engine NISSAN PICK-UP 1999 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PICK-UP, Model: NISSAN PICK-UP 1999Pages: 666, PDF Size: 16.21 MB

Page 1 of 666

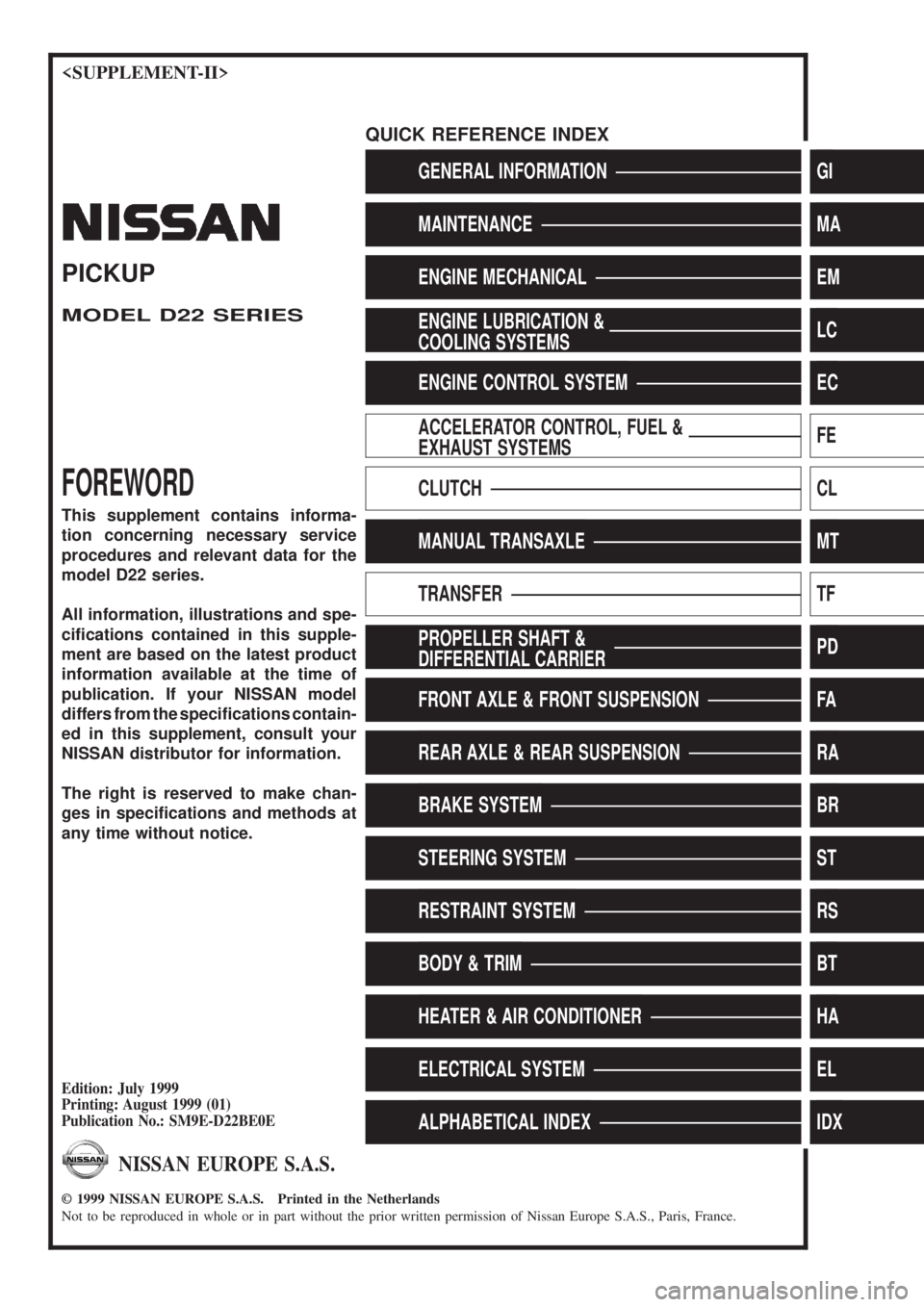

GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMSFE

CLUTCHCL

MANUAL TRANSAXLEMT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

PICKUP

MODEL D22 SERIES

FOREWORD

This supplement contains informa-

tion concerning necessary service

procedures and relevant data for the

model D22 series.

All information, illustrations and spe-

ci®cations contained in this supple-

ment are based on the latest product

information available at the time of

publication. If your NISSAN model

differs from the speci®cations contain-

ed in this supplement, consult your

NISSAN distributor for information.

