oil pressure NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 13 of 1659

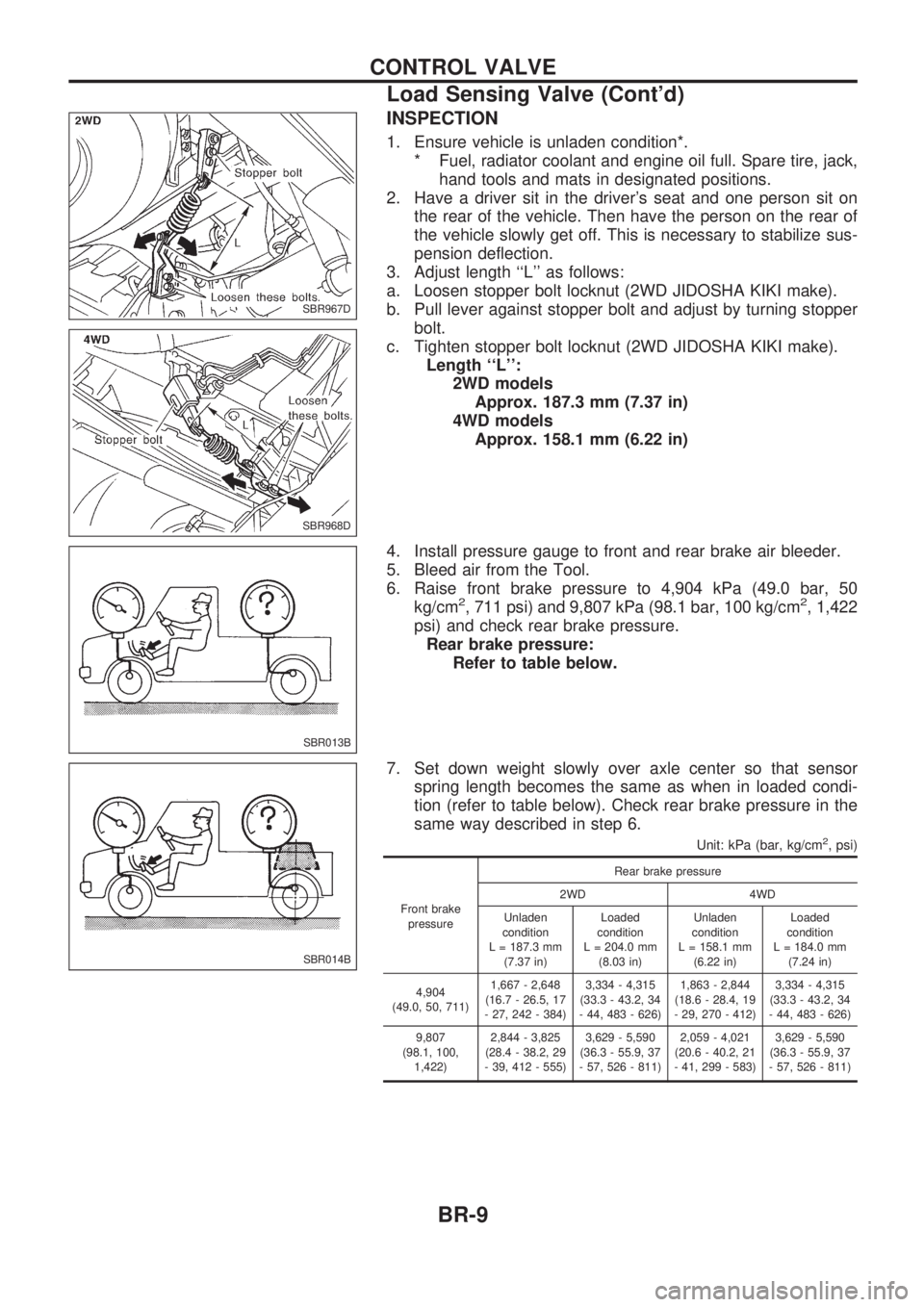

INSPECTION

1. Ensure vehicle is unladen condition*.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

2. Have a driver sit in the driver's seat and one person sit on

the rear of the vehicle. Then have the person on the rear of

the vehicle slowly get off. This is necessary to stabilize sus-

pension deflection.

3. Adjust length ``L'' as follows:

a. Loosen stopper bolt locknut (2WD JIDOSHA KIKI make).

b. Pull lever against stopper bolt and adjust by turning stopper

bolt.

c. Tighten stopper bolt locknut (2WD JIDOSHA KIKI make).

Length ``L'':

2WD models

Approx. 187.3 mm (7.37 in)

4WD models

Approx. 158.1 mm (6.22 in)

4. Install pressure gauge to front and rear brake air bleeder.

5. Bleed air from the Tool.

6. Raise front brake pressure to 4,904 kPa (49.0 bar, 50

kg/cm

2, 711 psi) and 9,807 kPa (98.1 bar, 100 kg/cm2, 1,422

psi) and check rear brake pressure.

Rear brake pressure:

Refer to table below.

7. Set down weight slowly over axle center so that sensor

spring length becomes the same as when in loaded condi-

tion (refer to table below). Check rear brake pressure in the

same way described in step 6.

Unit: kPa (bar, kg/cm2, psi)

Front brake

pressureRear brake pressure

2WD 4WD

Unladen

condition

L = 187.3 mm

(7.37 in)Loaded

condition

L = 204.0 mm

(8.03 in)Unladen

condition

L = 158.1 mm

(6.22 in)Loaded

condition

L = 184.0 mm

(7.24 in)

4,904

(49.0, 50, 711)1,667 - 2,648

(16.7 - 26.5, 17

- 27, 242 - 384)3,334 - 4,315

(33.3 - 43.2, 34

- 44, 483 - 626)1,863 - 2,844

(18.6 - 28.4, 19

- 29, 270 - 412)3,334 - 4,315

(33.3 - 43.2, 34

- 44, 483 - 626)

9,807

(98.1, 100,

1,422)2,844 - 3,825

(28.4 - 38.2, 29

- 39, 412 - 555)3,629 - 5,590

(36.3 - 55.9, 37

- 57, 526 - 811)2,059 - 4,021

(20.6 - 40.2, 21

- 41, 299 - 583)3,629 - 5,590

(36.3 - 55.9, 37

- 57, 526 - 811)

SBR967D

SBR968D

SBR013B

SBR014B

CONTROL VALVE

Load Sensing Valve (Cont'd)

