turn signal NISSAN PICK-UP 1999 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PICK-UP, Model: NISSAN PICK-UP 1999Pages: 666, PDF Size: 16.21 MB

Page 80 of 666

ELECTRICALSYSTEM

SECTION

EL

MODIFICATION NOTICE:

Wiring diagrams have been changed.

CONTENTS

PRECAUTIONS ................................................... 2003

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER'' .. 2003

POWER SUPPLY ROUTING ............................... 2004

Schematic ........................................................ 2004

Wiring Diagram - POWER -............................. 2005

STARTING SYSTEM ........................................... 2012

Wiring Diagram - START -/M/T Models .......... 2012

CHARGING SYSTEM .......................................... 2013

Wiring Diagram - CHARGE -/Gasoline

Engine .............................................................. 2013

Wiring Diagram - CHARGE -/Diesel Engine ... 2014

Construction ..................................................... 2015

Service Data and Specifications (SDS) ........... 2016

COMBINATION SWITCH .................................... 2017

Check ............................................................... 2017

HEADLAMP - Conventional Type - ................... 2018

Wiring Diagram - H/LAMP -/LHD Models ........ 2018

Wiring Diagram - H/LAMP -/RHD Models ....... 2020

HEADLAMP - Daytime Light System - ............. 2022

Wiring Diagram - DTRL - ................................. 2022

HEADLAMP - Dim-dip Lamp System - ............. 2025

Wiring Diagram - DIMDIP -.............................. 2025

HEADLAMP - Headlamp Aiming Control - ....... 2028

Wiring Diagram - H/AIM - ................................ 2028

PARKING, LICENSE AND TAIL LAMPS ........... 2030

Wiring Diagram - TAIL/L -/Except LHD

Models.............................................................. 2030

Wiring Diagram - TAIL/L -/LHD Models........... 2032

STOP LAMP ........................................................ 2034

Wiring Diagram - STOP/L - ............................. 2034

BACK-UP LAMP .................................................. 2035

Wiring Diagram - BACK/L -/M/T Models ......... 2035 REAR FOG LAMP

............................................... 2036

Wiring Diagram - R/FOG -/LHD Models .......... 2036

Wiring Diagram - R/FOG -/RHD Models ......... 2037

TURN SIGNAL AND HAZARD WARNING

LAMPS ................................................................. 2038

Wiring Diagram - TURN -/Type-1 .................... 2038

Wiring Diagram - TURN -/Type-2 .................... 2040

ILLUMINATION .................................................... 2043

Wiring Diagram - ILL -/LHD Models ................ 2043

Wiring Diagram - ILL -/RHD Models................ 2045

INTERIOR ROOM LAMP ..................................... 2047

Wiring Diagram - ROOM/L - ............................ 2047

SPOT LAMP ........................................................ 2048

Wiring Diagram - INT/L - ................................. 2048

METER AND GAUGES ....................................... 2049

Combination Meter........................................... 2049

Wiring Diagram - METER -/Gasoline Engine

with Tachometer .............................................. 2052

Wiring Diagram - METER -/Diesel Engine with

Tachometer ...................................................... 2054

Wiring Diagram - METER -/Gasoline Engine

without Tachometer ......................................... 2056

Wiring Diagram - METER -/Diesel Engine

without Tachometer ......................................... 2057

Unified Control Meter System Description ...... 2058

Meter/gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode ................ 2058

