cooling NISSAN PULSAR 1987 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 198 of 238

198 Electrical System

(3) Replenish the coolant in the radiator. Refer

to the Cooling and Heating Systems section for the

correct procedure.

TO DISMANTLE

Bosch Alternator

Remove the alternator from the vehicle as

previously described.

Scribe a mark across the drive end bracket,

stator and slip ring end bracket to facilitate correct

alignment during assembly. Remove the screws and washers securing the

regulator and brush holder assembly. Withdraw the

regulator and brush holder assembly from the alter-

nator. Remove the long screws securing the drive

end bracket to the slip ring end bracket and withdraw

the drive end bracket, rotor and pulley assembly.

NOTE: Ensure that the wave washer behind

the rotor shaft rear bearing in the slip ring

end bracket is not mislaid.

Holding the rotor in a soft jawed vice,

remove the split drive pulley retaining nut, washer

and spacer from the rotor shaft. Remove the split driv e pulley, spacer, plate

washer and fan from the rotor shaft. Using a suitable pres s and press plates,

support the drive end bracket with the pulley end of

the rotor shaft uppermost a nd carefully press the rotor

shaft from the spacer, bearing and the drive end

bracket.

Remove the spacer and the bearing retainer

plate screws from the drive end bracket. Remove the bearing retainer plate and the

bearing from the drive end bracket. If necessary, using a bearing puller, remove

the rear bearing from the rotor shaft. Remove the nut, spring washer and output

terminal components from the {B + ) terminal on the

outside of the slip ring end bracket.

(12) Working inside the slip ring end bracket,

remove the screws securing the diode pack to the

bracket and withdraw the stator and diode pack as an

assembly. Remove the insulating spacer and washer

from the (B +) terminal.

NOTE: The diode pack is supplied as an

assembly and in the event of a component

'failure, must be renewed as a complete unit.

Mark all wiring connections prior to removal

to aid assembly. Where necessary, unsolder the stator leads

from the connector terminals to separate the diode

pack.

NOTE: When soldering or unsoldering the

stator leads from the diodes, grip the leads

with a pair of long nosed pliers. This will

safeguard the diodes by transferring any

excess heat to the jaws of the pliers.

Hitachi Alternator

Remove the alternator from the vehicle as

previously described.

Scribe a mark across the drive end bracket,

stator and slip ring end bracket to facilitate correct

alignment during assembly. Remove the through bolts retaining the drive

end bracket to the slip ring end bracket. Apply a heated 200 watt soldering iron to the

slip ring end bracket at the bearing mounting boss for

3-4 minutes to heat the bracket and allow the removal

of the slip ring end bearing. Carefully prise the slip ring end bracket and

stator assembly from the drive end bracket and rotor

assembly using suitable levers. Do not insert the levers

too far or damage to the stator will occur.

Hold the rotor and driv e end bracket assem-

bly in a soft jawed vice and remove the nut retaining

the drive pulley to the rotor. Remove the washer, pulley and spacer

washer from the rotor shaft.

Using a soft faced hammer, drive the rotor

shaft assembly from the drive end bracket and remove

the inner spacer washer from the rotor shaft.

Remove the bearing retainer plate screws

and remove the plate. Using a suitable drift, drive the

bearing from the bracket. Remove the retaining nut and insulator

washer from the alternator terminal. Remove the slip ring end bracket retaining

nuts and separate the diode pack, stator and regulator

assembly.