The right is reserved to make chan-

ges in speci®cations and methods at

any time without notice.

Edition: July 1999

Printing: August 1999 (01)

Publication No.: SM9E-D22BE0E

NISSAN EUROPE S.A.S.

1999 NISSAN EUROPE S.A.S. Printed in the Netherlands

Not to be reproduced in whole or in part without the prior written permission of Nissan Europe S.A.S., Paris, France.

QUICK REFERENCE INDEX

Page 2 of 666

FOREWORD

This manual contains maintenance and repair procedures for NISSAN

PICKUP, model D22 series.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in speci-

®cations and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the

technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a man-

ner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician and the

tools and parts available. Accordingly, anyone using service procedures,

tools or parts which are not speci®cally recommended by NISSAN must

®rst completely satisfy himself that neither his safety nor the vehicle's

safety will be jeopardized by the service method selected.

NISSAN EUROPE S.A.S.

Service Engineering Section

Paris, France

Page 46 of 666

ENGINECONTROLSYSTEM

SECTION

EC

MODIFICATION NOTICE:

Gasoline engine

Diesel engine

lWiring diagrams have been changed.

CONTENTS

PRECAUTIONS AND PREPARATION ............... 2003

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER'' .. 2003

KA24E

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM............................................................... 2004

Circuit Diagram ................................................ 2004

TROUBLE DIAGNOSIS FOR POWER

SUPPLY ............................................................... 2005

Main Power Supply and Ground Circuit .......... 2005

TROUBLE DIAGNOSIS FOR ``CAMSHAFT

POSI SEN'' (DTC 11) ........................................... 2007

Camshaft Position Sensor (CMPS) ................. 2007

TROUBLE DIAGNOSIS FOR ``MASS AIR FLOW

SEN'' (DTC 12) .................................................... 2008

Mass Air Flow Sensor (MAFS) ........................ 2008

TROUBLE DIAGNOSIS FOR

NON-DETECTABLE ITEMS ................................ 2009

Vehicle Speed Sensor (VSS) .......................... 2009

Heated Oxygen Sensor (HO2S)

- LHD Models - ................................................ 2010

Idle Air Control Valve (IACV) - Auxiliary Air

Control (AAC) Valve ........................................ 2011 Park/Neutral Position Switch ........................... 2012

EVAP Canister Purge Control Solenoid

Valve ................................................................ 2013

Start Signal ...................................................... 2014

Fuel Pump........................................................ 2015

Power Steering Oil Pressure Switch ............... 2016

Swirl Control Valve Control Solenoid Valve .... 2017

IACV-FICD Solenoid Valve .............................. 2018

MIL & Data Link Connectors ........................... 2019

TD

QUICK-GLOW SYSTEM ...................................... 2020

Circuit Diagram ................................................ 2020

Wiring Diagram ................................................ 2021

EGR SYSTEM ...................................................... 2027

Wiring Diagram ................................................ 2027

SOLENOID TIMER .............................................. 2031

Wiring Diagram ................................................ 2031

FUEL HEATER SYSTEM .................................... 2033

Wiring Diagram ................................................ 2033

FAST IDLE CONTROL CIRCUIT ........................ 2034

Wiring Diagram ................................................ 2034

EC

Page 49 of 666

Circuit Diagram

HEC631

ENGINE AND EMISSION CONTROL OVERALL SYSTEMKA24E

EC-2004

Page 65 of 666

Circuit Diagram

TD25 AND TD25Ti ENGINES

HEC693

QUICK-GLOW SYSTEMTD

EC-2020

Page 66 of 666

Wiring Diagram

LHD MODELS WITH TD25 AND TD25Ti ENGINES

HEC706

QUICK-GLOW SYSTEMTD

EC-2021

Page 69 of 666

RHD MODELS WITH TD25 AND TD25Ti ENGINES

HEC709

QUICK-GLOW SYSTEMTD

Wiring Diagram (Cont'd)

EC-2024

Page 72 of 666

Wiring Diagram

TD25 & TD25Ti ENGINES (LHD)

HEC712

EGR SYSTEMTD

EC-2027

Page 74 of 666

TD25 & TD25Ti ENGINES (RHD)

HEC714

EGR SYSTEMTD

Wiring Diagram (Cont'd)

EC-2029

Page 76 of 666

Wiring Diagram

TD25 & TD25Ti ENGINE (LHD)

HEC718

SOLENOID TIMERTD

EC-2031