BR-9

Page 151 of 1659

TROUBLE DIAGNOSIS FOR POWER SUPPLY.... 75

Main Power Supply and Ground Circuit .............. 75

TROUBLE DIAGNOSIS FOR ``CAMSHAFT

POSI SEN'' (DTC 11).............................................. 82

Camshaft Position Sensor (CMPS) ..................... 82

TROUBLE DIAGNOSIS FOR ``MASS AIR

FLOW SEN'' (DTC 12)............................................ 89

Mass Air Flow Sensor (MAFS) ............................ 89

TROUBLE DIAGNOSIS FOR ``COOLANT TEMP

SEN'' (DTC 13)........................................................ 95

Engine Coolant Temperature Sensor (ECTS) ..... 95

TROUBLE DIAGNOSIS FOR ``IGN SIGNAL-

PRIMARY'' (DTC 21)............................................... 99

Ignition Signal ...................................................... 99

TROUBLE DIAGNOSIS FOR ``OVER HEAT''

(DTC 28)................................................................. 106

Overheat ............................................................ 106

TROUBLE DIAGNOSIS FOR ``INT AIR TEMP

SEN'' (DTC 41)...................................................... 109

Intake Air Temperature Sensor ......................... 109

TROUBLE DIAGNOSIS FOR ``THROTTLE POSI

SEN'' (DTC 43)...................................................... 113

Throttle Position Sensor .................................... 113

TROUBLE DIAGNOSIS FOR

NON-DETECTABLE ITEMS.................................. 118

Vehicle Speed Sensor (VSS) ............................ 118

Heated Oxygen Sensor (HO2S)

- LHD Models - .................................................. 123

Heated Oxygen Sensor Heater

- LHD Models - .................................................. 127

Idle Air Control Valve (IACV) - Auxiliary Air

Control (AAC) Valve .......................................... 131

Neutral Position Switch ...................................... 136

EVAP Canister Purge Control Solenoid Valve .. 140

Injector ............................................................... 144

Start Signal ........................................................ 149

Fuel Pump.......................................................... 151

Power Steering Oil Pressure Switch ................. 157

Swirl Control Valve Control Solenoid Valve ...... 161

IACV-FICD Solenoid Valve ................................ 168

MIL & Data Link Connectors ............................. 173

TD

INJECTION SYSTEM............................................ 176

Fuel System ....................................................... 176

INJECTION PUMP................................................. 178

Inspection ........................................................... 178

Removal ............................................................. 178

Installation and Adjustment................................ 180

Disassembly ....................................................... 183

Load Timer Adjustment...................................... 183

Start Q Adjustment Lever .................................. 184

INJECTION NOZZLE............................................. 186Removal and Installation ................................... 186

