set clock NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 62 of 238

Engine

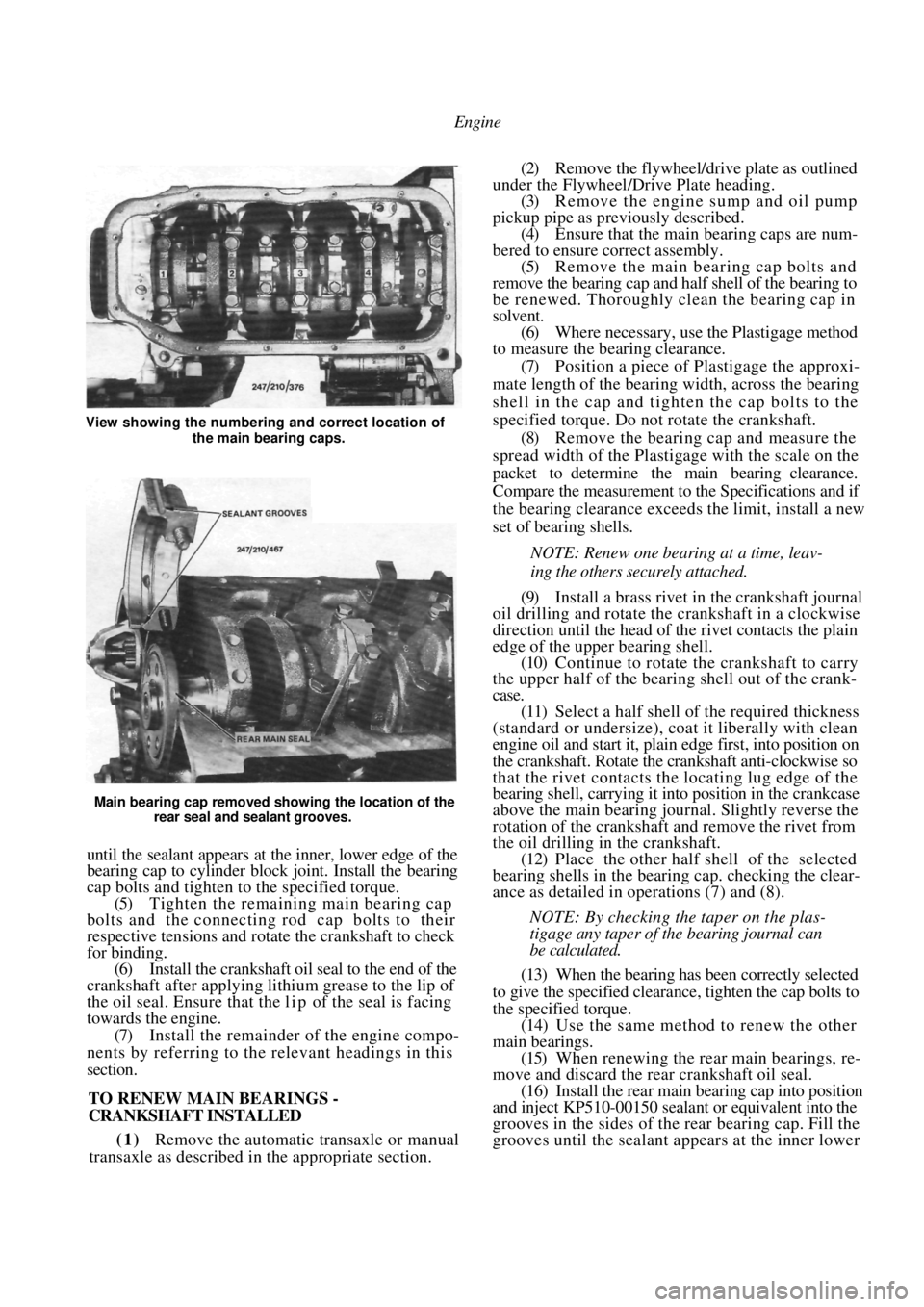

Main bearing cap removed showing the location of the rear seal and sealant grooves.

until the sealant appears at the inner, lower edge of the

bearing cap to cylinder block joint. Install the bearing

cap bolts and tighten to the specified torque.

