wheel torque NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 5 of 1226

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''

The Supplemental Restraint System such as ``AIR BAG'' and ``SEAT BELT PRE-TENSIONER'' used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+ To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag in¯ation, all maintenance must be performed

by an authorized NISSAN dealer.

+ Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+ Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral Cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

Precautions for Brake System

+Use brake ¯uid ``DOT 3''.

+ Never reuse drained brake ¯uid.

+ Be careful not to splash brake ¯uid on painted areas; it

may cause paint damage. If brake ¯uid is splashed on

painted areas, wash it away with water immediately.

+ To clean master cylinder parts, disc brake caliper parts or

wheel cylinder parts, use clean brake ¯uid.

+ Never use mineral oils such as gasoline or kerosene. They

will ruin rubber parts of hydraulic system.

+ Use ¯are nut wrench when removing and installing brake

tubes.

+ Always torque brake lines when installing.

WARNING:

Clean brakes with a vacuum dust collector to minimize risk of

health hazard from powder caused by friction.

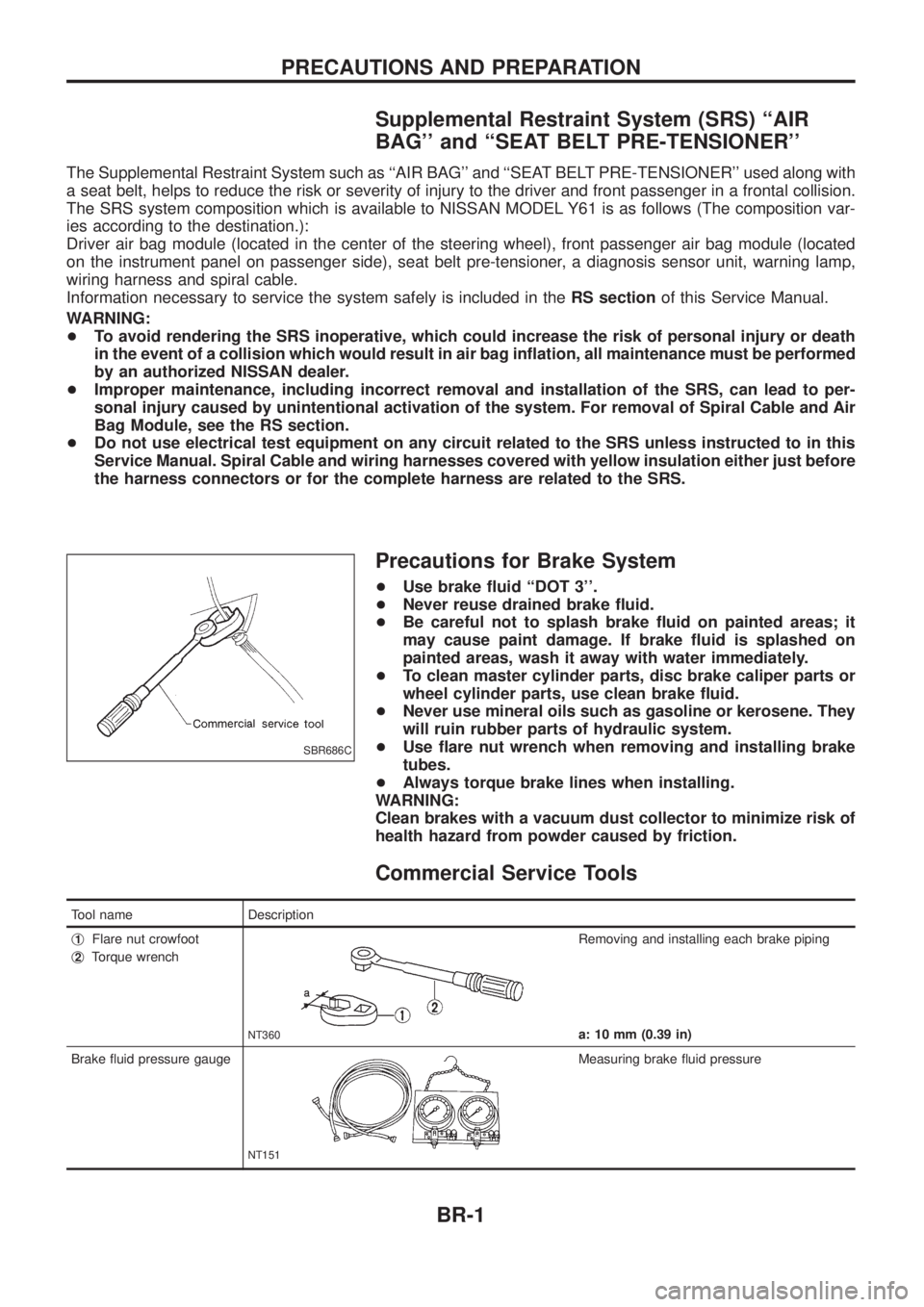

Commercial Service Tools

Tool name Description

j

1Flare nut crowfoot

j

2Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Brake ¯uid pressure gauge

NT151

Measuring brake ¯uid pressure

SBR686C

PRECAUTIONS AND PREPARATION

BR-1

Page 734 of 1226

Precautions

+When installing rubber parts, ®nal tightening must be car-

ried out under unladen condition* with tires on ground.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+Use ¯are nut wrench when removing and installing brake

tubes.

+After installing removed suspension parts, check wheel

alignment and adjust if necessary.

+Always torque brake lines when installing.