If necessary, file the ends of the brush

assembly retaining rivets, caref ully unsolder the ter-

minal plate and remove the brush assembly and

terminal plate from the diode pack. If necessary, remove the fan guide retaining

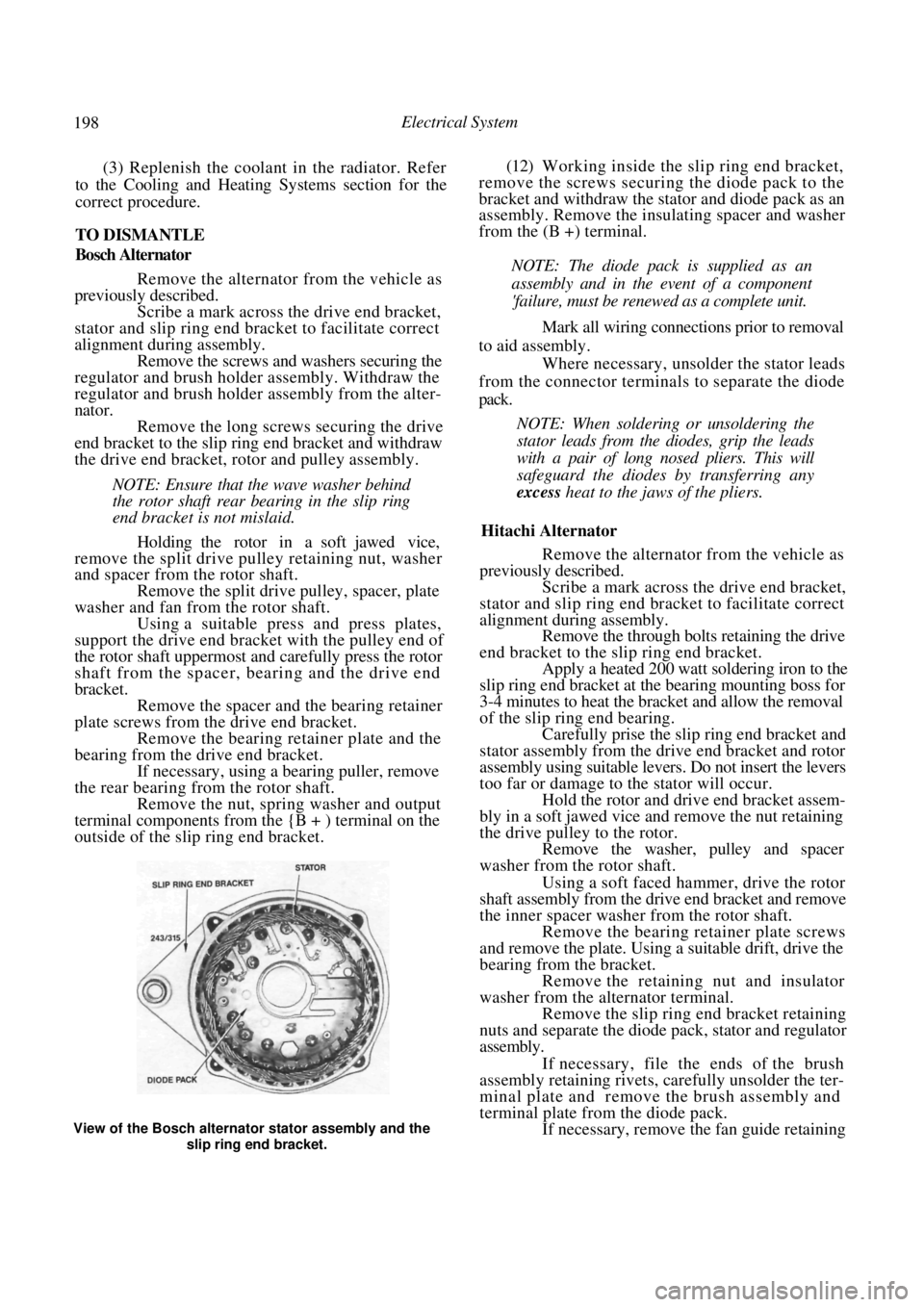

View of the Bosch alternator stator assembly and the

slip ring end bracket.

Page 209 of 238

Electrical System 209

12. INSTRUMENT CLUSTER

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Remove the retaining screws from the instru-

ment cluster surround. Carefully withdraw the instrument cluster

surround from the instrument panel sufficiently to

enable the wiring to be disconnected. Remove the

surround from the vehicle.

.

FLEXIBLE PRINTED

CIRCUIT

Rear view of the instrument cluster removed from the

vehicle.

(4) Remove the instrument cluster assembly

retaining screws and gently ease the assembly from the

instrument panel sufficiently to enable the wiring to be

disconnected.

If necessary, remove the instruments as follows:

Carefully depress the retaining clips on the

front lens and remove the front lens. On models equipped with a tachometer, slide

the plastic rib from between the speedometer and the

tachometer. Remove the screws retaining the speedome-

ter and the tachometer or fuel/temperature gauges

from the rear of the instrument cluster.

CLUSTER ASSEMBLY

(d) Withdraw both instruments from the front of

the instrument cluster being careful as these instru-

ments are held by protruding pin terminals.

NOTE: Do not touch the faces of the instru-

ment dials as they mark easily.

(e) On models equipped with a tachometer,

remove the retaining nuts and remove the tempera-

ture and/or the fuel gauge from the cluster assembly.

Installation is a reversal of the removal procedure

ensuring that all electrical connectors are correctly

installed.

13. BLOWER FAN

The removal and installation procedure for the

blower fan is described in the Cooling and Heating

Systems section.

14. RADIO/CASSETTE

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Remove the release hole covers on each side

of the radio/cassette.

Dismantled view of the instrument cluster.

Illustration of the radio/cass ette removal tool showing

the required dimensions.

BULB HOLDERS

BULB HOLDERS

Removing the release hole covers from the radio/cas-

sette.

