lock NISSAN QASHQAI 2014 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: QASHQAI, Model: NISSAN QASHQAI 2014Pages: 338, PDF Size: 4.87 MB

Page 249 of 338

4. Loosen each wheel bolt by one or two turns

anticlockwise with the wheel wrench.

Do not remove the wheel bolts until the tyre is

off the ground.

Models with wheel lock bolts (where fitted):

If the wheel is equipped with a wheel lock bolt,

insert the wheel lock key

j1 and loosen it as pre-

viously described.

The wheel lock bolt can only be removed with the

wheel lock key. A key number is necessary if you

need to duplicate the wheel lock key.

Record the key number as shown on the key

code card on the “Security information” page at

the end of this manual and keep it in a safe place,

not in the vehicle. If you loose the wheel lock key,

see your NISSAN dealer for a duplicate with the

original wheel lock key code.Make sure to keep the lock key in the vehicle.

Otherwise, wheels cannot be removed and the

service cannot be performed.

5. To lift the vehicle, securely hold and turn the

handle clockwise as shown.

6. Carefully raise the vehicle until the tyre clears the

ground.

7. Remove the wheel bolts, then remove the wheel

with the flat tyre.

CAUTION

The wheel is heavy. Be sure that your feet are

clear of the wheel and use gloves as necessary

to avoid injury.

Installing the wheel

WARNING

•The temporary use spare tyre (where fitted) is

designed for emergency use. See “Spare tyre”

earlier in this section.

•Never use wheel bolts other than those pro-

vided with your vehicle. Incorrect wheel bolts

or improperly tightened wheel bolts may

cause the wheel to become loose or come

off. This could cause an accident.

•Never use oil or grease on the wheel bolts.

This may cause the wheel bolts to become

loose.

jATighten

jBLoosen

1. Clean any mud or dirt from the surface between

the wheel and the hub.

2. Carefully fit the wheel and tighten the wheel bolts

with your fingers. Check that all the wheel bolts

contact the wheel surface horizontally and on the

bevelled side.

Models with wheel lock bolt (where fitted):

Insert the wheel lock key into the wheel lock bolt

and tighten into the wheel finger tight.

NCE143Z

NCE309

NCE198Z

In case of emergency6-5

Page 250 of 338

3. With the wheel wrench, tighten the wheel bolts

alternately and evenly in the sequence as illus-

trated (

j1-j5 ) until they are tight.

4. Lower the vehicle slowly until the tyre touches

the ground.

5. Tighten the wheel bolts securely using the wheel

wrench in the sequence as illustrated.

6. Lower the vehicle completely.

7. Install the wheel cover (where fitted).

NOTE

Before installation, align NISSAN logo (centre

cap) with the wheel bolts/or perpendicular to

valve hole (where fitted), to correctly align to

the centre.

Wheel bolt tightening torque:

113 N•m (12 kg-m, 83 ft-lb)

As soon as possible, tighten the wheel bolts to

the specified torque with a torque wrench.

WARNING

Retighten the wheel bolts after the vehicle has

been driven for 1,000 km (600 miles) (also in

cases of a flat tyre, etc.).

The wheel bolts must be kept tightened to specifi-

cation at all times. It is recommended that the wheel

bolts be tightened to specification at each mainte-

nance interval.

Adjust the tyre pressure to the COLD pressure.COLD pressure is the tyre pressure as measured

after the vehicle has been parked for three hours or

more or driven for less than 1.6 km (1 mile).

COLD tyre pressures are shown on the tyre placard

affixed to the driver’s side centre pillar.

Stowing the wheel and tools

Securely store the wheel with the flat tyre, the jack

and the tools in the specified storage areas.