Flexible Print Circuit (FPC) (Models with

Tachometer) ..................................................... 2059

Trouble Diagnoses/Models with Tachometer .. 2060

Trouble Diagnoses/Models without

Tachometer ...................................................... 2065

Electrical Components Inspection ................... 2070

EL

Page 117 of 666

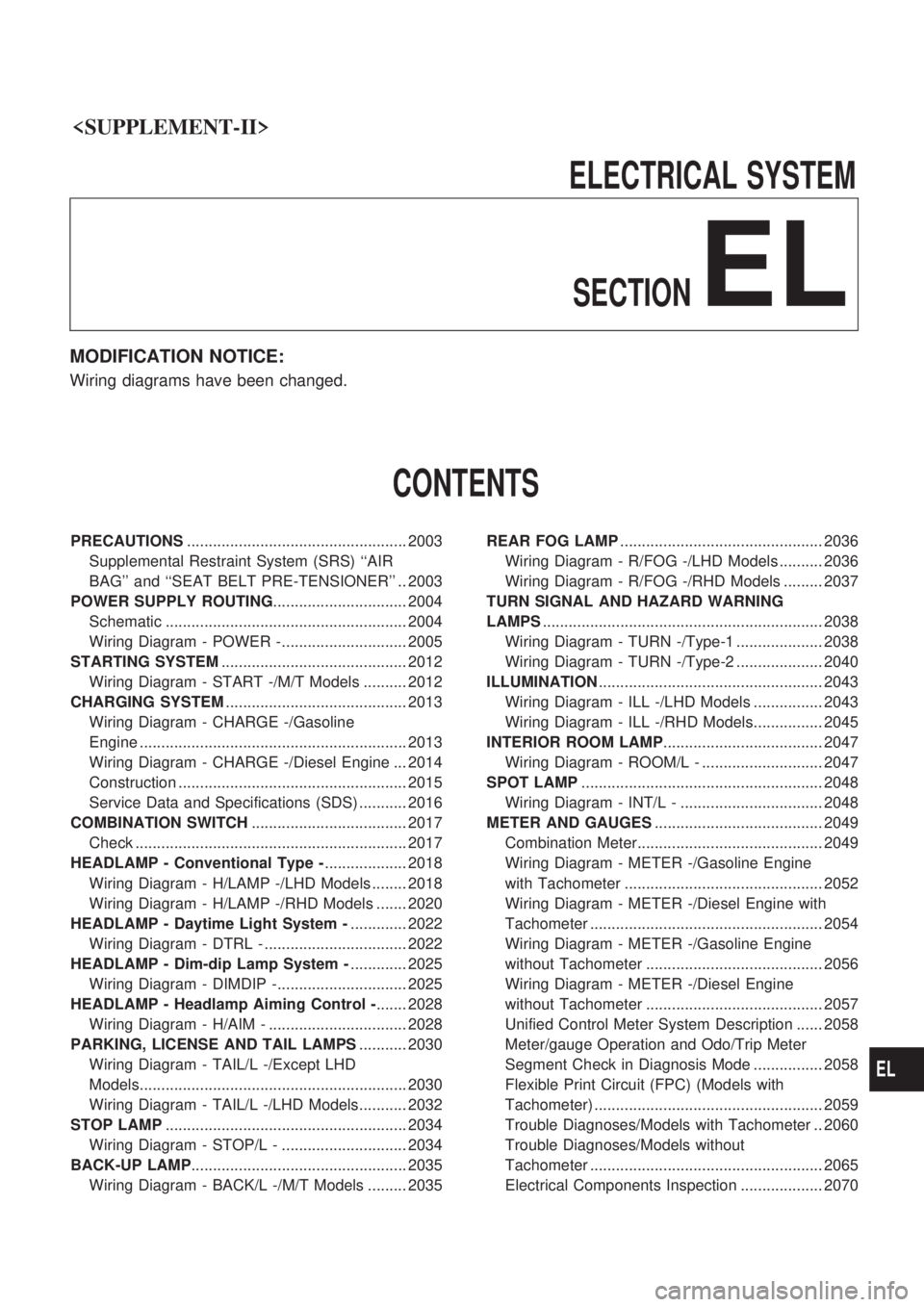

Wiring Diagram Ð TURN Ð/Type-1

FOR EUROPE (Single cab)

HEL703A

TURN SIGNAL AND HAZARD WARNING LAMPS

EL-2038

Page 118 of 666

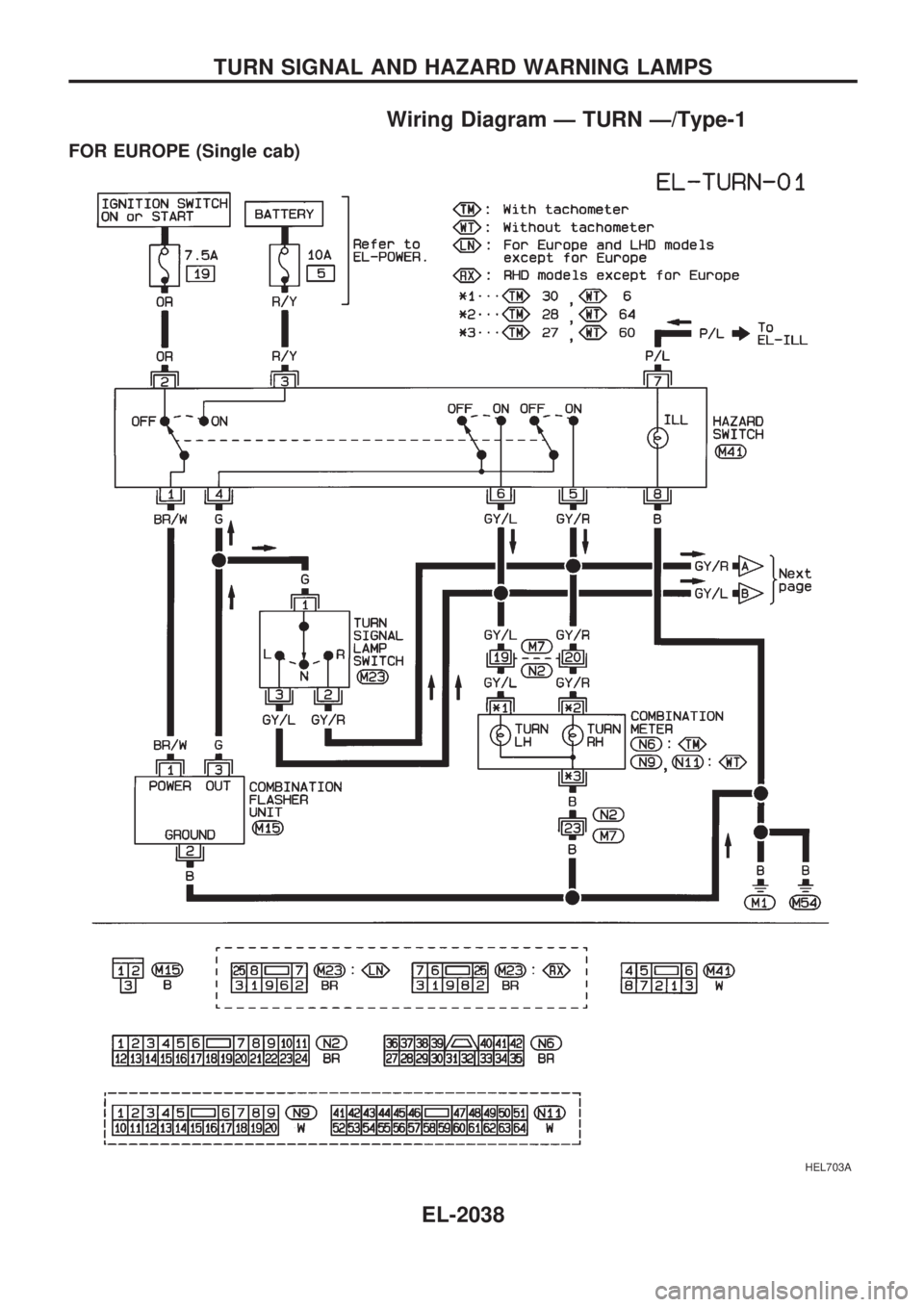

HEL704A

TURN SIGNAL AND HAZARD WARNING LAMPS

Wiring Diagram Ð TURN Ð/Type-1 (Cont'd)

