service NISSAN SERENA 1993 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1993, Model line: SERENA, Model: NISSAN SERENA 1993Pages: 1254, PDF Size: 89.68 MB

Page 890 of 1254

BRAKE

BOOSTEB

r*w On-vehicle

Service

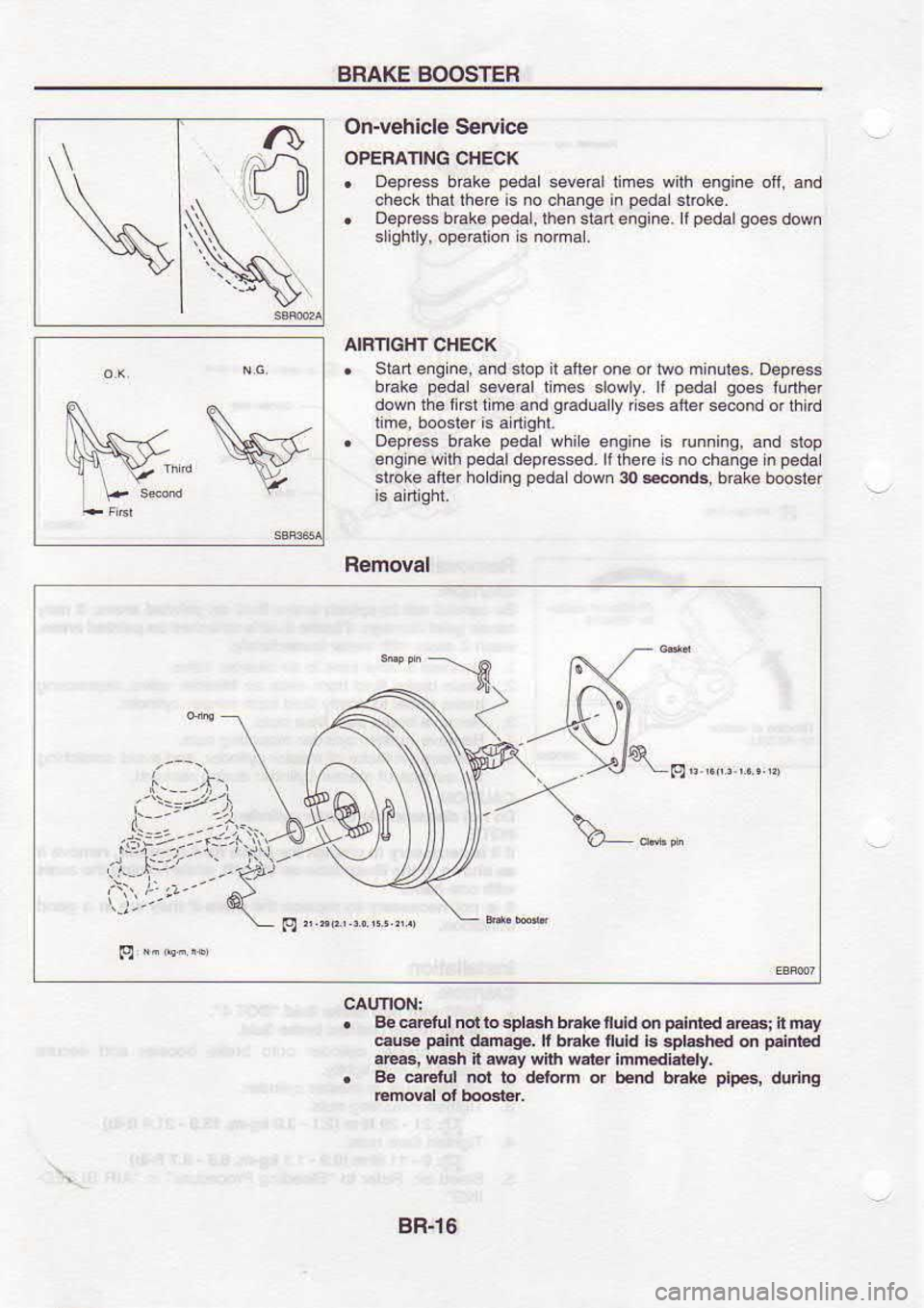

OPEFATING CHECK

. oep@s brake pedal

seveal times wilh engine ofi, and

check that th€G is no change in p6dalslrck€.