(5) Tighten the remaining main bearing cap

bolts and the connecting rod cap bolts to their

respective tensions and rotate the crankshaft to check

for binding. (6) Install the crankshaft oil seal to the end of the

crankshaft after applying lithium grease to the lip of

the oil seal. Ensure that the l i p of the seal is facing

towards the engine.

(7) Install the remainder of the engine compo-

nents by referring to the relevant headings in this

section.

TO RENEW MAIN BEARINGS -

CRANKSHAFT INSTALLED

(1) Remove the automatic transaxle or manual

transaxle as described in the appropriate section.

(2) Remove the flywheel/drive plate as outlined

under the Flywheel/Drive Plate heading. (3) Remove the engine sump and oil pump

pickup pipe as previously described. (4) Ensure that the main bearing caps are num-

bered to ensure correct assembly. (5) Remove the main bearing cap bolts and

remove the bearing cap and half shell of the bearing to

be renewed. Thoroughly clean the bearing cap in

solvent. (6) Where necessary, use the Plastigage method

to measure the bearing clearance.

(7) Position a piece of Plastigage the approxi-

mate length of the bearing width, across the bearing

shell in the cap and tigh ten the cap bolts to the

specified torque. Do not rotate the crankshaft. (8) Remove the bearing cap and measure the

spread width of the Plastigage with the scale on the

packet to determine the main bearing clearance.

Compare the measurement to the Specifications and if

the bearing clearance exceeds the limit, install a new

set of bearing shells.

NOTE: Renew one bearing at a time, leav-

ing the others securely attached.

(9) Install a brass rivet in the crankshaft journal

oil drilling and rotate the crankshaft in a clockwise

direction until the head of the rivet contacts the plain

edge of the upper bearing shell. (10) Continue to rotate the crankshaft to carry

the upper half of the bearing shell out of the crank-

case.

(11) Select a half shell of the required thickness

(standard or undersize), coat it liberally with clean

engine oil and start it, plai n edge first, into position on

the crankshaft. Rotate the crankshaft anti-clockwise so

that the rivet contacts the locating lug edge of the

bearing shell, carrying it into position in the crankcase

above the main bearing journal. Slightly reverse the

rotation of the crankshaft and remove the rivet from

the oil drilling in the crankshaft. (12) Place the other half shell of the selected

bearing shells in the bear ing cap. checking the clear-

ance as detailed in operations (7) and (8).

NOTE: By checking the taper on the plas-

tigage any taper of the bearing journal can

be calculated.

(13) When the bearing has been correctly selected

to give the specified clearance, tighten the cap bolts to

the specified torque. (14) Use the same method to renew the other

main bearings. (15) When renewing the rear main bearings, re-

move and discard the rear crankshaft oil seal. (16) Install the rear main bearing cap into position

and inject KP510-00150 sealant or equivalent into the

grooves in the sides of the rear bearing cap. Fill the

grooves until the sealant a ppears at the inner lower

View showing the numbering and correct location of

the main bearing caps.

