Rele NISSAN QASHQAI 2007 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: QASHQAI, Model: NISSAN QASHQAI 2007Pages: 297, PDF Size: 4.09 MB

Page 202 of 297

Downloaded from www.Manualslib.com manuals search engine The brake system has two separate hydraulic cir-

cuits. If one circuit malfunctions, you will still have

braking ability with two wheels.

BRAKE PRECAUTIONS

Vacuum assisted brake

The brake booster aids braking by using engine

vacuum. If the engine stops or the drive belt is bro-

ken, you can stop the vehicle by depressing the

brake pedal. However, greater foot pressure on the

brake pedal will be required to stop the vehicle and

the stopping distance will be longer.

Wet brakes

When the vehicle is washed or driven through wa-

ter, the brakes may get wet. As a result, your brak-

ing distance will be longer and the vehicle may pull

to one side during braking.

To dry brakes, drive the vehicle at a safe speed

while lightly pressing the brake pedal to heat up the

brakes. Do this until the brakes return to normal.

Avoid driving the vehicle at high speeds until the

brakes function correctly.

Using the brakes

Avoid resting your foot on the brake pedal while

driving. This will overheat the brakes, wear out the

brake linings and pads faster and reduce fuel

economy performance.

To help reduce brake wear and to prevent the brakes

from overheating, reduce speed and downshift to a

lower gear before going down a slope or long down-hill gradient. Overheated brakes may reduce brak-

ing performance and could result in loss of vehicle

control.

CAUTION

While driving on a slippery surface, be careful

when braking, accelerating or downshifting.

Abrupt braking actions or sudden acceleration

could cause the wheels to skid and result in an

accident.

Be aware that brakes will fade if repeated heavy

brake applications are made.

Driving uphill

When starting on a steep gradient, it is sometimes

difficult to operate the brake (AT or CVT models) or

both the brake and clutch (MT models). Use the

handbrake to hold the vehicle. Do not slip the clutch

(MT models). When ready to start, slowly release

the handbrake while depressing the accelerator

pedal and releasing the clutch (MT models) or de-

pressing the accelerator pedal (AT or CVT models).

Driving downhill

The engine braking action is effective for controlling

the vehicle while descending hills.

The gear lever (MT models) should be placed in a

gear position low enough to obtain sufficient engine

braking.

For the AT or CVT models, a low gear position in

the manual shift mode, low enough to obtain suffi-

cient engine braking, should be selected.

ANTI-LOCK BRAKING SYSTEM (ABS)

WARNING

The Anti-lock Braking System (ABS) is a so-

phisticated device, but it cannot prevent acci-

dents resulting from careless or dangerous

driving techniques. It can help maintain ve-

hicle control during braking on slippery sur-

faces. Remember that stopping distances

may also be longer on rough, gravel or snow

covered roads, or if you are using snow

chains. Always maintain a safe distance from

the vehicle in front of you. Ultimately, the

driver is responsible for safety.

Tyre type and condition may also affect brak-

ing effectiveness.

– When replacing tyres, install the specified

size of tyres on all four wheels.

– When installing a spare tyre, make sure it is the proper size and type as specified on

the tyre placard. See “Vehicle

identification” in the “9. Technical

information” section for the tyre placard

location.

– For detailed information, see “Wheels and tyres” in the “8. Maintenance and

do-it-yourself” section.

The Anti-lock Braking System (ABS) controls the

brakes so that the wheels do not lock during hard

braking or when braking on slippery surfaces. The

system detects the rotation speed at each wheel

BRAKE SYSTEM

Starting and driving5-39

Page 203 of 297

Downloaded from www.Manualslib.com manuals search engine and varies the brake fluid pressure to prevent each

wheel from locking and sliding. By preventing each

wheel from locking, the system helps the driver to

maintain steering control and helps to minimise

swerving and spinning on slippery surfaces.

Using the system

Depress the brake pedal and hold it down. Depress

the brake pedal with firm steady pressure, but do

not pump the brakes. The ABS will operate to pre-

vent the wheels from locking up. Steer the vehicle to

avoid obstacles.

WARNING

Do not pump the brake pedal. Doing so may in-

crease the stopping distance.

Self-test feature

The ABS includes electronic sensors, electric

pumps, hydraulic solenoids and a computer. The

computer has a built-in diagnostic feature that tests

the system each time you start the engine and move

thevehicleatalowspeedinforwardorreverse.

When the self-test occurs, you may hear a “clunk”

noise and/or feel a pulsation in the brake pedal. This

is normal and does not indicate a malfunction. If the

computer senses a malfunction, it switches the ABS

off and illuminates the ABS warning light on the

instrument panel. The brake system then operates

normally, but without anti-lock assistance.

If the ABS warning light illuminates during the self-

test or while driving, have the vehicle checked by a

NISSAN dealer or qualified workshop.