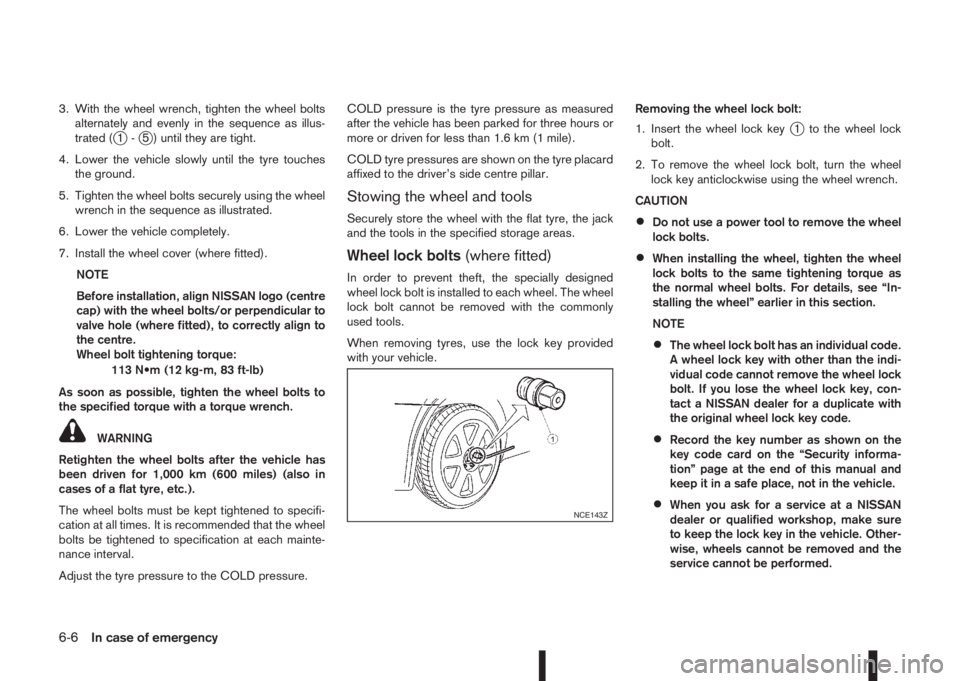

Wheel lock bolts(where fitted)

In order to prevent theft, the specially designed

wheel lock bolt is installed to each wheel. The wheel

lock bolt cannot be removed with the commonly

used tools.

When removing tyres, use the lock key provided

with your vehicle.Removing the wheel lock bolt:

1. Insert the wheel lock key

j1 to the wheel lock

bolt.

2. To remove the wheel lock bolt, turn the wheel

lock key anticlockwise using the wheel wrench.

CAUTION

•Do not use a power tool to remove the wheel

lock bolts.

•When installing the wheel, tighten the wheel

lock bolts to the same tightening torque as

the normal wheel bolts. For details, see “In-

stalling the wheel” earlier in this section.

NOTE

•The wheel lock bolt has an individual code.

A wheel lock key with other than the indi-

vidual code cannot remove the wheel lock

bolt. If you lose the wheel lock key, con-

tact a NISSAN dealer for a duplicate with

the original wheel lock key code.

•Record the key number as shown on the

key code card on the “Security informa-

tion” page at the end of this manual and

keep it in a safe place, not in the vehicle.

•When you ask for a service at a NISSAN

dealer or qualified workshop, make sure

to keep the lock key in the vehicle. Other-

wise, wheels cannot be removed and the

service cannot be performed.NCE143Z

6-6In case of emergency

Page 256 of 338

4. Switch off all unnecessary electrical systems

(headlights, hazard lights etc,).

5. Ensure that the ignition switch of the vehicle be-

ing jump-started is in the LOCK position.

6. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

7. Remove the vent caps (where fitted) on the bat-

tery and cover the battery with an old cloth.

8. Connect the jump leads in the sequence (

j1→j2→j3→j4 ) as illustrated.

CAUTION

•Always connect positivej+ to positivej+

and negativej- to body ground (for ex-

ample, engine mount, etc.) – not to the

battery’s negative

j-.

•An incorrect connection could damage the

charging system.

