ECU NISSAN PICK-UP 1999 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PICK-UP, Model: NISSAN PICK-UP 1999Pages: 666, PDF Size: 16.21 MB

Page 138 of 666

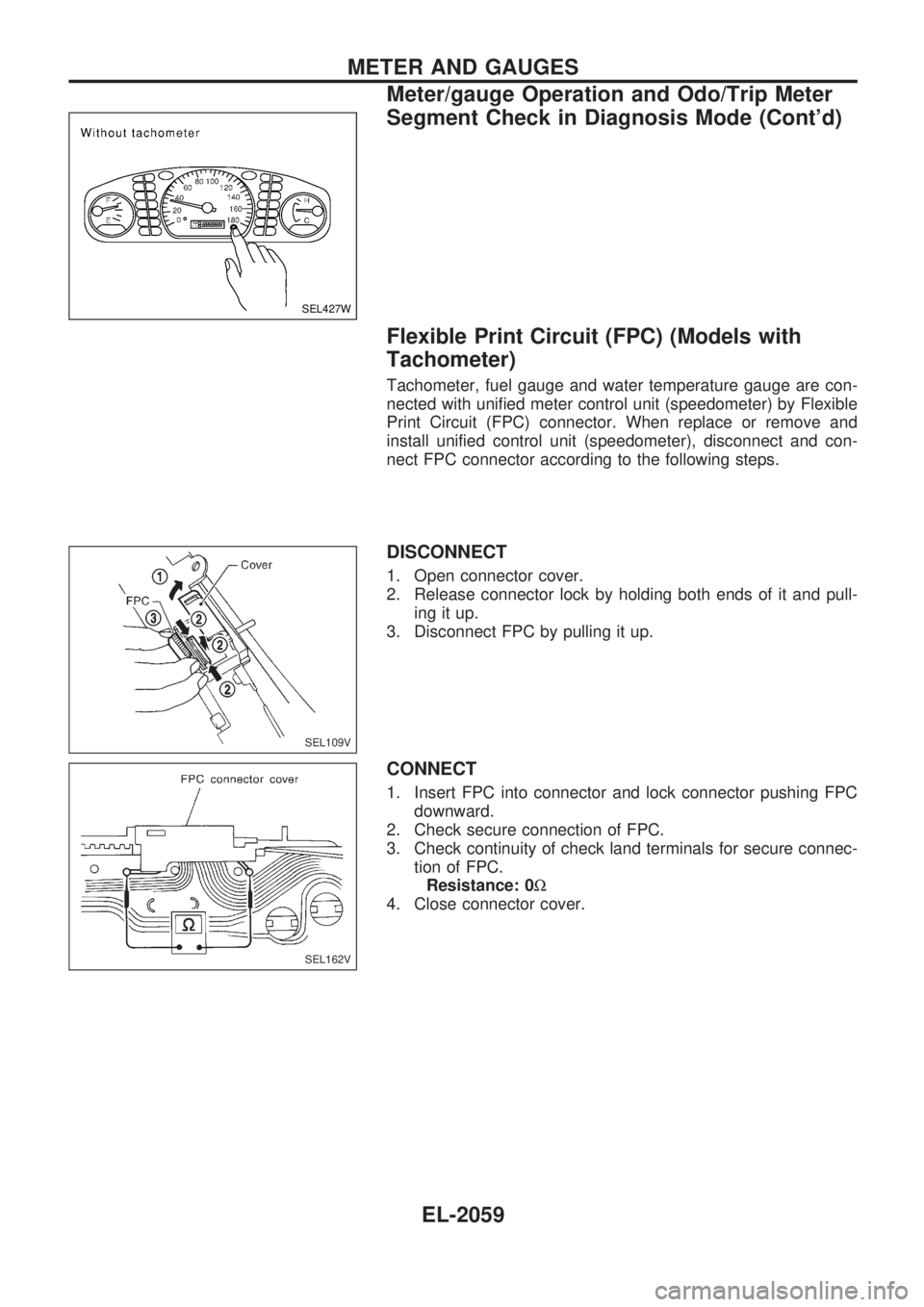

Flexible Print Circuit (FPC) (Models with

Tachometer)

Tachometer, fuel gauge and water temperature gauge are con-

nected with unified meter control unit (speedometer) by Flexible

Print Circuit (FPC) connector. When replace or remove and

install unified control unit (speedometer), disconnect and con-

nect FPC connector according to the following steps.

DISCONNECT

1. Open connector cover.

2. Release connector lock by holding both ends of it and pull-

ing it up.

3. Disconnect FPC by pulling it up.

CONNECT

1. Insert FPC into connector and lock connector pushing FPC

downward.

2. Check secure connection of FPC.

3. Check continuity of check land terminals for secure connec-

tion of FPC.

Resistance: 0W

4. Close connector cover.

SEL427W

SEL109V

SEL162V

METER AND GAUGES

Meter/gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode (Cont'd)