Normal operation

The ABS will not initiate at speeds below 5 to 10

km/h (3 to 6 MPH). The speeds will vary according

to road conditions.

When the ABS senses that one or more wheels are

close to locking up, the actuator rapidly applies and

releases hydraulic pressure. This action is similar to

pumping the brakes very quickly. You may feel a

pulsation in the brake pedal and hear a noise from

the actuator under the bonnet when it is operating.

This is normal and indicates that the ABS is working

properly. However, the pulsation may indicate that

road conditions are hazardous and extra care is re-

quired while driving. When accelerating, driving on slippery surfaces or

suddenly avoiding obstacles on roads, the vehicle

might swerve or slip. The Electronic Stability Pro-

gramme (ESP) system continuously monitors and

compares the driver’s intended speed and the travel

direction. The system adjusts wheel brake pressure

and engine torque to assist in improving vehicle sta-

bility.

When the ESP system is operating, the “SLIP”

indicator light () in the combination meter

blinks.

When only the traction control (TCS) system in

the ESP system is operating, the “SLIP” indica-

tor light (

) in the combination meter will also

blink.

If the “SLIP” indicator light () blinks, the

road conditions are slippery. Be sure to drive

carefully. See “Warning/indicator lights and au-

dible reminders” in the “2. Instruments and

controls” section.

Indicator light

If a malfunction occurs in the system, the “SLIP”

indicator light (

) and the ESP indicator light

() come on in the combination meter.

As long as these indicator lights are on, the trac-

tion control function is cancelled.

The ESP system uses Active Brake Limited Slip

(ABLS) system to improve vehicle traction. The Ac-

tive Brake Limited Slip (ABLS) system works when

one of the driving wheels is spinning on a slippery

ELECTRONIC STABILITY

PROGRAMME (ESP) SYSTEM

(where fitted)

5-40Starting and driving

Page 204 of 297

Downloaded from www.Manualslib.com manuals search engine surface. The Active Brake Limited Slip (ABLS) sys-

tem, brakes the spinning wheel to distribute the driv-

ing power to the other driving wheel.

If the vehicle is operated with the ESP system turned

off, all ESP and TCS functions will be turned off.

The Active Brake Limited Slip (ABLS) system and

ABS will still operate with the ESP system off. If the

Active Brake Limited Slip (ABLS) system or the ABS

is activated, the “SLIP” indicator light (

) will

blink and you may hear a clunk noise and/or feel a

pulsation in the brake pedal. This is normal and does

not indicate a malfunction.

While the ESP system is operating, you may feel a

pulsation in the brake pedal and hear a noise or

vibration from under the bonnet. This is normal and

indicates that the ESP system is working properly.

The ESP computer has a built in diagnostic feature

that tests the system each time the engine is started

and the vehicle moves forwards or reverses at a

slow speed. When the self-test occurs, you may

hear a clunk noise and/or feel a pulsation in the

brake pedal. This is normal and is not an indication

of a malfunction.

WARNING

The ESP system is designed to help improve

driving stability but does not prevent accidents

caused by abrupt steering operation at high

speeds, or careless or dangerous driving

techniques. Reduce vehicle speed and be es-

pecially careful when driving and cornering on

slippery surfaces. Always drive carefully.

If engine related parts, such as a muffler, are

not standard equipment or are extremely de-

teriorated, the ESP OFF indicator light (

)

and/or the “SLIP” indicator light () may

illuminate.

If brake related parts, such as brake pads,

rotors and callipers, are not standard equip-

ment or are extremely deteriorated, the ESP

system may not operate properly and the ESP

OFF indicator light (

) and/or the “SLIP”

indicator light () may illuminate.

Do not modify the vehicle’s suspension. If

suspension parts, such as shock absorbers,

struts, springs, stabiliser bars and bushings,

are not NISSAN-approved or are extremely

deteriorated, the ESP system may not oper-

ate properly. This could adversely affect ve-

hicle handling performance and the ESP OFF

indicator light (

) and/or the “SLIP” indi-

cator light () may illuminate.

When driving on extremely inclined surfaces,

such as higher banked corners, the ESP sys-

tem may not operate properly and the ESP

OFF indicator light (

) and/or the “SLIP”

indicator light () may illuminate. Do not

drive on these types of roads. If ESP OFF indi-

cator light

does illuminate after driving

on extreme surfaces, restart the engine to re-

set the ESP system.

If wheels or tyres other than the

recommended ones are used, the ESP sys-

tem may not operate properly and the ESP OFF indicator light (

) and/or the “SLIP”

indicator light () may illuminate.

The ESP system is not a substitute for winter

tyres or snow chains on a snow covered road.

NOTE

The ESP system should be switched on under

normal circumstances although it may be ad-

vantageous to switch off the ESP system to

allow wheelspin under the following condi-

tions:

– When driving in deep snow or mud.

– When trying to rock a vehicle free that is stuck in snow.

– When driving with snow chains.