Disassembly ....................................................... 186

Inspection ........................................................... 187

Cleaning ............................................................. 187

Assembly............................................................ 189

Test and Adjustment .......................................... 189

FUEL SYSTEM CHECK........................................ 191

Bleeding Fuel System ........................................ 191

Bleeding Fuel Filter ............................................ 192

Checking Priming Pump .................................... 192

Checking Fuel Filter Switch ............................... 192

POSITIVE CRANKCASE VENTILATION.............. 193

Description ......................................................... 193

Inspection ........................................................... 193

QUICK-GLOW SYSTEM........................................ 194

Component Parts Location ................................ 194

Circuit Diagram .................................................. 195

Description ......................................................... 196

Wiring Diagram .................................................. 197

Glow Control Unit Circuit Inspection (For Cold

Areas)................................................................. 203

Glow Control Unit Circuit Inspection (Except

for Cold Areas)................................................... 206

Component Inspection ....................................... 208

EGR SYSTEM........................................................ 210

Component Parts Location ................................ 210

Description ......................................................... 211

Operation ........................................................... 212

Wiring Diagram .................................................. 213

System Inspection.............................................. 217

Component Inspection ....................................... 218

SOLENOID TIMER................................................ 220

Description ......................................................... 220

Operation ........................................................... 220

Wiring Diagram .................................................. 222

Inspection ........................................................... 224

FUEL CUT SYSTEM.............................................. 225

Wiring Diagram .................................................. 225

FUEL HEATER SYSTEM...................................... 226

Description ......................................................... 226

Wiring Diagram .................................................. 227

System Inspection.............................................. 228

Component Inspection ....................................... 228

FAST IDLE CONTROL CIRCUIT.......................... 230

Wiring Diagram .................................................. 230

Electrical Components Inspection ..................... 231

KA

SERVICE DATA AND SPECIFICATIONS (SDS). 232

General Specifications ....................................... 232

Inspection and Adjustment ................................ 232

Page 165 of 1659

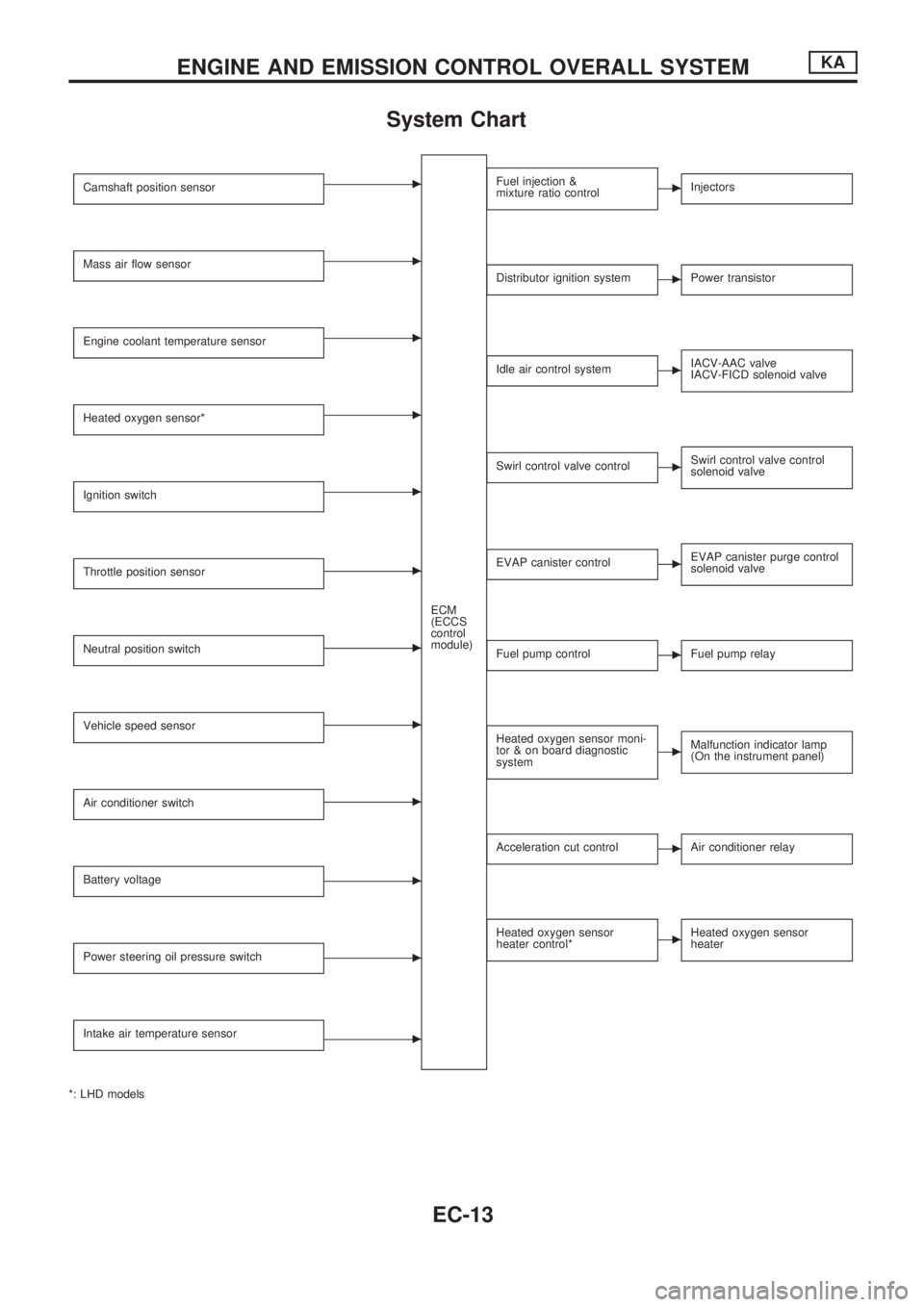

System Chart

Camshaft position sensorc

ECM

(ECCS

control

module)

Mass air flow sensorc

Engine coolant temperature sensorc

Heated oxygen sensor*c

Ignition switchc

Throttle position sensorc

Neutral position switchc

Vehicle speed sensorc

Air conditioner switchc

Battery voltagec

Power steering oil pressure switchc

Intake air temperature sensorc

*: LHD models

Fuel injection &

mixture ratio controlcInjectors

Distributor ignition systemcPower transistor

Idle air control systemcIACV-AAC valve

IACV-FICD solenoid valve

Swirl control valve controlcSwirl control valve control

solenoid valve

EVAP canister controlcEVAP canister purge control

solenoid valve

Fuel pump controlcFuel pump relay

Heated oxygen sensor moni-

tor & on board diagnostic

systemcMalfunction indicator lamp

(On the instrument panel)

Acceleration cut controlcAir conditioner relay

Heated oxygen sensor

heater control*cHeated oxygen sensor

heater

ENGINE AND EMISSION CONTROL OVERALL SYSTEMKA

EC-13

Page 175 of 1659

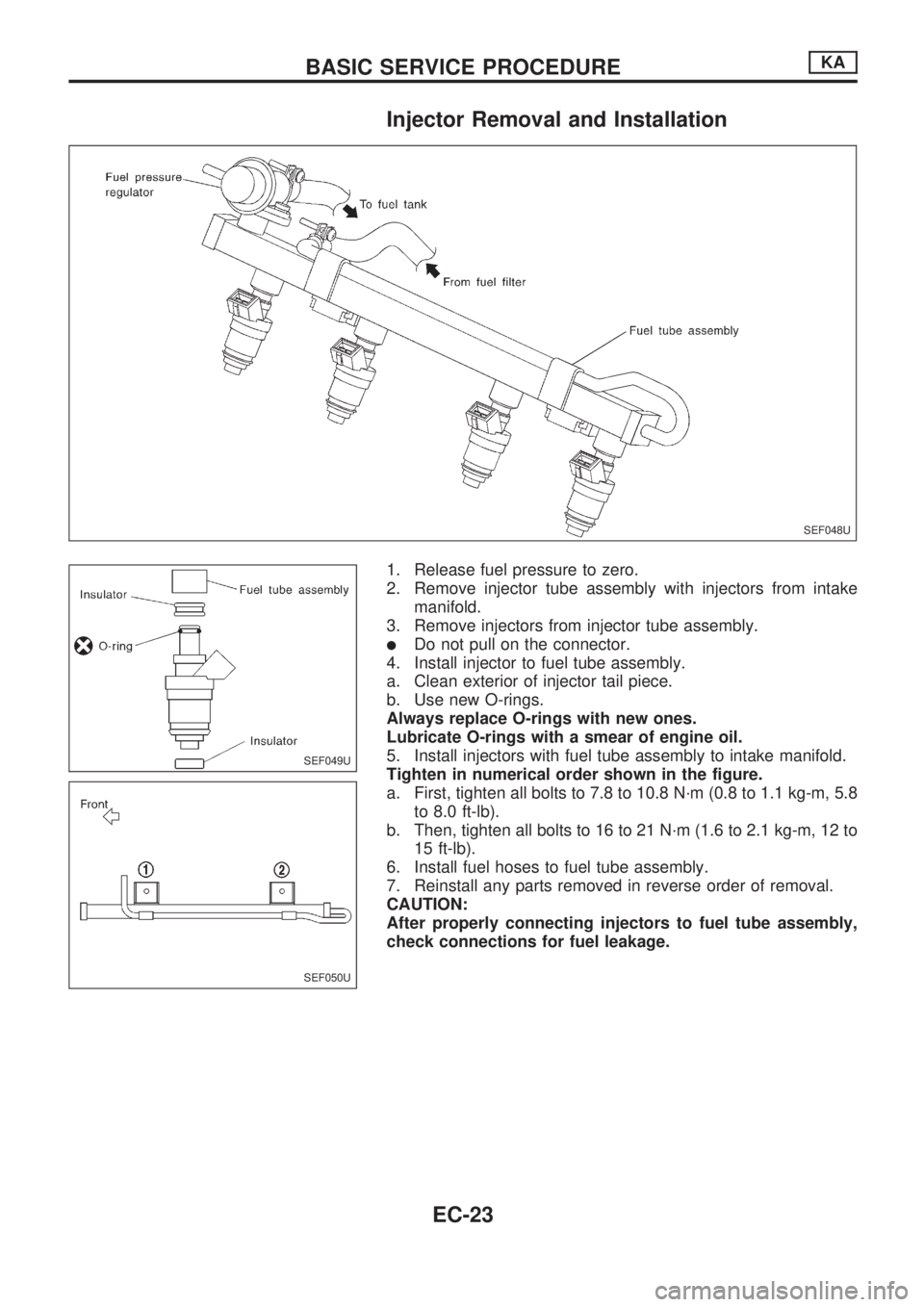

Injector Removal and Installation

1. Release fuel pressure to zero.

2. Remove injector tube assembly with injectors from intake

manifold.