•Be sure that the jumper cables do not

touch moving parts in the engine compart-

ment.

•Be careful not to allow contact between

the positive jump lead connector and the

vehicle or the negative lead during con-

nection and disconnection.

9. Start the engine of the other vehicle

jA and let it

run for a few minutes. Keep the engine speed at

about 2,000 rpm.10. Start the engine of your vehicle

jB in the nor-

mal way.

CAUTION

Do not keep the starter motor engaged for

more than 10 seconds. If the engine does not

start immediately, turn the ignition switch to

“OFF” and wait 10 seconds before trying

again.

11. After starting the engine of your vehicle, care-

fully disconnect the negative lead and then the

positive lead (

j4→j3→j2→j1).

12. Remove and dispose of the cloth that was used

to cover the vent holes as it may be contami-

nated with corrosive acid.

13. Install the vent caps (where fitted).

14. Close the bonnet.

NOTE

For models which incorporate the Stop/Start

System:

•Ensure that the battery fitted is the special

battery that is enhanced with regard to the

charge-discharge capacity and life perfor-

mance. Avoid using any other battery for the

Stop/Start System, as this may cause early

deterioration of the battery or a malfunction

of the Stop/Start System. It is recommended

that a Genuine NISSAN battery is fitted. For

more information, contact a NISSAN dealer or

qualified workshop

•If the battery terminal is disconnected (for bat-

tery replacement, etc.) and then reconnected,

there may be some delay before the Stop/

Start System reactivates.

6-12In case of emergency

Page 259 of 338

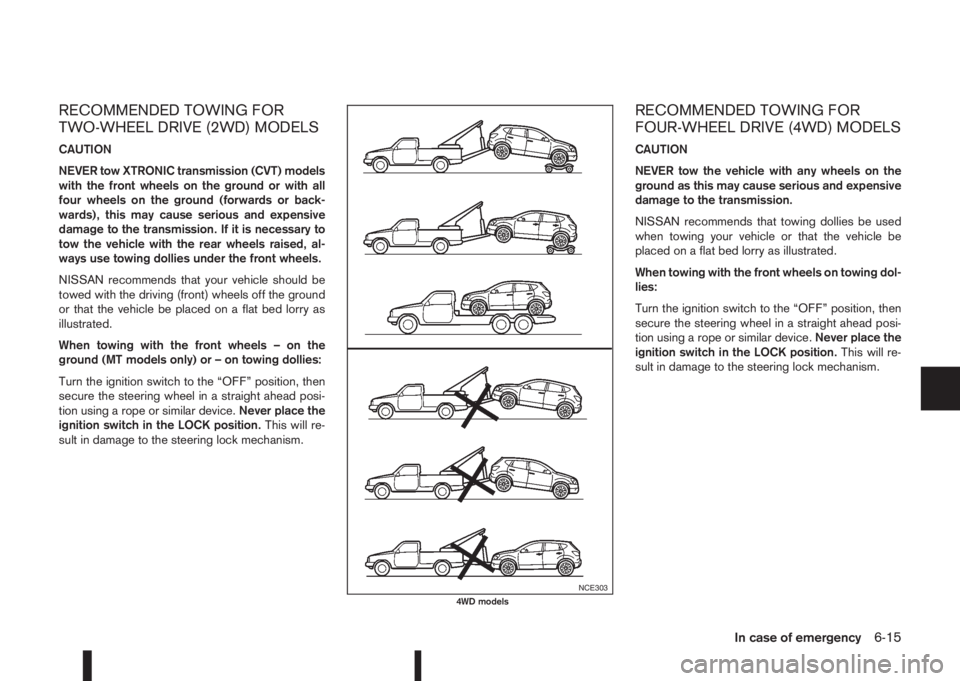

RECOMMENDED TOWING FOR

TWO-WHEEL DRIVE (2WD) MODELS

CAUTION

NEVER tow XTRONIC transmission (CVT) models

with the front wheels on the ground or with all

four wheels on the ground (forwards or back-

wards), this may cause serious and expensive

damage to the transmission. If it is necessary to

tow the vehicle with the rear wheels raised, al-

ways use towing dollies under the front wheels.