If the ESP system has been switched off, drive

carefully with reduced speed. When road con-

ditions allow, ESP should be switched back

on.

Starting and driving5-41

Page 210 of 297

Downloaded from www.Manualslib.com manuals search engine 6. Turn off the engine.

7. Open the bonnet (for details, see “Bonnetrelease” in the “3. Pre-driving checks and

adjustments” section) in order to:

Warn other traffic.

Signal to professional road assistance that

you require assistance.

8. Have all passengers exit the vehicle and stand in a safe place, away from traffic and clear of the

vehicle.

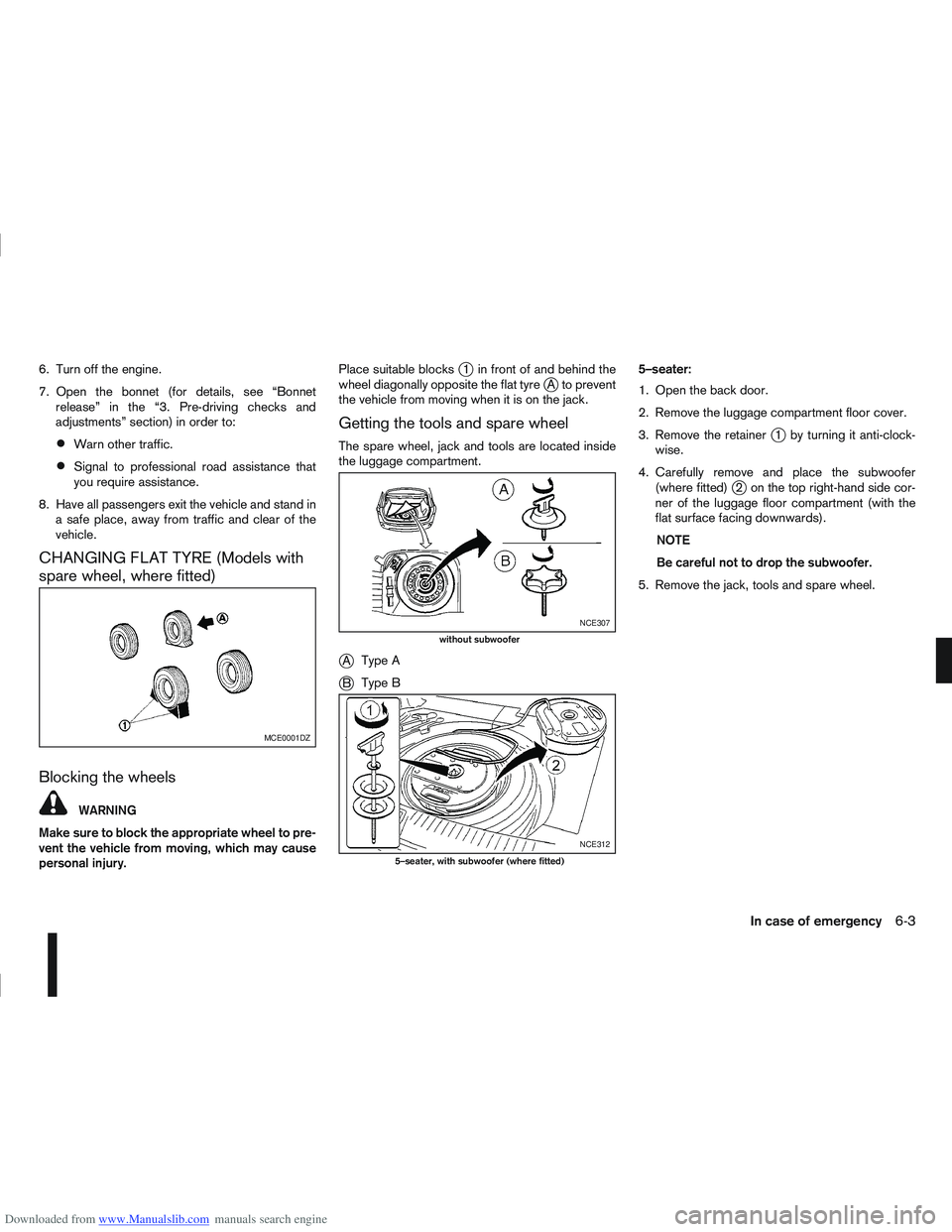

CHANGING FLAT TYRE (Models with

spare wheel, where fitted)

Blocking the wheels

WARNING

Make sure to block the appropriate wheel to pre-

vent the vehicle from moving, which may cause

personal injury. Place suitable blocks

j1 in front of and behind the

wheel diagonally opposite the flat tyrejA to prevent

the vehicle from moving when it is on the jack.

Getting the tools and spare wheel

The spare wheel, jack and tools are located inside

the luggage compartment.

jA Type A

jB Type B 5–seater:

1. Open the back door.

2. Remove the luggage compartment floor cover.

3. Remove the retainer

j1 by turning it anti-clock-

wise.