3. Remove injectors from injector tube assembly.

lDo not pull on the connector.

4. Install injector to fuel tube assembly.

a. Clean exterior of injector tail piece.

b. Use new O-rings.

Always replace O-rings with new ones.

Lubricate O-rings with a smear of engine oil.

5. Install injectors with fuel tube assembly to intake manifold.

Tighten in numerical order shown in the figure.

a. First, tighten all bolts to 7.8 to 10.8 N´m (0.8 to 1.1 kg-m, 5.8

to 8.0 ft-lb).

b. Then, tighten all bolts to 16 to 21 N´m (1.6 to 2.1 kg-m, 12 to

15 ft-lb).

6. Install fuel hoses to fuel tube assembly.

7. Reinstall any parts removed in reverse order of removal.

CAUTION:

After properly connecting injectors to fuel tube assembly,

check connections for fuel leakage.

SEF048U

SEF049U

SEF050U

BASIC SERVICE PROCEDUREKA

EC-23

Page 177 of 1659

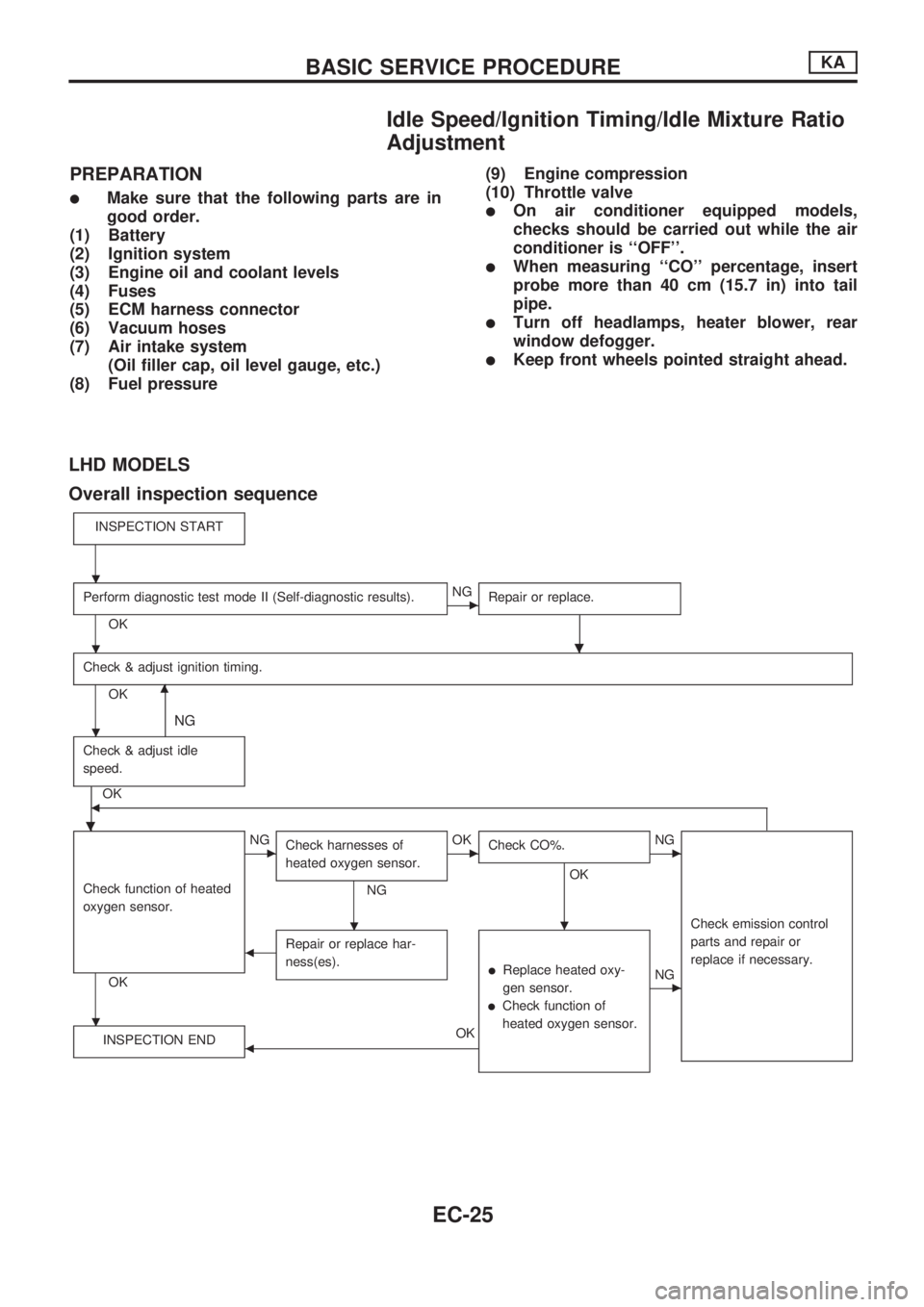

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment

PREPARATION

lMake sure that the following parts are in

good order.

(1) Battery

(2) Ignition system

(3) Engine oil and coolant levels

(4) Fuses

(5) ECM harness connector

(6) Vacuum hoses

(7) Air intake system

(Oil filler cap, oil level gauge, etc.)

(8) Fuel pressure(9) Engine compression

(10) Throttle valvelOn air conditioner equipped models,

checks should be carried out while the air

conditioner is ``OFF''.

lWhen measuring ``CO'' percentage, insert

probe more than 40 cm (15.7 in) into tail

pipe.

lTurn off headlamps, heater blower, rear

window defogger.

lKeep front wheels pointed straight ahead.

LHD MODELS

Overall inspection sequence

INSPECTION START

Perform diagnostic test mode II (Self-diagnostic results).

OK

cNG

Repair or replace.

.

Check & adjust ignition timing.

OKm

NG

Check & adjust idle

speed.

.

OKb

Check function of heated

oxygen sensor.

OK

cNG

Check harnesses of

heated oxygen sensor.

NG

cOK

Check CO%.

OK

.

cNG

Check emission control

parts and repair or

replace if necessary.

bRepair or replace har-

ness(es).

lReplace heated oxy-

gen sensor.

lCheck function of

heated oxygen sensor.

cNG

INSPECTION END

bOK

.