NISSAN recommends that your vehicle should be

towed with the driving (front) wheels off the ground

or that the vehicle be placed on a flat bed lorry as

illustrated.

When towing with the front wheels – on the

ground (MT models only) or – on towing dollies:

Turn the ignition switch to the “OFF” position, then

secure the steering wheel in a straight ahead posi-

tion using a rope or similar device.Never place the

ignition switch in the LOCK position.This will re-

sult in damage to the steering lock mechanism.

RECOMMENDED TOWING FOR

FOUR-WHEEL DRIVE (4WD) MODELS

CAUTION

NEVER tow the vehicle with any wheels on the

ground as this may cause serious and expensive

damage to the transmission.

NISSAN recommends that towing dollies be used

when towing your vehicle or that the vehicle be

placed on a flat bed lorry as illustrated.

When towing with the front wheels on towing dol-

lies:

Turn the ignition switch to the “OFF” position, then

secure the steering wheel in a straight ahead posi-

tion using a rope or similar device.Never place the

ignition switch in the LOCK position.This will re-

sult in damage to the steering lock mechanism.

NCE3034WD models

In case of emergency6-15

Page 262 of 338

In order to maintain the appearance of your vehicle,

it is important to take proper care of it.

Whenever possible, park your vehicle inside a ga-

rage or in a covered area to minimise the chances

of damaging the paint surface of your vehicle.

When it is necessary to park outside, park in a shady

area or protect the vehicle with a body cover.Be

careful not to scratch the paint surface when put-

ting on or removing the body cover.

WASHING

In the following instances, wash your vehicle as soon

as possible to protect the paint surface:

•After a rainfall, to prevent possible damage from

acid rain.

•After driving on coastal roads.

•When contaminants such as soot, bird drop-

pings, tree sap, metal particles or insects get on

the paint surface.

•When dust or mud builds up on the paint sur-

face.

1. Wash the vehicle surface with a wet sponge and

plenty of water.

2. Clean the vehicle surface gently and thoroughly

using a mild soap or a special vehicle wash sham-

poo mixed with clean, lukewarm (never hot) wa-

ter.CAUTION

•Do not wash the vehicle with strong house-

hold soap, strong chemical detergents, petrol

or solvents.

•Do not wash the vehicle in direct sunlight or

while the vehicle body is hot, as the paint sur-

face may become water-spotted.

•Avoid using tight-napped or rough cloths,

such as washing mitts. Care must be taken

when removing caked-on dirt or other foreign

substances so the paint surface is not

scratched or damaged.

3. Rinse the vehicle thoroughly with plenty of clean

water.

4. Use a damp chamois to dry the paint surface to

avoid leaving water spots.

When washing the vehicle, take care of the follow-

ing:

•Inside flanges, joints and folds on the doors, back

door and bonnet are particularly vulnerable to

the effects of road salt. Therefore, these areas

must be cleaned regularly.

•Be sure that the drain holes in the lower edge of

the doors are not clogged.

•Spray water to the underbody and in the wheel

wells to loosen the dirt and/or wash away road

salt.

•If using a high pressure washer always follow

the recommendations on the equipment (pres-

sure and spraying distance).

CAUTION

Do not spray directly into the engine compart-

ment with a high-pressure washer/hose this

could damage the engine.

•If there are damaged areas on the vehicle (e.g.

painted bumpers or headlamp assembly), it is

not recommended to direct the high pressure jet

on to them. Carefully wash these areas by hand.

•Avoid the entry of water into the locks.

REMOVING SPOTS

Remove tar and oil spots, industrial dust, insects,

and tree sap as quickly as possible from the paint

surface to avoid lasting damage or staining. Special

cleaning products are available at a NISSAN dealer

or any automotive accessory store.