EL-2039

Page 119 of 666

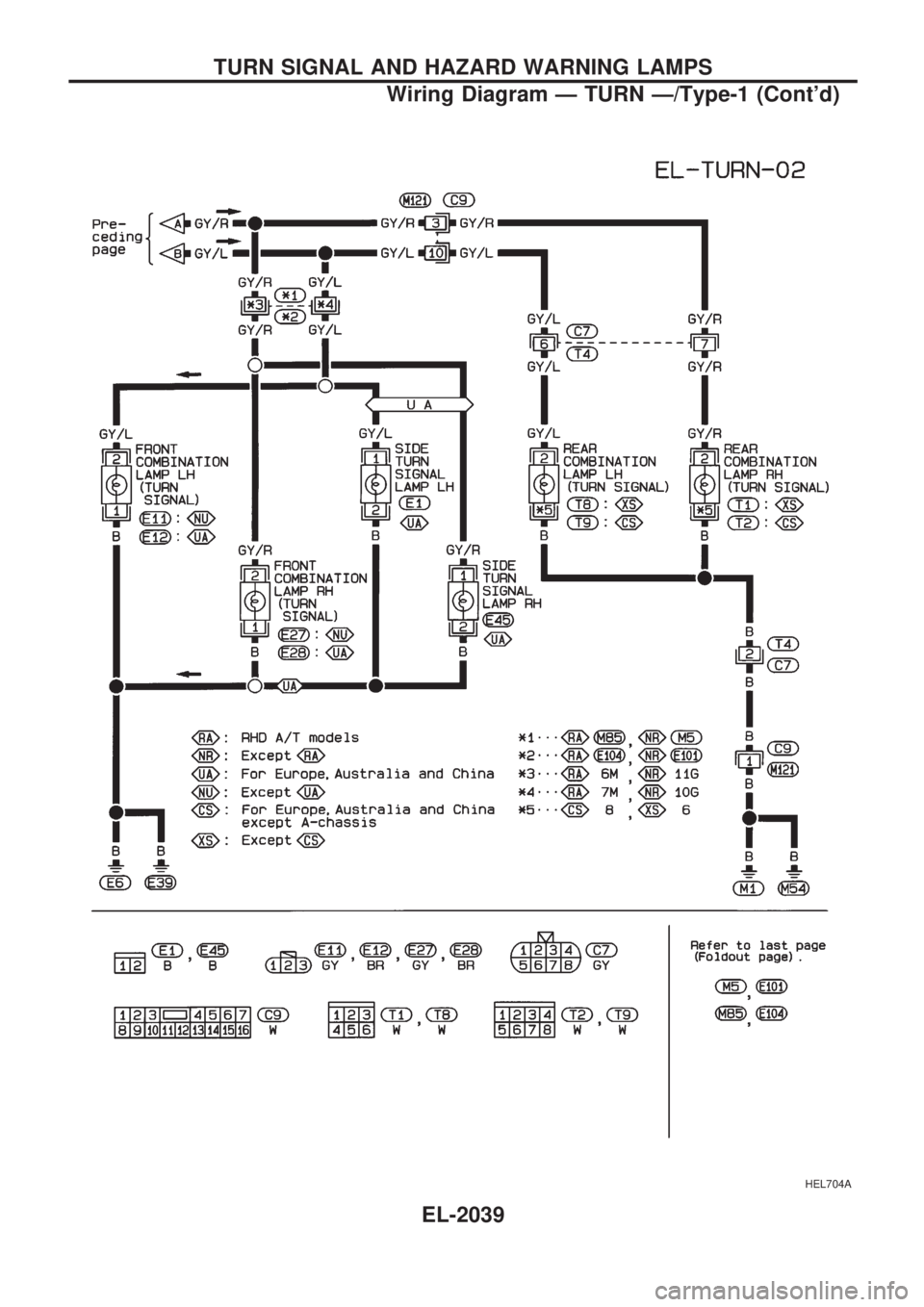

Wiring Diagram Ð TURN Ð/Type-2

FOR EUROPE (King cab and Double cab)

