lock NISSAN SENTRA 2023 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2023, Model line: SENTRA, Model: NISSAN SENTRA 2023Pages: 556, PDF Size: 6.11 MB

Page 426 of 556

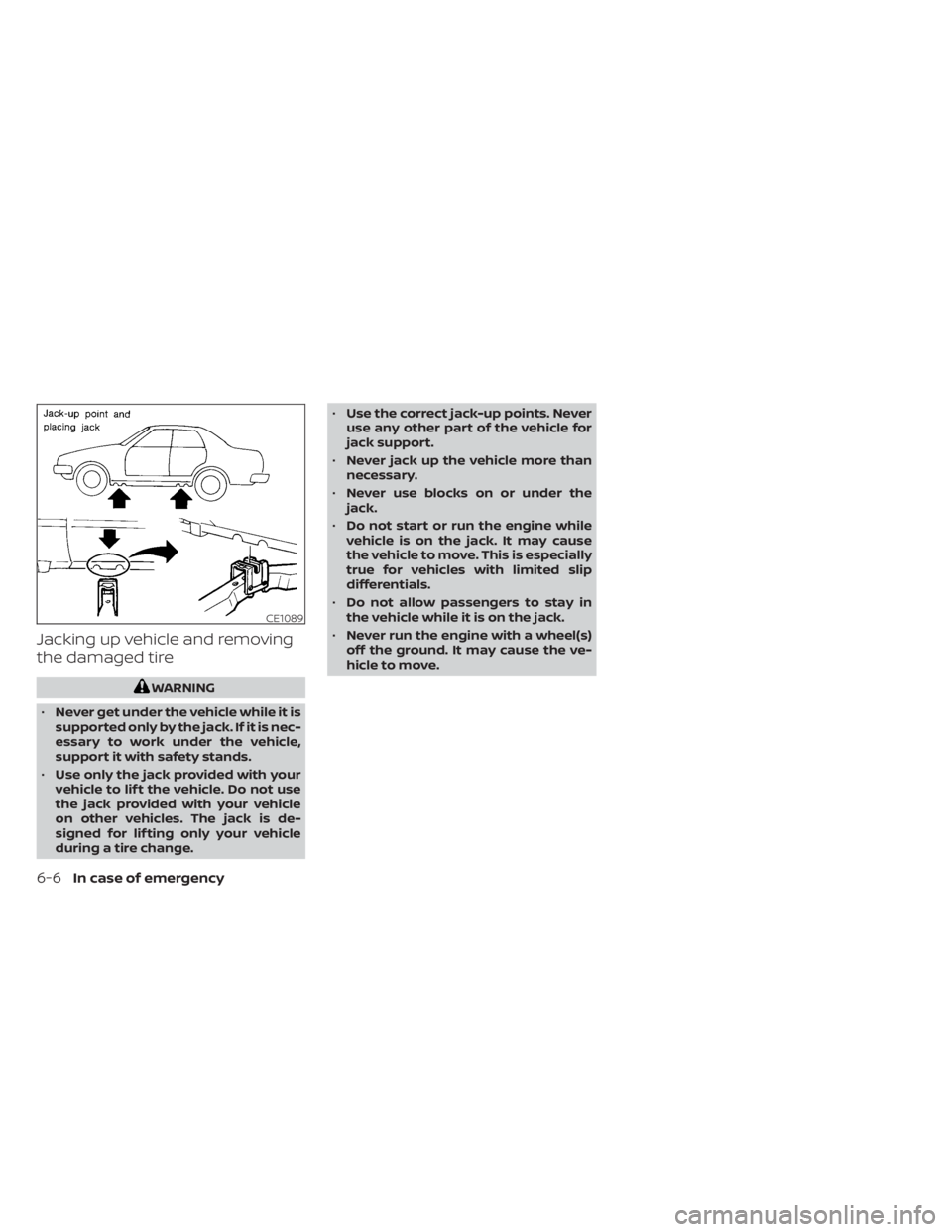

Jacking up vehicle and removing

the damaged tire

WARNING

• Never get under the vehicle while it is

supported only by the jack. If it is nec-

essary to work under the vehicle,

support it with safety stands.

• Use only the jack provided with your

vehicle to lif t the vehicle. Do not use

the jack provided with your vehicle

on other vehicles. The jack is de-

signed for lif ting only your vehicle

during a tire change. •

Use the correct jack-up points. Never

use any other part of the vehicle for

jack support.