WAXING

Regular waxing protects the paint surface and helps

to retain a new vehicle appearance.

After waxing, polishing is recommended to remove

built-up residue.

A NISSAN dealer or qualified workshop can assist

you in choosing the appropriate waxing products.

CAUTION

•Wash your vehicle thoroughly and completely

before applying wax to the paint surface.

CLEANING EXTERIOR

7-2Appearance and care

Page 270 of 338

Some day-to-day and regular maintenance is essen-

tial to maintain your NISSAN’s good mechanical

condition, as well as its emission and engine perfor-

mance.

It is the owner’s responsibility to make sure that the

specified maintenance, as well as general mainte-

nance, is performed.

As the vehicle owner, you are the only one who can

ensure that your vehicle receives the proper mainte-

nance care.

SCHEDULED MAINTENANCE

For your convenience, the required scheduled main-

tenance items are described and listed in the sepa-

rate Warranty Information and Maintenance book-

let. You must refer to that booklet to ensure that

necessary maintenance is performed on your

NISSAN vehicle at regular intervals.

GENERAL MAINTENANCE

General maintenance includes those items which

should be checked during normal day-to-day opera-

tion of the vehicle. They are essential if your vehicle

is to continue to operate properly. It is your respon-

sibility to perform these procedures regularly as pre-

scribed.

Performing general maintenance checks requires

minimal mechanical skill and a few general automo-

tive tools.

These checks or inspections can be done by your-

self, a qualified technician or, if you prefer, your

NISSAN dealer or qualified workshop.

WHERE TO GO FOR SERVICE

If maintenance service is required or your vehicle

appears to malfunction, have the systems checked

and tuned by an authorised NISSAN dealer or quali-

fied workshop.During the normal day-to-day operation of the ve-

hicle, general maintenance should be performed

regularly as prescribed in this section. If you detect

any unusual sounds, vibrations or smell, be sure to

check for the cause or have a NISSAN dealer or

qualified workshop do it promptly. In addition, you

should notify a NISSAN dealer or qualified work-

shop if repairs are required.

When performing any checks or maintenance work,

closely observe the “Maintenance precautions” later

in this section.

EXPLANATION OF GENERAL

MAINTENANCE ITEMS

Additional information on the following items with

an asterisk (*) is found later in this section.

The maintenance items listed here should be per-

formed from time to time, unless otherwise speci-

fied.

Outside the vehicle

Back door, doors and bonnet:

Check that the back door, all doors and the bonnet

operate properly. Also ensure that all latches lock

securely. Lubricate hinges and latches if necessary.

Make sure that the secondary latch keeps the bon-

net from opening when the primary latch is released.

When driving in areas using road salt or other cor-

rosive materials, check for lubrication frequently.

MAINTENANCE REQUIREMENTS GENERAL MAINTENANCE

8-2Maintenance and do-it-yourself

Page 272 of 338

longer to stop, contact a NISSAN dealer or qualified

workshop immediately. Keep the floor mat away

from the pedal.

Parking brake*:

Confirm that your vehicle is held securely on a fairly

steep hill with only the parking brake applied.

Seats:

Check seat position controls such as seat adjust-

ers, seatback recliner, etc. to ensure they operate

smoothly and all latches lock securely in every posi-

tion. Check that the head restraints move up and

down smoothly and the locks hold securely in all

latched positions.

Seat belts:

Check that all parts of the seat belt system (e.g.

buckles, anchors, adjusters and retractors) operate

properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or

damage. See “Seat belts” in the “1. Safety — Seats,

Seat belts and Supplemental Restraint System” sec-

tion for further details.

Steering wheel:

Check for any change in the steering conditions,

such as excessive free play, hard steering or strange

noises.