Page 221 of 238

Electrical System 221

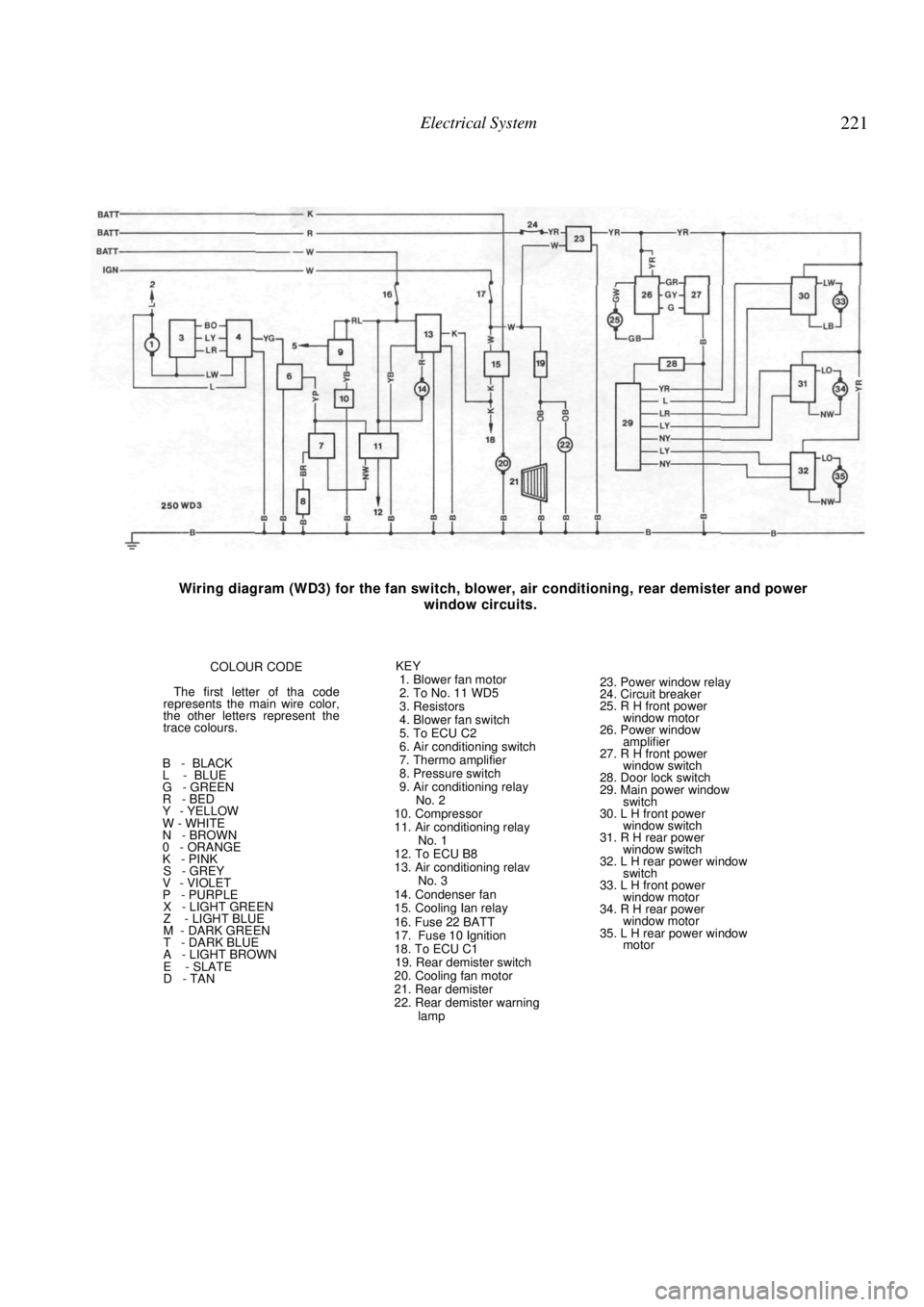

Wiring diagram (WD3) for the fan switch, blower, air conditioning, rear demister and power

window circuits.

COLOUR CODE

The first letter of tha code

represents the main wire color,

the other letters represent the

trace colours.

B - BLACK

L - BLUE

G - GREEN

R - BED

Y - YELLOW

W - WHITE

N - BROWN

0 - ORANGE

K - PINK

S - GREY

V - VIOLET

P - PURPLE

X - LIGHT GREEN

Z - LIGHT BLUE

M - DARK GREEN

T - DARK BLUE

A - LIGHT BROWN

E - SLATE

D - TAN KEY

1. Blower fan motor

2. To No. 11 WD5

3. Resistors

4. Blower fan switch

5. To ECU C2

6. Air conditioning switch

7. Thermo amplifier

8. Pressure switch

9. Air conditioning relay No. 2

10. Compressor

11. Air conditioning relay No. 1

12. To ECU B8

13. Air conditioning relav No. 3

14. Condenser fan

15. Cooling Ian relay

16. Fuse 22 BATT

17. Fuse 10 Ignition

18. To ECU C1

19. Rear demister switch

20. Cooling fan motor

21. Rear demister

22. Rear demister warning lamp

23. Power window relay

24. Circuit breaker

25. R H front power

window motor

26. Power window amplifier

27. R H front power window switch

28. Door lock switch

29. Main power window switch

30. L H front power

window switch

31. R H rear power window switch

32. L H rear power window switch

33. L H front power

window motor

34. R H rear power window motor

35. L H rear power window motor