4. Carefully remove and place the subwoofer (where fitted)

j2 on the top right-hand side cor-

ner of the luggage floor compartment (with the

flat surface facing downwards).

NOTE

Be careful not to drop the subwoofer.

5. Remove the jack, tools and spare wheel.

MCE0001DZ

NCE307

without subwoofer

NCE312

5–seater, with subwoofer (where fitted)

In case of emergency6-3

Page 211 of 297

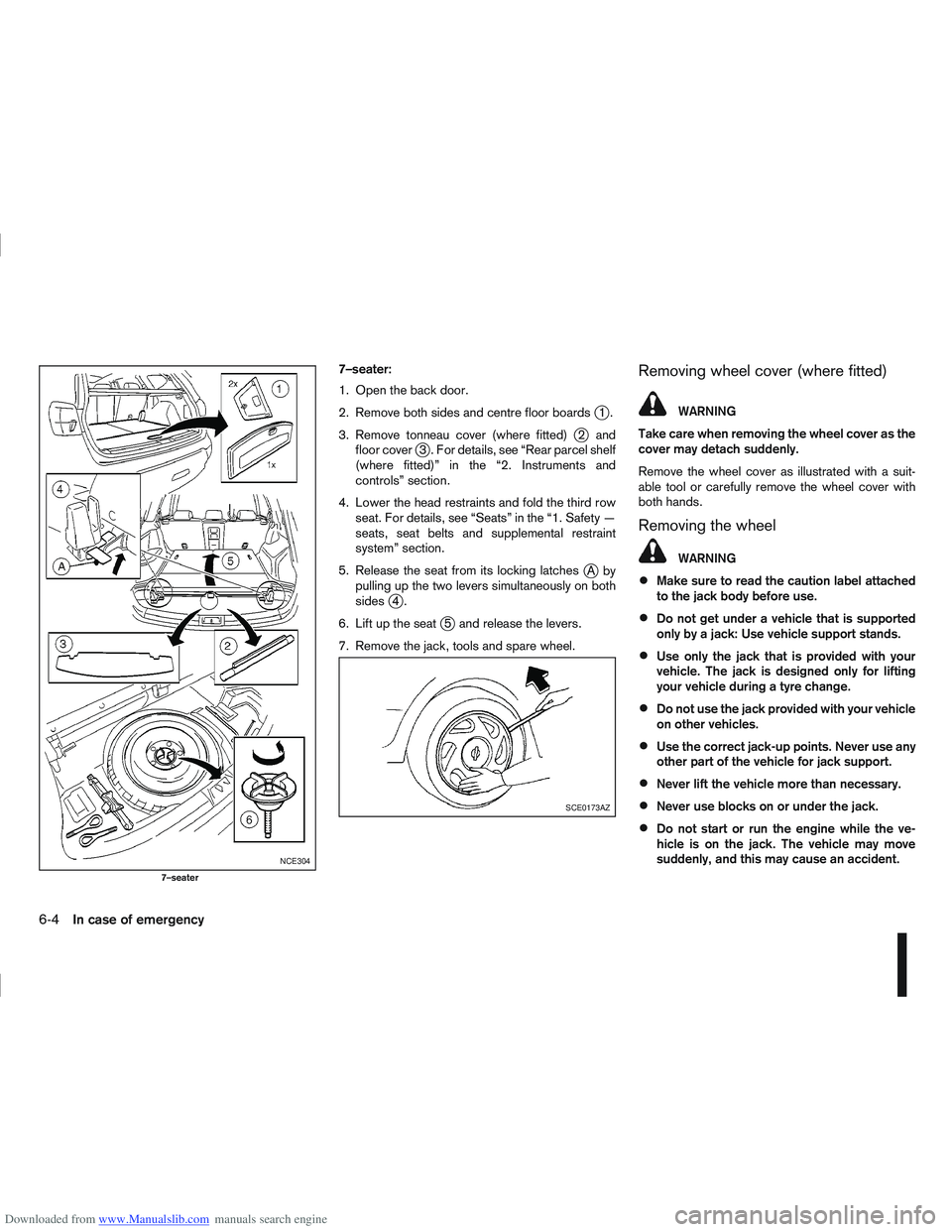

Downloaded from www.Manualslib.com manuals search engine 7–seater:

1. Open the back door.

2. Remove both sides and centre floor boards

j1.

3. Remove tonneau cover (where fitted)

j2 and

floor coverj3 . For details, see “Rear parcel shelf

(where fitted)” in the “2. Instruments and

controls” section.

4. Lower the head restraints and fold the third row seat. For details, see “Seats” in the “1. Safety —

seats, seat belts and supplemental restraint

system” section.

5. Release the seat from its locking latches

jAby

pulling up the two levers simultaneously on both

sides

j4.

6. Lift up the seat

j5 and release the levers.