Warning lights and audible reminders:

Make sure that all warning/indicator lights and au-

dible reminders are operating properly.Windscreen defogger:

Check that the air comes out of the defogger outlets

properly when operating the heater or air condi-

tioner.

Windscreen wiper and washer*:

Check that the wipers and washer operate properly

and that the wipers do not streak.When performing any inspection or maintenance

work on your vehicle, always take care to prevent

serious accidental injury to yourself or damage to

the vehicle. The following are general precautions

which should be closely observed.

•Park the vehicle on a level surface, apply the

parking brake securely and block the wheels

to prevent the vehicle from moving. For

manual transmission models, move the shift

lever to N (Neutral) position.For continuously

variable transmission models: move the shift

lever to P (Park) position.

•Do not work under the engine bonnet while

the engine is hot. Turn off the engine and wait

until it cools down.

•Be sure to turn the ignition switch to the “OFF”

or LOCK position.

When the ignition switch is in the ON or Acc

position, the cooling fan may start to operate

suddenly even when the engine is not run-

ning. To avoid injury, always disconnect the

negative battery cable before working near

the engine.

•If you must work with the engine running,

keep your hands, clothing, hair and tools away

from moving fans, belts and any other moving

parts.

•It is advisable to remove ties and any jewel-

lery, such as rings, watches, etc. before work-

ing on your vehicle.

MAINTENANCE PRECAUTIONS

8-4Maintenance and do-it-yourself

Page 275 of 338

MR20DD, MR16DE or R9M engine

1. Set the heater or air conditioner temperature

control to the maximum “HOT” position.

2. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

3. Open the engine coolant reservoir cap

j1to

help drain the coolant.

4. Loosen the engine coolant radiator drain plug

j3

to help drain the coolant.

5. Disconnect the end of the hose

j2 to drain the

coolant.

6. Flush the cooling system by running clean water

through the engine coolant reservoir.

7. Install the hose

j2.

8. Tighten the engine coolant radiator drain plug

j3.

9. Fill the coolant reservoir up to the MAX level.

See “Capacities and recommended fuel/

lubricants” in the “9. Technical information” sec-

tion for cooling system capacity.

10. Install the engine coolant reservoir cap.

11. Start the engine, and rev the engine two or

three times under no load.

12. Touch the radiator hose and feel if the water

flows.

13. Keep racing the engine at a speed of 3,000 rpm

for about 10 minutes.14. Observe the coolant temperature gauge for

signs of overheating.

15. Stop the engine and check coolant level, allow

to cool and refill up to the MAX level.

16. Check radiator lower hose for any signs of leak-

age.

17. Close the bonnet.HRA2DDT or K9K engine

1. Set the heater or air conditioner temperature

control to the maximum “HOT” position.

2. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

3. Loosen the engine coolant radiator drain plug

j1

to help drain the coolant.

4. Disconnect the radiator lower hose

j2 and open

the drain plugj3 on the engine block.5. Open the engine coolant reservoir cap to help to

drain the coolant.

6. Flush the cooling system by running fresh water

through the engine coolant reservoir.

7. Install the hose

j2 and securely tighten the en-

gine block drain plugj3.

8. Tighten the engine coolant radiator drain plug

j1.

9. Fill the reservoir up to the MAX level with cool-

ant. See “Capacities and recommended

fuel/lubricants” in the “9. Technical information”

section for cooling system capacity.

10. Install the engine coolant reservoir cap.

11. Start the engine, and rev the engine two or

three times under no load.

12. Touch the radiator hose and feel if the water

flows.

13. Keep racing the engine at a speed of 2,000 –

2,500 rpm for about 10 minutes.

14. Observe the coolant temperature gauge for

signs of overheating.

15. Stop the engine and check coolant level, allow

to cool and refill up to the MAX level.

16. Check the radiator lower hose for any signs of

leakage.