. o6p€.6

b6k. p.da|lhen

sl,an engine.It pedalgoes

down

slighlly, opediion is nomal.

AIRTIGHT CHECK

. Siart enqine, and stop il after one of two minut6s. D.press

bEke p6dal

s€voEl lim6s slowly. It pedal

goes

lunher

down lh. lircl I m€ and gEdlally

nses atler s@nd or third

lim€. boosl.r i5 ainighl.

. O6p€65

bEke pedal

whie engine is runninq, and srop

enqine wilh pedaldepressed.lllherc

s no chang€ in pedal

sloke alter holding p€da

down lO sond6,

brake b@ster

Removal

. Bs

cetu|nd lo sdBh

bFlG nud on

t lnled

aE6; hn.y

d4 Finr d.m.ge,

lf bhke nu|d b 3preh.d d p.ilned

'w, wah ft away whh wat6r ififi€diai€ly.

. Be

6r.tu1 noi to d.fom or

bend bElc pbe.r

dudng

aa

f-4

;;'{Lt;::t":'itf

,11,1,','{

8R.16

Page 952 of 1254

ON.VEHICLE

SERVICE

Bl€€dlng Hyd6ulic

Syslem

L Baise iiont 6nd of vehi.le

lnllwheels a€ cl6ar ol

the

2. Add lluid

inio oilla.klo specili€d

evel Meanwhite quickty

lurn deenng wh6el lully

to right

and ett and tiqhity

tolch

B€peal sleeling wheel opBr.rion u|li lllid

tevet no ong6r

Rep€l sl€p 2 abov6.

. -6rp6l€

ar bleed'rg fll eus€ r€ ,ol,osng

lo olcu.

when lhis happens, bl6€d.n

again

a. Genehton ol an bubb 6s in €seflo r i'nk

b. Gen€Ellof

ol clicki.g noi* in oi pump

c. Exesilre

buzz ng in oilplmp

Whi6 5e ver-Lte 's

sarion€-y o whte

novnq -€

stee'i.g

wheal slowly, lluid nois€ may

occur in the valvB or oil pump.

Tl^': nobe s 'nh€E.l r

rr^'s sleefg syst€n.