HEL705A

TURN SIGNAL AND HAZARD WARNING LAMPS

EL-2040

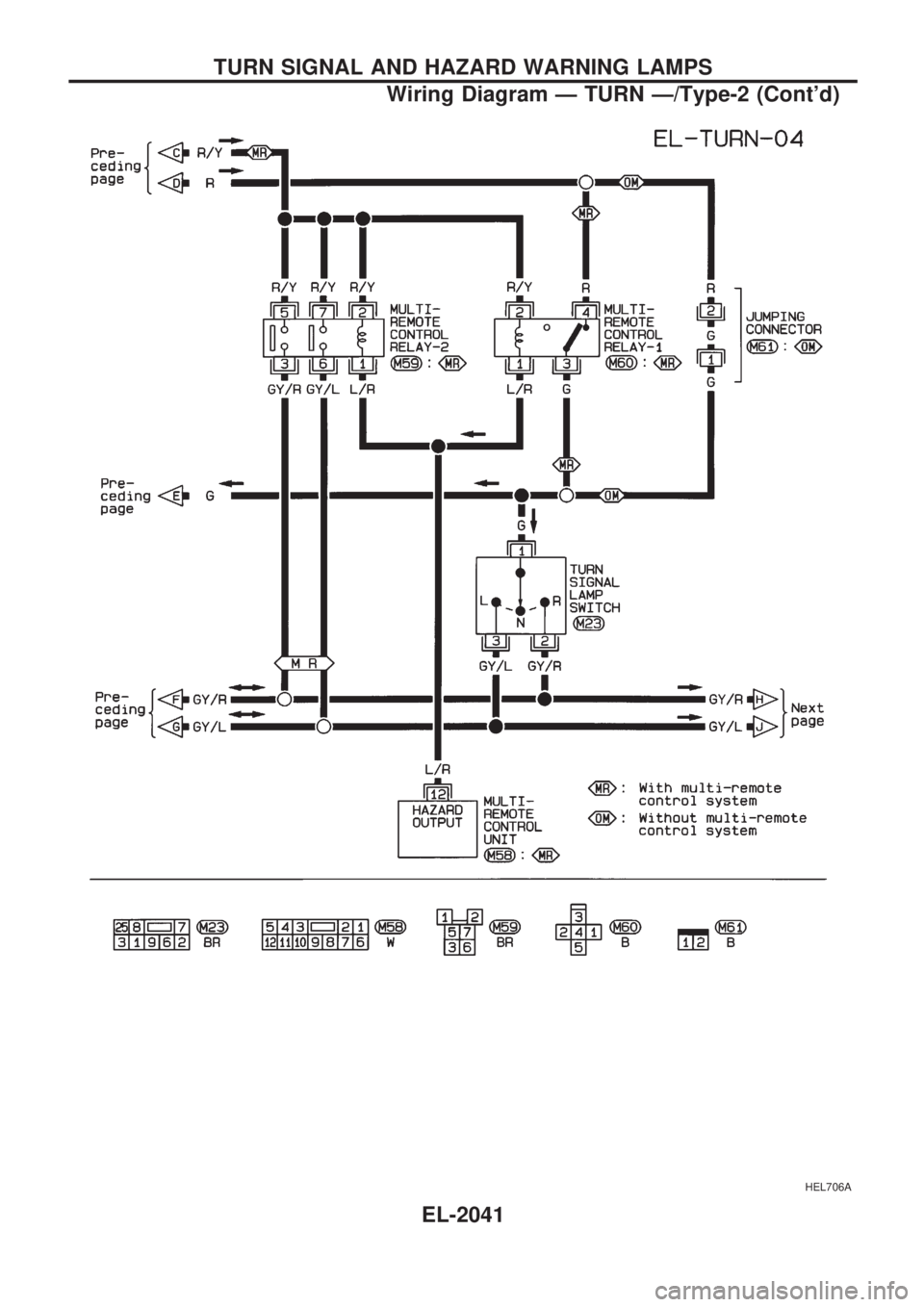

Page 120 of 666

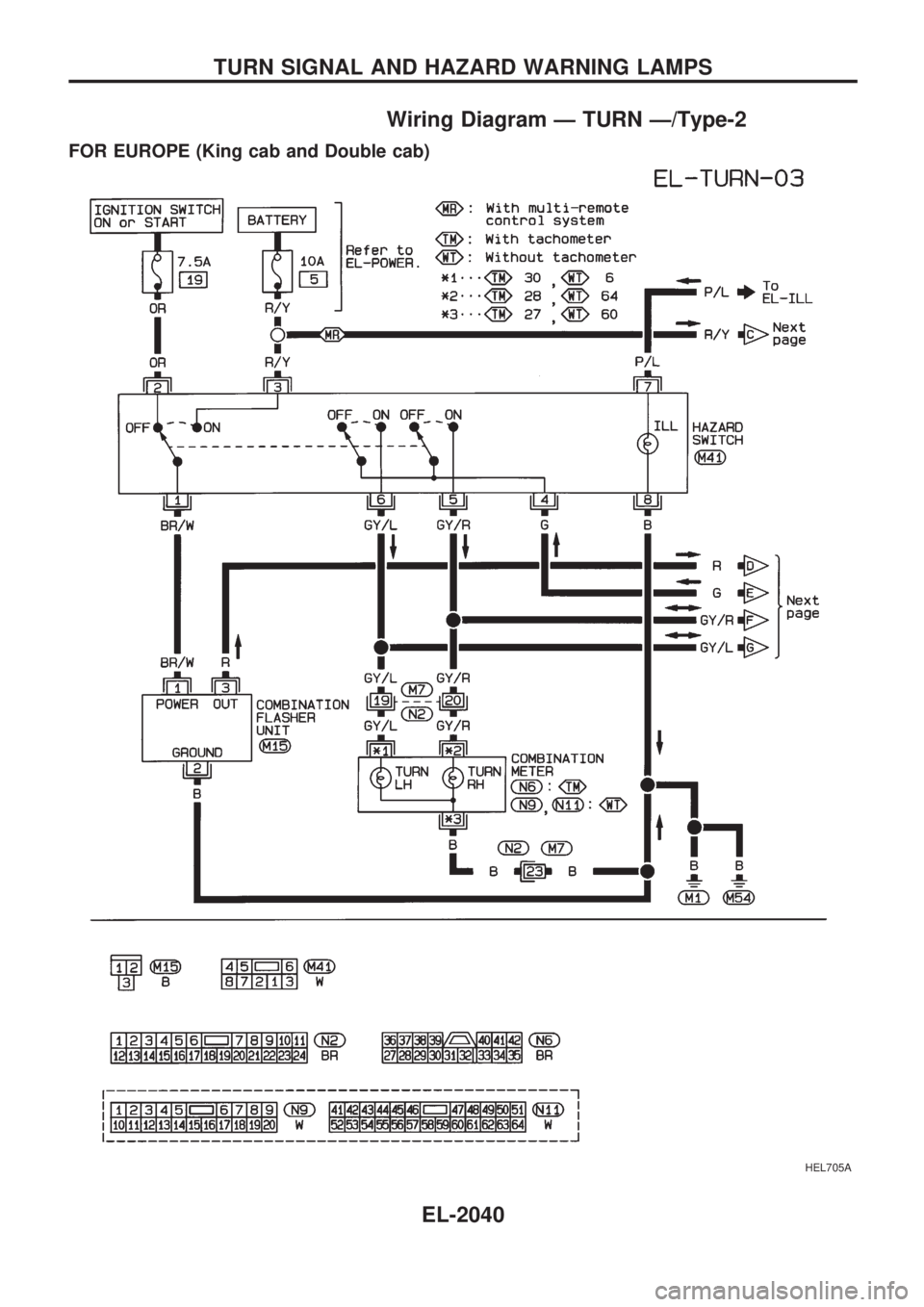

HEL706A

TURN SIGNAL AND HAZARD WARNING LAMPS

