clock NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 10 of 238

10 General Information

If tools are to be stored for any length of time, it is

good policy to wipe them with an oily cloth.

Bladed screwdrivers should be checked for dam-

age to the tip. If necessary, the tip can be returned to

its original profile by careful grinding. Do not grind

screwdriver tips to a sharp point.

Hammer heads should be secure on their handles

and should be regularly checked for cracking or other

damage.

Chisels and punches should be checked for dam-

age or 'mushrooming' of the head. Any faults should

be rectified by grinding.

Hydraulic jacks should be regularly checked for

fluid leaks. Chassis stands and car ramps should be

checked for damage and cracks. Any equipment that

is suspect should not be used.

STORES

For routine maintenance, stores of automotive

oils, greases and additives should be kept on hand.

The following is a suggested list.

Engine oil.

Brake fluid.

Manual transmission or automatic transmission

oil — automatic transmission oil is also used in

the power steering system.

Rear axle oil.

Cooling system corrosion inhibitor/antifreeze.

Chassis grease.

High melting point grease, for hub bearings etc.

Penetrating oil or spray.

Kerosene or similar cleaning solvent.

Methylated spirits.

Oils and greases are available in handy pack size for

do-it-yourself lube jobs.

2. SAFETY

PERSONAL SAFETY

Safety when working on a motor vehicle is basical-

ly a matter of commonsense. Some safety precautions

to prevent personal in juries are as follows.

Raising a Vehicle

Always jack a vehicle on firm, level ground and at

the specified jacking points . Ensure that the wheels

remaining on the ground are fully chocked.

After raising the vehicle, place chassis stands

underneath and allow the weight of the vehicle to rest

on them. Do not use bricks, blocks of wood or similar

material.

NOTE: Never work under a vehicle which is

only supported by a jack.

Electrical System

Always disconnect the negative battery terminal

when working on any electrical components. Avoid

wearing metal watches, rings and chains which may

short across live terminals.

As battery gases are explosive, keep naked flames

and sparks clear of the work area. When connecting

and disconnecting jumper leads, use extreme caution

to avoid sparking.

Electronic Ignition Systems

Electronic ignition systems produce dangerous

high tension voltages in bo th the primary and second-

ary circuits which can be fatal. Exercise extreme

caution when working on or near any ignition system

components. Do not disconnect high tension leads

while the engine is running.

Work Area

Do not run the engine in a confined space. Ensure

that the work area is adequately ventilated.

Spilt oil or water should be cleaned immediately

to avoid the possibility of slipping.

Fuel System

Always disconnect the negative battery terminal

when working on any fuel components. Do not smoke.

Keep naked flames and sparks clear of the work area.

Do not siphon fuel using the mouth. Use a hand

pump or suitable siphon.

Do not attempt to repair a fuel tank by welding it.

This is an extremely hazardous procedure and should

be entrusted to a specialist.

Cooling System

To avoid scalding, use caution when releasing the

radiator cap on an engine wh ich is at normal operating

temperature. Turn the cap anti-clockwise to the first

stop and allow any pressure in the system to release.

When the pressure is released, remove the cap from

the radiator.

Brakes

As asbestos is used in some brake lining material,

avoid inhaling brake dust. Do not use compressed air

to remove the dust. Gentle brushing with a small

brush or using a vacuum cleaner with a hose attach-

ment are the safest methods of cleaning the brakes.

The above precautions also apply to the clutch plate

lining material.

Page 36 of 238

36 Roadside Trouble Shooting

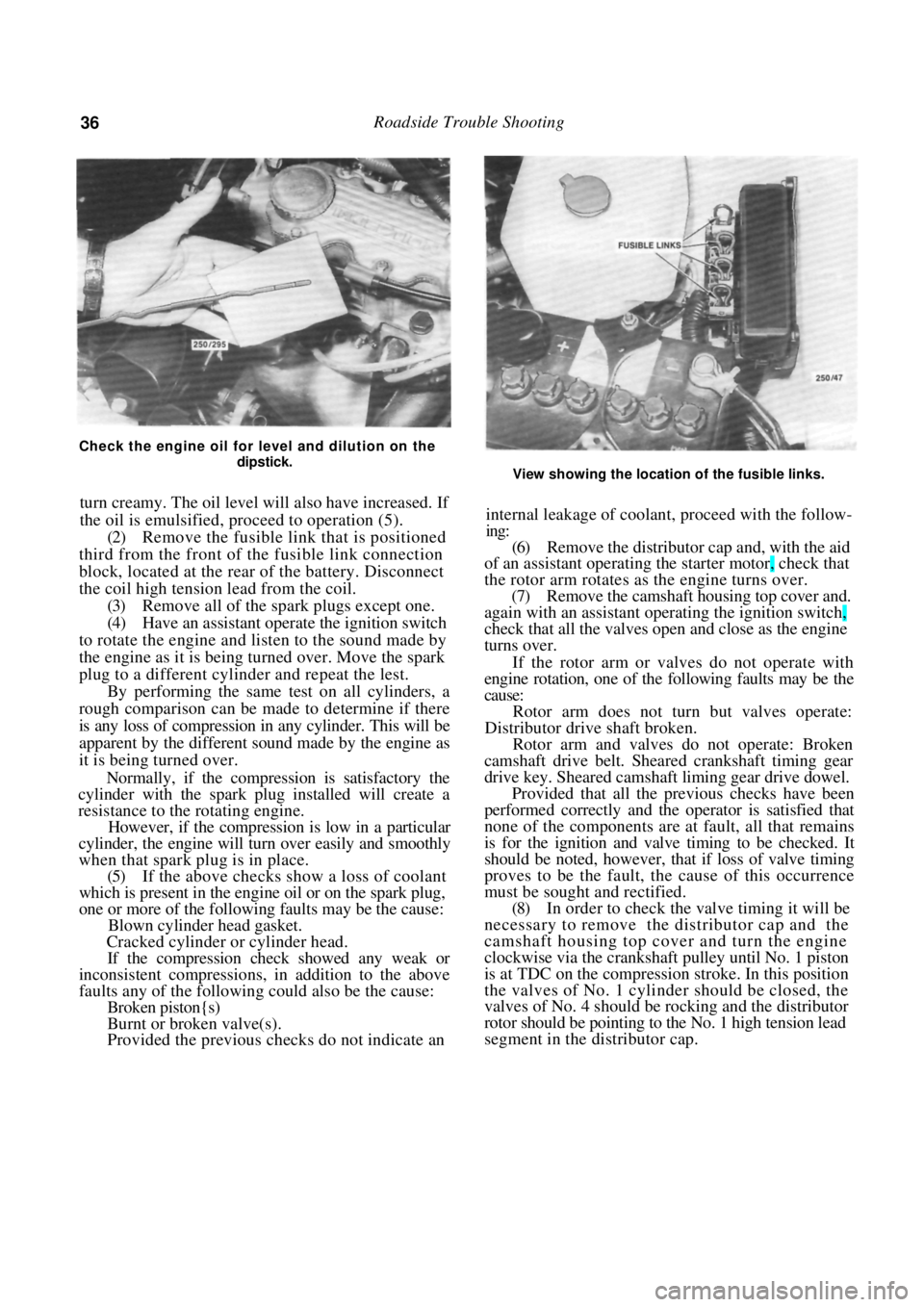

Check the engine oil for level and dilution on the dipstick.

turn creamy. The oil level will also have increased. If

the oil is emulsified, proceed to operation (5).