and 'l

{t nor

arlecl p€rtomance

o' durab ry ol lh€ sysrem

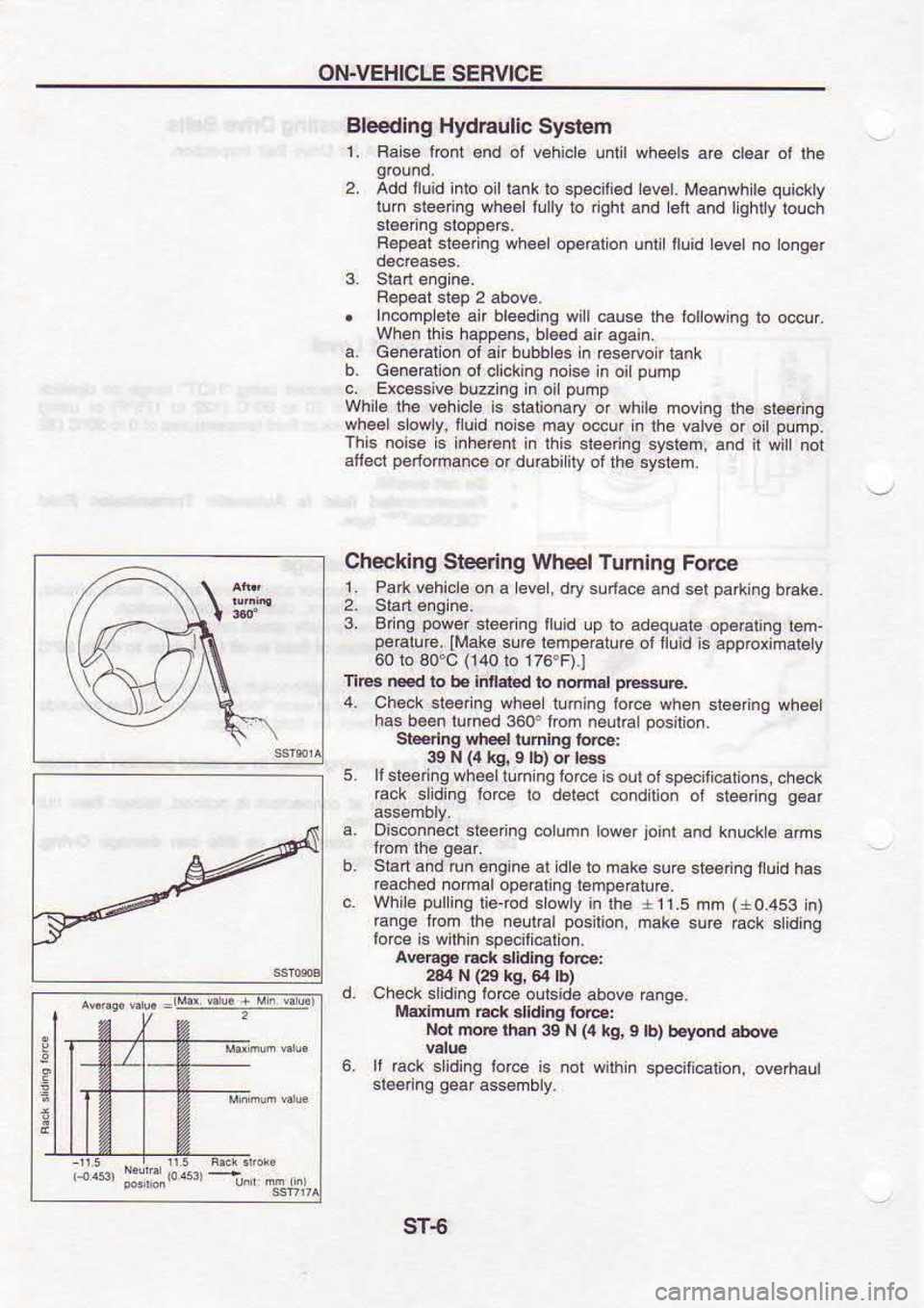

Checking Steering Wheel Tuming

Force

' oaAv€h'.6

dn a level,

dry sLd.ce

a.d sel

ea*'no br:re

2. Slan€ndrn6

3. Bdng poiwer

steeing lllid

!p to adequab op€ratinq

iem-

peraturc. ll'rake 6u@

lempeEture otlluid s

apprcximabty

60 lo 30'C (140lo

176.F).1

Tl@ Ed ro h.Iniated

to nornd pl*(E,

4. Ch€c qt@'ng

whee r.minq'Io'ce s

ea s.eernq wheel

has b€en

turned 3606 kom neul'a posrt'on.

S_teedng ehe6l turning io@:

39 N (4

ks, 9 lb)

or la

5. llsr66rifg wheeltln

ngtorc6 i6

outofspeciti€lons, check

raok slding lorc€

lo delecl condlion ol

steeing g€ar

a. Oisconn€cl

slaerno @lumn low6r

ioi.t and

knucke ams

Stan snd 'un

e.g'ne al d€ iom.kesure

st€€ nq tlu'd

has

rcached noroar op6rarinq remperature.

while puling

li6{od slowly

in lh6 r11.5

mm (+0.453

n)

ra.q€ rrom rhe

nellral posilion,

make s!rc Ecl 6tid'.o

lorce is w'lh

n sp€cihcai'on

a@Eg€ Eck didlng

force:

234 N (29

kq, 64 tb)

Check sliding iorce

oulside above

Mdimum Eck slldlng for:

Not moe rhin 39 N

{4 kg,

9

ll rack sliding lor.e

is nol wilhtn

!