.

.

.

.

BASIC SERVICE PROCEDUREKA

EC-25

Page 199 of 1659

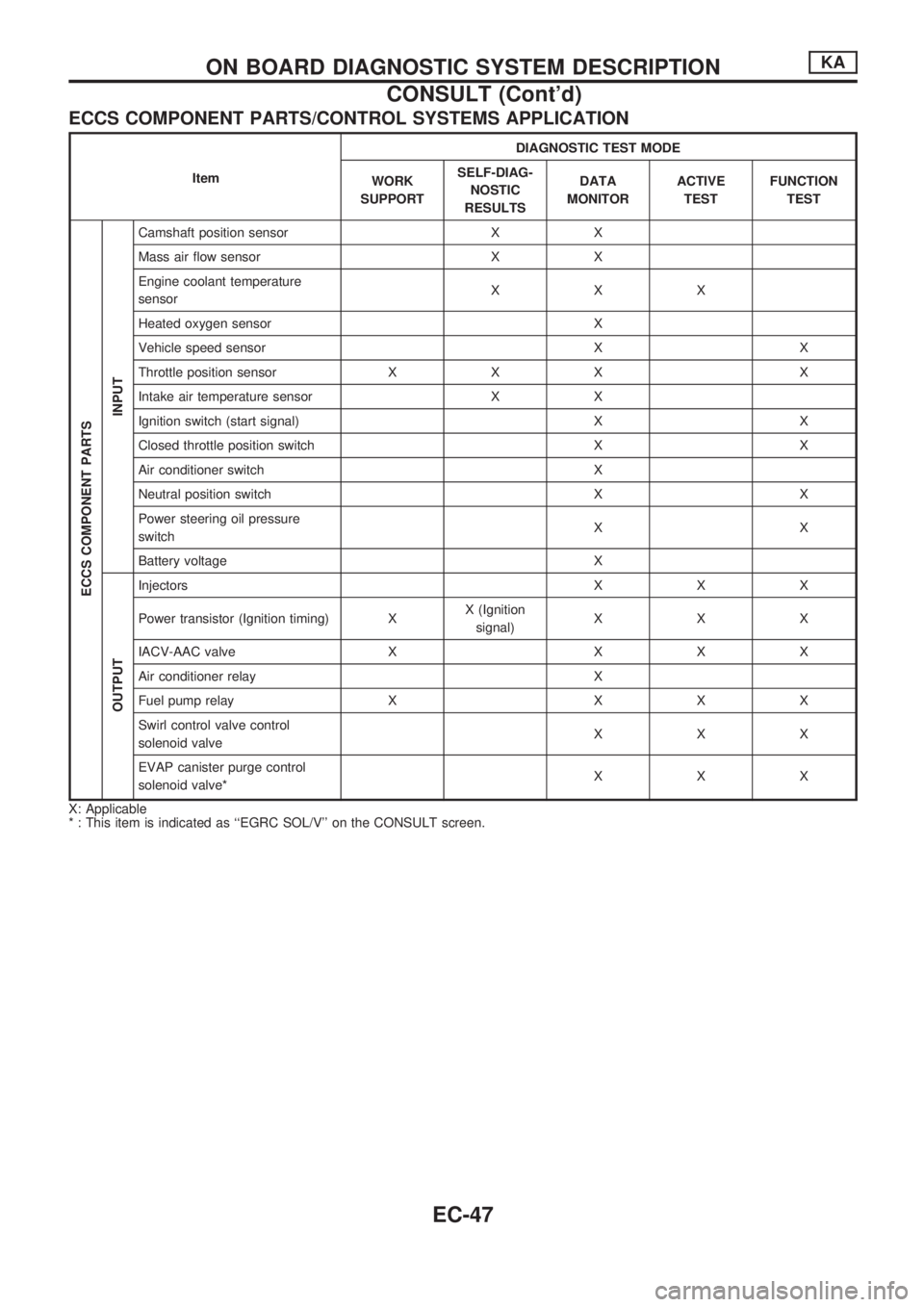

ECCS COMPONENT PARTS/CONTROL SYSTEMS APPLICATION

ItemDIAGNOSTIC TEST MODE

WORK

SUPPORTSELF-DIAG-

NOSTIC

RESULTSDATA

MONITORACTIVE

TESTFUNCTION

TEST

ECCS COMPONENT PARTS

INPUT

Camshaft position sensor X X

Mass air flow sensor X X

Engine coolant temperature

sensorXXX

Heated oxygen sensor X

Vehicle speed sensor X X

Throttle position sensor X X X X

Intake air temperature sensor X X

Ignition switch (start signal) X X

Closed throttle position switch X X

Air conditioner switch X

Neutral position switch X X

Power steering oil pressure

switchXX

Battery voltage X

OUTPUT

Injectors X X X

Power transistor (Ignition timing) XX (Ignition

signal)XXX

IACV-AAC valve X X X X

Air conditioner relay X

Fuel pump relay X X X X

Swirl control valve control

solenoid valveXXX

EVAP canister purge control

solenoid valve*XXX

X: Applicable

* : This item is indicated as ``EGRC SOL/V'' on the CONSULT screen.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-47

Page 200 of 1659

![NISSAN PICK-UP 1998 Repair Manual SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX, EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescr NISSAN PICK-UP 1998 Repair Manual SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX, EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescr](/img/5/57374/w960_57374-199.png)

SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS'' mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX'', EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

CMPSRPM

(POS) [rpm]

jj

lIndicates the engine speed computed

from the POS signal (1É signal) of the

camshaft position sensor.

MAS AIR/FL SE [V]

jjlThe signal voltage of the mass air flow

sensor is displayed.lWhen the engine is stopped, a certain

value is indicated.

COOLAN TEMP/S

[ÉC] or [ÉF]

jj

lThe engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is displayed.lWhen the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine coolant

temperature determined by the ECM is

displayed.

O2 SEN [V]

jjlThe signal voltage of the heated oxygen

sensor is displayed.lLHD models only

M/R F/C MNT

[RICH/LEAN]

jj

lDisplay of heated oxygen sensor signal

during air-fuel ratio feedback control:

RICH ... means the mixture became

``rich'', and control is being affected

toward a leaner mixture.

LEAN ... means the mixture became

``lean'', and control is being affected

toward a rich mixture.lAfter turning ON the ignition switch,

``RICH'' is displayed until air-fuel mixture

ratio feedback control begins.

lWhen the air-fuel ratio feedback is

clamped, the value just before the clamp-

ing is displayed continuously.

lLHD models only

VHCL SPEED SE

[km/h] or [mph]

jjlThe vehicle speed computed from the

vehicle speed sensor signal is displayed.