Wiring Diagram Ð TURN Ð/Type-2 (Cont'd)

EL-2041

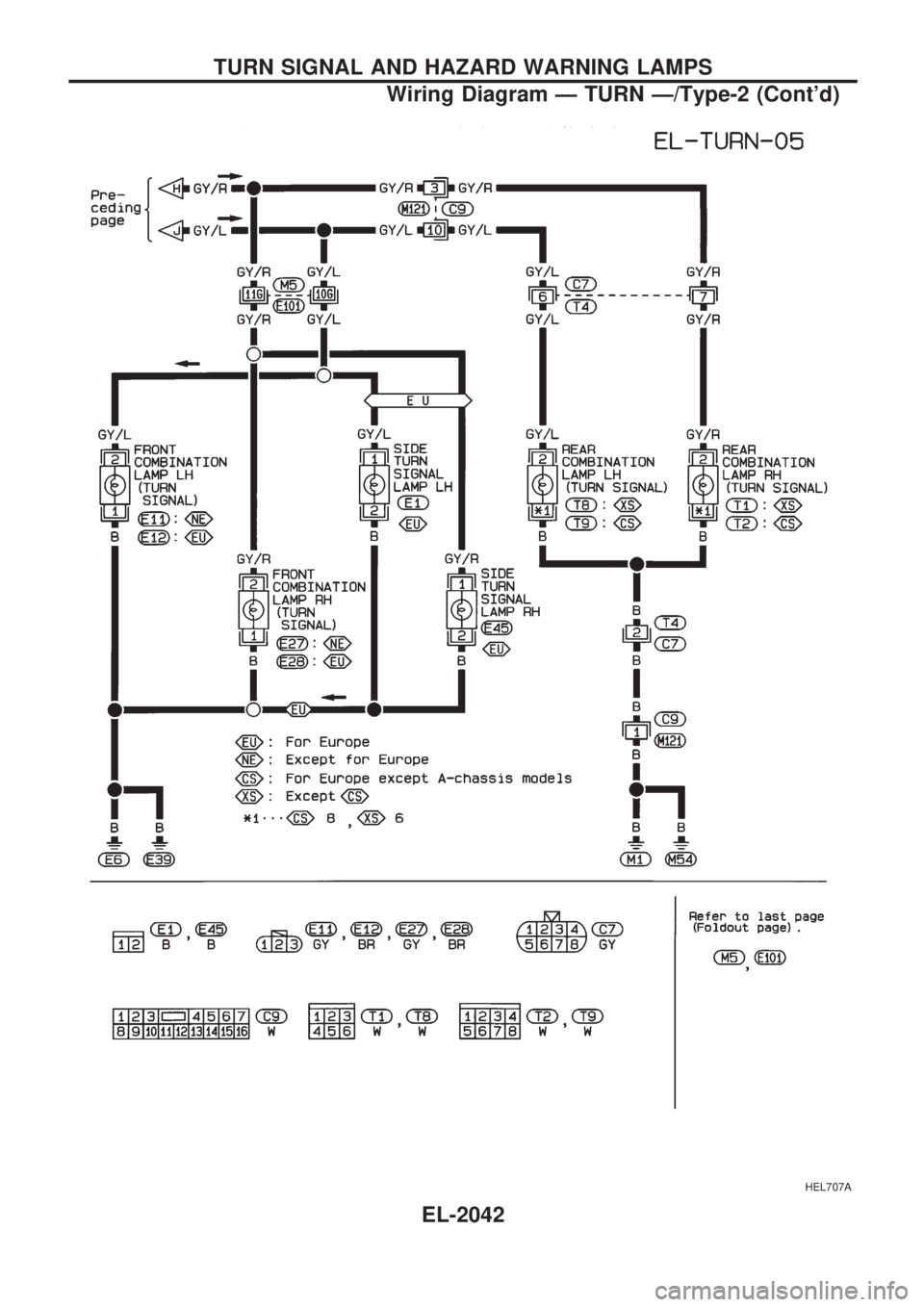

Page 121 of 666

HEL707A

TURN SIGNAL AND HAZARD WARNING LAMPS

Wiring Diagram Ð TURN Ð/Type-2 (Cont'd)