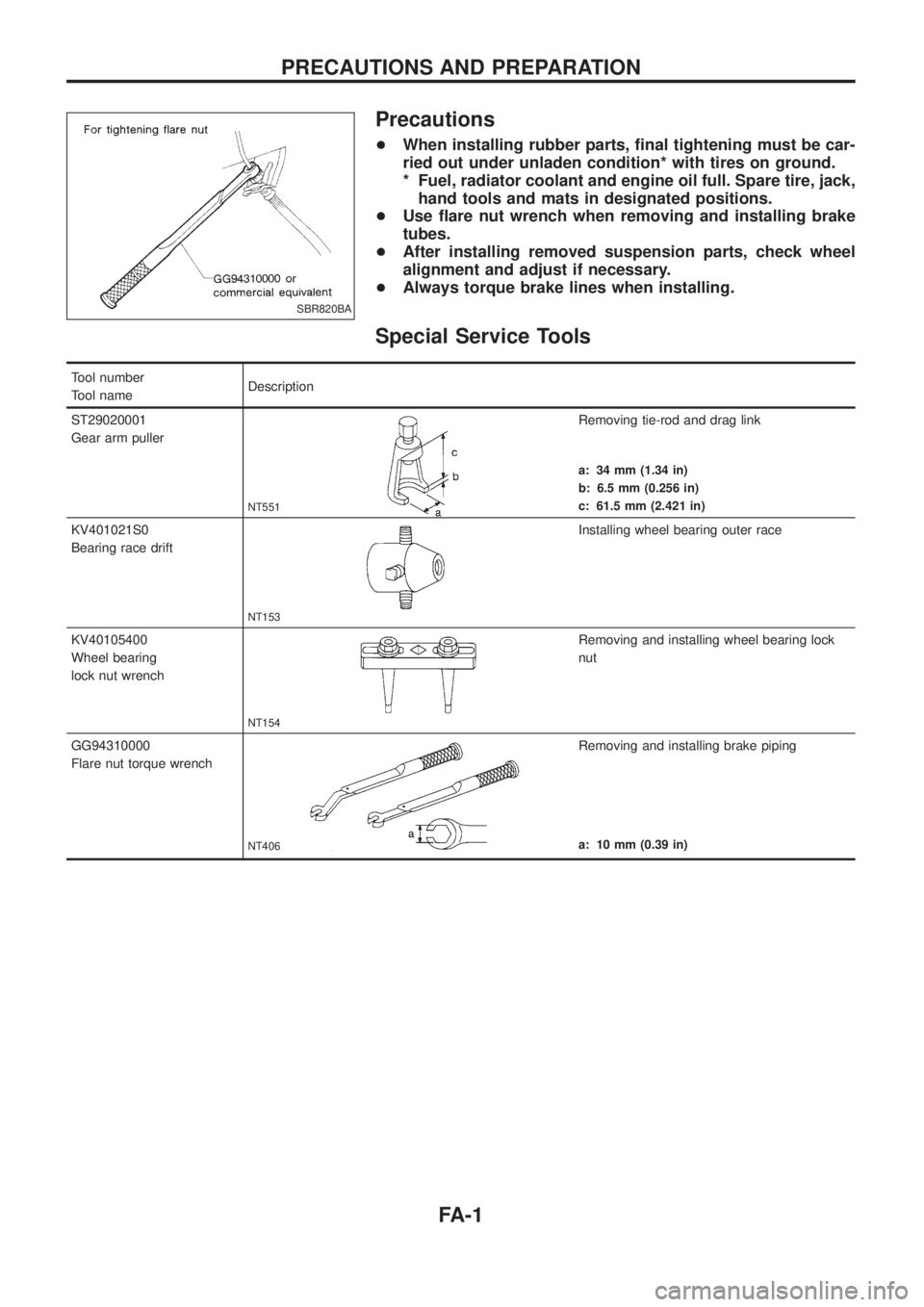

Special Service Tools

Tool number

Tool nameDescription

ST29020001

Gear arm puller

NT551

Removing tie-rod and drag link

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

KV401021S0

Bearing race drift

NT153

Installing wheel bearing outer race

KV40105400

Wheel bearing

lock nut wrench

NT154

Removing and installing wheel bearing lock

nut

GG94310000

Flare nut torque wrench

NT406

Removing and installing brake piping

a: 10 mm (0.39 in)

SBR820BA

PRECAUTIONS AND PREPARATION

FA-1

Page 738 of 1226

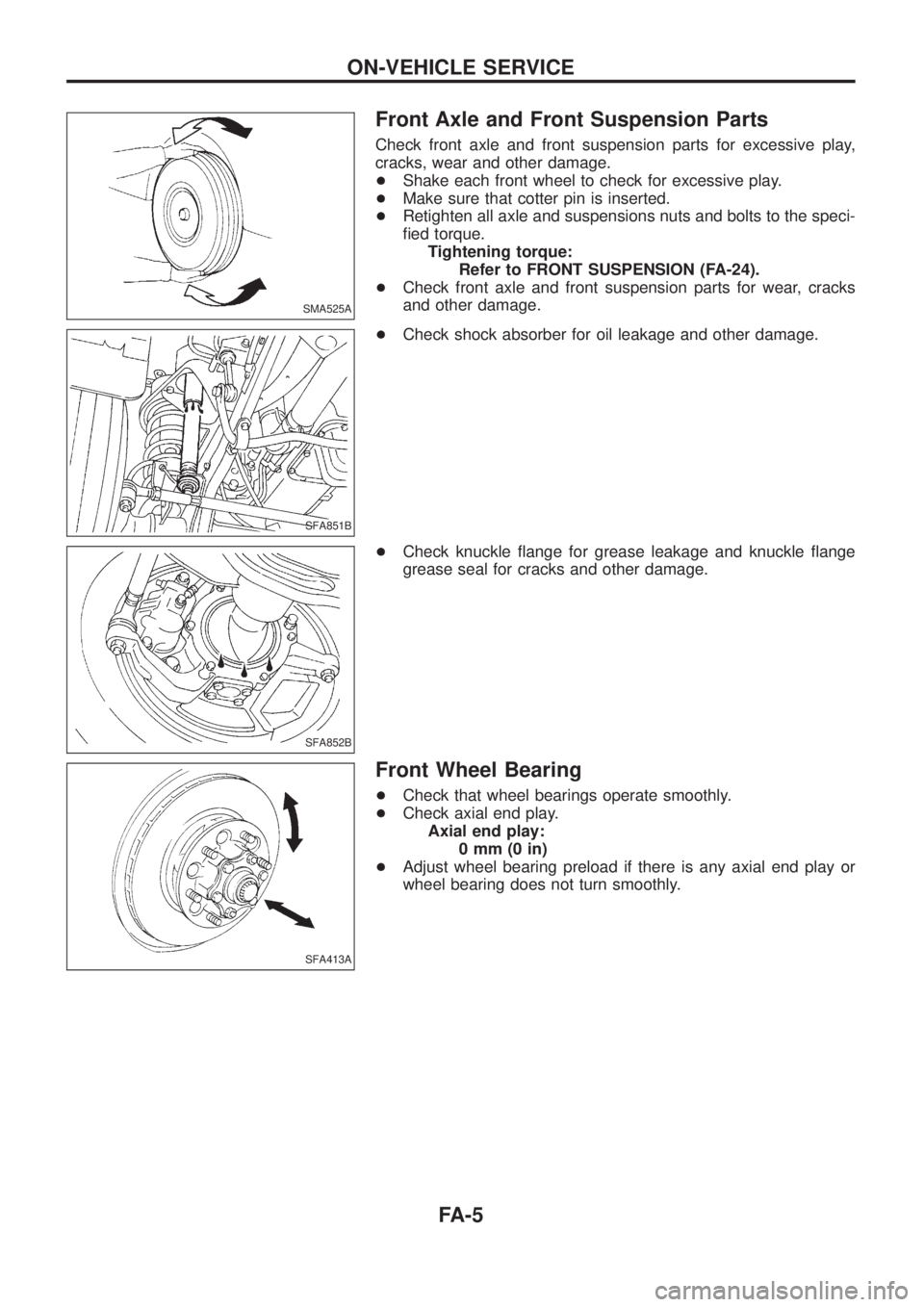

Front Axle and Front Suspension Parts

Check front axle and front suspension parts for excessive play,

cracks, wear and other damage.