7. Remove the jack, tools and spare wheel.

Removing wheel cover (where fitted)

WARNING

Take care when removing the wheel cover as the

cover may detach suddenly.

Remove the wheel cover as illustrated with a suit-

able tool or carefully remove the wheel cover with

both hands.

Removing the wheel

WARNING

Make sure to read the caution label attached

to the jack body before use.

Do not get under a vehicle that is supported

only by a jack: Use vehicle support stands.

Use only the jack that is provided with your

vehicle. The jack is designed only for lifting

your vehicle during a tyre change.

Do not use the jack provided with your vehicle

on other vehicles.

Use the correct jack-up points. Never use any

other part of the vehicle for jack support.

Never lift the vehicle more than necessary.

Never use blocks on or under the jack.

Do not start or run the engine while the ve-

hicle is on the jack. The vehicle may move

suddenly, and this may cause an accident.

NCE304

7–seater

SCE0173AZ

6-4In case of emergency

Page 218 of 297

Downloaded from www.Manualslib.com manuals search engine 6. Open the bonnet. For details, see “Bonnetrelease” in the “3. Pre-driving checks and

adjustments” section.

7. Remove the vent caps (where fitted) on the bat- tery and cover the battery with an old cloth.

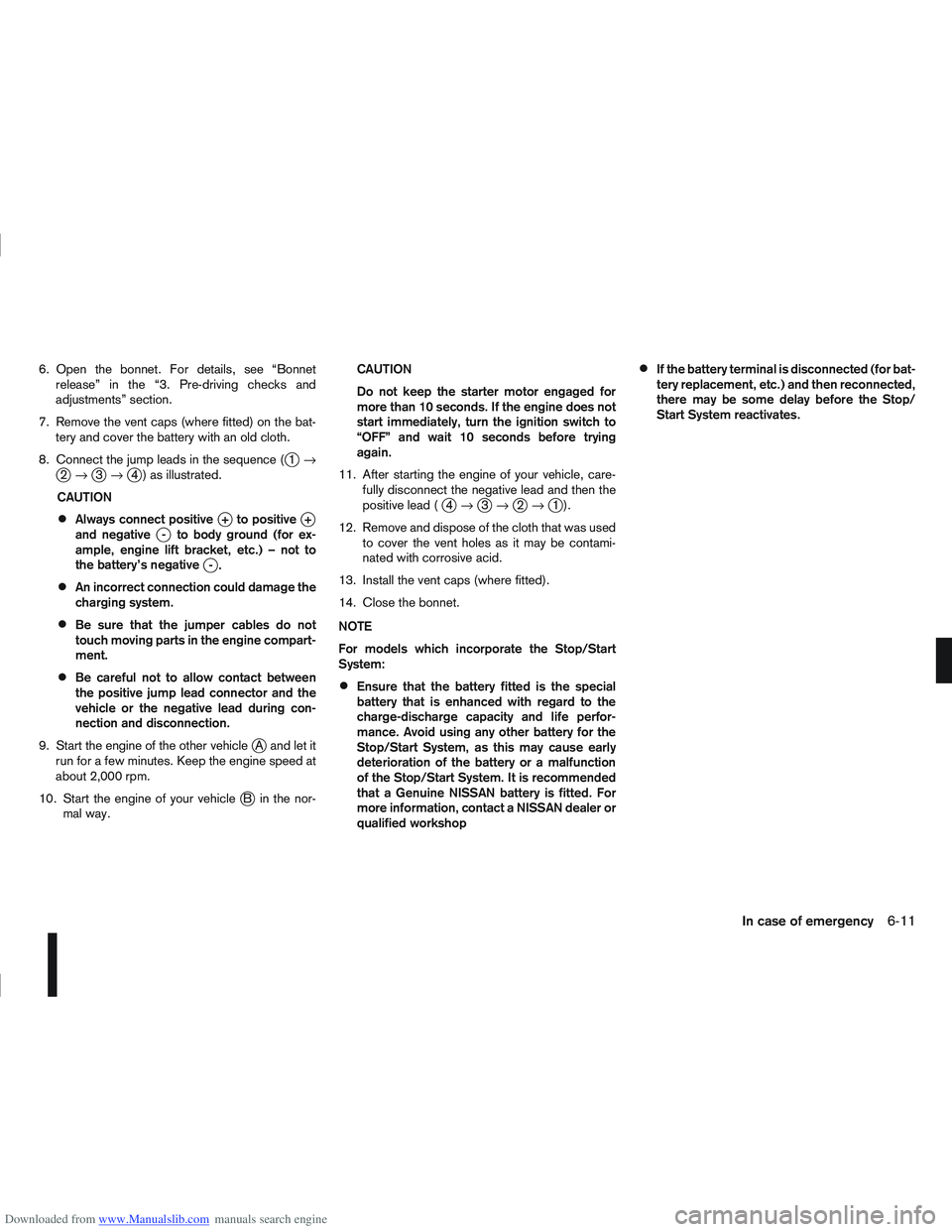

8. Connect the jump leads in the sequence (

j1 →j2→j3→j4 ) as illustrated.