EL-2042

Page 142 of 666

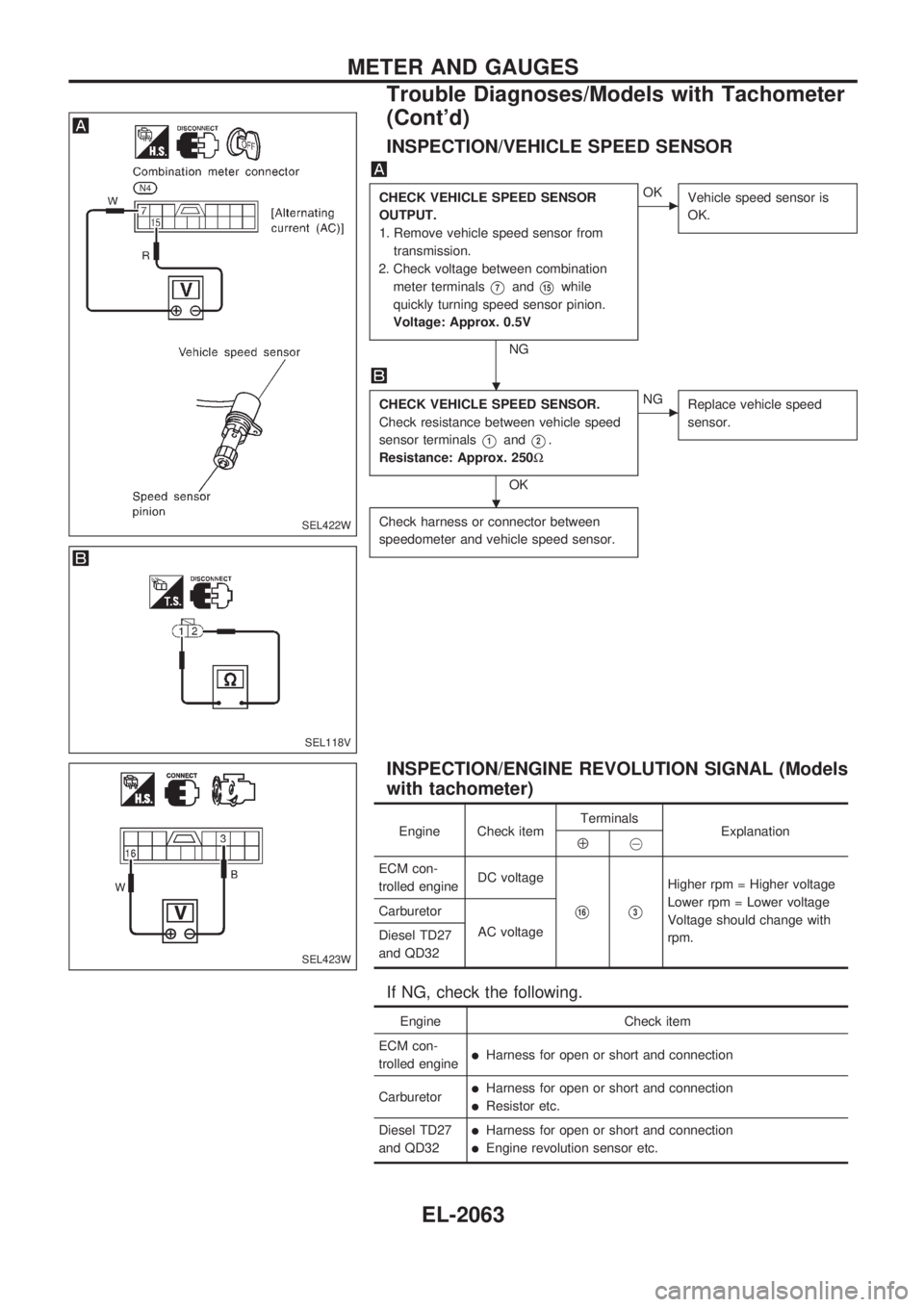

INSPECTION/VEHICLE SPEED SENSOR

CHECK VEHICLE SPEED SENSOR

OUTPUT.

1. Remove vehicle speed sensor from

transmission.

2. Check voltage between combination

meter terminals

V7andV15while

quickly turning speed sensor pinion.

Voltage: Approx. 0.5V

NG

cOK

Vehicle speed sensor is

OK.

CHECK VEHICLE SPEED SENSOR.

Check resistance between vehicle speed

sensor terminals

V1andV2.

Resistance: Approx. 250W

OK

cNG

Replace vehicle speed

sensor.

Check harness or connector between

speedometer and vehicle speed sensor.

INSPECTION/ENGINE REVOLUTION SIGNAL (Models

with tachometer)

Engine Check itemTerminals

ExplanationÅ@

ECM con-

trolled engineDC voltage

V16V3

Higher rpm = Higher voltage

Lower rpm = Lower voltage

Voltage should change with

rpm. Carburetor

AC voltage

Diesel TD27

and QD32

If NG, check the following.

Engine Check item

ECM con-

trolled engine

lHarness for open or short and connection

Carburetor

lHarness for open or short and connection

lResistor etc.

Diesel TD27

and QD32

lHarness for open or short and connection

lEngine revolution sensor etc.

SEL422W

SEL118V

SEL423W

.

.

METER AND GAUGES

Trouble Diagnoses/Models with Tachometer

(Cont'd)