• Never jack up the vehicle more than

necessary.

• Never use blocks on or under the

jack.

• Do not start or run the engine while

vehicle is on the jack. It may cause

the vehicle to move. This is especially

true for vehicles with limited slip

differentials.

• Do not allow passengers to stay in

the vehicle while it is on the jack.

• Never run the engine with a wheel(s)

off the ground. It may cause the ve-

hicle to move.

CE1089

6-6In case of emergency

Page 427 of 556

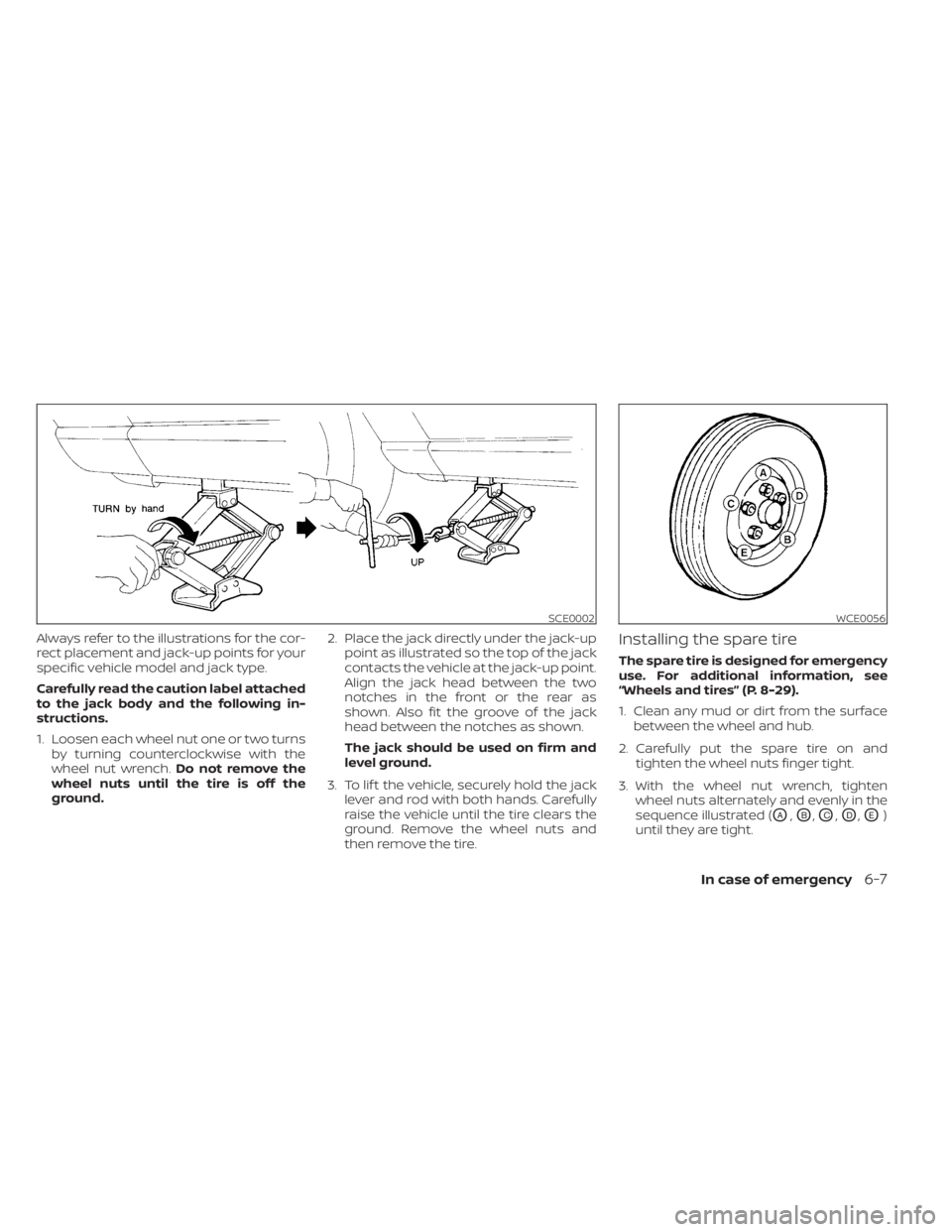

Always refer to the illustrations for the cor-

rect placement and jack-up points for your

specific vehicle model and jack type.

