front Wheel Alignment'' in FA section

*3: Including differential gear with differential lock

Maintenance for off-road driving

Whenever you drive off-road through sand, mud or water as deep as the wheel hub, more frequent mainte-

nance may be required of the following items:

mBrake pads and discs

mBrake lining and drums

mBrake lines and hoses

mWheel bearing grease and free-running hub grease

mDifferential, transmission and transfer oil

mSteering linkage

mPropeller shafts and front drive shafts

mAir cleaner ®lter

mClutch housing (Check water entry. Refer to MA-21.)

PERIODIC MAINTENANCE

MA-8