+Shake each front wheel to check for excessive play.

+Make sure that cotter pin is inserted.

+Retighten all axle and suspensions nuts and bolts to the speci-

®ed torque.

Tightening torque:

Refer to FRONT SUSPENSION (FA-24).

+Check front axle and front suspension parts for wear, cracks

and other damage.

+Check shock absorber for oil leakage and other damage.

+Check knuckle ¯ange for grease leakage and knuckle ¯ange

grease seal for cracks and other damage.

Front Wheel Bearing

+Check that wheel bearings operate smoothly.

+Check axial end play.

Axial end play:

0mm(0in)

+Adjust wheel bearing preload if there is any axial end play or

wheel bearing does not turn smoothly.

SMA525A

SFA851B

SFA852B

SFA413A

ON-VEHICLE SERVICE

FA-5

Page 739 of 1226

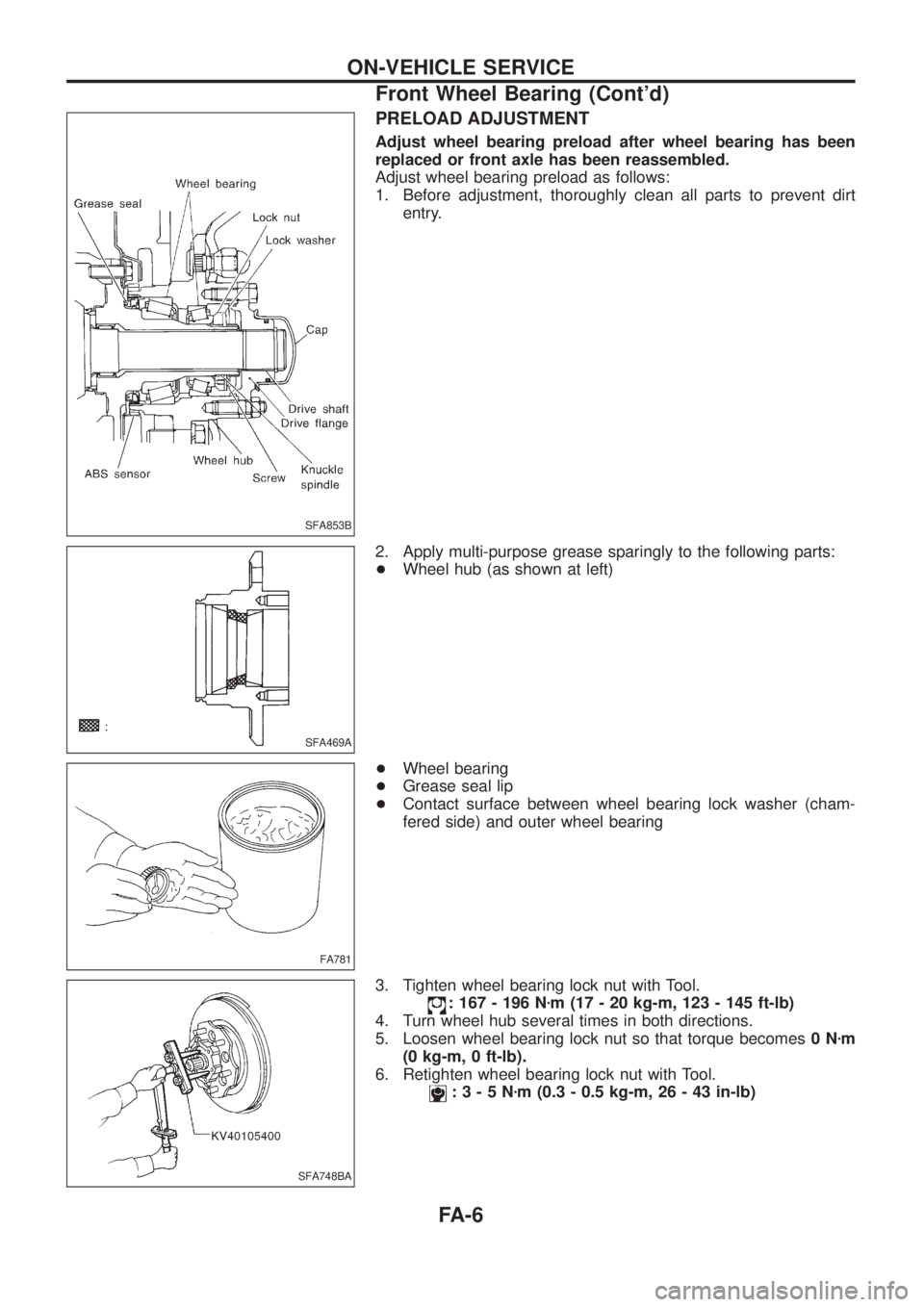

PRELOAD ADJUSTMENT

Adjust wheel bearing preload after wheel bearing has been

replaced or front axle has been reassembled.

Adjust wheel bearing preload as follows:

1. Before adjustment, thoroughly clean all parts to prevent dirt

entry.

2. Apply multi-purpose grease sparingly to the following parts:

+Wheel hub (as shown at left)

+Wheel bearing

+Grease seal lip

+Contact surface between wheel bearing lock washer (cham-

fered side) and outer wheel bearing

3. Tighten wheel bearing lock nut with Tool.

: 167 - 196 Nzm (17 - 20 kg-m, 123 - 145 ft-lb)

4. Turn wheel hub several times in both directions.

5. Loosen wheel bearing lock nut so that torque becomes0Nzm

(0 kg-m, 0 ft-lb).