BATTERY VOLT [V]

jjlThe power supply voltage of ECM is dis-

played.

THRTL POS SEN [V]

jjlThe throttle position sensor signal volt-

age is displayed.

INT/A TEMP SE

[ÉC] or [ÉF]

j

lThe intake air temperature (determined

by the signal voltage of the intake air

temperature sensor) is indicated.

START SIGNAL

[ON/OFF]

jjlIndicates [ON/OFF] condition from the

starter signal.lAfter starting the engine, [OFF] is

displayed regardless of the starter signal.

CLSD THL/POSI

[ON/OFF]

jj

lIndicates [ON/OFF] condition from the

throttle position sensor signal.

AIR COND SIG

[ON/OFF]

jj

lIndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

P/N POSI SW

[ON/OFF]

jj

lIndicates [ON/OFF] condition from the

park/neutral position switch signal.

PW/ST SIGNAL

[ON/OFF]

jj

l[ON/OFF] condition of the power steering

oil pressure switch determined by the

power steering oil pressure signal is indi-

cated.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-48

Page 204 of 1659

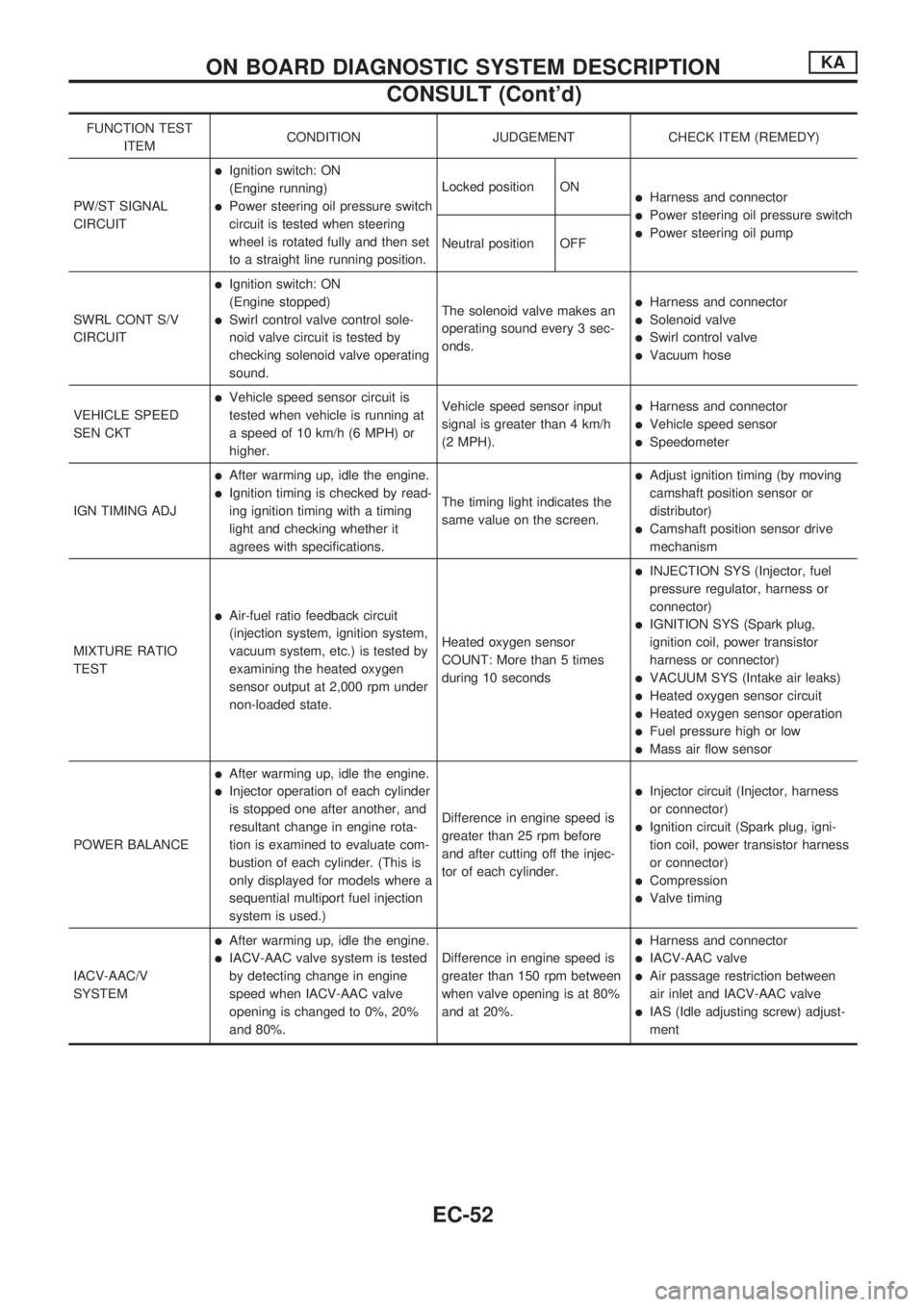

FUNCTION TEST

ITEMCONDITION JUDGEMENT CHECK ITEM (REMEDY)

PW/ST SIGNAL

CIRCUIT

lIgnition switch: ON

(Engine running)

lPower steering oil pressure switch

circuit is tested when steering

wheel is rotated fully and then set

to a straight line running position.Locked position ONlHarness and connector

lPower steering oil pressure switch

lPower steering oil pump

Neutral position OFF

SWRL CONT S/V

CIRCUIT

lIgnition switch: ON

(Engine stopped)

lSwirl control valve control sole-

noid valve circuit is tested by

checking solenoid valve operating

sound.The solenoid valve makes an

operating sound every 3 sec-

onds.

lHarness and connector

lSolenoid valve

lSwirl control valve

lVacuum hose

VEHICLE SPEED

SEN CKT

lVehicle speed sensor circuit is

tested when vehicle is running at

a speed of 10 km/h (6 MPH) or

higher.Vehicle speed sensor input

signal is greater than 4 km/h

(2 MPH).lHarness and connector

lVehicle speed sensor

lSpeedometer

IGN TIMING ADJ

lAfter warming up, idle the engine.

lIgnition timing is checked by read-

ing ignition timing with a timing

light and checking whether it

agrees with specifications.The timing light indicates the

same value on the screen.