sT6

Page 953 of 1254

OI$VEHICLE

SERVICE

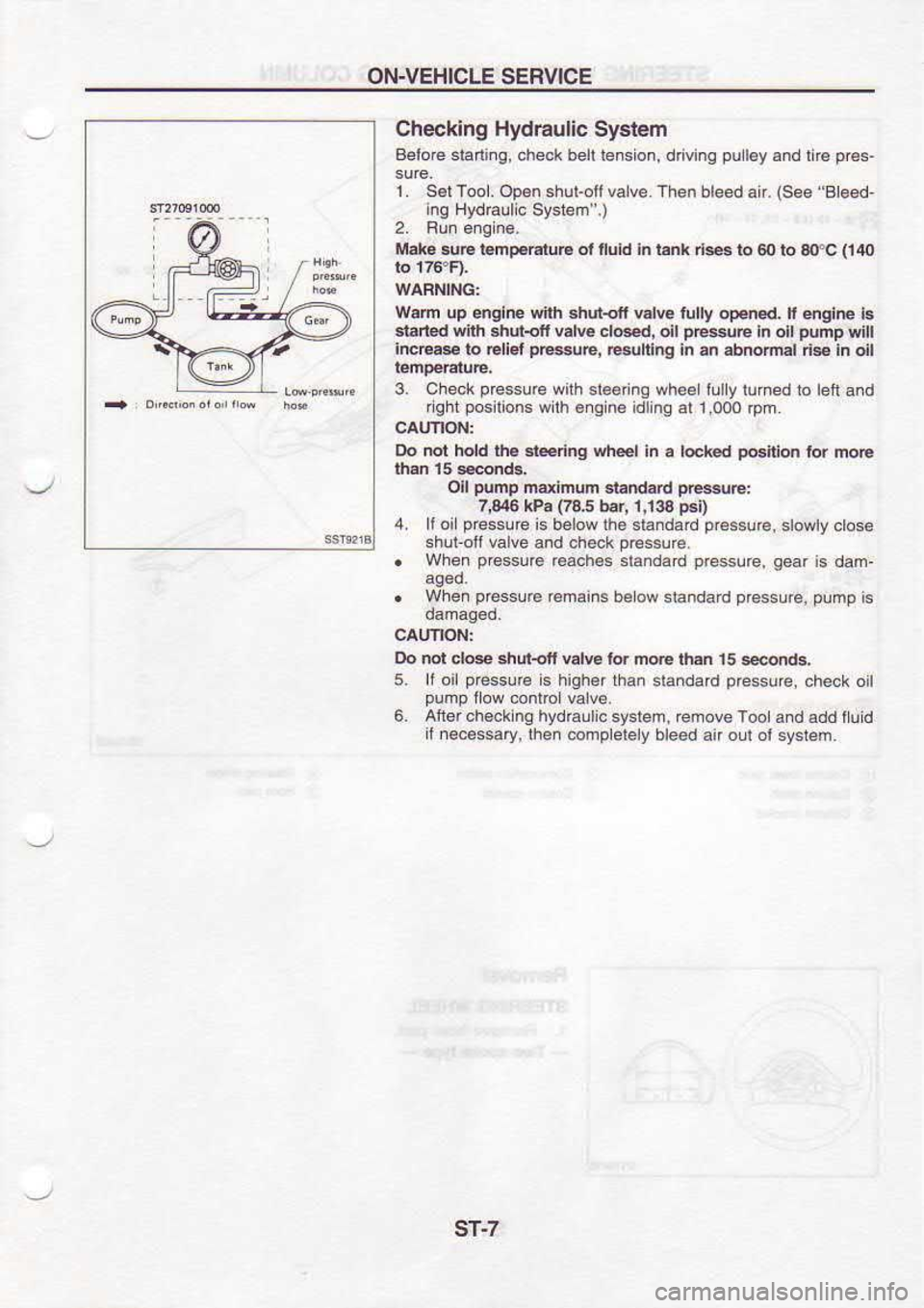

Checking Hydraulic System

Belo@ staning, check beft lension, d ving pul6yand

ri€ pr€s-

1. SelTool. Op€n.hutofivalve.

Then bleed air. (See

Beed-

ing HydElllc Systen".)

Mako sud tomp.EruB ol nuid in r.nk ds

to 60 to grc

fi lo

Wam up englne {ith shur{tt vdE lully oFned.

lt 4glre ls

slarted snh shur{fi vdE clG.d,

oll pEse

In olt plmp

yitl

incE.e ro Eliet pt!g@,

culing h an abtumd ds in dl

3. Cheok prcssurewith

3l€6rino wheelillly

luhed to bnand

fght posilions

wilh €nq n€ idlinq

al 1,000

lpm.