6. Retighten wheel bearing lock nut with Tool.

:3-5Nzm (0.3 - 0.5 kg-m, 26 - 43 in-lb)

SFA853B

SFA469A

FA781

SFA748BA

ON-VEHICLE SERVICE

Front Wheel Bearing (Cont'd)

FA-6

Page 742 of 1226

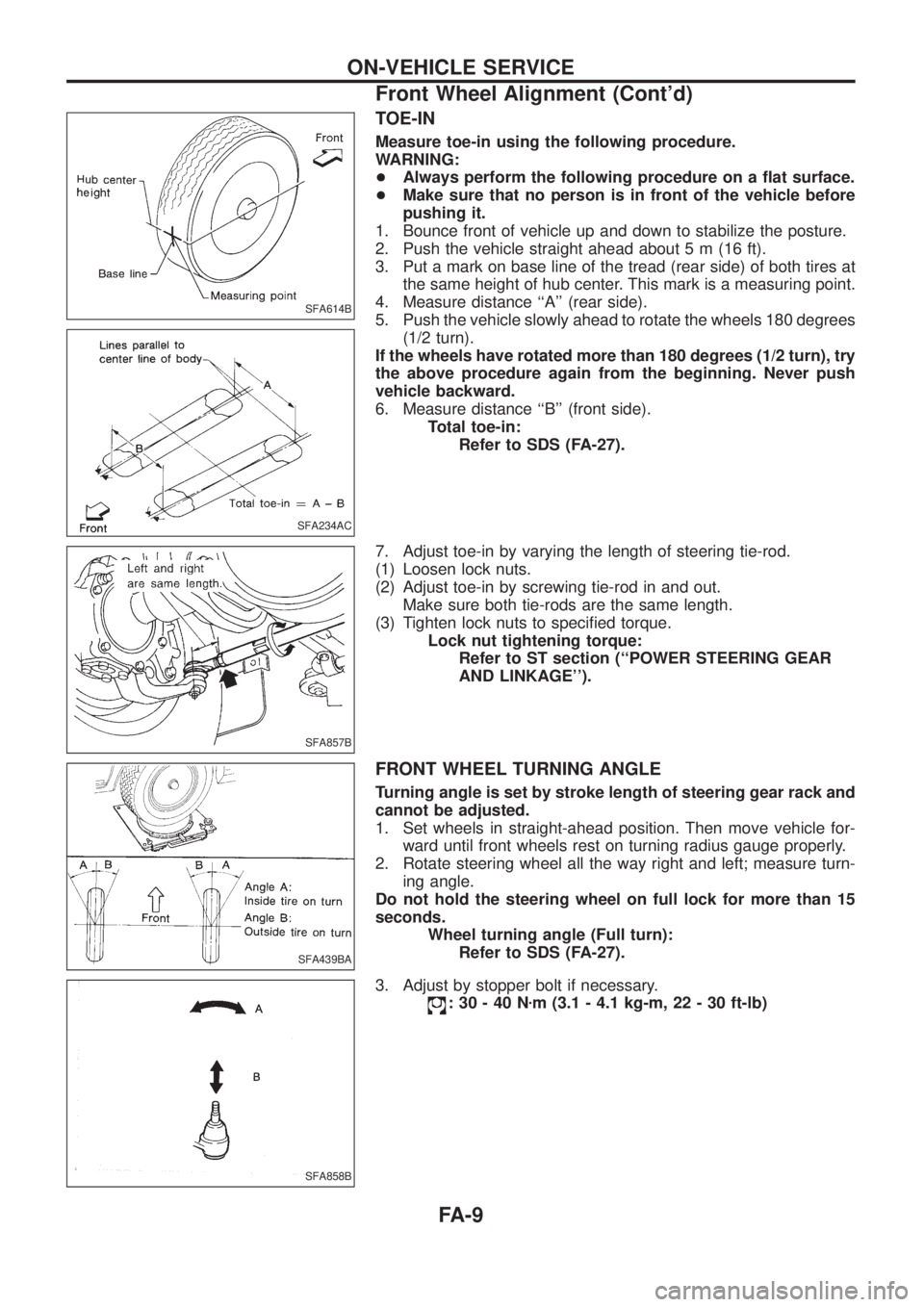

TOE-IN

Measure toe-in using the following procedure.

WARNING:

+Always perform the following procedure on a ¯at surface.

+Make sure that no person is in front of the vehicle before

pushing it.

1. Bounce front of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of both tires at

the same height of hub center. This mark is a measuring point.

4. Measure distance ``A'' (rear side).

5. Push the vehicle slowly ahead to rotate the wheels 180 degrees

(1/2 turn).

If the wheels have rotated more than 180 degrees (1/2 turn), try

the above procedure again from the beginning. Never push

vehicle backward.

6. Measure distance ``B'' (front side).

Total toe-in:

Refer to SDS (FA-27).

7. Adjust toe-in by varying the length of steering tie-rod.

(1) Loosen lock nuts.

(2) Adjust toe-in by screwing tie-rod in and out.

Make sure both tie-rods are the same length.

(3) Tighten lock nuts to speci®ed torque.

Lock nut tightening torque:

Refer to ST section (``POWER STEERING GEAR

AND LINKAGE'').

FRONT WHEEL TURNING ANGLE

Turning angle is set by stroke length of steering gear rack and

cannot be adjusted.

1. Set wheels in straight-ahead position. Then move vehicle for-

ward until front wheels rest on turning radius gauge properly.

2. Rotate steering wheel all the way right and left; measure turn-

ing angle.

Do not hold the steering wheel on full lock for more than 15

seconds.

Wheel turning angle (Full turn):

Refer to SDS (FA-27).

3. Adjust by stopper bolt if necessary.

:30-40Nzm (3.1 - 4.1 kg-m, 22 - 30 ft-lb)

SFA614B

SFA234AC

SFA857B

SFA439BA

SFA858B

ON-VEHICLE SERVICE

Front Wheel Alignment (Cont'd)