EL-2059

Page 139 of 666

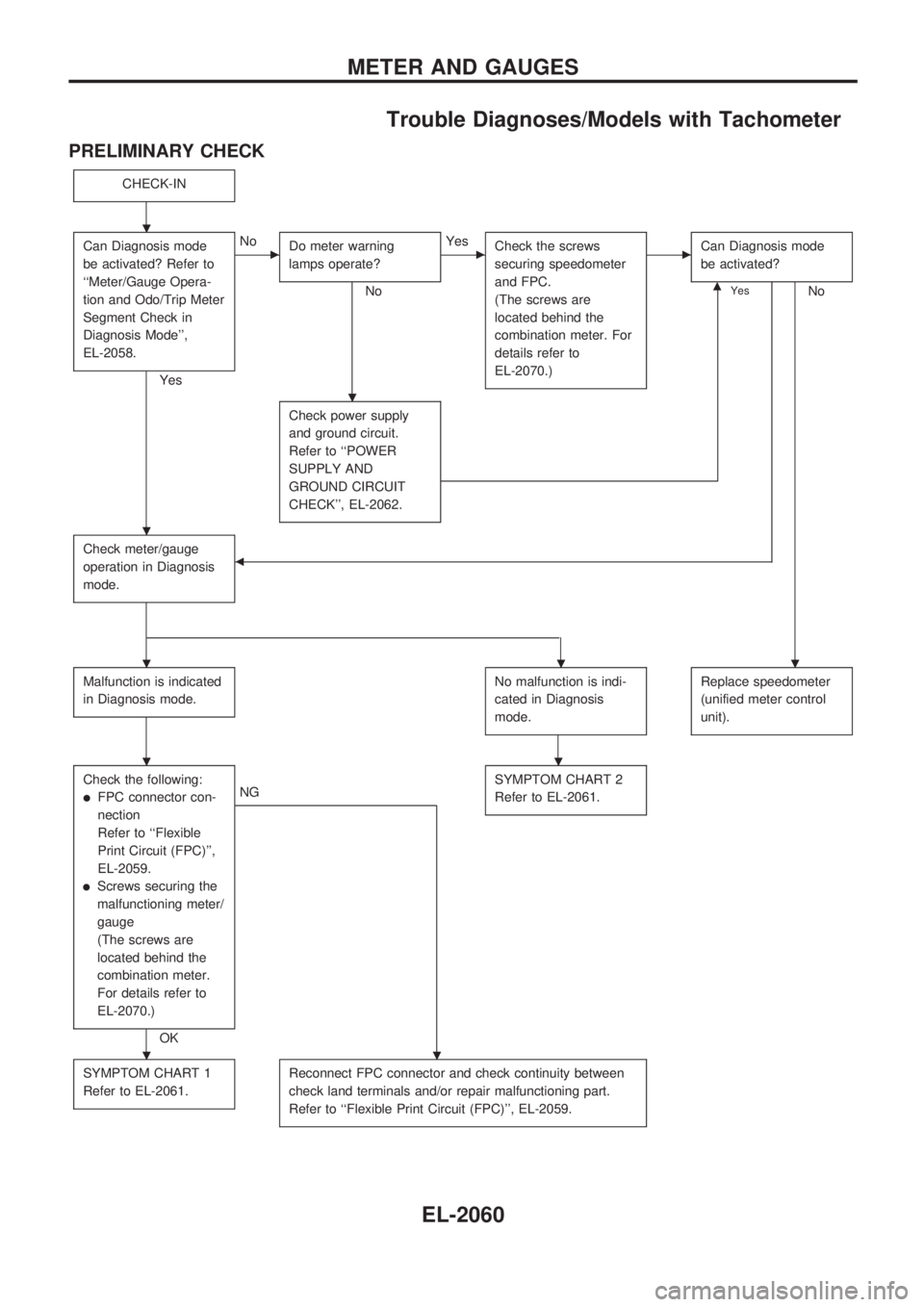

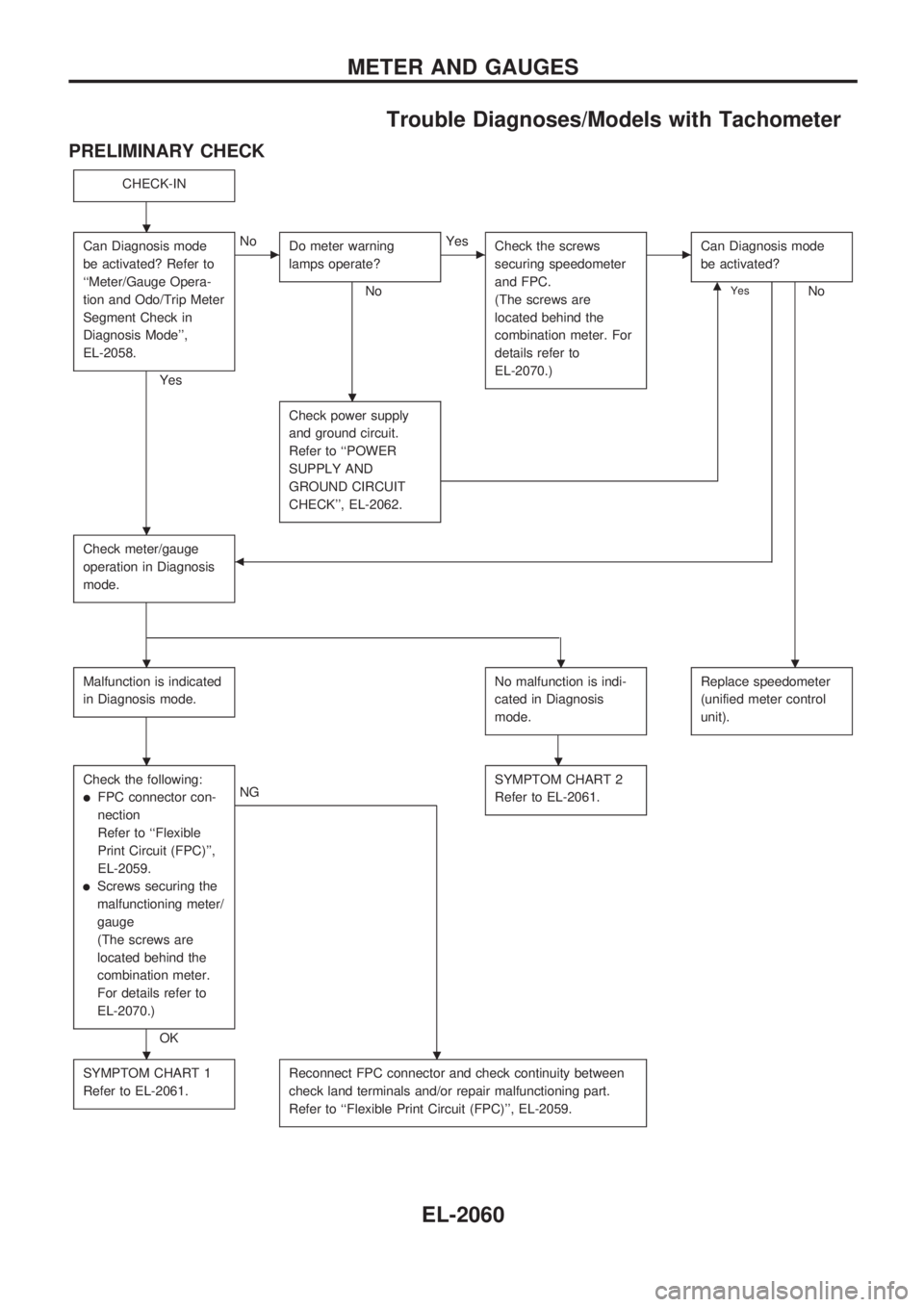

Trouble Diagnoses/Models with Tachometer

PRELIMINARY CHECK

CHECK-IN

Can Diagnosis mode

be activated? Refer to

``Meter/Gauge Opera-

tion and Odo/Trip Meter

Segment Check in

Diagnosis Mode'',

EL-2058.