17. Close the bonnet.

NDI1491

Maintenance and do-it-yourself8-7

Page 285 of 338

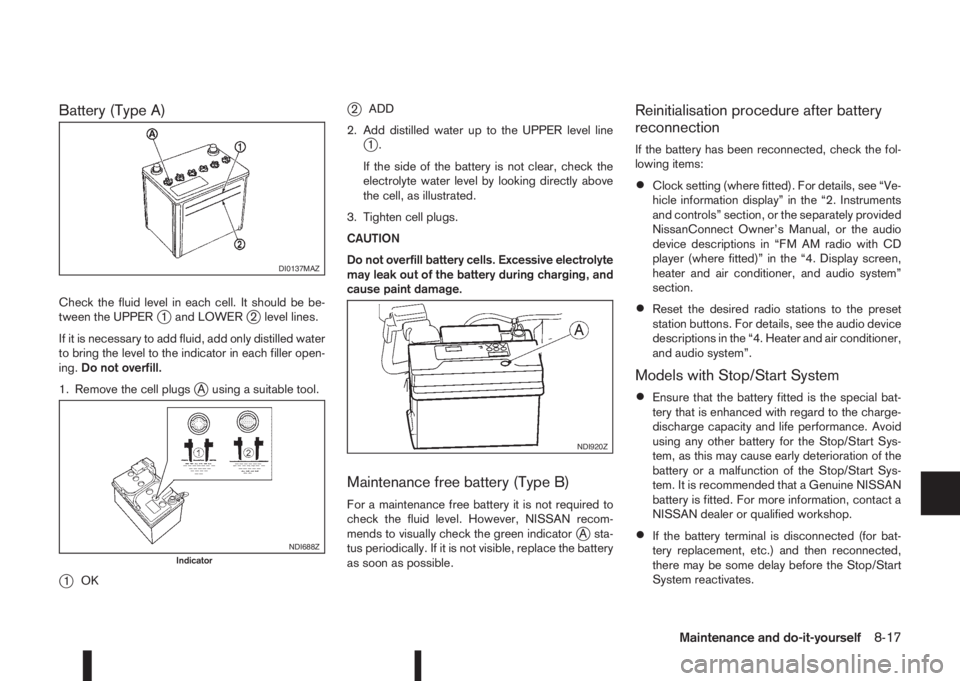

Battery (Type A)

Check the fluid level in each cell. It should be be-

tween the UPPERj1 and LOWERj2 level lines.

If it is necessary to add fluid, add only distilled water

to bring the level to the indicator in each filler open-

ing.Do not overfill.

1. Remove the cell plugs

jA using a suitable tool.

j1OK

j2ADD

2. Add distilled water up to the UPPER level line

j1.

If the side of the battery is not clear, check the

electrolyte water level by looking directly above

the cell, as illustrated.

3. Tighten cell plugs.

CAUTION

Do not overfill battery cells. Excessive electrolyte

may leak out of the battery during charging, and

cause paint damage.

Maintenance free battery (Type B)

For a maintenance free battery it is not required to

check the fluid level. However, NISSAN recom-

mends to visually check the green indicator

jA sta-

tus periodically. If it is not visible, replace the battery

as soon as possible.

Reinitialisation procedure after battery

reconnection

If the battery has been reconnected, check the fol-

lowing items:

•Clock setting (where fitted). For details, see “Ve-

hicle information display” in the “2. Instruments

and controls” section, or the separately provided

NissanConnect Owner’s Manual, or the audio

device descriptions in “FM AM radio with CD

player (where fitted)” in the “4. Display screen,

heater and air conditioner, and audio system”

section.

•Reset the desired radio stations to the preset

station buttons. For details, see the audio device

descriptions in the “4. Heater and air conditioner,

and audio system”.

Models with Stop/Start System

•Ensure that the battery fitted is the special bat-

tery that is enhanced with regard to the charge-

discharge capacity and life performance. Avoid

using any other battery for the Stop/Start Sys-

tem, as this may cause early deterioration of the

battery or a malfunction of the Stop/Start Sys-

tem. It is recommended that a Genuine NISSAN

battery is fitted. For more information, contact a

NISSAN dealer or qualified workshop.