FA-9

Page 761 of 1226

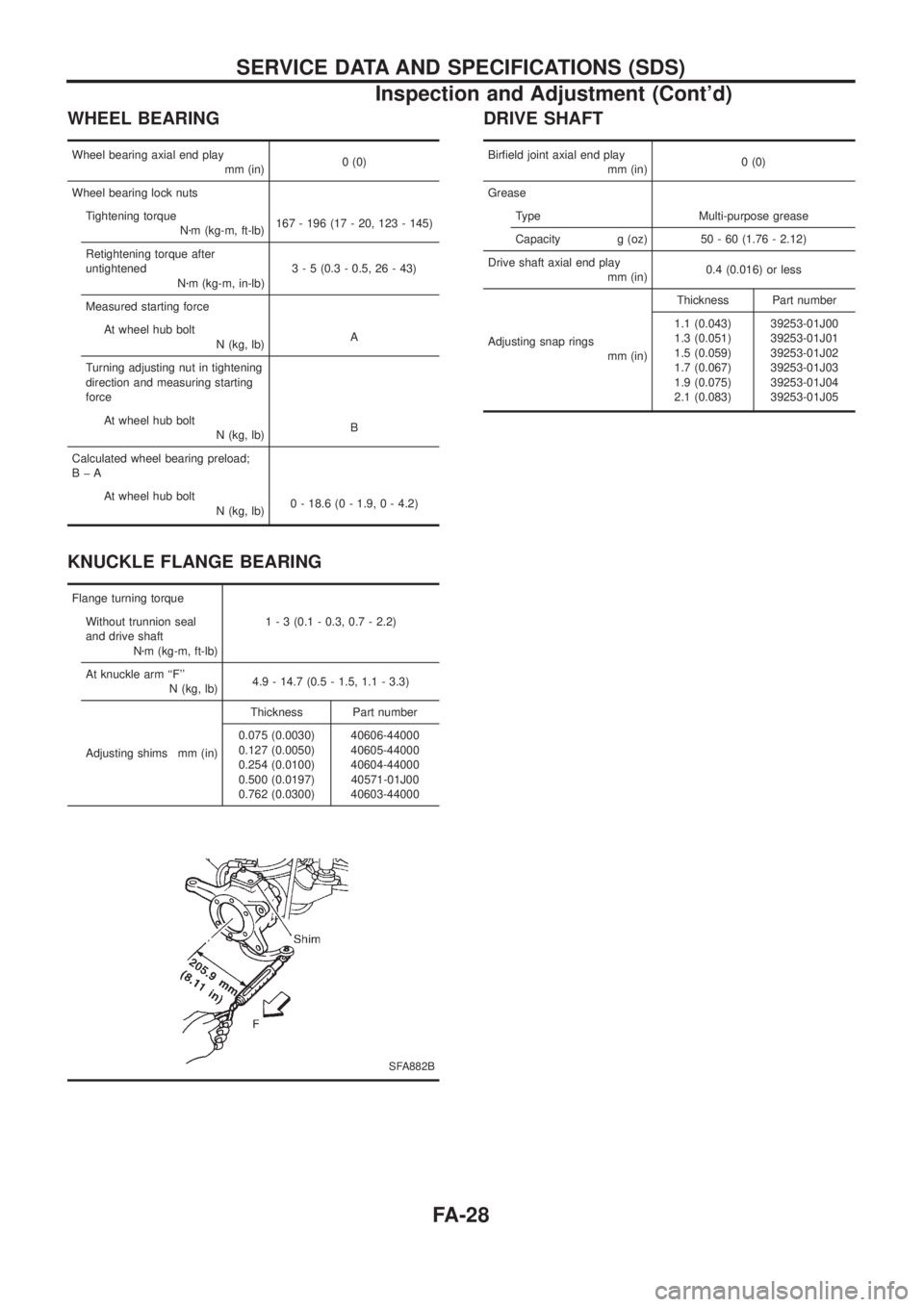

WHEEL BEARING

Wheel bearing axial end play

mm (in)0 (0)

Wheel bearing lock nuts

Tightening torque

Nzm (kg-m, ft-lb)167 - 196 (17 - 20, 123 - 145)

Retightening torque after

untightened

Nzm (kg-m, in-lb)3 - 5 (0.3 - 0.5, 26 - 43)

Measured starting force

At wheel hub bolt

N (kg, lb)A

Turning adjusting nut in tightening

direction and measuring starting

force

At wheel hub bolt

N (kg, lb)B

Calculated wheel bearing preload;

BþA

At wheel hub bolt

N (kg, lb)0 - 18.6 (0 - 1.9, 0 - 4.2)

KNUCKLE FLANGE BEARING

Flange turning torque

Without trunnion seal

and drive shaft

Nzm (kg-m, ft-lb)1 - 3 (0.1 - 0.3, 0.7 - 2.2)

At knuckle arm ``F''

N (kg, lb)4.9 - 14.7 (0.5 - 1.5, 1.1 - 3.3)

Adjusting shims mm (in)Thickness Part number

0.075 (0.0030)

0.127 (0.0050)

0.254 (0.0100)

0.500 (0.0197)

0.762 (0.0300)40606-44000

40605-44000

40604-44000

40571-01J00

40603-44000

SFA882B

DRIVE SHAFT

Bir®eld joint axial end play

mm (in)0 (0)

Grease

Type Multi-purpose grease

Capacity g (oz) 50 - 60 (1.76 - 2.12)

Drive shaft axial end play

mm (in)0.4 (0.016) or less

Adjusting snap rings

mm (in)Thickness Part number

1.1 (0.043)

1.3 (0.051)

1.5 (0.059)

1.7 (0.067)

1.9 (0.075)

2.1 (0.083)39253-01J00

39253-01J01

39253-01J02

39253-01J03

39253-01J04

39253-01J05

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection and Adjustment (Cont'd)