Page 79 of 238

Cooling and Heating Systems 79

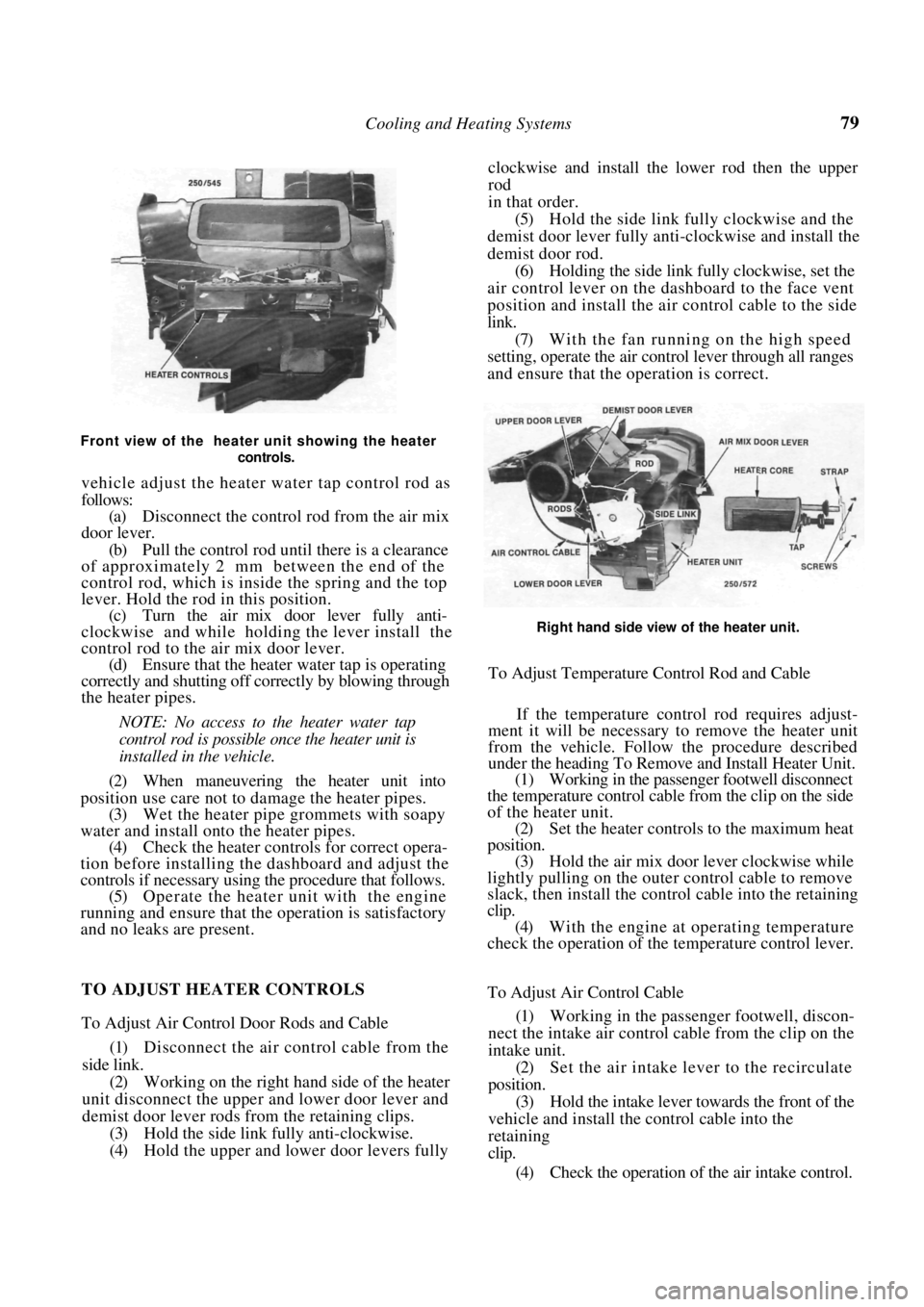

Front view of the heater unit showing the heater controls.

vehicle adjust the heater water tap control rod as

follows:

(a) Disconnect the control rod from the air mix

door lever.

(b) Pull the control rod un til there is a clearance

of approximately 2 mm between the end of the

control rod, which is inside the spring and the top

lever. Hold the rod in this position.

(c) Turn the air mix door lever fully anti-

clockwise and while holding the lever install the

control rod to the air mix door lever. (d) Ensure that the heater water tap is operating

correctly and shutting off correctly by blowing through

the heater pipes.

NOTE: No access to the heater water tap

control rod is possible once the heater unit is

installed in the vehicle.

(2) When maneuvering the heater unit into

position use care not to damage the heater pipes. (3) Wet the heater pipe grommets with soapy

water and install onto the heater pipes. (4) Check the heater controls for correct opera-

tion before installing the dashboard and adjust the

controls if necessary using the procedure that follows. (5) Operate the heater unit with the engine

running and ensure that the operation is satisfactory

and no leaks are present. clockwise and install the lower rod then the upper

rod

in that order.