(2) Remove the fusible link that is positioned

third from the front of th e fusible link connection

block, located at the rear of the battery. Disconnect

the coil high tension lead from the coil. (3) Remove all of the spark plugs except one.

(4) Have an assistant operate the ignition switch

to rotate the engine and listen to the sound made by

the engine as it is being turned over. Move the spark

plug to a different cylinder and repeat the lest. By performing the same test on all cylinders, a

rough comparison can be made to determine if there

is any loss of compression in any cylinder. This will be

apparent by the different sound made by the engine as

it is being turned over.

Normally, if the compression is satisfactory the

cylinder with the spark plug installed will create a

resistance to the rotating engine.

However, if the compression is low in a particular

cylinder, the engine will tu rn over easily and smoothly

when that spark plug is in place.

(5) If the above checks show a loss of coolant

which is present in the engine oil or on the spark plug,

one or more of the following faults may be the cause:

Blown cylinder head gasket.

Cracked cylinder or cylinder head.

If the compression check showed any weak or

inconsistent compressions, in addition to the above

faults any of the following could also be the cause:

Broken piston{s)

Burnt or broken valve(s).

Provided the previous checks do not indicate an

View showing the location of the fusible links.

internal leakage of coolant, proceed with the follow-

ing:

(6) Remove the distributor cap and, with the aid

of an assistant operating th e starter motor, check that

the rotor arm rotates as the engine turns over. (7) Remove the camshaft hous ing top cover and.

again with an assistant operating the ignition switch,

check that all the valves open and close as the engine

turns over.

If the rotor arm or valves do not operate with

engine rotation, one of the following faults may be the

cause:

Rotor arm does not turn but valves operate:

Distributor drive shaft broken.

Rotor arm and valves do not operate: Broken

camshaft drive belt. Sheare d crankshaft timing gear

drive key. Sheared camshaft liming gear drive dowel.

Provided that all the previous checks have been

performed correctly and the operator is satisfied that

none of the components are at fault, all that remains

is for the ignition and valve timing to be checked. It

should be noted, however, that if loss of valve timing

proves to be the fault, th e cause of this occurrence

must be sought and rectified.

(8) In order to check the valve timing it will be

necessary to remove the distributor cap and the

camshaft housing top cover and turn the engine

clockwise via the crankshaft pulley until No. 1 piston

is at TDC on the compression stroke. In this position

the valves of No. 1 cylinder should be closed, the

valves of No. 4 should be rocking and the distributor

rotor should be pointing to the No. 1 high tension lead

segment in the distributor cap.

Page 62 of 238

Engine

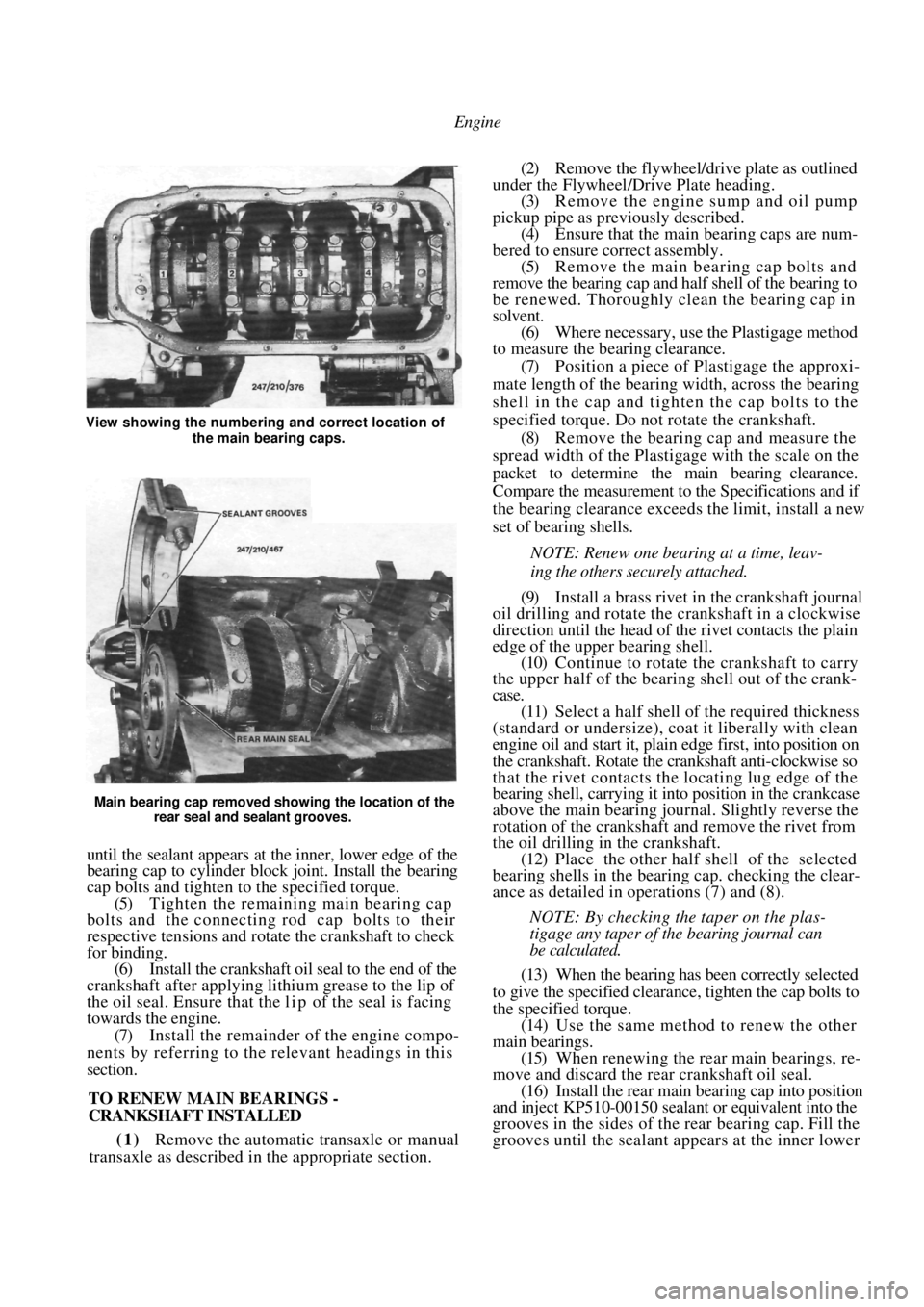

Main bearing cap removed showing the location of the rear seal and sealant grooves.