FA-28

Page 780 of 1226

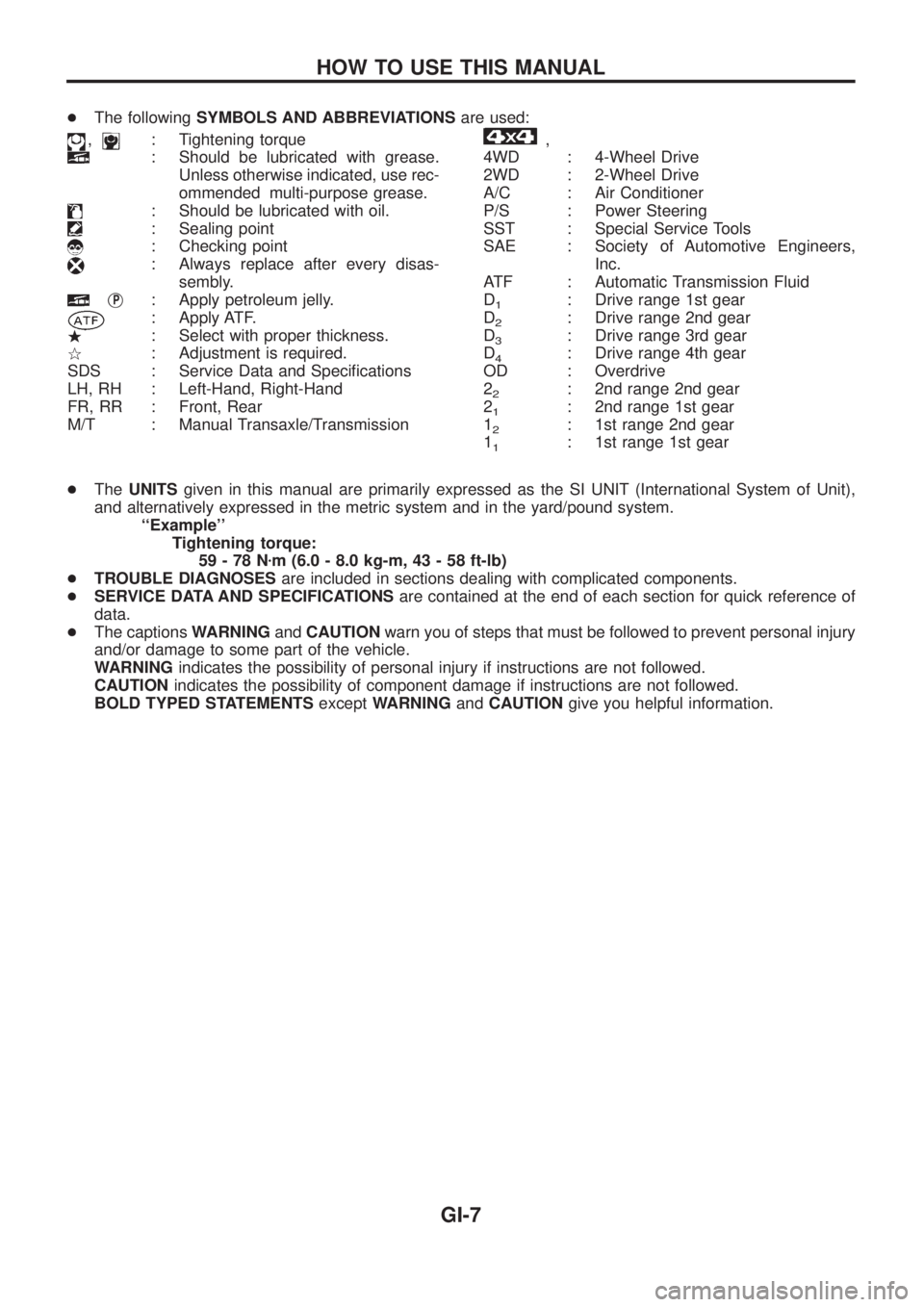

+The followingSYMBOLS AND ABBREVIATIONSare used:

,: Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use rec-

ommended multi-purpose grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

: Always replace after every disas-

sembly.

jP: Apply petroleum jelly.

: Apply ATF.

.: Select with proper thickness.

>: Adjustment is required.

SDS : Service Data and Speci®cations

LH, RH : Left-Hand, Right-Hand

FR, RR : Front, Rear

M/T : Manual Transaxle/Transmission

,

4WD : 4-Wheel Drive

2WD : 2-Wheel Drive

A/C : Air Conditioner

P/S : Power Steering

SST : Special Service Tools

SAE : Society of Automotive Engineers,

Inc.

ATF : Automatic Transmission Fluid

D

1: Drive range 1st gear

D

2: Drive range 2nd gear

D

3: Drive range 3rd gear

D

4: Drive range 4th gear

OD : Overdrive

2

2: 2nd range 2nd gear

2

1: 2nd range 1st gear

1

2: 1st range 2nd gear

1

1: 1st range 1st gear

+TheUNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

``Example''

Tightening torque:

59-78Nzm (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

+TROUBLE DIAGNOSESare included in sections dealing with complicated components.

+SERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference of

data.

+The captionsWARNINGandCAUTIONwarn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

WARNINGindicates the possibility of personal injury if instructions are not followed.

CAUTIONindicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTSexceptWARNINGandCAUTIONgive you helpful information.