Carefully read the caution label attached

to the jack body and the following in-

structions.

1. Loosen each wheel nut one or two turnsby turning counterclockwise with the

wheel nut wrench. Do not remove the

wheel nuts until the tire is off the

ground. 2. Place the jack directly under the jack-up

point as illustrated so the top of the jack

contacts the vehicle at the jack-up point.

Align the jack head between the two

notches in the front or the rear as

shown. Also fit the groove of the jack

head between the notches as shown.

The jack should be used on firm and

level ground.

3. To lif t the vehicle, securely hold the jack lever and rod with both hands. Carefully

raise the vehicle until the tire clears the

ground. Remove the wheel nuts and

then remove the tire.Installing the spare tire

The spare tire is designed for emergency

use. For additional information, see

“Wheels and tires” (P. 8-29).

1. Clean any mud or dirt from the surfacebetween the wheel and hub.

2. Carefully put the spare tire on and tighten the wheel nuts finger tight.

3. With the wheel nut wrench, tighten wheel nuts alternately and evenly in the

sequence illustrated (

OA,OB,OC,OD,OE)

until they are tight.

SCE0002WCE0056

In case of emergency6-7

Page 430 of 556

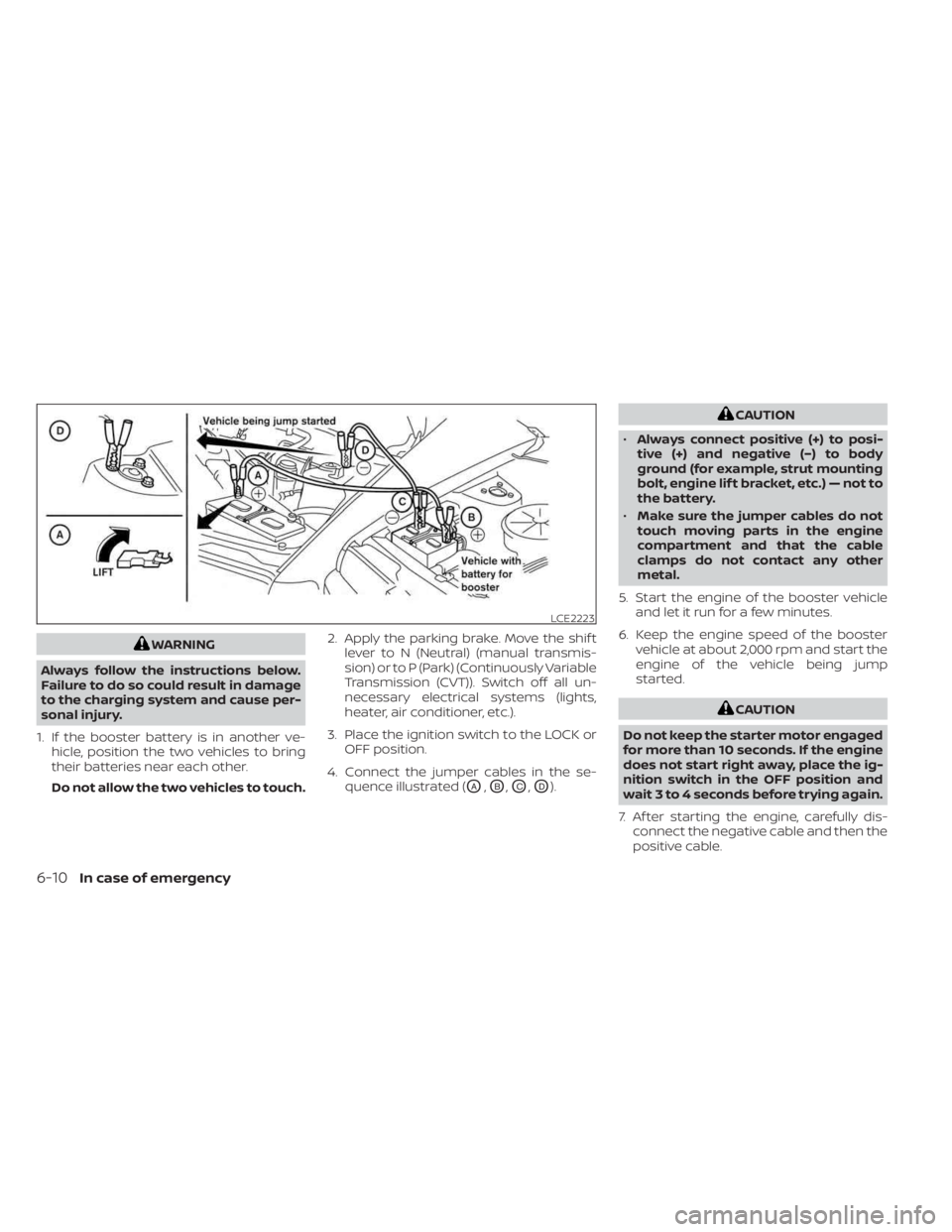

WARNING

Always follow the instructions below.