until the sealant appears at the inner, lower edge of the

bearing cap to cylinder block joint. Install the bearing

cap bolts and tighten to the specified torque.

(5) Tighten the remaining main bearing cap

bolts and the connecting rod cap bolts to their

respective tensions and rotate the crankshaft to check

for binding. (6) Install the crankshaft oil seal to the end of the

crankshaft after applying lithium grease to the lip of

the oil seal. Ensure that the l i p of the seal is facing

towards the engine.

(7) Install the remainder of the engine compo-

nents by referring to the relevant headings in this

section.

TO RENEW MAIN BEARINGS -

CRANKSHAFT INSTALLED

(1) Remove the automatic transaxle or manual

transaxle as described in the appropriate section.

(2) Remove the flywheel/drive plate as outlined

under the Flywheel/Drive Plate heading. (3) Remove the engine sump and oil pump

pickup pipe as previously described. (4) Ensure that the main bearing caps are num-

bered to ensure correct assembly. (5) Remove the main bearing cap bolts and

remove the bearing cap and half shell of the bearing to

be renewed. Thoroughly clean the bearing cap in

solvent. (6) Where necessary, use the Plastigage method

to measure the bearing clearance.

(7) Position a piece of Plastigage the approxi-

mate length of the bearing width, across the bearing

shell in the cap and tigh ten the cap bolts to the

specified torque. Do not rotate the crankshaft. (8) Remove the bearing cap and measure the

spread width of the Plastigage with the scale on the

packet to determine the main bearing clearance.

Compare the measurement to the Specifications and if

the bearing clearance exceeds the limit, install a new

set of bearing shells.

NOTE: Renew one bearing at a time, leav-

ing the others securely attached.

(9) Install a brass rivet in the crankshaft journal

oil drilling and rotate the crankshaft in a clockwise

direction until the head of the rivet contacts the plain

edge of the upper bearing shell. (10) Continue to rotate the crankshaft to carry

the upper half of the bearing shell out of the crank-

case.

(11) Select a half shell of the required thickness

(standard or undersize), coat it liberally with clean

engine oil and start it, plai n edge first, into position on

the crankshaft. Rotate the crankshaft anti-clockwise so

that the rivet contacts the locating lug edge of the

bearing shell, carrying it into position in the crankcase

above the main bearing journal. Slightly reverse the

rotation of the crankshaft and remove the rivet from

the oil drilling in the crankshaft. (12) Place the other half shell of the selected

bearing shells in the bear ing cap. checking the clear-

ance as detailed in operations (7) and (8).

NOTE: By checking the taper on the plas-

tigage any taper of the bearing journal can

be calculated.

(13) When the bearing has been correctly selected

to give the specified clearance, tighten the cap bolts to

the specified torque. (14) Use the same method to renew the other

main bearings. (15) When renewing the rear main bearings, re-

move and discard the rear crankshaft oil seal. (16) Install the rear main bearing cap into position

and inject KP510-00150 sealant or equivalent into the

grooves in the sides of the rear bearing cap. Fill the

grooves until the sealant a ppears at the inner lower

View showing the numbering and correct location of

the main bearing caps.