lAdjust ignition timing (by moving

camshaft position sensor or

distributor)

lCamshaft position sensor drive

mechanism

MIXTURE RATIO

TEST

lAir-fuel ratio feedback circuit

(injection system, ignition system,

vacuum system, etc.) is tested by

examining the heated oxygen

sensor output at 2,000 rpm under

non-loaded state.Heated oxygen sensor

COUNT: More than 5 times

during 10 seconds

lINJECTION SYS (Injector, fuel

pressure regulator, harness or

connector)

lIGNITION SYS (Spark plug,

ignition coil, power transistor

harness or connector)

lVACUUM SYS (Intake air leaks)

lHeated oxygen sensor circuit

lHeated oxygen sensor operation

lFuel pressure high or low

lMass air flow sensor

POWER BALANCE

lAfter warming up, idle the engine.

lInjector operation of each cylinder

is stopped one after another, and

resultant change in engine rota-

tion is examined to evaluate com-

bustion of each cylinder. (This is

only displayed for models where a

sequential multiport fuel injection

system is used.)Difference in engine speed is

greater than 25 rpm before

and after cutting off the injec-

tor of each cylinder.lInjector circuit (Injector, harness

or connector)

lIgnition circuit (Spark plug, igni-

tion coil, power transistor harness

or connector)

lCompression

lValve timing

IACV-AAC/V

SYSTEM

lAfter warming up, idle the engine.

lIACV-AAC valve system is tested

by detecting change in engine

speed when IACV-AAC valve

opening is changed to 0%, 20%

and 80%.Difference in engine speed is

greater than 150 rpm between

when valve opening is at 80%

and at 20%.

lHarness and connector

lIACV-AAC valve

lAir passage restriction between

air inlet and IACV-AAC valve

lIAS (Idle adjusting screw) adjust-

ment

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-52

Page 214 of 1659

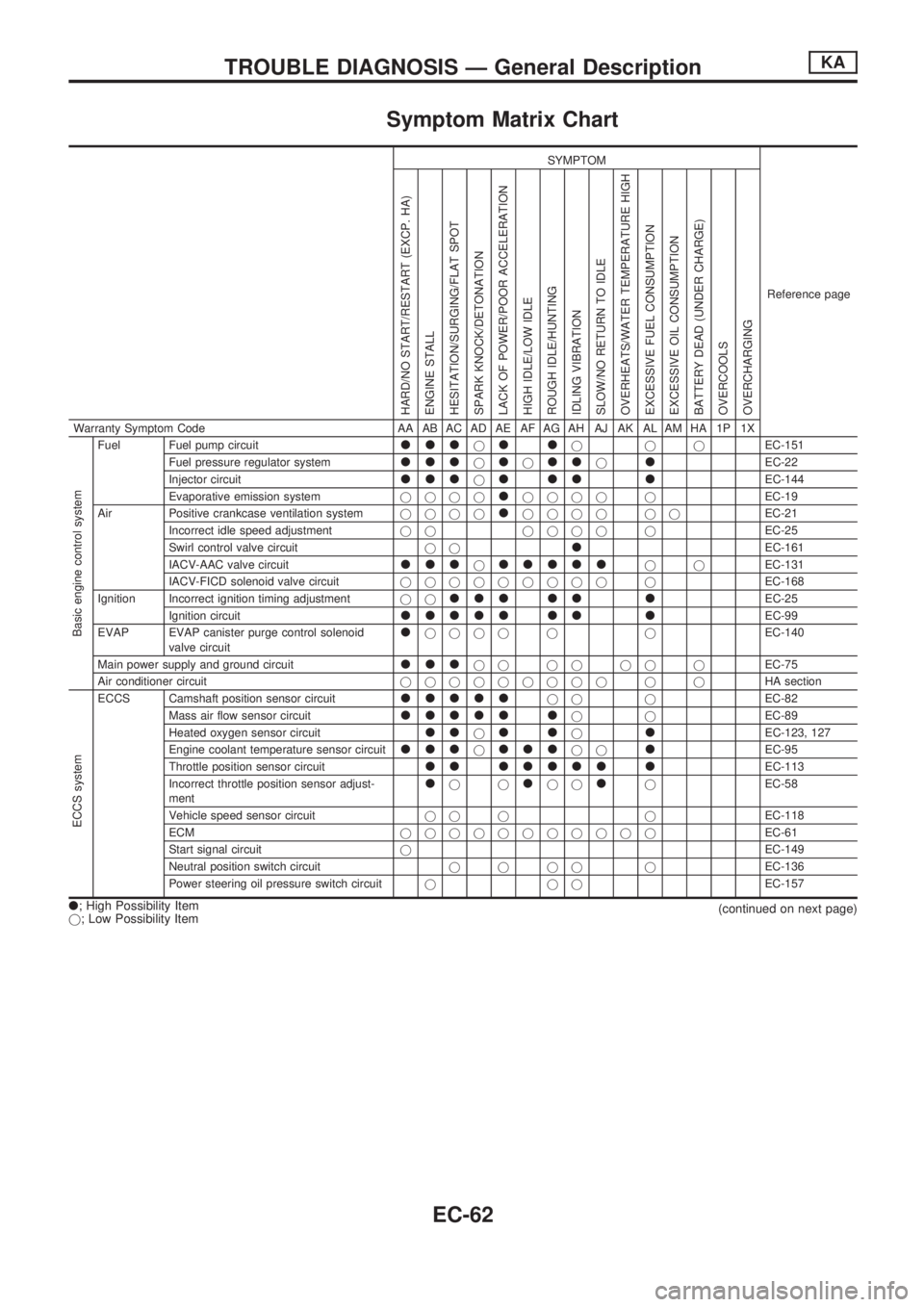

Symptom Matrix Chart

SYMPTOM

Reference page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

OVERCOOLS

OVERCHARGING

Warranty Symptom Code AA AB AC AD AE AF AG AH AJ AK AL AM HA 1P 1X

Basic engine control system

Fuel Fuel pump circuitllljlljjjEC-151

Fuel pressure regulator system

llljljlljlEC-22

Injector circuit

llljlll lEC-144

Evaporative emission systemjjjj

ljjjj jEC-19

Air Positive crankcase ventilation systemjjjj

ljjjj jjEC-21

Incorrect idle speed adjustmentjj jjjj jEC-25

Swirl control valve circuitjj

lEC-161

IACV-AAC valve circuit

llljllllljjEC-131

IACV-FICD solenoid valve circuitjjjjjjjjj jEC-168

Ignition Incorrect ignition timing adjustmentjj

lll ll lEC-25

Ignition circuit

lllll ll lEC-99

EVAP EVAP canister purge control solenoid

valve circuit

ljjjj j jEC-140

Main power supply and ground circuit

llljj jj jj jEC-75

Air conditioner circuitjjjjjjjjj j jHA section

ECCS system

ECCS Camshaft position sensor circuitllllljj jEC-82

Mass air flow sensor circuit

lllll ljjEC-89

Heated oxygen sensor circuit

lljlljlEC-123, 127

Engine coolant temperature sensor circuit

llljllljjlEC-95

Throttle position sensor circuit

ll lllll lEC-113

Incorrect throttle position sensor adjust-

ment

ljjljjljEC-58

Vehicle speed sensor circuitjj j jEC-118

ECMjjjjjjjjjjjEC-61

Start signal circuitjEC-149

Neutral position switch circuitjjjj jEC-136

Power steering oil pressure switch circuitjjjEC-157

l; High Possibility Item

j; Low Possibility Item(continued on next page)