Do not hold th6 .l€.dng whel

ln a l@ked po€ilion

tor m@

oll p{mp

ndifrum d..d5d pe$uE:

7,046 kPa

{t85 bar,

1,133 p€D

4. It oi p.essure

is below lh6 slandard pressure,

slowlv close

shui-ofl @lve and check prassurc

. When p€ssurc

r€ach€s sl.ndad pGssure,

qear is dam,

. W'ea o e.sLE '€m:'n

ess.r€. pump

's

Oo .ot do* shublt €lv6 ld m@ rh.n 15

seMds,

5 ll

oil pressurc

s higher than

standad pressure,

ch6ck oil

pump low conrrcl valve.

6. Aft6rch6ckln9 hydEulicsyslem,

redoveToo a.d add lluid

il n€cessary,

lhen @dplelely bleed an oul oi system

sT-7

Page 1128 of 1254

BATTERY

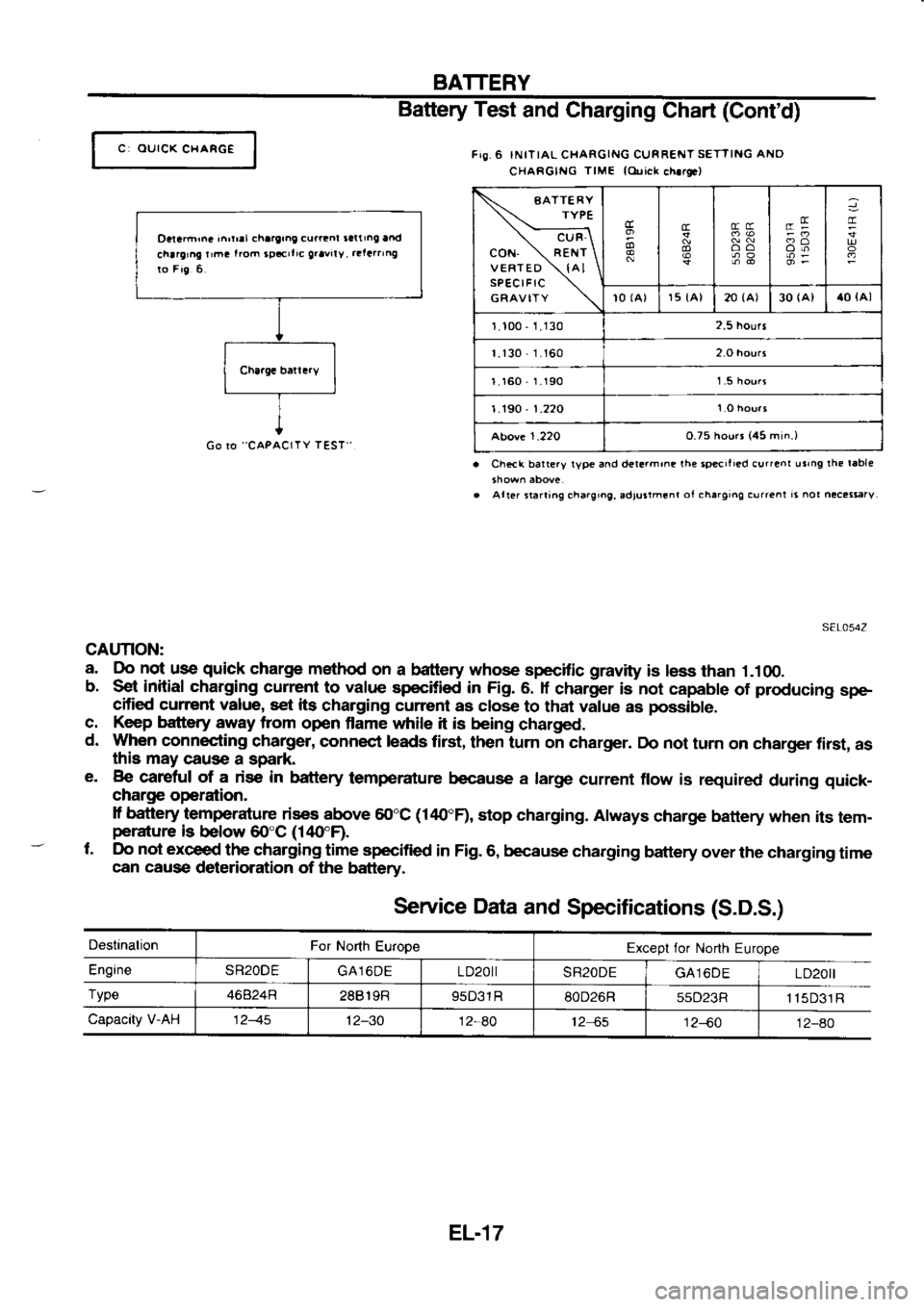

C OUICK

CHAFGE

CAUTION:

a. b.