Page 70 of 238

70 Cooling and Heating Systems

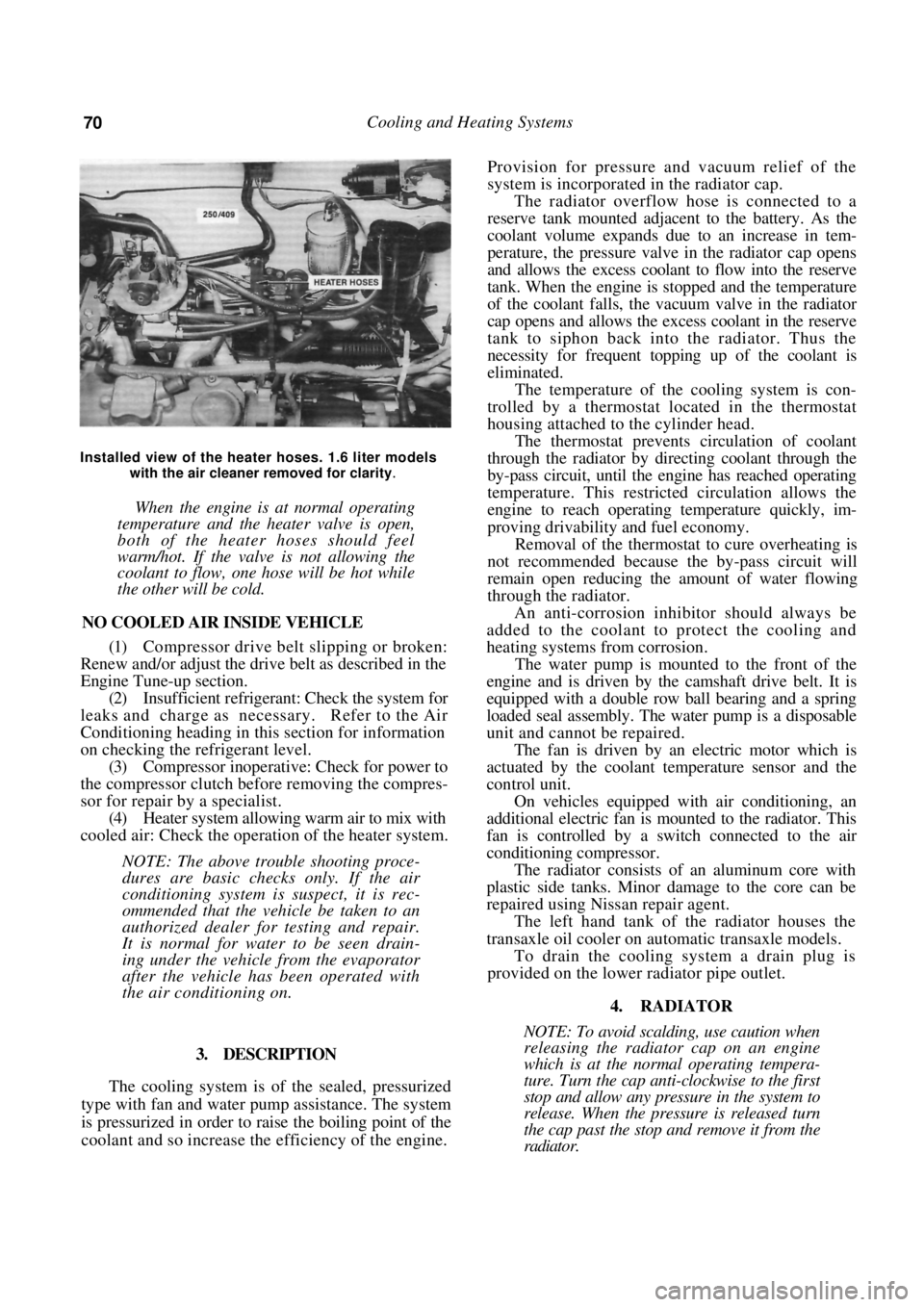

Installed view of the heater hoses. 1.6 liter models with the air cleaner removed for clarity

.

When the engine is at normal operating

temperature and the heater valve is open,

both of the heater hoses should feel

warm/hot. If the valve is not allowing the

coolant to flow, one hose will be hot while

the other will be cold.

NO COOLED AIR INSIDE VEHICLE

(1) Compressor drive belt slipping or broken:

Renew and/or adjust the drive belt as described in the

Engine Tune-up section.

(2) Insufficient refrigerant: Check the system for

leaks and charge as necessary. Refer to the Air

Conditioning heading in th is section for information

on checking the refrigerant level. (3) Compressor inoperative: Check for power to

the compressor clutch before removing the compres-

sor for repair by a specialist. (4) Heater system allowing warm air to mix with

cooled air: Check the operation of the heater system.

NOTE: The above trouble shooting proce-

dures are basic checks only. If the air

conditioning system is suspect, it is rec-

ommended that the vehicle be taken to an

authorized dealer for testing and repair.

It is normal for water to be seen drain-

ing under the vehicle from the evaporator

after the vehicle has been operated with

the air conditioning on.

3. DESCRIPTION

The cooling system is of the sealed, pressurized

type with fan and water pump assistance. The system

is pressurized in order to raise the boiling point of the

coolant and so increase the efficiency of the engine.

Provision for pressure a nd vacuum relief of the

system is incorporated in the radiator cap.

The radiator overflow hose is connected to a

reserve tank mounted adjacent to the battery. As the

coolant volume expands due to an increase in tem-

perature, the pressure valve in the radiator cap opens

and allows the excess coolant to flow into the reserve

tank. When the engine is stopped and the temperature

of the coolant falls, the vacuum valve in the radiator

cap opens and allows the excess coolant in the reserve

tank to siphon back into the radiator. Thus the

necessity for frequent topping up of the coolant is

eliminated.

The temperature of the cooling system is con-

trolled by a thermostat located in the thermostat

housing attached to the cylinder head.

The thermostat prevents circulation of coolant

through the radiator by directing coolant through the

by-pass circuit, until the engine has reached operating

temperature. This restricted circulation allows the

engine to reach operating temperature quickly, im-

proving drivability and fuel economy.

Removal of the thermostat to cure overheating is

not recommended because th e by-pass circuit will

remain open reducing the amount of water flowing

through the radiator.

An anti-corrosion inhibitor should always be

added to the coolant to protect the cooling and

heating systems from corrosion.

The water pump is mounted to the front of the

engine and is driven by the camshaft drive belt. It is

equipped with a double row ball bearing and a spring

loaded seal assembly. The water pump is a disposable

unit and cannot be repaired.

The fan is driven by an electric motor which is

actuated by the coolant temperature sensor and the

control unit.

On vehicles equipped with air conditioning, an

additional electric fan is m ounted to the radiator. This

fan is controlled by a sw itch connected to the air

conditioning compressor.

The radiator consists of an aluminum core with

plastic side tanks. Minor damage to the core can be

repaired using Nissan repair agent.

The left hand tank of the radiator houses the

transaxle oil cooler on automatic transaxle models.

To drain the cooling system a drain plug is

provided on the lower radiator pipe outlet.

4. RADIATOR

NOTE: To avoid scalding, use caution when

releasing the radiator cap on an engine

which is at the normal operating tempera-

ture. Turn the cap anti-clockwise to the first

stop and allow any pressure in the system to

release. When the pressure is released turn

the cap past the stop and remove it from the

radiator.