CAUTION

Always connect positivej+ to positivej+

and negativej- to body ground (for ex-

ample, engine lift bracket, etc.) – not to

the battery’s negative

j-.

An incorrect connection could damage the

charging system.

Be sure that the jumper cables do not

touch moving parts in the engine compart-

ment.

Be careful not to allow contact between

the positive jump lead connector and the

vehicle or the negative lead during con-

nection and disconnection.

9. Start the engine of the other vehicle

jA and let it

run for a few minutes. Keep the engine speed at

about 2,000 rpm.

10. Start the engine of your vehicle

jB in the nor-

mal way. CAUTION

Do not keep the starter motor engaged for

more than 10 seconds. If the engine does not

start immediately, turn the ignition switch to

“OFF” and wait 10 seconds before trying

again.

11. After starting the engine of your vehicle, care- fully disconnect the negative lead and then the

positive lead (

j4→j3→j2→j1).

12. Remove and dispose of the cloth that was used to cover the vent holes as it may be contami-

nated with corrosive acid.

13. Install the vent caps (where fitted).

14. Close the bonnet.

NOTE

For models which incorporate the Stop/Start

System:

Ensure that the battery fitted is the special

battery that is enhanced with regard to the

charge-discharge capacity and life perfor-

mance. Avoid using any other battery for the

Stop/Start System, as this may cause early

deterioration of the battery or a malfunction

of the Stop/Start System. It is recommended

that a Genuine NISSAN battery is fitted. For

more information, contact a NISSAN dealer or

qualified workshop

If the battery terminal is disconnected (for bat-

tery replacement, etc.) and then reconnected,

there may be some delay before the Stop/

Start System reactivates.

In case of emergency6-11

Page 219 of 297

Downloaded from www.Manualslib.com manuals search engine CAUTION

Three-way catalyst equipped models should

not be started by pushing the vehicle as the

three-way catalyst may be damaged.

Automatic transmission (AT) or continuously

variable transmission (CVT) models cannot be

started by pushing the vehicle. This may cause

transmission damage.

Never try to start the vehicle by towing it; when

the engine starts, the forward surge could

cause the vehicle to collide with the tow ve-

hicle.

WARNING

Never continue driving if the engine of your

vehicle overheats. Doing so could cause a ve-

hicle fire.

Never open the bonnet if steam is coming

out.

Never remove engine coolant reservoir cap

when the engine is hot. If the engine coolant

reservoir cap is removed while the engine is

hot, pressurised hot water will spurt out and

possibly cause burning, scalding or serious

injury.

If steam or coolant is coming out of the en-

gine, stand clear of the vehicle to prevent get-

ting injured.

The engine cooling fan will start whenever the

coolant temperature exceeds preset degrees.

Be careful not to allow your hands, hair, jewel-

lery or clothing to come into contact with, or

get caught in, the cooling fan or drive belts.

If the engine of your vehicle is overheating (indi-

cated by the engine coolant temperature gauge) or

if you feel a lack of engine power, detect unusual

noise, etc., proceed as follows:

1. Move and park the vehicle safely off the road and away from traffic.

2. Turn on the hazard warning flasher lights.

3. Apply the handbrake. 4. Shift the gear lever (MT models) into the N (Neu-

tral) position [AT or CVT models, move the se-

lector lever to the P (Park) position].

DO NOT STOP THE ENGINE.

5. Open all windows.

6. Switch off the air conditioner system (where fit- ted).

7. Set the heater or air conditioner temperature control to maximum “HOT” and fan speed con-

trol to maximum speed.

8. Exit the vehicle.

9. Visually inspect and listen for steam or coolant escaping from the radiator before opening the

bonnet. Wait until no steam or coolant can be

seen before proceeding.

10. Open the bonnet. For details, see “Bonnet release” in the “3. Pre-driving checks and

adjustments” section.

11. Visually check if the cooling fan is running.

12. Visually check the radiator and radiator hoses for leakage.

WARNING

If coolant is leaking, the cooling fan belt is

missing or loose or the cooling fan is not run-

ning, stop the engine.

13. After the engine cools down, check the coolant level in the engine coolant reservoir with the

engine running.

PUSH-STARTING ENGINE OVERHEAT

6-12In case of emergency

Page 220 of 297

Downloaded from www.Manualslib.com manuals search engine 14. If the level is low, remove the engine coolantreservoir cap and add coolant slowly into the

reservoir. After refilling the reservoir to the MAX

level, install the reservoir cap.

WARNING

Before removing the engine coolant reservoir

cap and to avoid the danger of being scalded,

cover the reservoir cap with a rag and loosen

the reservoir cap to the first notch to allow the

steam to escape.