HOW TO USE THIS MANUAL

GI-7

Page 977 of 1226

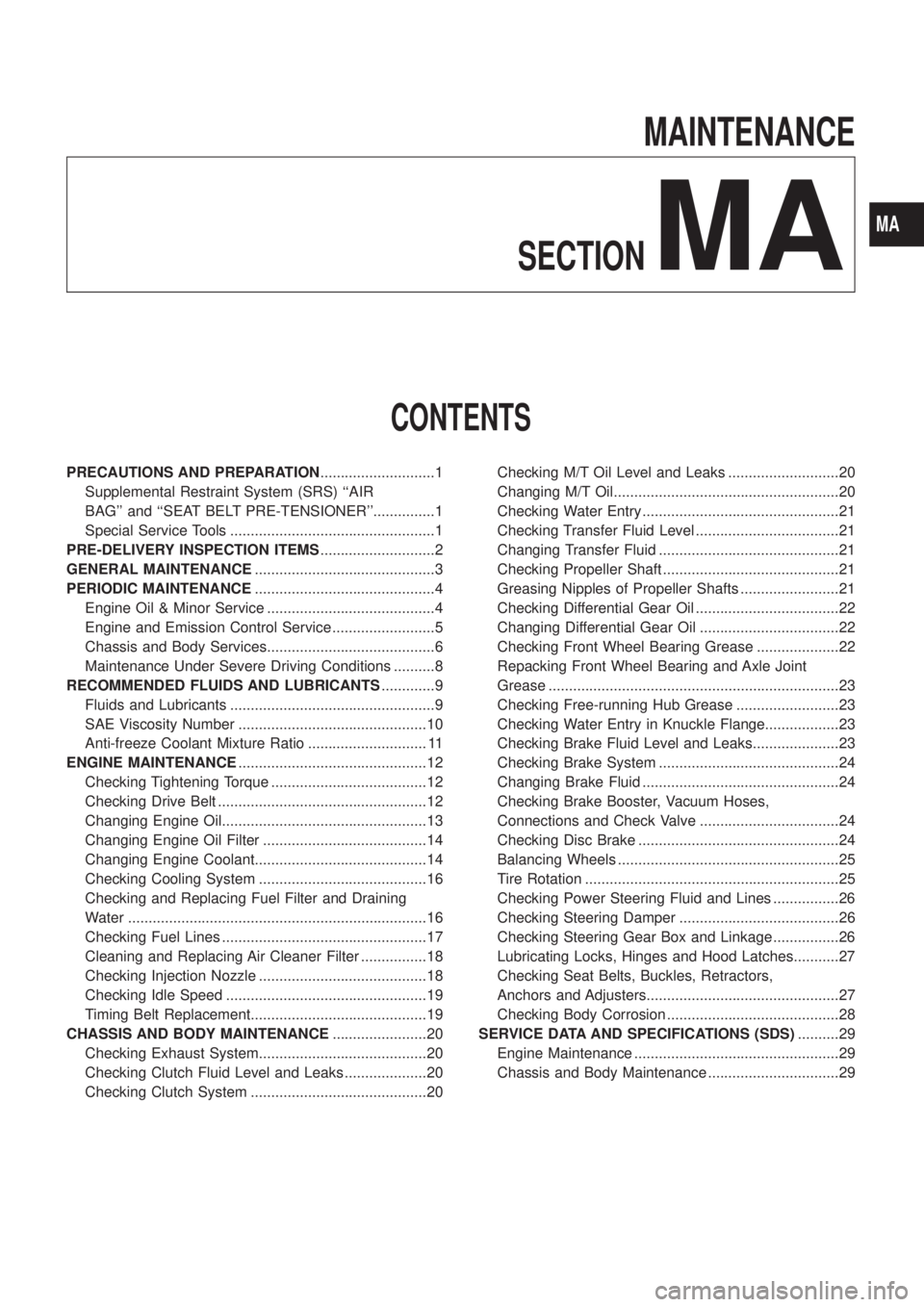

MAINTENANCE

SECTION

MA

CONTENTS

PRECAUTIONS AND PREPARATION............................1

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''...............1

Special Service Tools ..................................................1

PRE-DELIVERY INSPECTION ITEMS............................2

GENERAL MAINTENANCE............................................3

PERIODIC MAINTENANCE............................................4

Engine Oil & Minor Service .........................................4

Engine and Emission Control Service .........................5

Chassis and Body Services.........................................6

Maintenance Under Severe Driving Conditions ..........8

RECOMMENDED FLUIDS AND LUBRICANTS.............9

Fluids and Lubricants ..................................................9

SAE Viscosity Number ..............................................10

Anti-freeze Coolant Mixture Ratio ............................. 11

ENGINE MAINTENANCE..............................................12

Checking Tightening Torque ......................................12

Checking Drive Belt ...................................................12

Changing Engine Oil..................................................13

Changing Engine Oil Filter ........................................14

Changing Engine Coolant..........................................14

Checking Cooling System .........................................16

Checking and Replacing Fuel Filter and Draining

Water .........................................................................16

Checking Fuel Lines ..................................................17

Cleaning and Replacing Air Cleaner Filter ................18

Checking Injection Nozzle .........................................18

Checking Idle Speed .................................................19

Timing Belt Replacement...........................................19

CHASSIS AND BODY MAINTENANCE.......................20

Checking Exhaust System.........................................20

Checking Clutch Fluid Level and Leaks ....................20

Checking Clutch System ...........................................20Checking M/T Oil Level and Leaks ...........................20

Changing M/T Oil.......................................................20

Checking Water Entry ................................................21

Checking Transfer Fluid Level ...................................21

Changing Transfer Fluid ............................................21

Checking Propeller Shaft ...........................................21

Greasing Nipples of Propeller Shafts ........................21

Checking Differential Gear Oil ...................................22

Changing Differential Gear Oil ..................................22

Checking Front Wheel Bearing Grease ....................22

Repacking Front Wheel Bearing and Axle Joint

Grease .......................................................................23

Checking Free-running Hub Grease .........................23

Checking Water Entry in Knuckle Flange..................23

Checking Brake Fluid Level and Leaks.....................23

Checking Brake System ............................................24

Changing Brake Fluid ................................................24

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve ..................................24

Checking Disc Brake .................................................24

Balancing Wheels ......................................................25

Tire Rotation ..............................................................25

Checking Power Steering Fluid and Lines ................26

Checking Steering Damper .......................................26

Checking Steering Gear Box and Linkage ................26

Lubricating Locks, Hinges and Hood Latches...........27

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters...............................................27

Checking Body Corrosion ..........................................28

SERVICE DATA AND SPECIFICATIONS (SDS)..........29

Engine Maintenance ..................................................29

Chassis and Body Maintenance ................................29

MA

Page 1000 of 1226

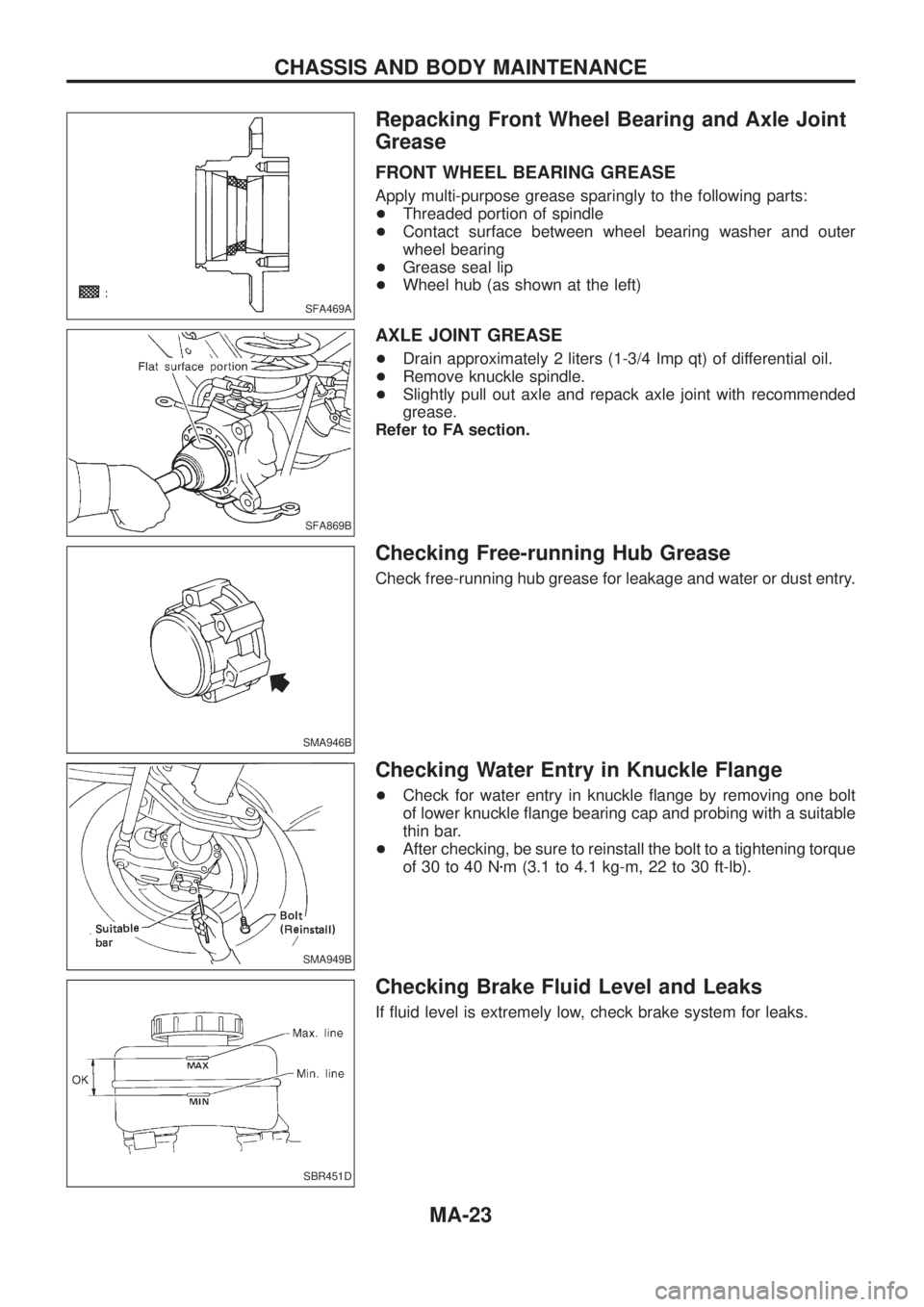

Repacking Front Wheel Bearing and Axle Joint

Grease

FRONT WHEEL BEARING GREASE

Apply multi-purpose grease sparingly to the following parts:

+Threaded portion of spindle

+Contact surface between wheel bearing washer and outer

wheel bearing

+Grease seal lip

+Wheel hub (as shown at the left)

AXLE JOINT GREASE

+Drain approximately 2 liters (1-3/4 Imp qt) of differential oil.