Page 79 of 238

Cooling and Heating Systems 79

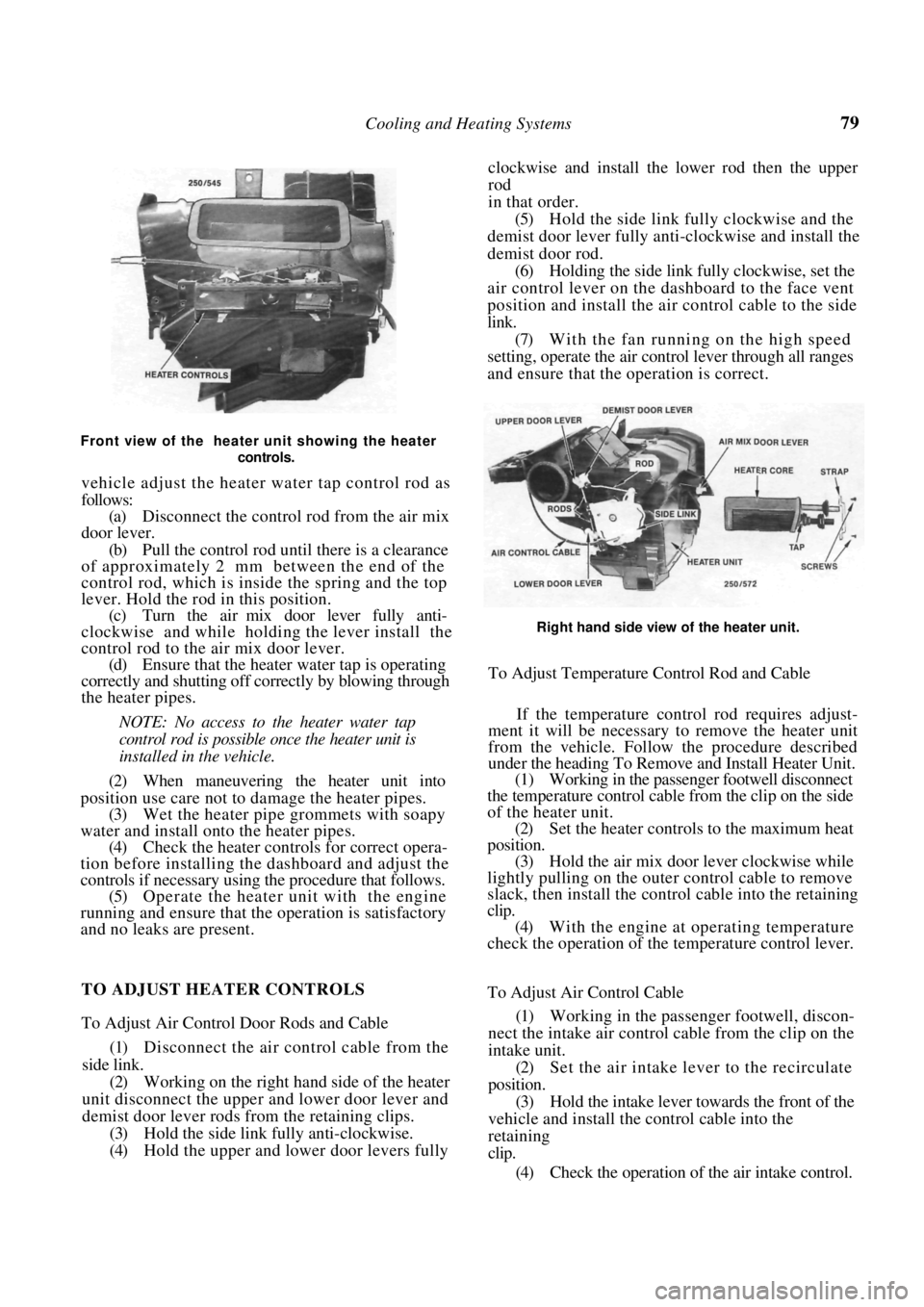

Front view of the heater unit showing the heater controls.

vehicle adjust the heater water tap control rod as

follows:

(a) Disconnect the control rod from the air mix

door lever.

(b) Pull the control rod un til there is a clearance

of approximately 2 mm between the end of the

control rod, which is inside the spring and the top

lever. Hold the rod in this position.

(c) Turn the air mix door lever fully anti-

clockwise and while holding the lever install the

control rod to the air mix door lever. (d) Ensure that the heater water tap is operating

correctly and shutting off correctly by blowing through

the heater pipes.

NOTE: No access to the heater water tap

control rod is possible once the heater unit is

installed in the vehicle.

(2) When maneuvering the heater unit into

position use care not to damage the heater pipes. (3) Wet the heater pipe grommets with soapy

water and install onto the heater pipes. (4) Check the heater controls for correct opera-

tion before installing the dashboard and adjust the

controls if necessary using the procedure that follows. (5) Operate the heater unit with the engine

running and ensure that the operation is satisfactory

and no leaks are present. clockwise and install the lower rod then the upper

rod

in that order.

(5)

Hold the side link fully clockwise and the

demist door lever fully anti-clockwise and install the

demist door rod. (6) Holding the side link fully clockwise, set the

air control lever on the dashboard to the face vent

position and install the air control cable to the side

link. (7) With the fan running on the high speed

setting, operate the air cont rol lever through all ranges

and ensure that the operation is correct.

Right hand side view of the heater unit.

To Adjust Temperature Control Rod and Cable

If the temperature control rod requires adjust-

ment it will be necessary to remove the heater unit

from the vehicle. Follow the procedure described

under the heading To Remove and Install Heater Unit.

(1) Working in the passenger footwell disconnect

the temperature control cable from the clip on the side

of the heater unit. (2) Set the heater controls to the maximum heat

position. (3) Hold the air mix door lever clockwise while

lightly pulling on the outer control cable to remove

slack, then install the control cable into the retaining

clip.

(4) With the engine at operating temperature

check the operation of the temperature control lever.

TO ADJUST HEATER CONTROLS

To Adjust Air Control Door Rods and Cable

(1) Disconnect the air control cable from the

side link. (2) Working on the right hand side of the heater

unit disconnect the upper and lower door lever and

demist door lever rods from the retaining clips.

(3) Hold the side link fully anti-clockwise.

(4) Hold the upper and lower door levers fully To Adjust Air Control Cable

(1)

Working in the passeng er footwell, discon-

nect the intake air control cable from the clip on the

intake unit. (2) Set the air intake lever to the recirculate

position. (3) Hold the intake lever to wards the front of the

vehicle and install the control cable into the

retaining

clip.

(4) Check the operation of the air intake control.

Page 82 of 238

82

FUEL AND ENGINE MANAGEMENT

CAUTION: To prevent severe electrical shock, extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text fo\

r

precautionary notes.

SPECIFICATIONS

FUEL INJECTION

Type:

1.6 liter engine .................................. Single point

1.8 liter engine................................... Multi point

FUEL PUMP

Type ................................................................ Electric

Pressure at idle:

1.6 liter engine ..................................... 62-90 kPa

1.8 liter engine ................................ 190-230 kPa

FUEL FILTER

Type ................................................ Inline, disposable

AIR FILTER

Type ................................... Disposable paper element

DISTRIBUTOR

Make ........................................................ Delco Remy

Advance contro l .......................................... Electronic

Rotation of rotor .................................. Anti-clockwise

Firing order....................................................1 -3-4-2

ADJUSTMENTS

Base idle speed ..................................... 550-650 rpm

Ignition timing.......................................... 10° BTDC

TORQUE WRENCH SETTINGS

Throttle body nuts.......................................... 10 Nm

*Throttle body bolts ........................................ 12 Nm

*Fuel hose fittings............................................ 35 Nm

Fuel rail bolts ....................................................8 Nm

Fuel tank drain plug ........................................ 24 Nm

Coolant temperature sensor ............................ 12 Nm

Oxygen sensor .................................................. 40 Nm

MAT sensor..................................................... 14 Nm

*1.6 liter engine

l . 8 liter engine

1. FUEL AND ENGINE MANAGEMENT

TROUBLE SHOOTING

NOTE: The following Trouble Shooting pro-

cedures are basic checks only. If these pro-

cedures fail to locate the fault, refer to the

System Diagnosis and Adjustments heading

for more thorough testing.