Failure to do so could result in damage

to the charging system and cause per-

sonal injury.

1. If the booster battery is in another ve- hicle, position the two vehicles to bring

their batteries near each other.

Do not allow the two vehicles to touch. 2. Apply the parking brake. Move the shif t

lever to N (Neutral) (manual transmis-

sion) or to P (Park) (Continuously Variable

Transmission (CVT)). Switch off all un-

necessary electrical systems (lights,

heater, air conditioner, etc.).

3. Place the ignition switch to the LOCK or OFF position.

4. Connect the jumper cables in the se- quence illustrated (

OA,OB,OC,OD).

CAUTION

• Always connect positive (+) to posi-

tive (+) and negative (−) to body

ground (for example, strut mounting

bolt, engine lif t bracket, etc.) — not to

the battery.

• Make sure the jumper cables do not

touch moving parts in the engine

compartment and that the cable

clamps do not contact any other

metal.

5. Start the engine of the booster vehicle and let it run for a few minutes.

6. Keep the engine speed of the booster vehicle at about 2,000 rpm and start the

engine of the vehicle being jump

started.

CAUTION

Do not keep the starter motor engaged

for more than 10 seconds. If the engine

does not start right away, place the ig-

nition switch in the OFF position and

wait 3 to 4 seconds before trying again.

7. Af ter starting the engine, carefully dis- connect the negative cable and then the

positive cable.

LCE2223

6-10In case of emergency

Page 433 of 556

Two-Wheel Drive models with

Continuously Variable

Transmission (CVT)

NISSAN recommends that your vehicle be

towed with the driving (front) wheels off the

ground or place the vehicle on a flatbed

truck as illustrated.

CAUTION

• Never tow CVT models with the front

wheels on the ground or four wheels

on the ground (forward or back-

ward), as this may cause serious and

expensive damage to the transmis-

sion. If it is necessary to tow the ve-

hicle with the rear wheels raised al-

ways use towing dollies under the

front wheels.

• When towing CVT models with the

rear wheels on the ground or on tow-

ing dollies: –

Place the ignition switch in the

OFF position, and secure the

steering wheel in a straight-ahead

position with a rope or similar de-

vice. Never secure the steering

wheel by placing the ignition

switch in the LOCK position. This

may damage the steering lock

mechanism (for models with a

steering lock mechanism).

LCE2345

In case of emergency6-13

Page 448 of 556

When performing any inspection or main-

tenance work on your vehicle, always take

care to prevent serious accidental injury to

yourself or damage to the vehicle. The fol-

lowing are general precautions which

should be closely observed.

WARNING

• Park the vehicle on a level surface,

apply the parking brake securely and

block the wheels to prevent the ve-

hicle from moving. For manual trans-

mission models, move the shif t lever

to N (Neutral). For CVT models, move

the shif t lever to P (Park).

• Be sure the ignition switch is in the

OFF or LOCK position when perform-

ing any parts replacement or repairs.

• If you must work with the engine run-

ning, keep your hands, clothing, hair

and tools away from moving fans,

belts and any other moving parts.

• It is advisable to secure or remove

any loose clothing and remove any

jewelry, such as rings, watches, etc.

before working on your vehicle.

• Always wear eye protection when-

ever you work on your vehicle. •

If you must run the engine in an en-

closed space such as a garage, be

sure there is proper ventilation for

exhaust gases to escape.

• Never get under the vehicle while it is

supported only by a jack. If it is nec-

essary to work under the vehicle,

support it with safety stands.

• Keep smoking materials, flame and

sparks away from the fuel tank and

battery.

• Because the fuel lines on gasoline

engine models are under high pres-

sure even when the engine is off, it is

recommended that you visit a

NISSAN dealer for service of the fuel

filter or fuel lines.