TROUBLE DIAGNOSIS Ð General DescriptionKA

EC-62

Page 224 of 1659

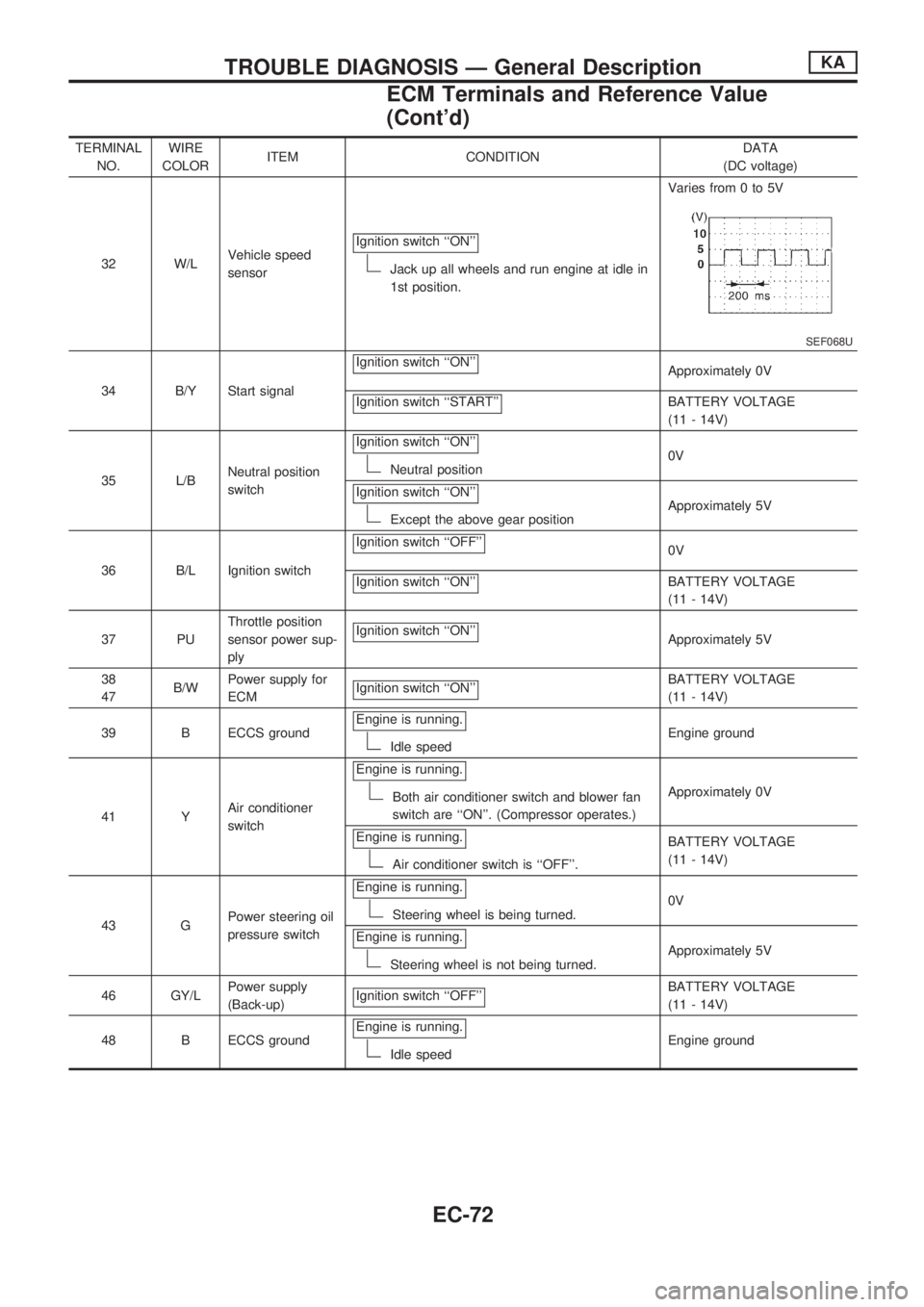

TERMINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC voltage)

32 W/LVehicle speed

sensorIgnition switch ``ON''

Jack up all wheels and run engine at idle in

1st position.Varies from 0 to 5V

SEF068U

34 B/Y Start signalIgnition switch ``ON''

Approximately 0V

Ignition switch ``START''

BATTERY VOLTAGE

(11 - 14V)

35 L/BNeutral position

switchIgnition switch ``ON''

Neutral position0V

Ignition switch ``ON''

Except the above gear positionApproximately 5V

36 B/L Ignition switchIgnition switch ``OFF''

0V

Ignition switch ``ON''

BATTERY VOLTAGE

(11 - 14V)

37 PUThrottle position

sensor power sup-

plyIgnition switch ``ON''

Approximately 5V

38

47B/WPower supply for

ECMIgnition switch ``ON''

BATTERY VOLTAGE

(11 - 14V)

39 B ECCS groundEngine is running.

Idle speedEngine ground

41 YAir conditioner

switchEngine is running.

Both air conditioner switch and blower fan

switch are ``ON''. (Compressor operates.)Approximately 0V

Engine is running.

Air conditioner switch is ``OFF''.BATTERY VOLTAGE

(11 - 14V)

43 GPower steering oil

pressure switchEngine is running.

Steering wheel is being turned.0V

Engine is running.

Steering wheel is not being turned.Approximately 5V

46 GY/LPower supply

(Back-up)Ignition switch ``OFF''

BATTERY VOLTAGE

(11 - 14V)

48 B ECCS groundEngine is running.

Idle speedEngine ground

TROUBLE DIAGNOSIS Ð General DescriptionKA

ECM Terminals and Reference Value

(Cont'd)

EC-72