Prior to performing any of the following

operations, refer to the Service Precautions

and Procedures heading.

ENGINE WILL NOT START OR HARD TO

START

(1) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(2) Fault in the power supply: Check the battery,

fusible links and fuses. Check for clean, secure con-

nections, particularly the earth connections. Check the

EG1 and fuel pump relays.

NOTE: If the fuel pump relay fails, power

will be supplied to the fuel pump via the oil

pressure switch. When starting the engine,

Check that the MAP sensor hose is not blocked or split

and ensure that all electrical connections are clean and

secure.

Page 181 of 238

Brakes 181

chor plate to the steering knuckle and slide the caliper

off the brake disc. Suspend the caliper clear of the

work area using wire or cord.

(3) Suitably mark the location of the disc in

relation to the hub.

(4) Slide the disc off the hub. If the disc is

difficult to remove, install two M8 x 1.25 mm bolts in

the disc and by alternatively tightening the bolts,

remove the disc.

Do not use a hammer to remove the disc.

Installation is a reversal of the removal procedure

ensuring that the mating face s of the disc and hub are

clean and free from burrs and that the marks made on

removal are aligned.

To Inspect

(1) Inspect the machined faces of the disc for

scores, cracks, wear and signs of overheating. (2) Using a micrometer, measure the thickness

of the disc at several positi ons around the face of the

disc. Renew the disc if the minimum thickness is

below Specifications.

Inspect the brake discs for scoring and wear.

(3) If the disc thickness is satisfactory but the

disc is scored, machine equal amounts from the

machined face on each side of the disc, to restore the

serviceability of the disc.

NOTE: Disc machining is best entrusted to

a reliable brake specialist who can advise on

disc serviceability.

6. REAR DISC BRAKES

Special Equipment Required:

To Check Disc Runout — Dial gauge

To Check Disc Thickness — Micrometer

TO CHECK AND RENEW BRAKE PADS

( 1 ) Raise the rear of the vehicle and place it on

chassis stands. Remove the rear wheels.

Renew the rear brake pads if the friction material is less

than 2 mm thick.

(2) Inspect the brake pads on both sides of the

vehicle. If the friction material on one or more of the

pads is less than 2 mm thick or contaminated with

fluid or grease, renew the brake pad as a set as follows.

NOTE: If the brake pads are contaminated

trace and rectify the cause prior to installing

the new set of pads.

(3) Drain approximately two thirds of the brake

fluid from the master cylinder reservoir. This can be

done by loosening the bleeder valve on the caliper and

allowing the fluid to drai n into a container. Discard

this fluid.

NOTE: Do not drain all the fluid from the

reservoir otherwise it will be necessary to

bleed the hydraulic system. The fluid is

drained from the reservoir to prevent over-

flow when the caliper piston is pushed back

into the caliper bore to facilitate pad re-

newal.

(4) Remove the guide bolts and lift the caliper

body clear of the disc.

NOTE: Do not allow the caliper to hang on

the brake hose.

(5) Noting the installed positions, remove the

brake pads, shims and spring clips from the anchor

plate.

(6) Using a pair of long nosed pliers with the

nose located in the recesses of the piston, rotate the

piston clockwise to retract it into the cylinder body.

Align the recesses between the brake pad retaining

lugs on the caliper body. Refer to the illustration. (7) If necessary, check the disc runout and

thickness as described under the Brake Disc heading.

(8) Ensure that the guide bolts move freely in the

caliper body and that the dust boots are in good

condition.

Page 183 of 238

Brakes 183

To Dismantle

(1) Raise the rear of the vehicle and place it on

chassis stands. Remove the relevant rear wheel.

(2) Remove the brake hose retaining bolt from

the caliper body and plug the hose to prevent the loss

of fluid and the ingress of dirt. (3) Remove the handbrake cable bracket retain-

ing bolt and disconnect the handbrake cable from the

cam lever.

(4) Remove the guide bolts and slide the caliper

body off the pads. (5) Using a pair of long nose pliers with the nose

located in the recesses of the piston, rotate the piston

anticlockwise to remove it from the caliper body.

(6) Remove the dust cover retaining clip and dust

cover. Discard the dust cover. (7) Using a thin blunt probe, preferably made

from wood or plastic, remove and discard the piston

seal from the groove in the caliper bore. (8) Using internal snap ring pliers, remove the

snap ring from the caliper bore. (9) Withdraw the spring cover, spring, key plate,

pushrod and link from the caliper bore. Do not mix

these components from the left and right hand sides as

they differ. (10) Remove and discard the O ring from the

pushrod. (11) Remove the spring, nut and washer from the

cam lever. Remove the cam lever and cam from the

caliper body. (12) Remove the cam seal from the caliper using a

screwdriver.

(13) Clean all the caliper components in methy-

lated spirits and arrange the components in order on a

clean dry surface to aid assembly.

To Inspect

(1) Inspect the caliper bore and piston for pit-

ting, wear or damage. Renew the caliper assembly or

piston if damage is evident.

NOTE: Slight rust spots in the caliper bore

may be removed with fine emery paper. The

piston must not be polished as the plated

surface will be damaged.

(2) Inspect the guide bolts for wear or damage

and renew as necessary.

(3) Inspect the threads of the pushrod for wear or

damage and renew as necessary. (4) Inspect the nut inside the piston for wear,

damage and security. Renew the piston if any damage

is evident. (5) Inspect the cam for wear, damage or pitting,

renew as necessary. (6) Inspect the cam bearing in the caliper body

for wear, damage or pitting and renew the seal and

bearing as necessary. (7) Inspect the guide bolt rubbers for deteriora-

tion, wear or damage. Renew as required. To Assemble

(1)

Lubricate the cam bearing with multipurpose

grease and install the seal. (2) Install the cam and cam lever to the

caliper

body. Install the cam lever spring, washer and nut, and

tighten the nut to the specified torque. (3) Install a new O ring to the pushrod and

install

the link, pushrod, key plate, spring and spring cover to

the caliper body. The key plate must engage the caliper

body. Secure the assembly with the snap ring. (4) Dip a new piston seal in clean hydraulic brake

fluid. Insert the seal into the groove in the caliper bore

ensuring that the seal is correctly seated and not

twisted. (5) Install a new dust cover to the piston prior

to

installing the piston to the caliper bore.