EL-2063

Page 150 of 666

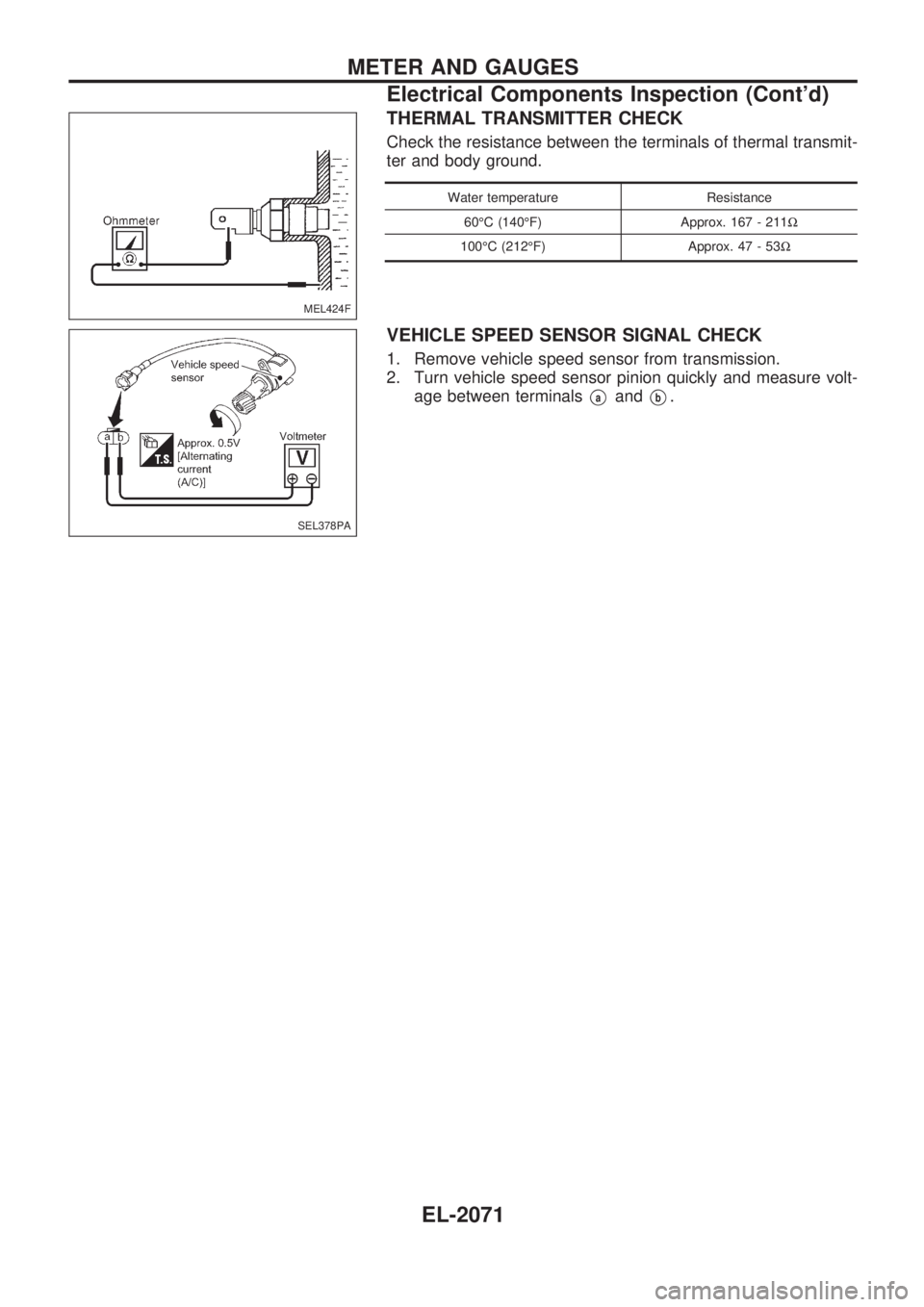

THERMAL TRANSMITTER CHECK

Check the resistance between the terminals of thermal transmit-

ter and body ground.

Water temperature Resistance

60ÉC (140ÉF) Approx. 167 - 211W

100ÉC (212ÉF) Approx. 47 - 53W

VEHICLE SPEED SENSOR SIGNAL CHECK

1. Remove vehicle speed sensor from transmission.

2. Turn vehicle speed sensor pinion quickly and measure volt-

age between terminals

VaandVb.

MEL424F

SEL378PA

METER AND GAUGES

Electrical Components Inspection (Cont'd)

EL-2071

Page 193 of 666

System Description/With Interruption

Detection Function

OUTLINE

Power window system consists of

lCPU (combined with power window main switch)

lfour power window regulators

When ignition switch is in the ``ON'' position, power window can be operated depending on power window

sub/main switch condition.

OPERATIVE CONDITION

lPower windows can be raised or lowered with each sub-switch or the power window main switch located

on the driver's door trim when ignition switch is in the ``ON'' position and power window lock switch on

the driver's door trim is unlocked.

lWhen power window lock switch is locked, no windows can be raised or lowered except for driver's side

window.

lWhen ignition switch is in the ``ON'' position, to fully open/close the driver's side window, press down/

pull up completely on the automatic switch (main switch) and release it; it needs not be held. The win-

dow will automatically open/close all the way. To stop the window, pull up/press down then release the

switch.

lAfter turning ignition switch to OFF, the driver's side window can be raised or lowered for 15 minutes.

The timer control for supplying power after turning ignition switch to ``OFF'' will be canceled when the

driver's side door is closed. (Except models for Europe)

INTERRUPTION DETECTION FUNCTION

CPU (combined with power window main switch) monitors the power window regulator motor operation and

the power window position (full closed or other) for driver's power window by the signals from encoder and

limit switch in front power window regulator (driver's side).

When CPU (combined with power window main switch) detects interruption during the following close

operation in the driver's side door,

lautomatic close operation when ignition switch is in the ``ON'' position

lautomatic close operation during power window timer operation

lmanual close operation during power window timer operation

CPU (combined with power window main switch) controls driver's power window regulator motor for open

and the power window will be lowered about 150 mm (5.91 in).