• Your vehicle is equipped with an au-

tomatic engine cooling fan. It may

come on at any time without

warning, even if the ignition switch is

in the OFF position and the engine is

not running. To avoid injury, always

disconnect the negative battery

cable before working near the fan.

CAUTION

• Do not work under the hood while

the engine is hot. Turn the engine off

and wait until it cools down. •

Avoid contact with used engine oil

and coolant. Improperly disposed

engine oil, engine coolant and/or

other vehicle fluids can damage the

environment. Always conform to lo-

cal regulations for disposal of vehicle

fluid.

• Never leave the engine or the trans-

mission related component harness

connector disconnected while the ig-

nition switch is in the ON position.

• Never connect or disconnect the bat-

tery or any transistorized compo-

nent while the ignition switch is in

the ON position.

This “Do-it-yourself ” section gives instruc-

tions regarding only those items which are

relatively easy for an owner to perform.

A Genuine NISSAN service manual is also

available. For additional information, see

“Owner's Manual/Service Manual order in-

formation” (P. 10-25).

You should be aware that incomplete or

improper servicing may result in operating

difficulties or excessive emissions, and

could affect warranty coverage. If in doubt

about any servicing, it is recommended

that you have it done by a NISSAN dealer.

MAINTENANCE PRECAUTIONS

8-2Do-it-yourself

Page 454 of 556

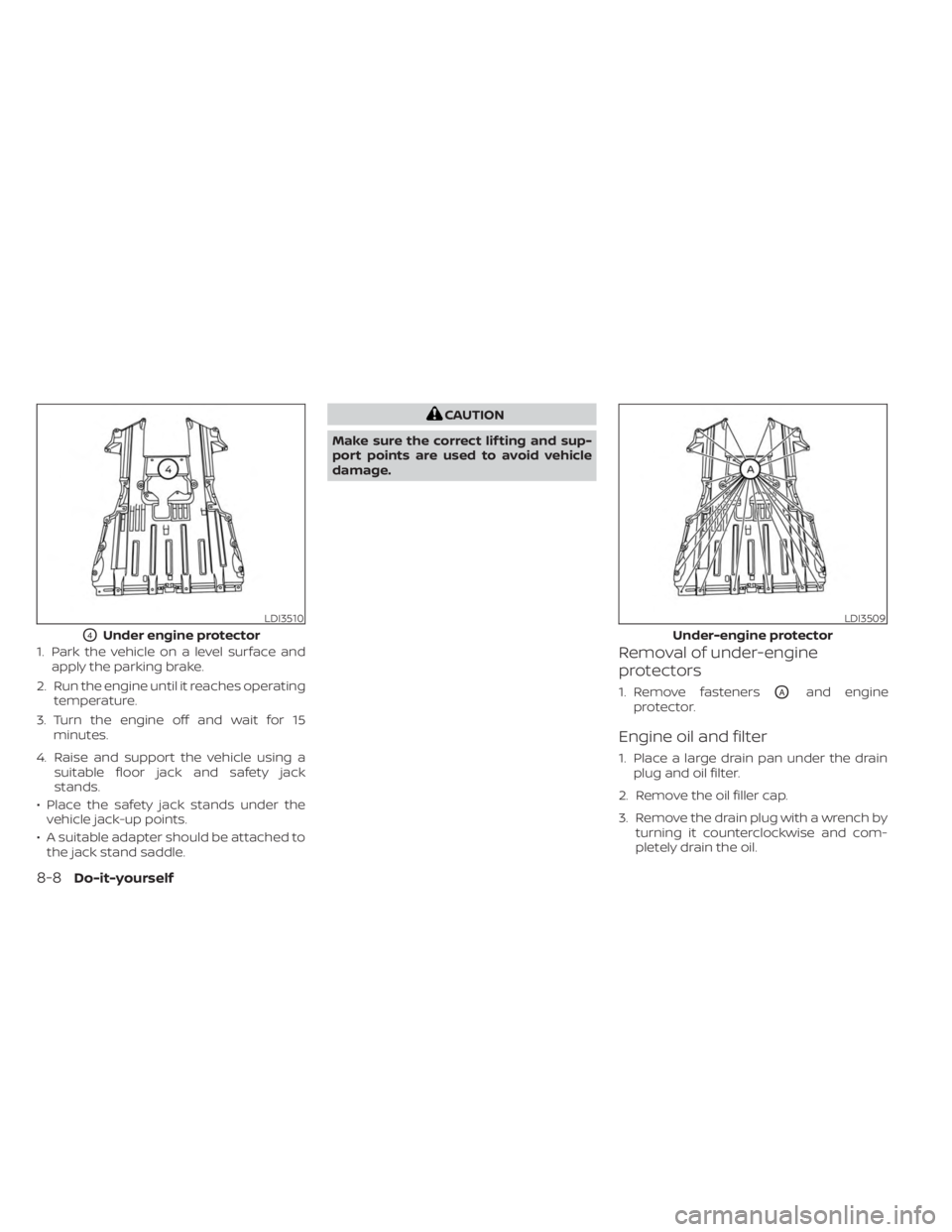

1. Park the vehicle on a level surface andapply the parking brake.

2. Run the engine until it reaches operating temperature.

3. Turn the engine off and wait for 15 minutes.

4. Raise and support the vehicle using a suitable floor jack and safety jack

stands.

• Place the safety jack stands under the vehicle jack-up points.

• A suitable adapter should be attached to the jack stand saddle.

CAUTION

Make sure the correct lif ting and sup-

port points are used to avoid vehicle

damage.

Removal of under-engine

protectors

1. Remove fastenersOAand engine

protector.

Engine oil and filter

1. Place a large drain pan under the drain plug and oil filter.

2. Remove the oil filler cap.

3. Remove the drain plug with a wrench by turning it counterclockwise and com-

pletely drain the oil.

LDI3510

O4Under engine protector

LDI3509

Under-engine protector

8-8Do-it-yourself

Page 455 of 556

CAUTION

Be careful not to burn yourself, as the

engine oil is hot.

WARNING