(6) Coat the piston and caliper bore with clean

hydraulic brake fluid and using long nose pliers rotate

the piston clockwise into the caliper bore. (7) Locate the dust seal in the groove of the

caliper body and install the retaining clip.

(8) Lubricate the guide bolts using a suitable

grease. Install the caliper body and tighten the guide

bolts to the specified torque. (9) Replenish the master cylinder reservoir with

the recommended fluid and bleed the brakes as

described under the Hydraulic System heading. (10) Install the rear wheel and lower the vehicle to

the ground. (11) Road test the vehicle and check for correct

brake operation.

BRAKE DISC

To Check Runout

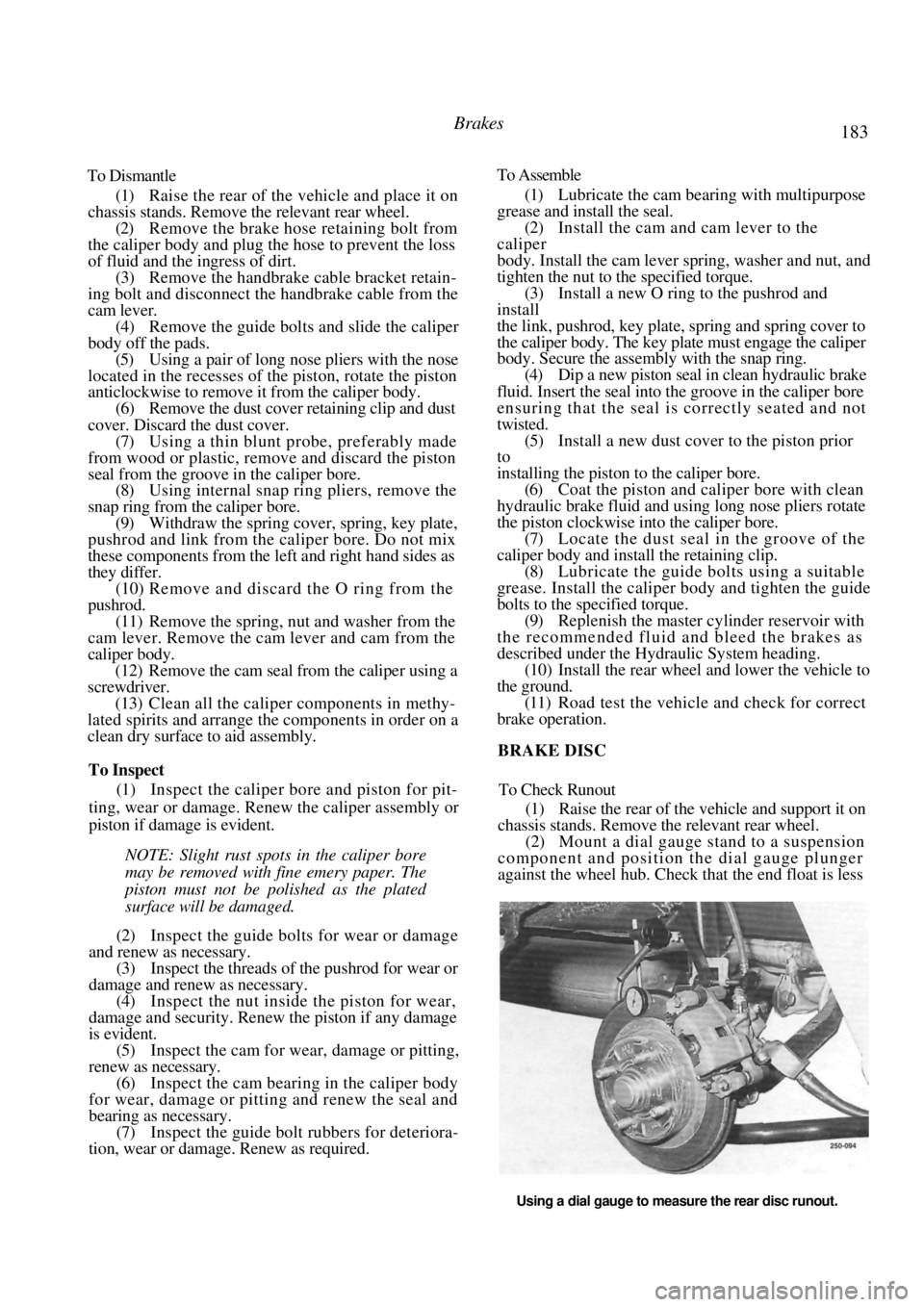

(1) Raise the rear of the vehicle and support it on

chassis stands. Remove the relevant rear wheel.

(2) Mount a dial gauge stand to a suspension

component and position the dial gauge plunger

against the wheel hub. Check that the end float is less

Using a dial gauge to measure the rear disc runout.

Page 211 of 238

Electrical System 211

When using an aiming board, position the

vehicle five meters from and square to the aiming

board. Gently rock the vehi cle and allow the suspen-

sion to stabilize. Mark a reference line on the board to

correspond with the horizontal centre line of the

headlamp low beam bulbs. Mark two reference lines on the board to

correspond with the vertical centre lines of

the

headlamp low beam bulbs. Switch on the headlamps and select low

beam. Adjust the headlamps by turning the adjust-

ing screws located at the rear of the headlamp

assemblies. Adjust the headlamps to comply with local

regulations. As a guide, adjust the lamps so that the

low beam pattern strikes the aiming board with the

horizontal cut off point 50 mm below the headlamp

bulb horizontal centre line and the point where the

beam raises from the horizontal is on the headlamp

low beam bulb vertical centre line.

To Renew Low Beam Bulb (Pulsar)

Remove the dust cover from the rear of the

headlamp assembly.

Disconnect the wiring from the end of the

bulb.

Remove the cover from the rear of the

headlamp housing. Release the retaining clip from the bulb

holder and withdraw the bulb from the headlamp. Installation is a reversal of the removal procedure

ensuring that the new bulb is correctly located in the

bulb holder.

NOTE: Care must be taken not to handle

the glass portion of the bulb as this will

shorten the life of the bulb. Accidental

fingerprints can be removed by applying

methylated spirits to the bulb and drying

with clean tissue or cloth.

To Renew High Beam Bulb (Pulsar) or

High/Low Beam Bulb (Astra) Disconnect the wiring connector and re-

move the dust cover from the rear of the headlamp. Release the retaining clip and remove the

bulb from the bulb holder. Install the new bulb to the headlamp ensur-

ing that the metal plate is correctly located in the

bulb holder.