Yes

cNo

Do meter warning

lamps operate?

No

cYes

Check the screws

securing speedometer

and FPC.

(The screws are

located behind the

combination meter. For

details refer to

EL-2070.)cCan Diagnosis mode

be activated?

NomYes

Check power supply

and ground circuit.

Refer to ``POWER

SUPPLY AND

GROUND CIRCUIT

CHECK'', EL-2062.

Check meter/gauge

operation in Diagnosis

mode.b

Malfunction is indicated

in Diagnosis mode.No malfunction is indi-

cated in Diagnosis

mode.Replace speedometer

(unified meter control

unit).

Check the following:

lFPC connector con-

nection

Refer to ``Flexible

Print Circuit (FPC)'',

EL-2059.

lScrews securing the

malfunctioning meter/

gauge

(The screws are

located behind the

combination meter.

For details refer to

EL-2070.)

OK

NGSYMPTOM CHART 2

Refer to EL-2061.

SYMPTOM CHART 1

Refer to EL-2061.Reconnect FPC connector and check continuity between

check land terminals and/or repair malfunctioning part.

Refer to ``Flexible Print Circuit (FPC)'', EL-2059.

.

.

.

...

..

..

METER AND GAUGES

EL-2060

Page 144 of 666

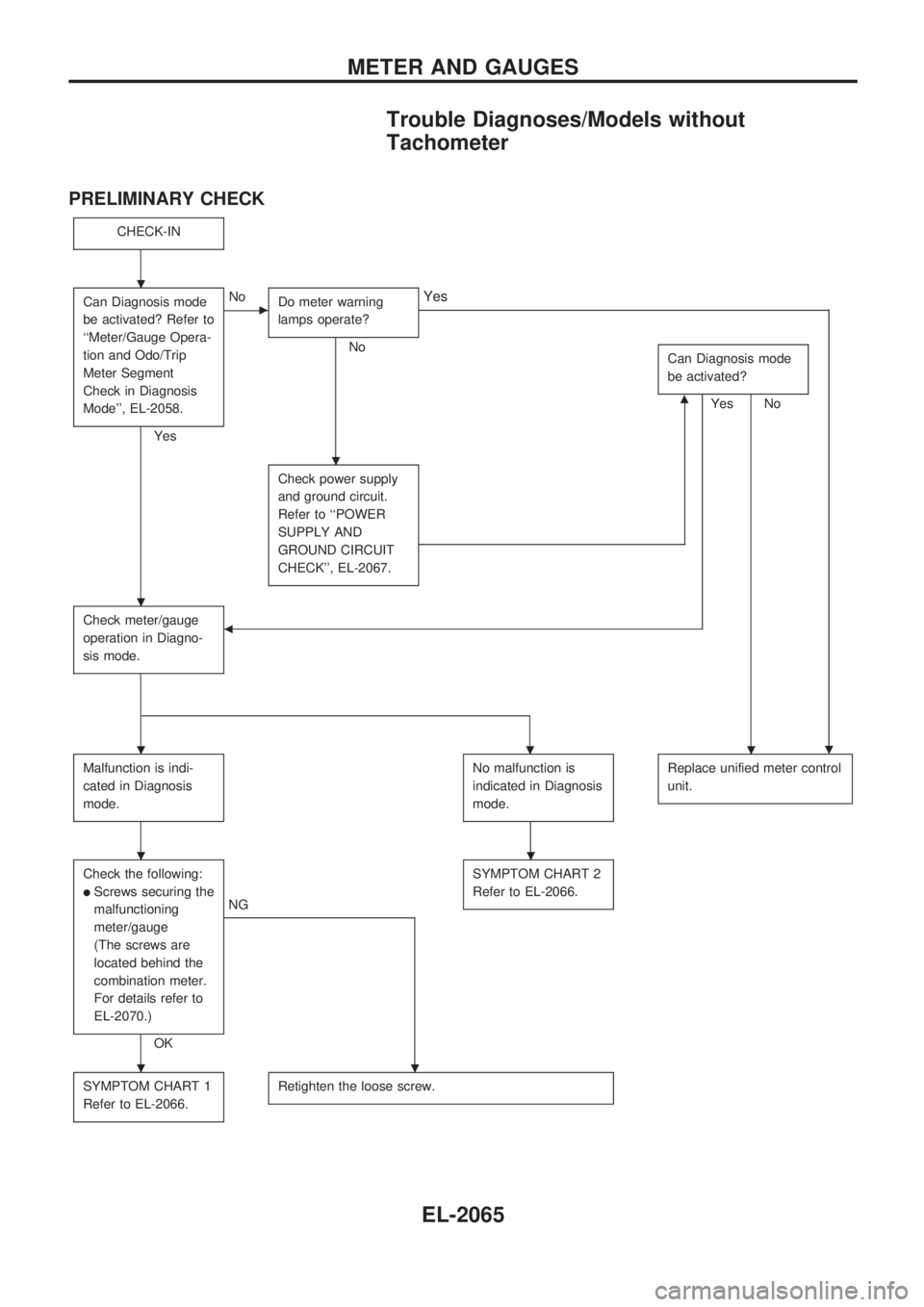

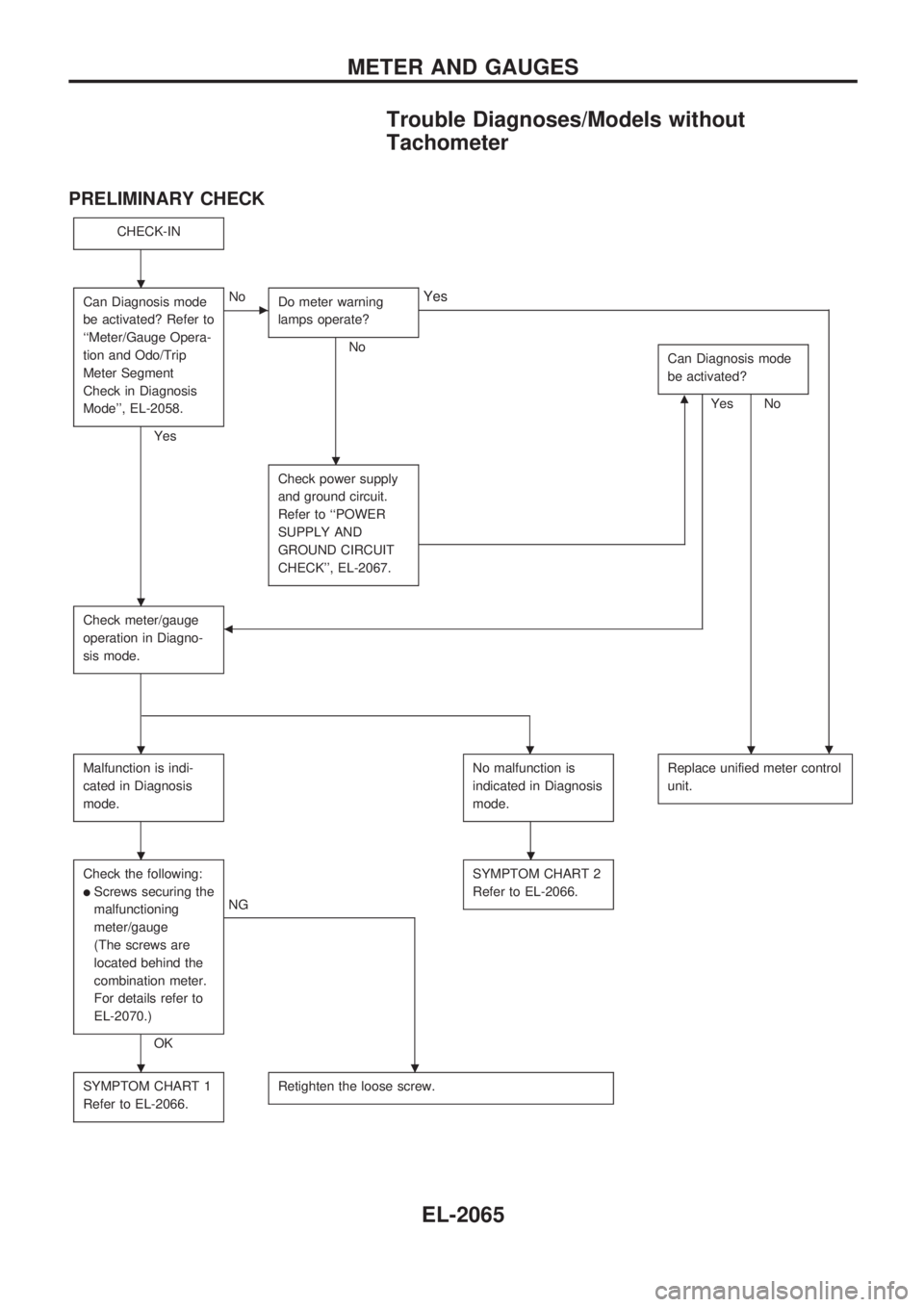

Trouble Diagnoses/Models without

Tachometer

PRELIMINARY CHECK

CHECK-IN

Can Diagnosis mode

be activated? Refer to

``Meter/Gauge Opera-

tion and Odo/Trip

Meter Segment

Check in Diagnosis

Mode'', EL-2058.

Yes

cNo

Do meter warning

lamps operate?

No

.

Yes

Can Diagnosis mode

be activated?

NomYes

Check power supply

and ground circuit.

Refer to ``POWER

SUPPLY AND

GROUND CIRCUIT

CHECK'', EL-2067.

Check meter/gauge

operation in Diagno-

sis mode.b

Malfunction is indi-

cated in Diagnosis

mode.No malfunction is

indicated in Diagnosis

mode.Replace unified meter control

unit.

Check the following:

lScrews securing the

malfunctioning

meter/gauge

(The screws are

located behind the

combination meter.

For details refer to

EL-2070.)

OK

NGSYMPTOM CHART 2

Refer to EL-2066.

SYMPTOM CHART 1

Refer to EL-2066.Retighten the loose screw.

.

.

.

...

..

..