• Prolonged and repeated contact

with used engine oil may cause skin

cancer.

• Try to avoid direct skin contact with

used oil. If skin contact is made, wash

thoroughly with soap or hand

cleaner as soon as possible.

• Keep used engine oil out of reach of

children.

4. Loosen the oil filter with an oil filter wrench by turning it counterclockwise.

Remove the oil filter by turning it by

hand.

5. Wipe the engine oil filter mounting sur- face with a clean rag.

CAUTION

Be sure to remove any old gasket ma-

terial remaining on the sealing surface

of the engine. Failure to do so could

lead to an oil leak and engine damage. •

The dipstick must be inserted in

place to prevent oil spillage from the

dipstick hole when filling the engine

with oil.

6. Coat the gasket on the new filter with clean engine oil.

7. Screw in the oil filter clockwise until a slight resistance is felt, then tighten addi-

tionally more than 2/3 turn.

Oil filter tightening torque: 11 to 15 f t-lb (14.7 to 20.6 N·m)

8. Clean and re-install the drain plug with a new washer. Securely tighten the drain

plug with a wrench. Do not use exces-

sive force.

Drain plug tightening torque: 22 to 29 f t-lb (29.4 to 39.2 N·m)

9. Refill the engine with the recommended oil through the oil filler opening, and in-

stall the oil filler cap securely.

For additional information about drain and

refill capacity, see “Recommended fluids/

lubricants and capacities” (P. 10-2). The

drain and refill capacity depends on the oil

temperature and drain time. Use these

specifications for reference only. Always use the dipstick to determine the proper

amount of oil in the engine.

10. Start the engine and check for leakage

around the drain plug and the oil filter.

Correct as required. Turn the engine off

and wait more than 15 minutes. Check

the oil level with the dipstick. Add en-

gine oil if necessary.

Af ter the operation

1. Reinstall under engine protector in re-verse order.

2. Lower the vehicle carefully to the ground.

3. Reset oil and oil filter maintenance re- minder and oil control system. For addi-

tional information, see “Vehicle informa-

tion display 4.2 inch (11 cm) Type A”

(P. 2-18) or “Vehicle information display 7

inch (18 cm) Type B” (P. 2-32).

• Dispose of waste oil and filter properly.

• Check your local regulations.

Do-it-yourself8-9

Page 461 of 556

CAUTION

• Do not ground accessories directly to

the battery terminal. Doing so will

bypass the variable voltage control

system and the vehicle battery may

not charge completely.