NOTE: Care must be taken not to handle

the glass portion of the bulb as this will

shorten the life of the bulb.

Accidental fingerprints can be re-

moved by applying methylated spirits to

the bulb and drying with clean tissue or

cloth.

(4) Secure the retaining clip, install the cover to

the headlamp and connect the wiring to the end of the

bulb.

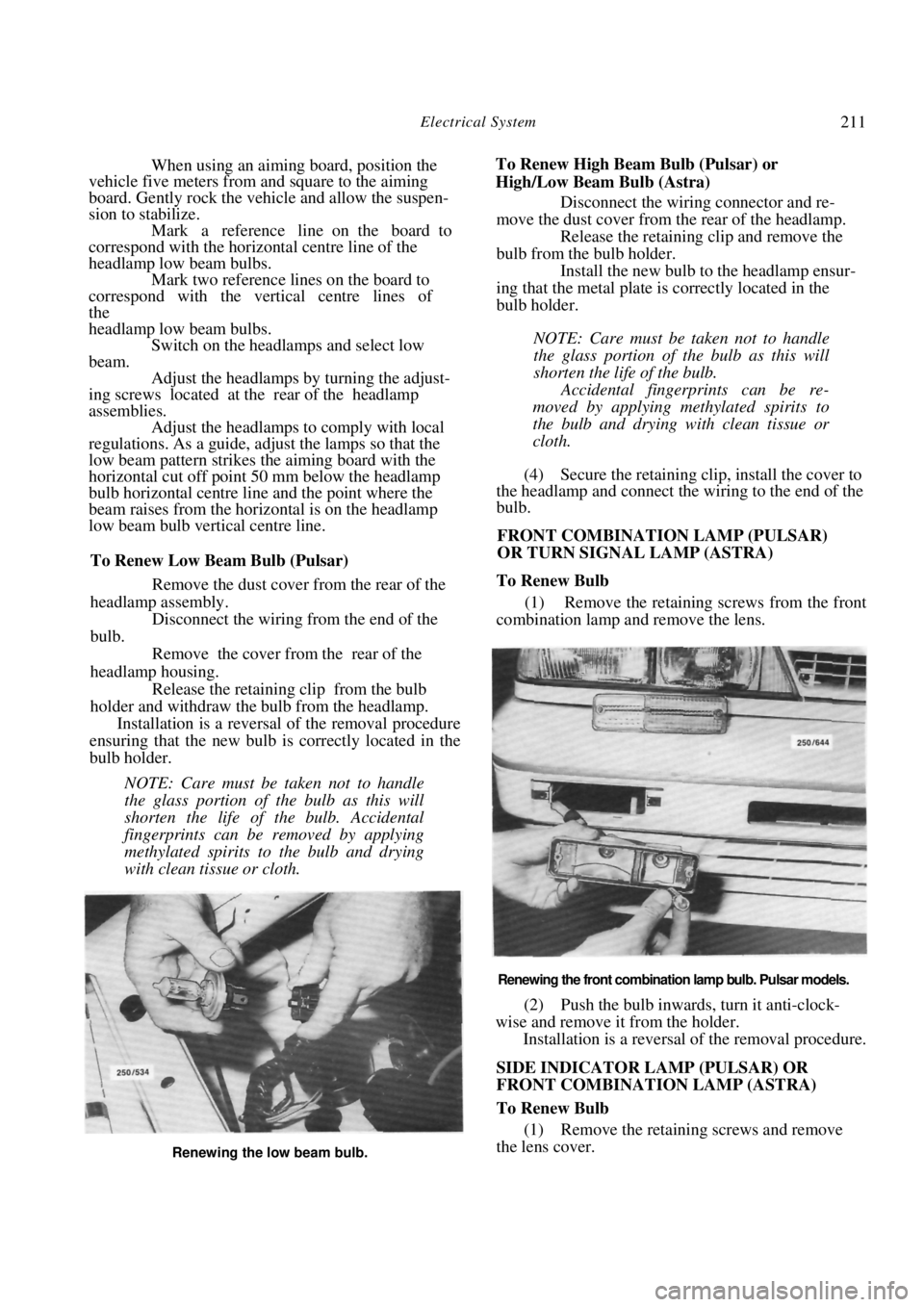

FRONT COMBINATION LAMP (PULSAR)

OR TURN SIGNAL LAMP (ASTRA)

To Renew Bulb

(1) Remove the retaining screws from the front

combination lamp and remove the lens.

Renewing the front combination lamp bulb. Pulsar models.

(2) Push the bulb inwards, turn it anti-clock-

wise and remove it from the holder. Installation is a reversal of the removal procedure.

SIDE INDICATOR LAMP (PULSAR) OR

FRONT COMBINATION LAMP (ASTRA)

To Renew Bulb

(1) Remove the retaining screws and remove

the lens cover.

Renewing the low beam bulb.

Page 212 of 238

212 Electrical System

Renewing the side indicator lamp bulb.

(2) Push the bulb inwards, turn it anti-clockwise

and remove it from the holder.

Installation is a reversal of the removal procedure.

REAR COMBINATION LAMP

To Renew Bulb

(1) Working inside the luggage compartment,

remove the combination lamp trim cover.

Renewing the rear combination lamp bulb.

Remove the desired bulb holder from the

combination lamp by twisting it anti-clockwise and

withdrawing it from the lamp body.

Push the bulb inwards, turn it anti-clockwise

and remove it from the holder.

Installation is a reversal of the removal procedure.

NUMBER PLATE LAMP

To Renew Bulb

(1) On Pulsar models, proceed as follows:

Carefully prise the number plate lamp unit

from the rear bumper bar. Remove the retaining screws and remove

the lens cover and lens.

Renewing the number plate lamp bulb.

(2) On Astra models, remove the retaining

screws and remove the lamp unit from the bumper

bar. Remove the bulb holder from the lamp unit.

(3) Remove the bulb from the lamp.

Installation is a reversal for the removal procedure.

COURTESY LAMP

To Renew Bulb

Turn the lamp lens anti-clockwise and lower

it from the lamp. Grip and remove the bulb from between the

bulb contacts.

Renewing the courtesy lamp bulb.

Installation is a reversal of the removal procedure

with attention to the following points:

Ensure that when the bulb is installed, the con-

tacts hold the bulb with enough tension to provide a

good electrical contact.

HIGH MOUNTED STOP LAMP

To Renew Bulb

(1) Remove the retaining screws from the cover

on the high mounted stop lamp and remove the cover.