15. Close the bonnet.

Have your vehicle inspected or repaired by a

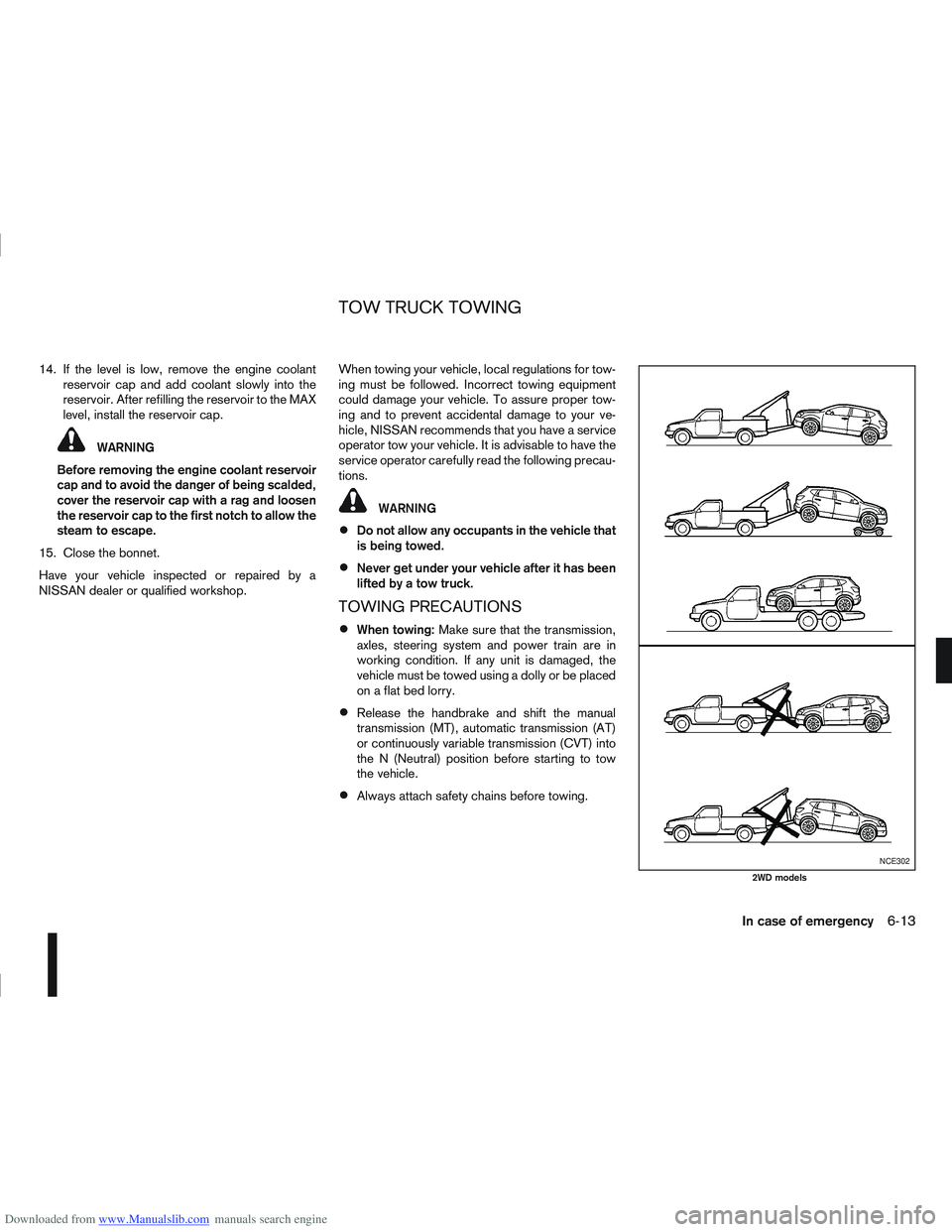

NISSAN dealer or qualified workshop. When towing your vehicle, local regulations for tow-

ing must be followed. Incorrect towing equipment

could damage your vehicle. To assure proper tow-

ing and to prevent accidental damage to your ve-

hicle, NISSAN recommends that you have a service

operator tow your vehicle. It is advisable to have the

service operator carefully read the following precau-

tions.

WARNING

Do not allow any occupants in the vehicle that

is being towed.

Never get under your vehicle after it has been

lifted by a tow truck.

TOWING PRECAUTIONS

When towing:

Make sure that the transmission,

axles, steering system and power train are in

working condition. If any unit is damaged, the

vehicle must be towed using a dolly or be placed

on a flat bed lorry.

Release the handbrake and shift the manual

transmission (MT), automatic transmission (AT)

or continuously variable transmission (CVT) into

the N (Neutral) position before starting to tow

the vehicle.

Always attach safety chains before towing.