• Use electrical accessories with the

engine running to avoid discharging

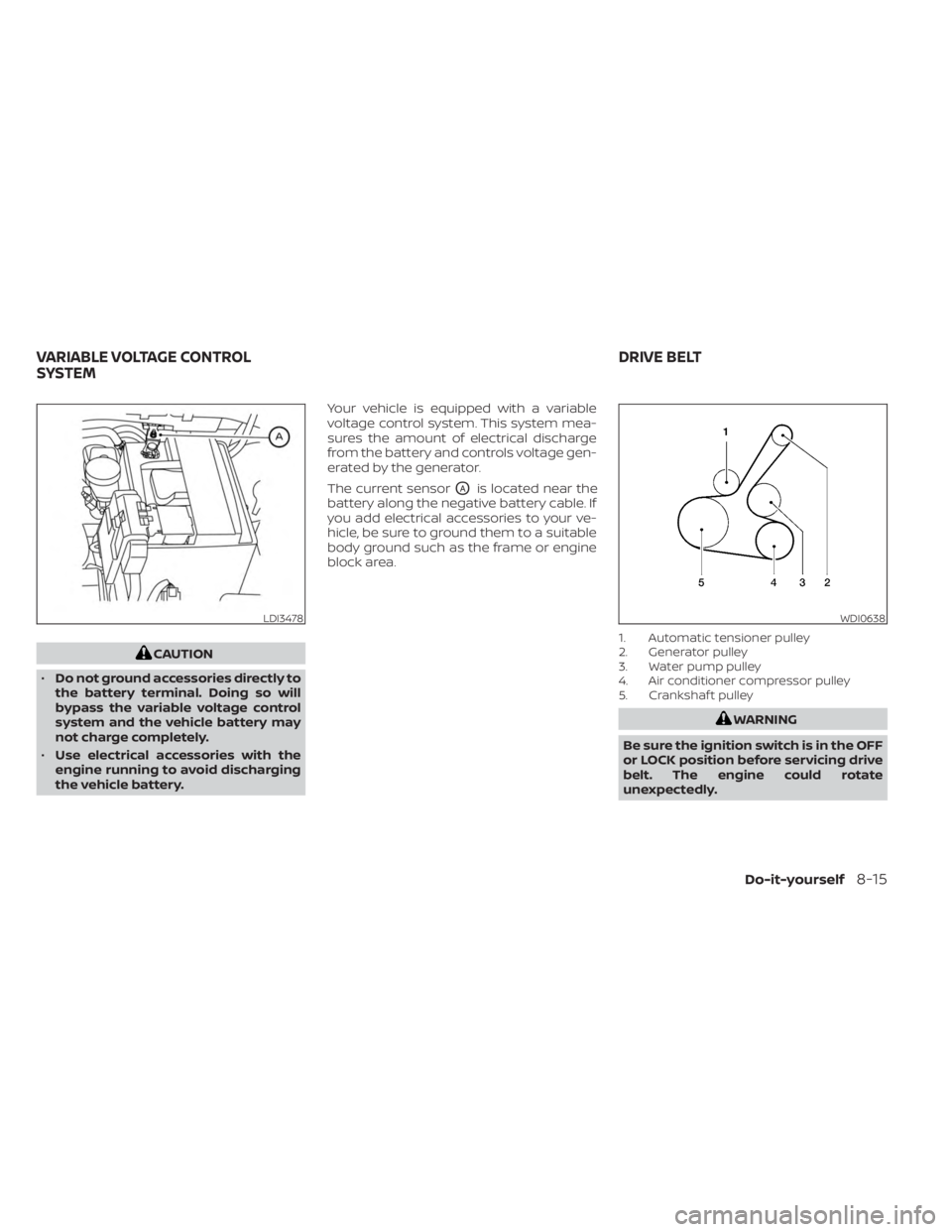

the vehicle battery. Your vehicle is equipped with a variable

voltage control system. This system mea-

sures the amount of electrical discharge

from the battery and controls voltage gen-

erated by the generator.

The current sensor

OAis located near the

battery along the negative battery cable. If

you add electrical accessories to your ve-

hicle, be sure to ground them to a suitable

body ground such as the frame or engine

block area.

1. Automatic tensioner pulley

2. Generator pulley

3. Water pump pulley

4. Air conditioner compressor pulley

5. Crankshaf t pulley

WARNING

Be sure the ignition switch is in the OFF

or LOCK position before servicing drive

belt. The engine could rotate

unexpectedly.