c.

d. Oo

not

use quick

charge method on a bdtery whose

specific gravity

is les.s

than 1.10O.

s€t initial charging

curent to valr.p

specified in

Fig. 6. lf

charger is not

capable of producing

spe

cified current value,

set its

charging current

as close

to that value

as possible.

Keep battery

away from

open llame while it

is being

charged.

When connecting charger, connect leads

tirst, then tum on charger.

Do not

turn on charger

tirst, as

this may

caus€ a spark.

e. 8e

careful of a rise in

battery temperature because a large

current flow is

required during quick-

charge operation.

lf battery

temperaturc rises

above 6O"C (1.10"D,

stop charging. Always

charge battery when its

tem-

perature is below 6O"C (lrO'D.

f. Do not exceed

the chargin-g

time specilied

in Fig. 6, because

charging battery over the charging

time

can cause

deterioration of the battery.

Service Data

and Specifications (S.D.S.)

Destination For North

Europe

Excepl for

North Europe

Engine SR2ODEGA16DE LD20tlSR2ODE

GA16DE LD20rl

Type 46824R

28819R95D31R 80D26R55D23R1 15D31

R

Capacity V-AH 1245

12-30'12-80

't245

12-60 12-aO

Oaarrhina

r^rt.l

chargrng curr!.1 lattrn9

and

chrrgrng rrmc lrom

tp.crfic g.avrly,

rltlrrrng

ro Frg 6

Go ro "CAPACITY

TEST" Battery

Test and Charging

Chart (Cont'd)

Frs. 6 lNtTlALCHARGING CURRENTSETTING ANo

CHARGI G TIME

lorick chrrg.)

1 BATTE

RY

\ TYPE

\\--

cuR

\

coN. RENr

VERTED \AI

SPECTFTC \

GRAVITY \c!

(!

cD iIC!

oo _t

3? E

10 tAl 15

lA) 20 (A)

30 (a)

40 (a)

1 100 -

1.130 2.5

hour3

r. r30 .

1. t60 2.O

hour3

1.160 -

r .190

1.190 -

1.220

Above 1.220

O.75 houri (45

mi^.)