METER AND GAUGES

EL-2065

Page 310 of 666

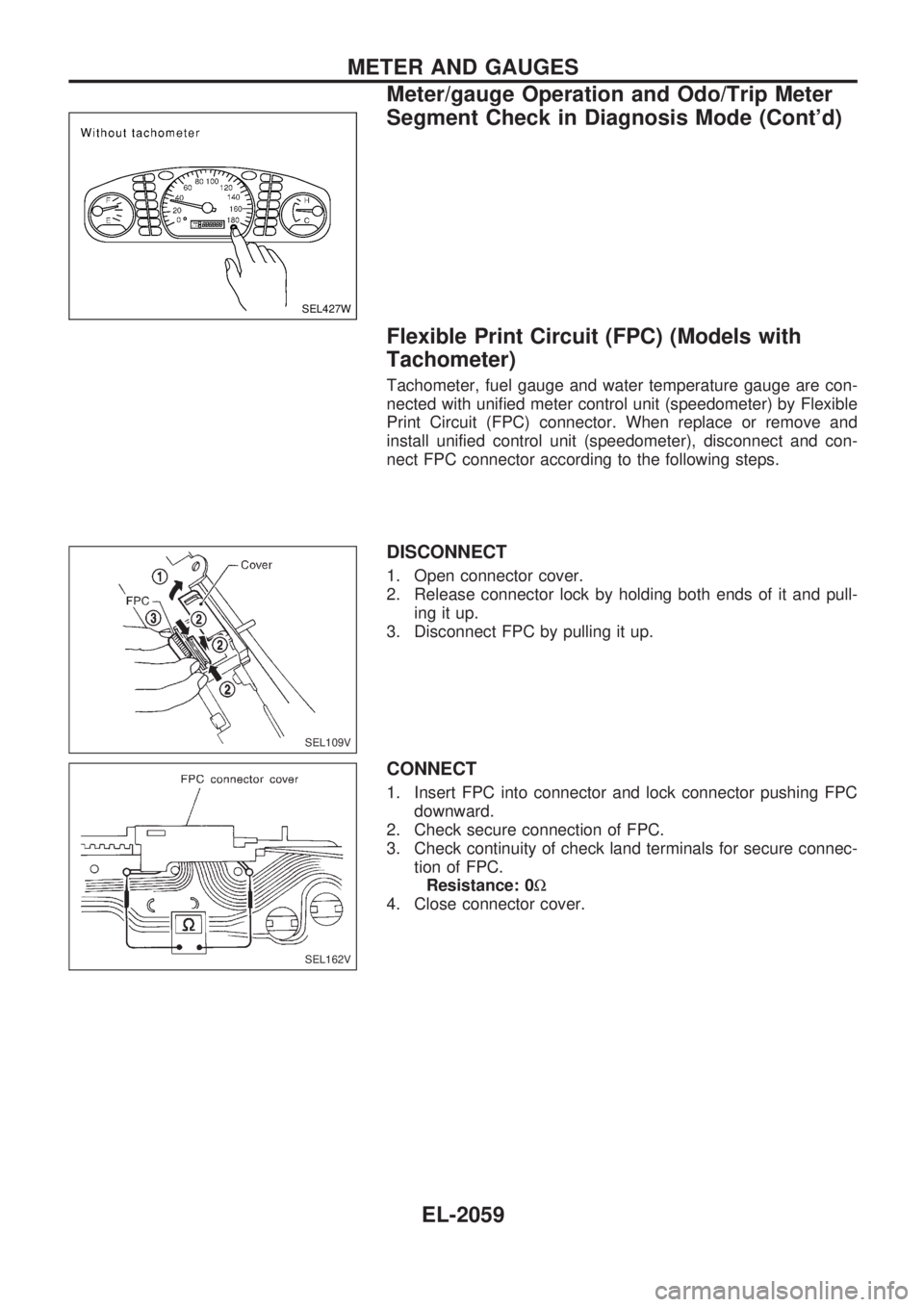

Flexible Print Circuit (FPC) (Models with

Tachometer)

Tachometer, fuel gauge and water temperature gauge are con-

nected with unified meter control unit (speedometer) by Flexible

Print Circuit (FPC) connector. When replace or remove and

install unified control unit (speedometer), disconnect and con-

nect FPC connector according to the following steps.

DISCONNECT

1. Open connector cover.

2. Release connector lock by holding both ends of it and pull-

ing it up.

3. Disconnect FPC by pulling it up.

CONNECT

1. Insert FPC into connector and lock connector pushing FPC

downward.

2. Check secure connection of FPC.

3. Check continuity of check land terminals for secure connec-

tion of FPC.

Resistance: 0W

4. Close connector cover.

SEL427W

SEL109V

SEL162V

METER AND GAUGES

Meter/gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode (Cont'd)

EL-2059

Page 311 of 666

Trouble Diagnoses/Models with Tachometer

PRELIMINARY CHECK

CHECK-IN

Can Diagnosis mode

be activated? Refer to

``Meter/Gauge Opera-

tion and Odo/Trip Meter

Segment Check in

Diagnosis Mode'',

EL-2058.

Yes

cNo

Do meter warning

lamps operate?

No

cYes

Check the screws

securing speedometer

and FPC.

(The screws are

located behind the

combination meter. For

details refer to

EL-2070.)cCan Diagnosis mode

be activated?

NomYes

Check power supply

and ground circuit.

Refer to ``POWER

SUPPLY AND

GROUND CIRCUIT

CHECK'', EL-2062.

Check meter/gauge

operation in Diagnosis

mode.b

Malfunction is indicated

in Diagnosis mode.No malfunction is indi-

cated in Diagnosis

mode.Replace speedometer

(unified meter control

unit).

Check the following:

lFPC connector con-

nection

Refer to ``Flexible

Print Circuit (FPC)'',

EL-2059.

lScrews securing the

malfunctioning meter/

gauge

(The screws are

located behind the

combination meter.

For details refer to

EL-2070.)

OK

NGSYMPTOM CHART 2

Refer to EL-2061.

SYMPTOM CHART 1

Refer to EL-2061.Reconnect FPC connector and check continuity between

check land terminals and/or repair malfunctioning part.

Refer to ``Flexible Print Circuit (FPC)'', EL-2059.

.

.

.

...

..

..

METER AND GAUGES

EL-2060

Page 316 of 666

Trouble Diagnoses/Models without

Tachometer

PRELIMINARY CHECK

CHECK-IN

Can Diagnosis mode

be activated? Refer to

``Meter/Gauge Opera-

tion and Odo/Trip

Meter Segment

Check in Diagnosis

Mode'', EL-2058.

Yes

cNo

Do meter warning

lamps operate?

No

.

Yes

Can Diagnosis mode

be activated?

NomYes

Check power supply

and ground circuit.

Refer to ``POWER

SUPPLY AND

GROUND CIRCUIT

CHECK'', EL-2067.

Check meter/gauge

operation in Diagno-

sis mode.b

Malfunction is indi-

cated in Diagnosis

mode.No malfunction is

indicated in Diagnosis

mode.Replace unified meter control

unit.

Check the following:

lScrews securing the

malfunctioning

meter/gauge

(The screws are

located behind the

combination meter.

For details refer to

EL-2070.)

OK

NGSYMPTOM CHART 2

Refer to EL-2066.

SYMPTOM CHART 1

Refer to EL-2066.Retighten the loose screw.

.

.

.

...

..

..