(5)

Hold the side link fully clockwise and the

demist door lever fully anti-clockwise and install the

demist door rod. (6) Holding the side link fully clockwise, set the

air control lever on the dashboard to the face vent

position and install the air control cable to the side

link. (7) With the fan running on the high speed

setting, operate the air cont rol lever through all ranges

and ensure that the operation is correct.

Right hand side view of the heater unit.

To Adjust Temperature Control Rod and Cable

If the temperature control rod requires adjust-

ment it will be necessary to remove the heater unit

from the vehicle. Follow the procedure described

under the heading To Remove and Install Heater Unit.

(1) Working in the passenger footwell disconnect

the temperature control cable from the clip on the side

of the heater unit. (2) Set the heater controls to the maximum heat

position. (3) Hold the air mix door lever clockwise while

lightly pulling on the outer control cable to remove

slack, then install the control cable into the retaining

clip.

(4) With the engine at operating temperature

check the operation of the temperature control lever.

TO ADJUST HEATER CONTROLS

To Adjust Air Control Door Rods and Cable

(1) Disconnect the air control cable from the

side link. (2) Working on the right hand side of the heater

unit disconnect the upper and lower door lever and

demist door lever rods from the retaining clips.

(3) Hold the side link fully anti-clockwise.

(4) Hold the upper and lower door levers fully To Adjust Air Control Cable

(1)

Working in the passeng er footwell, discon-

nect the intake air control cable from the clip on the

intake unit. (2) Set the air intake lever to the recirculate

position. (3) Hold the intake lever to wards the front of the

vehicle and install the control cable into the

retaining

clip.

(4) Check the operation of the air intake control.

Page 82 of 238

82

FUEL AND ENGINE MANAGEMENT

CAUTION: To prevent severe electrical shock, extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text fo\

r

precautionary notes.

SPECIFICATIONS

FUEL INJECTION

Type:

1.6 liter engine .................................. Single point

1.8 liter engine................................... Multi point

FUEL PUMP

Type ................................................................ Electric

Pressure at idle:

1.6 liter engine ..................................... 62-90 kPa

1.8 liter engine ................................ 190-230 kPa

FUEL FILTER

Type ................................................ Inline, disposable

AIR FILTER

Type ................................... Disposable paper element

DISTRIBUTOR

Make ........................................................ Delco Remy

Advance contro l .......................................... Electronic

Rotation of rotor .................................. Anti-clockwise

Firing order....................................................1 -3-4-2

ADJUSTMENTS

Base idle speed ..................................... 550-650 rpm

Ignition timing.......................................... 10° BTDC

TORQUE WRENCH SETTINGS

Throttle body nuts.......................................... 10 Nm

*Throttle body bolts ........................................ 12 Nm

*Fuel hose fittings............................................ 35 Nm

Fuel rail bolts ....................................................8 Nm

Fuel tank drain plug ........................................ 24 Nm

Coolant temperature sensor ............................ 12 Nm

Oxygen sensor .................................................. 40 Nm

MAT sensor..................................................... 14 Nm

*1.6 liter engine

l . 8 liter engine

1. FUEL AND ENGINE MANAGEMENT

TROUBLE SHOOTING

NOTE: The following Trouble Shooting pro-

cedures are basic checks only. If these pro-

cedures fail to locate the fault, refer to the

System Diagnosis and Adjustments heading

for more thorough testing.

Prior to performing any of the following

operations, refer to the Service Precautions

and Procedures heading.

ENGINE WILL NOT START OR HARD TO

START

(1) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(2) Fault in the power supply: Check the battery,

fusible links and fuses. Check for clean, secure con-

nections, particularly the earth connections. Check the

EG1 and fuel pump relays.

NOTE: If the fuel pump relay fails, power

will be supplied to the fuel pump via the oil

pressure switch. When starting the engine,

Check that the MAP sensor hose is not blocked or split

and ensure that all electrical connections are clean and

secure.

Page 181 of 238

Brakes 181

chor plate to the steering knuckle and slide the caliper

off the brake disc. Suspend the caliper clear of the

work area using wire or cord.

(3) Suitably mark the location of the disc in

relation to the hub.