LDI3478WDI0638

VARIABLE VOLTAGE CONTROL

SYSTEM DRIVE BELT

Do-it-yourself8-15

Page 471 of 556

HEADLIGHTS

For additional information on headlight

bulb replacement, refer to the instructions

outlined in this section.

Replacing the halogen headlight

bulb (if so equipped)

CAUTION

• Aiming is not necessary af ter replac-

ing the bulb. When aiming adjust-

ment is necessary, it is recom-

mended that you visit a NISSAN

dealer for this service. •

Do not leave the headlight assembly

open without a bulb installed for a

long period of time. Dust, moisture,

smoke, etc. entering the headlight

body may affect bulb performance.

Remove the bulb from the headlight

assembly just before a replacement

bulb is installed.

• Only touch the base when handling

the bulb. Never touch the glass enve-

lope. Touching the glass could sig-

nificantly affect bulb life and/or

headlight performance.

• High pressure halogen gas is sealed

inside the halogen bulb. The bulb

may break if the glass envelope is

scratched or the bulb is dropped.

• Use the same number and wattage

as shown in the chart.

1. Disconnect the negative battery cable.

2. Remove the electrical connector.

3. Rotate the high beam bulb

OAcounter-

clockwise and remove bulb.

4. Rotate the low beam bulb

OBcounter-

clockwise and remove bulb.

Reverse instructions to install bulbs.

LDI3512

Type A (if so equipped)

LIGHTS

Do-it-yourself8-25

Page 491 of 556

Doors and engine hood:Check that the

doors and engine hood operate properly.

Also ensure that all latches lock securely.

Lubricate hinges, latches, latch pins, rollers

and links if necessary. Make sure that the

secondary latch keeps the hood from

opening when the primary latch is

released.

When driving in areas using road salt or

other corrosive materials, check lubrica-

tion frequently.

Check that the gas stays or struts properly

and securely hold the hood, trunk, or rear

hatch fully open. If the hood, trunk, or rear

hatch is not held open, have the gas stays

or struts replaced.

Lights*: Clean the headlights on a regular

basis. Make sure that the headlights, stop

lights, tail lights, turn signal lights, and other

lights are all operating properly and in-

stalled securely. Also check headlight aim.

Road wheel nuts (lug nuts)*: When check-

ing the tires, make sure no wheel nuts are

missing, and check for any loose wheel

nuts. Tighten if necessary.

Tire rotation*: Rotate tires at the specified

interval shown in the maintenance

schedule. Tires*:

Check the pressure with a gauge

of ten and always prior to long distance

trips. If necessary, adjust the pressure in all

tires, including the spare, to the pressure

specified. Check carefully for damage, cuts

or excessive wear.

Tire Pressure Monitoring System (TPMS)

tire pressure sensor: It is recommended

that you replace the tire pressure sensor

assembly when the tires are replaced due

to wear or age.

Wheel alignment and balance: If the ve-

hicle should pull to either side while driving

on a straight and level road, or if you detect

uneven or abnormal tire wear, there may

be a need for wheel alignment. If the steer-

ing wheel or seat vibrates at normal high-

way speeds, wheel balancing may be

needed.

For additional information regarding tires,

refer to “Important Tire Safety Information”

(US) or “Tire Safety Information” (Canada) in

the Warranty Information Booklet.

Windshield: Clean the windshield on a

regular basis. Check the windshield at least

every six months for cracks or other dam-

age. Have a damaged windshield repaired

by a qualified repair facility. It is recom-

mended that you have a damaged wind- shield repaired by a NISSAN dealer, or a

NISSAN Certified Collision Center. To locate

a collision center in your area, refer to

http://collision.nissanusa.com.

Windshield wiper blades*:

Check for

cracks or wear if they do not wipe properly.

Inside the vehicle

The maintenance items listed here should

be checked on a regular basis, such as

when performing scheduled maintenance,

cleaning the vehicle, etc.

Accelerator pedal: Check the pedal for

smooth operation and make sure the

pedal does not catch or require uneven

effort. Keep the floor mat away from the

pedal.

Brake pedal: Check the pedal for smooth

operation. If the brake pedal suddenly goes

down further than normal, the pedal feels

spongy or the vehicle seems to take longer

to stop, have your vehicle checked imme-

diately. It is recommended that you visit a

NISSAN dealer for this service. Keep the

floor mat away from the pedal.

Brakes: Check that the brakes do not pull

the vehicle to one side when applied.

Maintenance and schedules9-3