METER AND GAUGES

EL-2065

Page 446 of 666

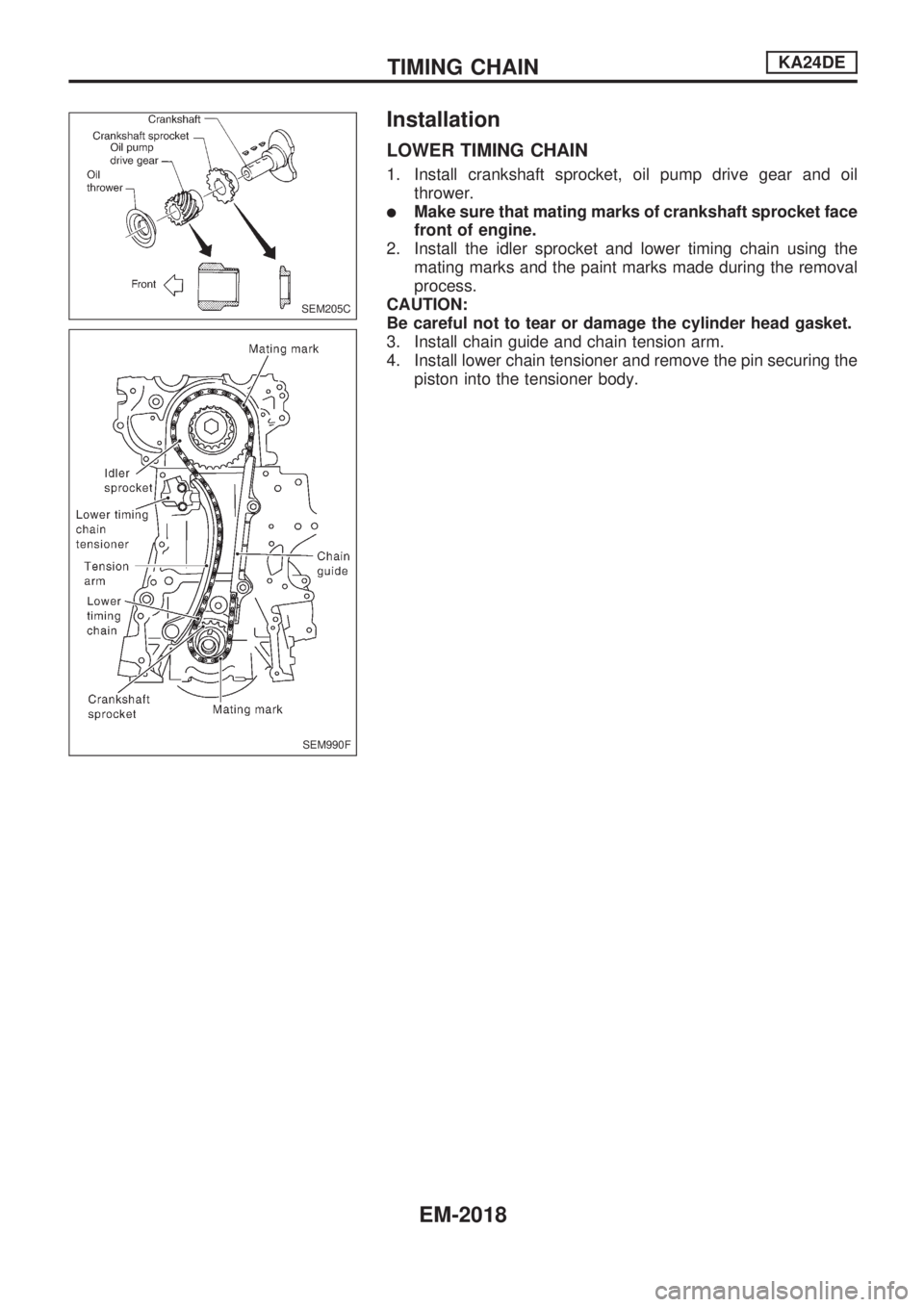

Installation

LOWER TIMING CHAIN

1. Install crankshaft sprocket, oil pump drive gear and oil

thrower.

lMake sure that mating marks of crankshaft sprocket face

front of engine.

2. Install the idler sprocket and lower timing chain using the

mating marks and the paint marks made during the removal

process.

CAUTION:

Be careful not to tear or damage the cylinder head gasket.

3. Install chain guide and chain tension arm.

4. Install lower chain tensioner and remove the pin securing the

piston into the tensioner body.