+Remove knuckle spindle.

+Slightly pull out axle and repack axle joint with recommended

grease.

Refer to FA section.

Checking Free-running Hub Grease

Check free-running hub grease for leakage and water or dust entry.

Checking Water Entry in Knuckle Flange

+Check for water entry in knuckle ¯ange by removing one bolt

of lower knuckle ¯ange bearing cap and probing with a suitable

thin bar.

+After checking, be sure to reinstall the bolt to a tightening torque

of 30 to 40 Nzm (3.1 to 4.1 kg-m, 22 to 30 ft-lb).

Checking Brake Fluid Level and Leaks

If ¯uid level is extremely low, check brake system for leaks.

SFA469A

SFA869B

SMA946B

SMA949B

SBR451D

CHASSIS AND BODY MAINTENANCE

MA-23

Page 1046 of 1226

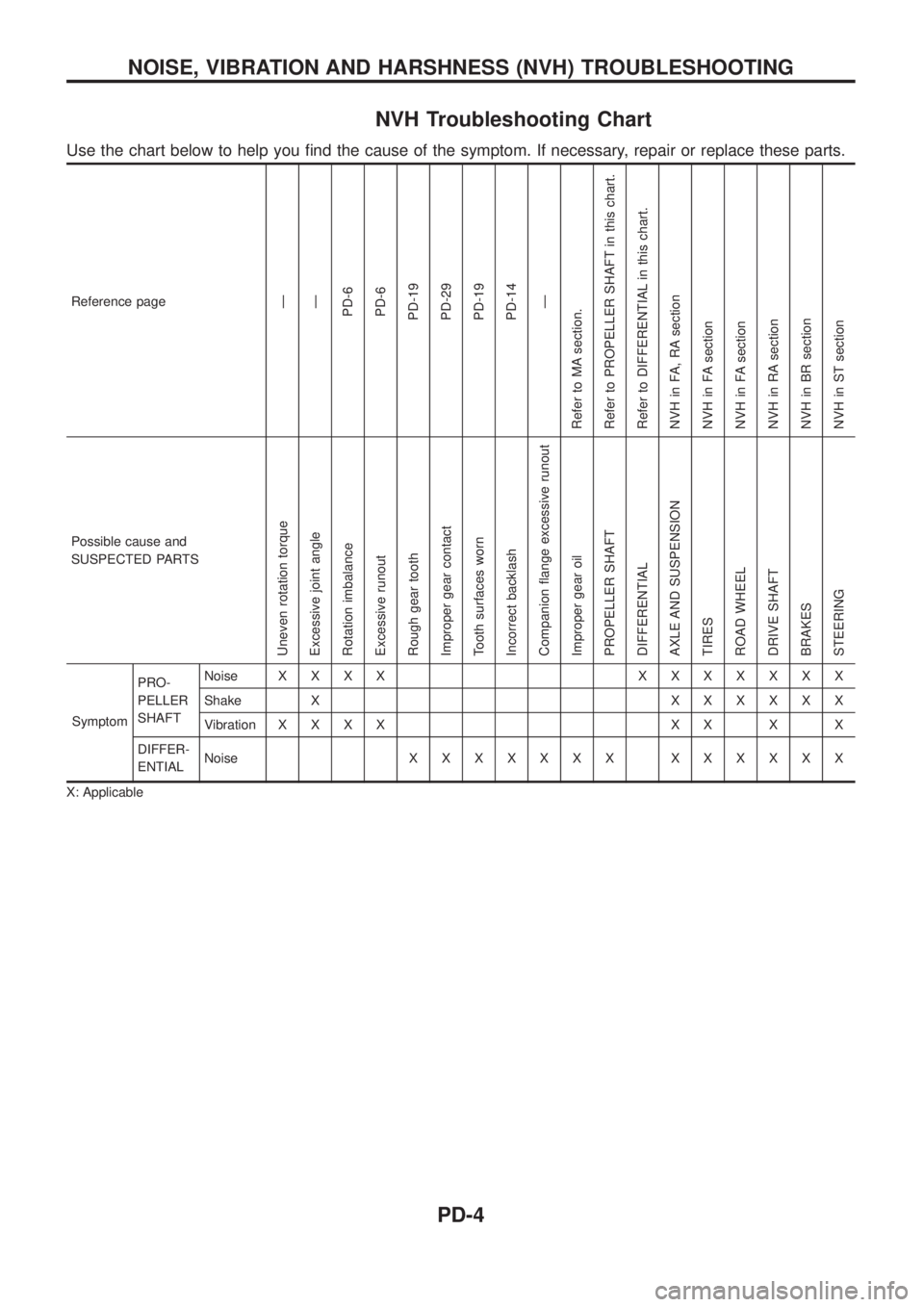

NVH Troubleshooting Chart

Use the chart below to help you ®nd the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

Ð

PD-6

PD-6

PD-19

PD-29

PD-19

PD-14

Ð

Refer to MA section.

Refer to PROPELLER SHAFT in this chart.

Refer to DIFFERENTIAL in this chart.

NVH in FA, RA section

NVH in FA section

NVH in FA section

NVH in RA section

NVH in BR section

NVH in ST section

Possible cause and

SUSPECTED PARTS

Uneven rotation torque

Excessive joint angle

Rotation imbalance

Excessive runout

Rough gear tooth

Improper gear contact

Tooth surfaces worn

Incorrect backlash

Companion ¯ange excessive runout

Improper gear oil

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

SymptomPRO-

PELLER

SHAFTNoiseXXXX XXXXXXX

Shake XXXXXXX

VibrationXXXX XX X X

DIFFER-

ENTIALNoiseXXXXXXX XXXXXX

X: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PD-4