POWER WINDOW

EL-2114

Page 199 of 666

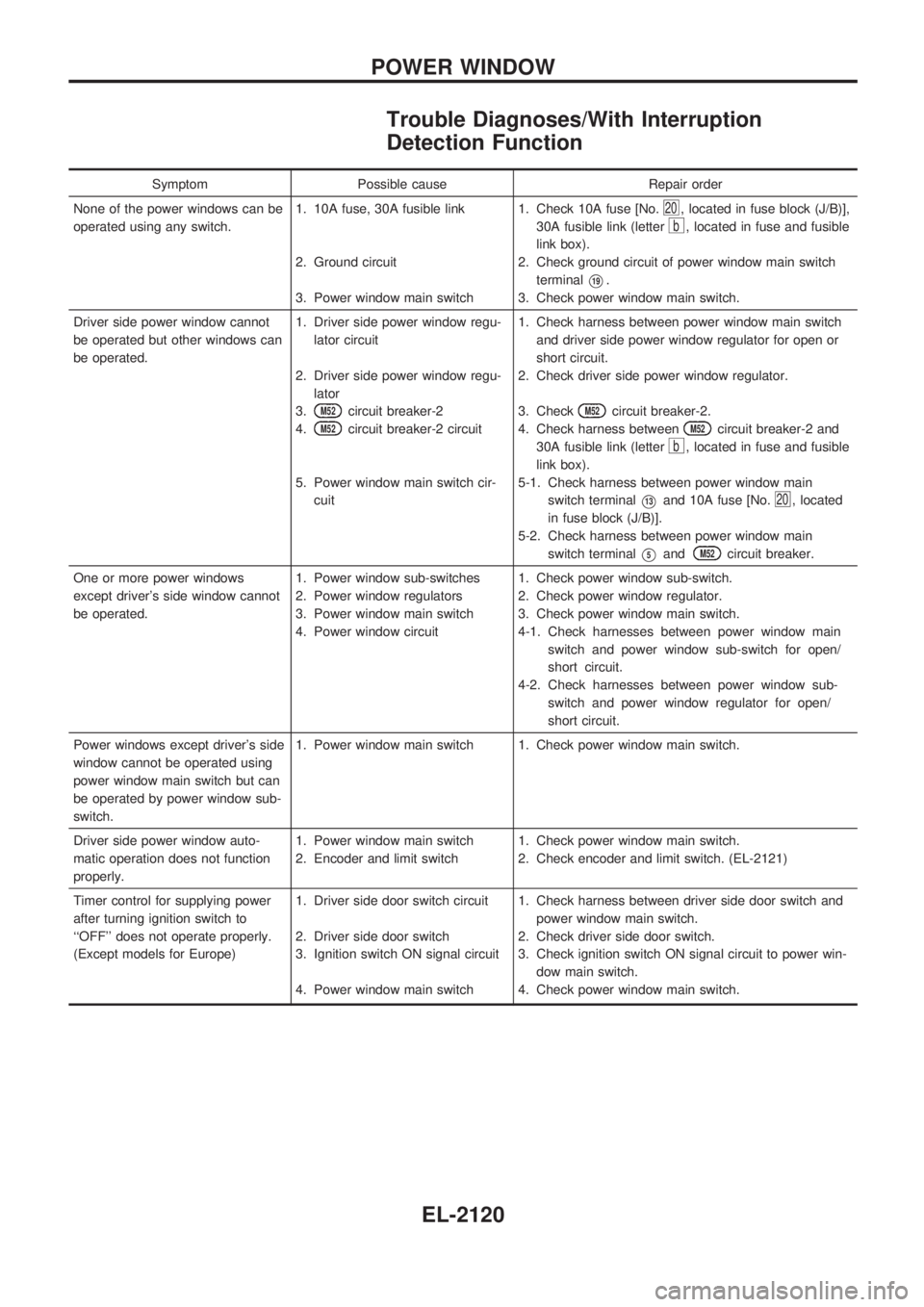

Trouble Diagnoses/With Interruption

Detection Function

Symptom Possible cause Repair order

None of the power windows can be

operated using any switch.1. 10A fuse, 30A fusible link

2. Ground circuit

3. Power window main switch1. Check 10A fuse [No.

20, located in fuse block (J/B)],

30A fusible link (letter

b, located in fuse and fusible

link box).

2. Check ground circuit of power window main switch

terminal

V19.

3. Check power window main switch.

Driver side power window cannot

be operated but other windows can

be operated.1. Driver side power window regu-

lator circuit

2. Driver side power window regu-

lator

3.

M52circuit breaker-2

4.

M52circuit breaker-2 circuit

5. Power window main switch cir-

cuit1. Check harness between power window main switch

and driver side power window regulator for open or

short circuit.

2. Check driver side power window regulator.

3. Check

M52circuit breaker-2.

4. Check harness between

M52circuit breaker-2 and

30A fusible link (letter

b, located in fuse and fusible

link box).

5-1. Check harness between power window main

switch terminal

V13and 10A fuse [No.20, located

in fuse block (J/B)].

5-2. Check harness between power window main

switch terminal

V5andM52circuit breaker.

One or more power windows

except driver's side window cannot

be operated.1. Power window sub-switches

2. Power window regulators

3. Power window main switch

4. Power window circuit1. Check power window sub-switch.

2. Check power window regulator.

3. Check power window main switch.

4-1. Check harnesses between power window main

switch and power window sub-switch for open/

short circuit.

4-2. Check harnesses between power window sub-

switch and power window regulator for open/

short circuit.

Power windows except driver's side

window cannot be operated using

power window main switch but can

be operated by power window sub-

switch.1. Power window main switch 1. Check power window main switch.

Driver side power window auto-

matic operation does not function

properly.1. Power window main switch

2. Encoder and limit switch1. Check power window main switch.

2. Check encoder and limit switch. (EL-2121)

Timer control for supplying power

after turning ignition switch to

``OFF'' does not operate properly.

(Except models for Europe)1. Driver side door switch circuit

2. Driver side door switch

3. Ignition switch ON signal circuit

4. Power window main switch1. Check harness between driver side door switch and

power window main switch.

2. Check driver side door switch.

3. Check ignition switch ON signal circuit to power win-

dow main switch.

4. Check power window main switch.

POWER WINDOW

EL-2120