SEM205C

SEM990F

TIMING CHAINKA24DE

EM-2018

Page 474 of 666

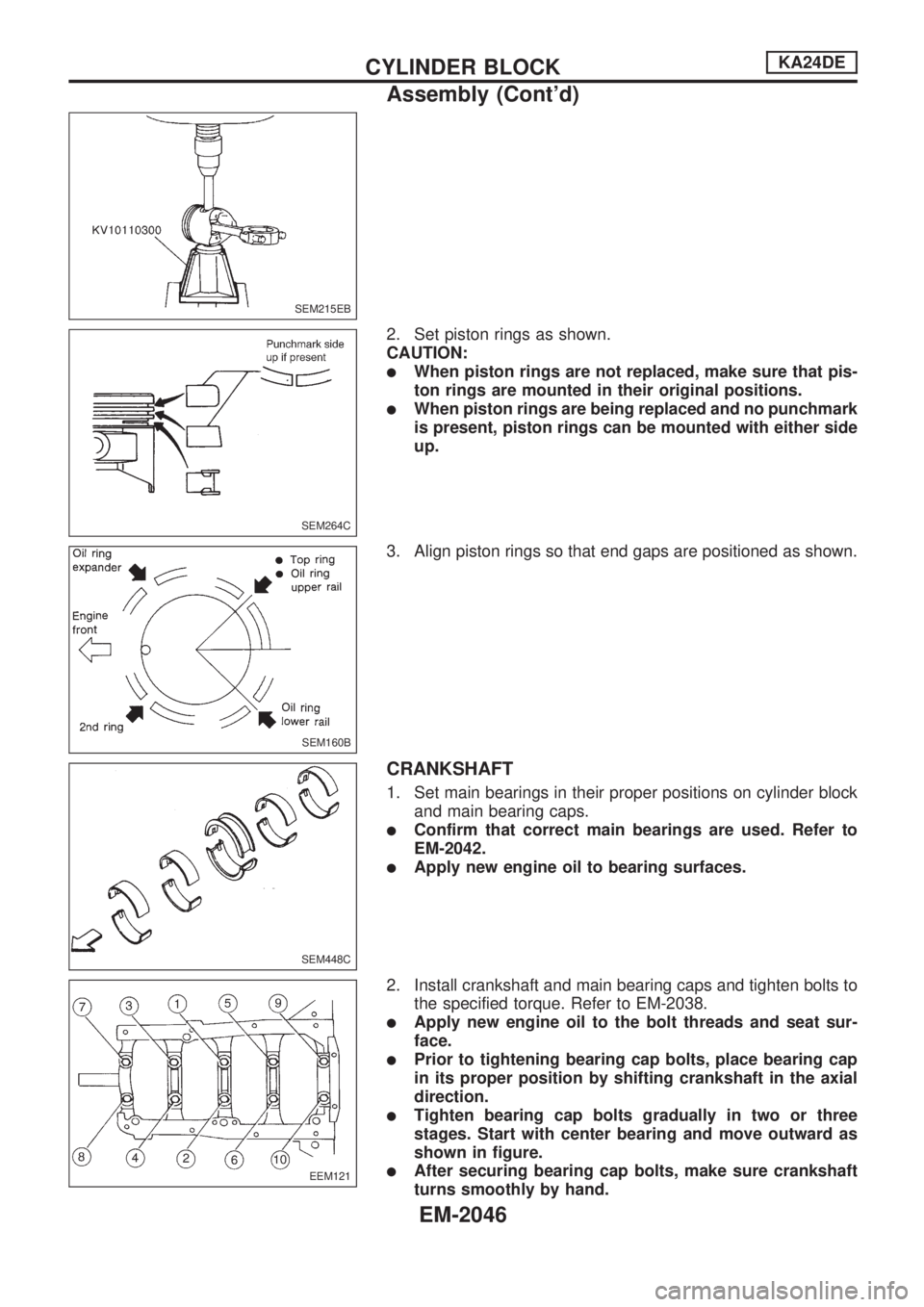

2. Set piston rings as shown.

CAUTION:

lWhen piston rings are not replaced, make sure that pis-

ton rings are mounted in their original positions.

lWhen piston rings are being replaced and no punchmark

is present, piston rings can be mounted with either side

up.

3. Align piston rings so that end gaps are positioned as shown.

CRANKSHAFT

1. Set main bearings in their proper positions on cylinder block

and main bearing caps.

lConfirm that correct main bearings are used. Refer to

EM-2042.

lApply new engine oil to bearing surfaces.

2. Install crankshaft and main bearing caps and tighten bolts to

the specified torque. Refer to EM-2038.

lApply new engine oil to the bolt threads and seat sur-

face.

lPrior to tightening bearing cap bolts, place bearing cap

in its proper position by shifting crankshaft in the axial

direction.

lTighten bearing cap bolts gradually in two or three

stages. Start with center bearing and move outward as

shown in figure.

lAfter securing bearing cap bolts, make sure crankshaft

turns smoothly by hand.

SEM215EB

SEM264C

SEM160B

SEM448C

EEM121

CYLINDER BLOCKKA24DE

Assembly (Cont'd)

EM-2046

Page 557 of 666

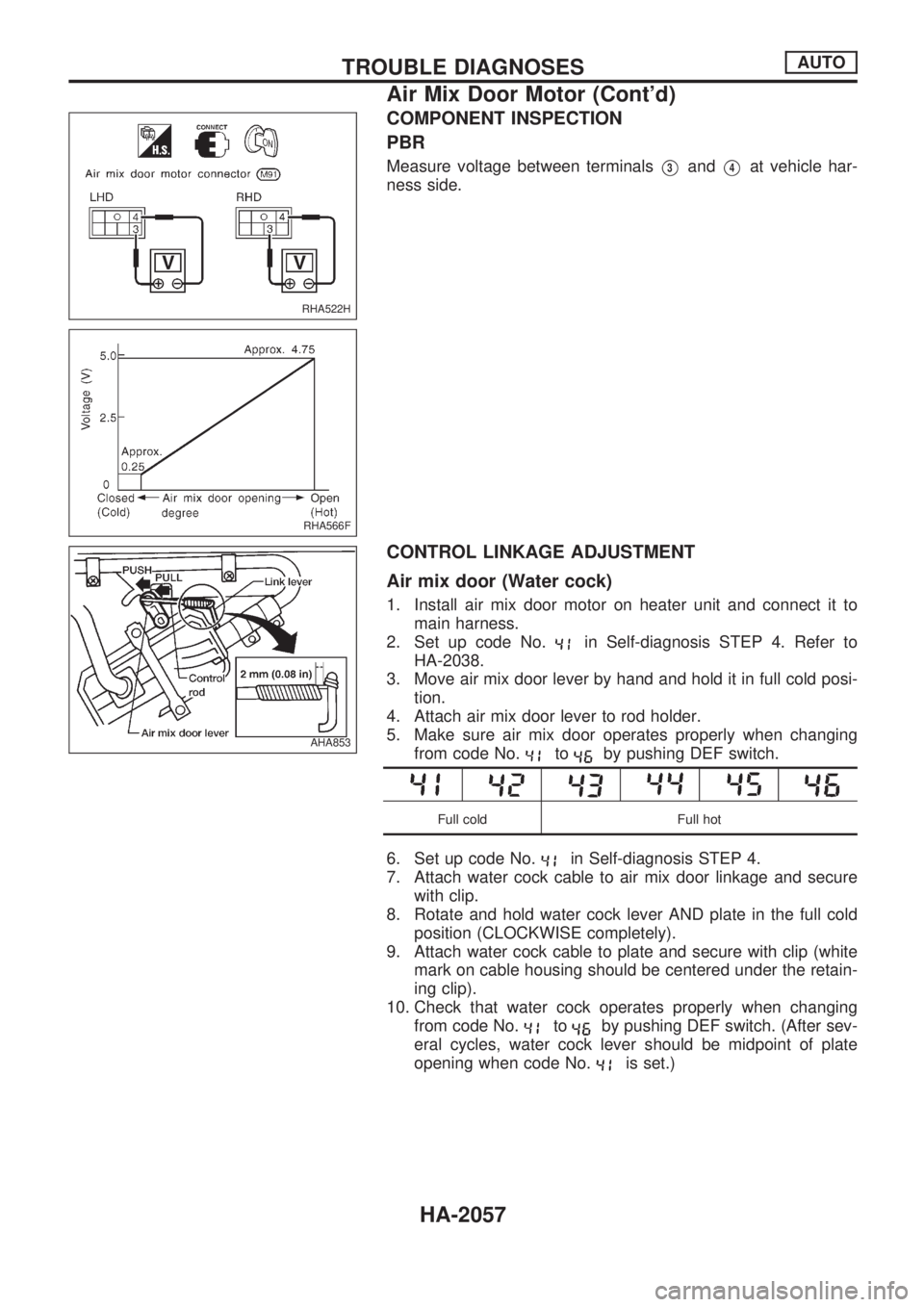

COMPONENT INSPECTION

PBR

Measure voltage between terminalsV3andV4at vehicle har-

ness side.