•If the battery terminal is disconnected (for bat-

tery replacement, etc.) and then reconnected,

there may be some delay before the Stop/Start

System reactivates.

DI0137MAZ

NDI688ZIndicator

NDI920Z

Maintenance and do-it-yourself8-17

Page 288 of 338

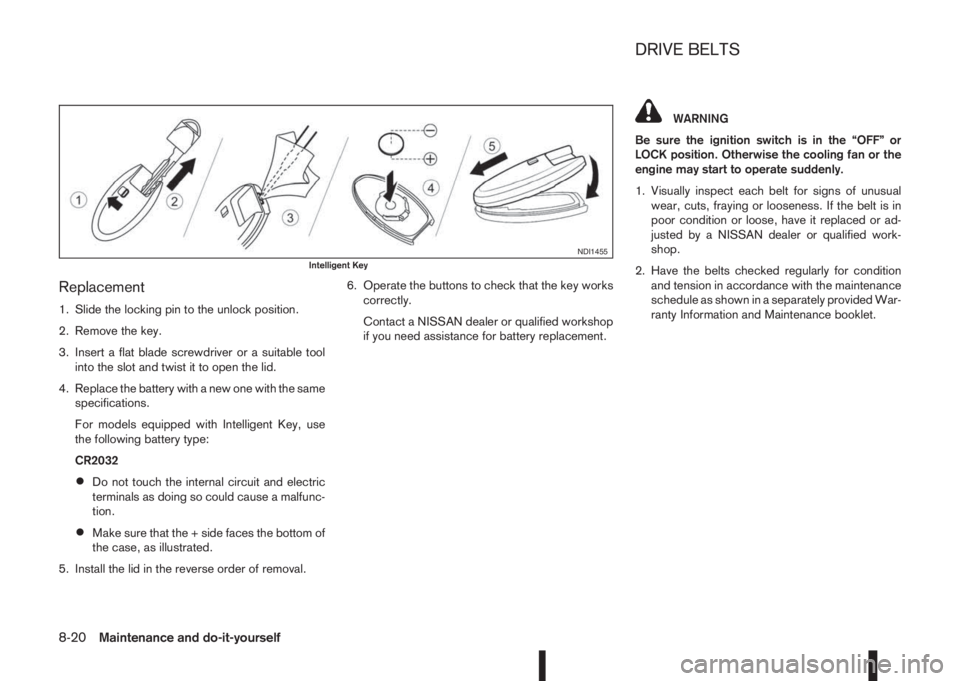

Replacement

1. Slide the locking pin to the unlock position.

2. Remove the key.

3. Insert a flat blade screwdriver or a suitable tool

into the slot and twist it to open the lid.

4. Replace the battery with a new one with the same

specifications.

For models equipped with Intelligent Key, use

the following battery type:

CR2032

•Do not touch the internal circuit and electric

terminals as doing so could cause a malfunc-

tion.

•Make sure that the + side faces the bottom of

the case, as illustrated.

5. Install the lid in the reverse order of removal.6. Operate the buttons to check that the key works

correctly.

Contact a NISSAN dealer or qualified workshop

if you need assistance for battery replacement.

WARNING

Be sure the ignition switch is in the “OFF” or

LOCK position. Otherwise the cooling fan or the

engine may start to operate suddenly.

1. Visually inspect each belt for signs of unusual

wear, cuts, fraying or looseness. If the belt is in

poor condition or loose, have it replaced or ad-

justed by a NISSAN dealer or qualified work-

shop.

2. Have the belts checked regularly for condition

and tension in accordance with the maintenance

schedule as shown in a separately provided War-

ranty Information and Maintenance booklet.

NDI1455Intelligent Key

DRIVE BELTS

8-20Maintenance and do-it-yourself