NCE302

2WD models

TOW TRUCK TOWING

In case of emergency6-13

Page 233 of 297

Downloaded from www.Manualslib.com manuals search engine Your new NISSAN has been designed to have mini-

mum maintenance requirements with longer service

intervals, to save you both time and money. How-

ever, some day-to-day and regular maintenance is

essential to maintain your NISSAN’s good mechani-

cal condition, as well as its emission and engine

performance.

It is the owner’s responsibility to make sure that the

specified maintenance, as well as general mainte-

nance, is performed.

As the vehicle owner, you are the only one who can

ensure that your vehicle receives the proper mainte-

nance care.

SCHEDULED MAINTENANCE

For your convenience, the required scheduled main-

tenance items are described and listed in the sepa-

rate Warranty Information and Maintenance book-

let. You must refer to that booklet to ensure that

necessary maintenance is performed on your

NISSAN vehicle at regular intervals.

GENERAL MAINTENANCE

General maintenance includes those items which

should be checked during normal day-to-day opera-

tion of the vehicle. They are essential if your vehicle

is to continue to operate properly. It is your respon-

sibility to perform these procedures regularly as pre-

scribed.

Performing general maintenance checks requires

minimal mechanical skill and a few general automo-

tive tools.These checks or inspections can be done by your-

self, a qualified technician or, if you prefer, your

NISSAN dealer or qualified workshop.

WHERE TO GO FOR SERVICE

If maintenance service is required or your vehicle

appears to malfunction, have the systems checked

and tuned by an authorised NISSAN dealer or quali-

fied workshop.

During the normal day-to-day operation of the ve-

hicle, general maintenance should be performed

regularly as prescribed in this section. If you detect

any unusual sounds, vibrations or smell, be sure to

check for the cause or have a NISSAN dealer or

qualified workshop do it promptly. In addition, you

should notify a NISSAN dealer or qualified work-

shop if repairs are required.

When performing any checks or maintenance work,

closely observe the “Maintenance precautions” later

in this section.

EXPLANATION OF GENERAL

MAINTENANCE ITEMS

Additional information on the following items with

an asterisk (*) is found later in this section.

The maintenance items listed here should be per-

formed from time to time, unless otherwise speci-

fied.

Outside the vehicle

Back door, doors and bonnet:

Check that the back door, all doors and the bonnet

operate properly. Also ensure that all latches lock

securely. Lubricate hinges and latches if necessary.

Make sure that the secondary latch keeps the bon-

net from opening when the primary latch is released.

When driving in areas using road salt or other cor-

rosive materials, check for lubrication frequently.

MAINTENANCE REQUIREMENTS

GENERAL MAINTENANCE

8-2Maintenance and do-it-yourself

Page 238 of 297

Downloaded from www.Manualslib.com manuals search engine HR16DE, MR20DE, M9R or R9M

engine

1. Set the heater or air conditioner temperaturecontrol to the maximum “HOT” position.

2. Open the bonnet. For details, see “Bonnet release” in the “3. Pre-driving checks and

adjustments” section.

3. Open the engine coolant reservoir cap

j1to

help to drain the coolant.

4. Disconnect the end of the hose

j2 to drain the

coolant.

5. Flush the cooling system by running clean water through the engine coolant reservoir.

6. Install the hose

j2.

7. Fill the coolant reservoir up to the MAX level. See “Capacities and recommended

fuel/lubricants” in the “9. Technical information”

section for cooling system capacity.

8. Install the engine coolant reservoir cap.

9. Start the engine, and rev the engine two or three times under no load.

10. Touch the radiator hose and feel if the water flows.

11. Keep racing the engine at a speed of 3,000 rpm for about 10 minutes.

12. Observe the coolant temperature gauge for signs of overheating. 13. Stop the engine and check coolant level, allow

to cool and refill up to the MAX level.

14. Check radiator lower hose for any signs of leak- age.

15. Close the bonnet.

K9K engine

1. Set the heater or air conditioner temperature control to the maximum “HOT” position.

2. Open the bonnet. For details, see “Bonnet release” in the “3. Pre-driving checks and

adjustments” section.

3. Disconnect the radiator lower hose

j1 and open

the drain plugj2 on the engine block.

4. Open the engine coolant reservoir cap to help to drain the coolant.

5. Flush the cooling system by running fresh water through the engine coolant reservoir. 6. Install the hose and securely tighten the engine

block drain plug.

7. Fill the reservoir up to the MAX level with cool- ant. See “Capacities and recommended

fuel/lubricants” in the “9. Technical information”

section for cooling system capacity.

8. Install the engine coolant reservoir cap.

9. Start the engine, and rev the engine two or three times under no load.

10. Touch the radiator hose and feel if the water flows.

11. Keep racing the engine at a speed of 2,000 – 2,500 rpm for about 10 minutes.

12. Observe the coolant temperature gauge for signs of overheating.

13. Stop the engine and check coolant level, allow to cool and refill up to the MAX level.

14. Check the radiator lower hose for any signs of leakage.

15. Close the bonnet.

NDI941Z

Maintenance and do-it-yourself8-7