CONTROL LINKAGE ADJUSTMENT

Air mix door (Water cock)

1. Install air mix door motor on heater unit and connect it to

main harness.

2. Set up code No.

in Self-diagnosis STEP 4. Refer to

HA-2038.

3. Move air mix door lever by hand and hold it in full cold posi-

tion.

4. Attach air mix door lever to rod holder.

5. Make sure air mix door operates properly when changing

from code No.

toby pushing DEF switch.

Full cold Full hot

6. Set up code No.in Self-diagnosis STEP 4.

7. Attach water cock cable to air mix door linkage and secure

with clip.

8. Rotate and hold water cock lever AND plate in the full cold

position (CLOCKWISE completely).

9. Attach water cock cable to plate and secure with clip (white

mark on cable housing should be centered under the retain-

ing clip).

10. Check that water cock operates properly when changing

from code No.

toby pushing DEF switch. (After sev-

eral cycles, water cock lever should be midpoint of plate

opening when code No.

is set.)

RHA522H

RHA566F

AHA853

TROUBLE DIAGNOSESAUTO

Air Mix Door Motor (Cont'd)

HA-2057

Page 612 of 666

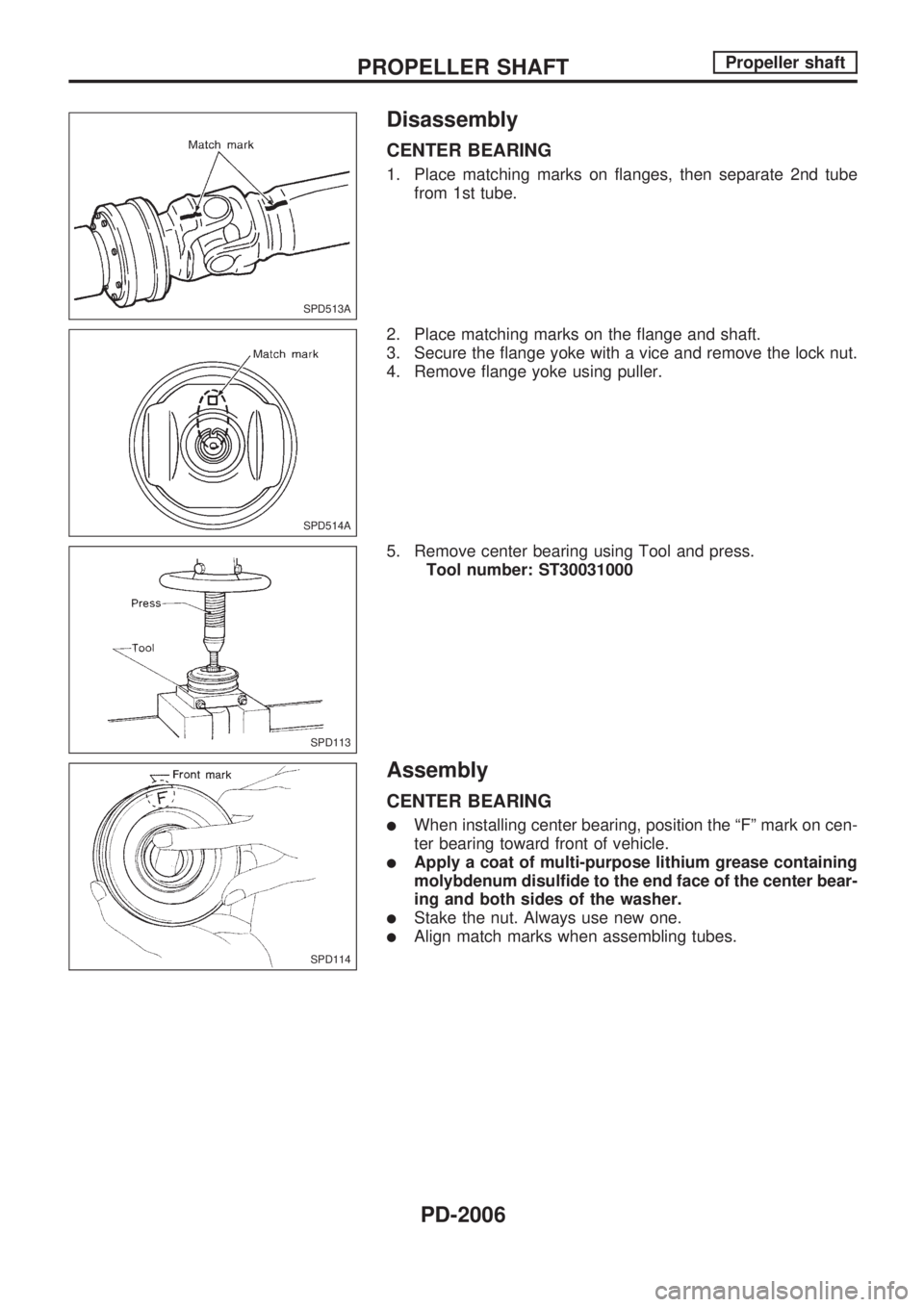

Disassembly

CENTER BEARING

1. Place matching marks on flanges, then separate 2nd tube

from 1st tube.

2. Place matching marks on the flange and shaft.

3. Secure the flange yoke with a vice and remove the lock nut.

4. Remove flange yoke using puller.

5. Remove center bearing using Tool and press.

Tool number: ST30031000

Assembly

CENTER BEARING

lWhen installing center bearing, position the ªFº mark on cen-

ter bearing toward front of vehicle.

lApply a coat of multi-purpose lithium grease containing

molybdenum disulfide to the end face of the center bear-

ing and both sides of the washer.

lStake the nut. Always use new one.

lAlign match marks when assembling tubes.

SPD513A

SPD514A

SPD113

SPD114

PROPELLER SHAFTPropeller shaft

PD-2006