(4) Slide the disc off the hub. If the disc is

difficult to remove, install two M8 x 1.25 mm bolts in

the disc and by alternatively tightening the bolts,

remove the disc.

Do not use a hammer to remove the disc.

Installation is a reversal of the removal procedure

ensuring that the mating face s of the disc and hub are

clean and free from burrs and that the marks made on

removal are aligned.

To Inspect

(1) Inspect the machined faces of the disc for

scores, cracks, wear and signs of overheating. (2) Using a micrometer, measure the thickness

of the disc at several positi ons around the face of the

disc. Renew the disc if the minimum thickness is

below Specifications.

Inspect the brake discs for scoring and wear.

(3) If the disc thickness is satisfactory but the

disc is scored, machine equal amounts from the

machined face on each side of the disc, to restore the

serviceability of the disc.

NOTE: Disc machining is best entrusted to

a reliable brake specialist who can advise on

disc serviceability.

6. REAR DISC BRAKES

Special Equipment Required:

To Check Disc Runout — Dial gauge

To Check Disc Thickness — Micrometer

TO CHECK AND RENEW BRAKE PADS

( 1 ) Raise the rear of the vehicle and place it on

chassis stands. Remove the rear wheels.

Renew the rear brake pads if the friction material is less

than 2 mm thick.

(2) Inspect the brake pads on both sides of the

vehicle. If the friction material on one or more of the

pads is less than 2 mm thick or contaminated with

fluid or grease, renew the brake pad as a set as follows.

NOTE: If the brake pads are contaminated

trace and rectify the cause prior to installing

the new set of pads.

(3) Drain approximately two thirds of the brake

fluid from the master cylinder reservoir. This can be

done by loosening the bleeder valve on the caliper and

allowing the fluid to drai n into a container. Discard

this fluid.

NOTE: Do not drain all the fluid from the

reservoir otherwise it will be necessary to

bleed the hydraulic system. The fluid is

drained from the reservoir to prevent over-

flow when the caliper piston is pushed back

into the caliper bore to facilitate pad re-

newal.

(4) Remove the guide bolts and lift the caliper

body clear of the disc.

NOTE: Do not allow the caliper to hang on

the brake hose.

(5) Noting the installed positions, remove the

brake pads, shims and spring clips from the anchor

plate.

(6) Using a pair of long nosed pliers with the

nose located in the recesses of the piston, rotate the

piston clockwise to retract it into the cylinder body.

Align the recesses between the brake pad retaining

lugs on the caliper body. Refer to the illustration. (7) If necessary, check the disc runout and

thickness as described under the Brake Disc heading.

(8) Ensure that the guide bolts move freely in the

caliper body and that the dust boots are in good

condition.

Page 222 of 238

222 Electrical System

Wiring diagram (WD4) for the horn, audio, front wiper/washer and rear wiper/washer circuits.

COLOUR CODE

The first letter of the code

represents the main wire color.

the other letters represent the

trace colors.

B - BLACK

L - BLUE

G - GREEN

R - RED

Y - YELLOW

W - WHITE

N - BROWN

O - ORANGE

K - PINK

S - GREY V - VIOLET

P - PURPLE X - LIGHT GREEN

Z - LIGHT BLUE

M - DARK GREEN

T - DARK BLUE

A - LIGHT BROWN

E - SLATE

D - TAN

KEY 1. Fuse No. 18 Batt

2. Horn relay

3. Horn switch

4. Horn

5. Stop lamp switch

6. L H stop lamp

7. R H stop lamp

8. To No. 28 WD2

9. To No. 14 WD6

10. To No. 8 WD1

11. Radio cassette and clock

12. L H front speaker

13. L H rear speaker

14. R H front speaker

15. R H rear speaker

16. Fuse No. 19 Batt

17. Fuse No. 20 Batt

18. Fuse No. 6 ACC

19. Rear washer motor

20. Rear wiper/washer

motor

21. Rear wiper motor

22. Fuse No. 7 ACC

23. Front wiper motor

24. Front washer motor

25. Intermittent wiper relay

26. Front wiper/washer

switch

27. Variable intermittent

switch