Ch.ck bartery typ€ and detcrmrn? th€

speciljed current utrng the

lable

alrer rrarr'n9 cha.grh9, adturih?.t ol

chargrng curr€^l r3

nor nacargfv

EL.17

Page 1138 of 1254

STARTING

SYSTEM -

Starter -

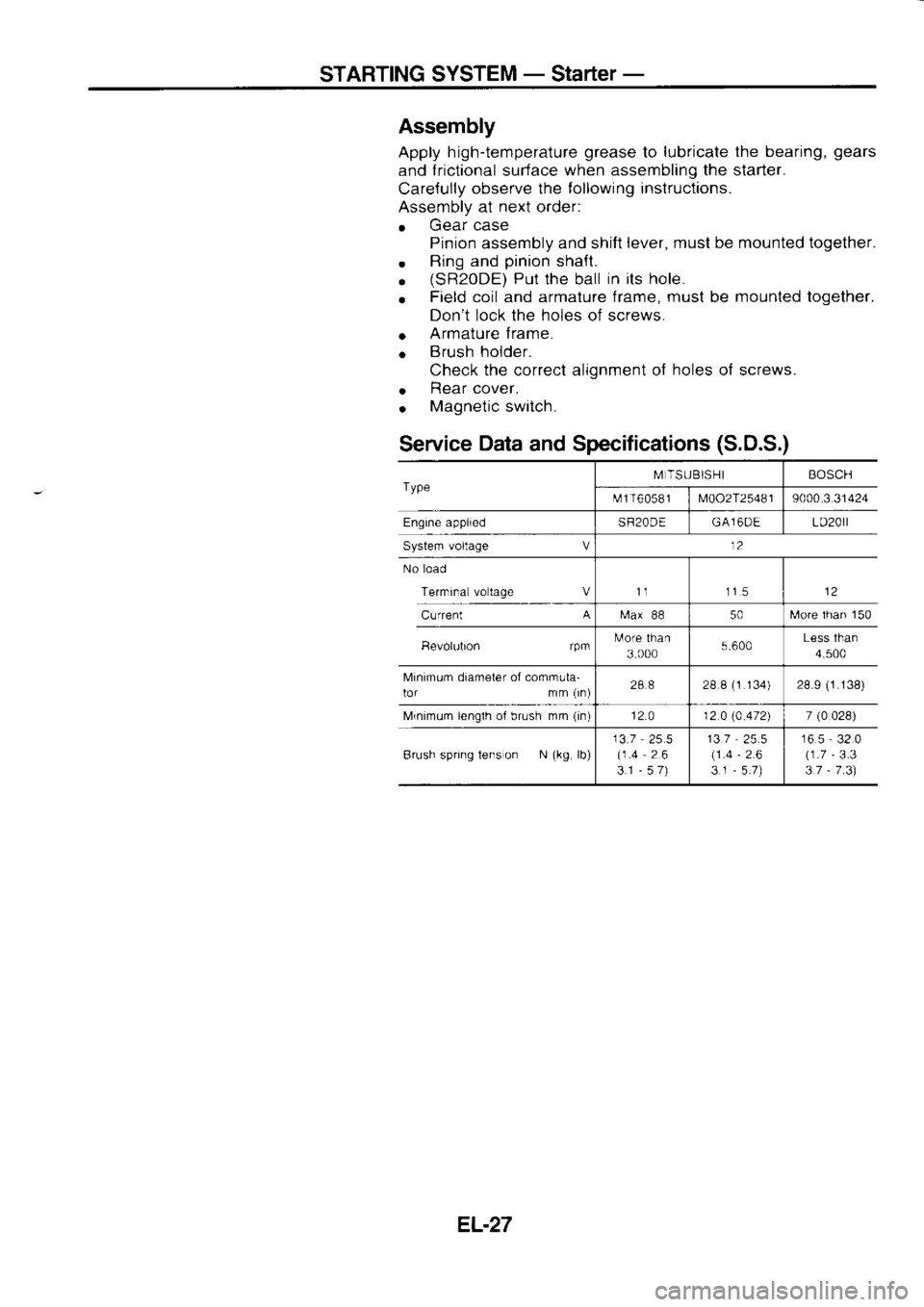

Assembly

Apply h igh-temperature grease

to lubricate

the bearing, gears

and frictional

surface when

assembling the starter.

Care{ully observe

the following inslructions.

Assembly at next

order:

. Gear

case

Pinion assembly and shift lever,

musl be mounted together.

. Ring

and pinion

shaft.

. (sR20DE)

Put the ball in

its hole.

o Field

coil and armature frame, must

be mounted

together.

Don't lock the holes of screws.

o Armature

f rame.

o Brush

holder.

Check the correct alignment of holes

of screws.

o Rear

cover.

. Magnetic

switch.

Service Data

and Specifications (S.D.S.)

Type M

TSUBISHI BOSCH

t\.rf 1 T6

05 8 I

M002T25481 9000.3

31424

Engine applied SR20DEGA16DE LD20rl

System voltage V 12

No load

Terrnrna voltage Vt1 115

Current A

[ra.x

88 50[,,lore

lhan 150

Bevolubon rpmtulore

than

3 000 5.600Less

than

4,500

Minimum diameter of comrnula-

lor mm (rn) 288

28 8 (1

134) 28.9 (1.138)

Mrnimum lenglh of brush mm (in)

12.0 12 0 (4.472)

7 (0

028)

Brush spring tens on N (kg,

lb) 13.7

25.5

(1.4 26

3.1 -57) 137

(1 .4

3.1 -

2.6 16.5

32.0

(1.7 -

3.3

3.7 -

7 .3)

EL.27

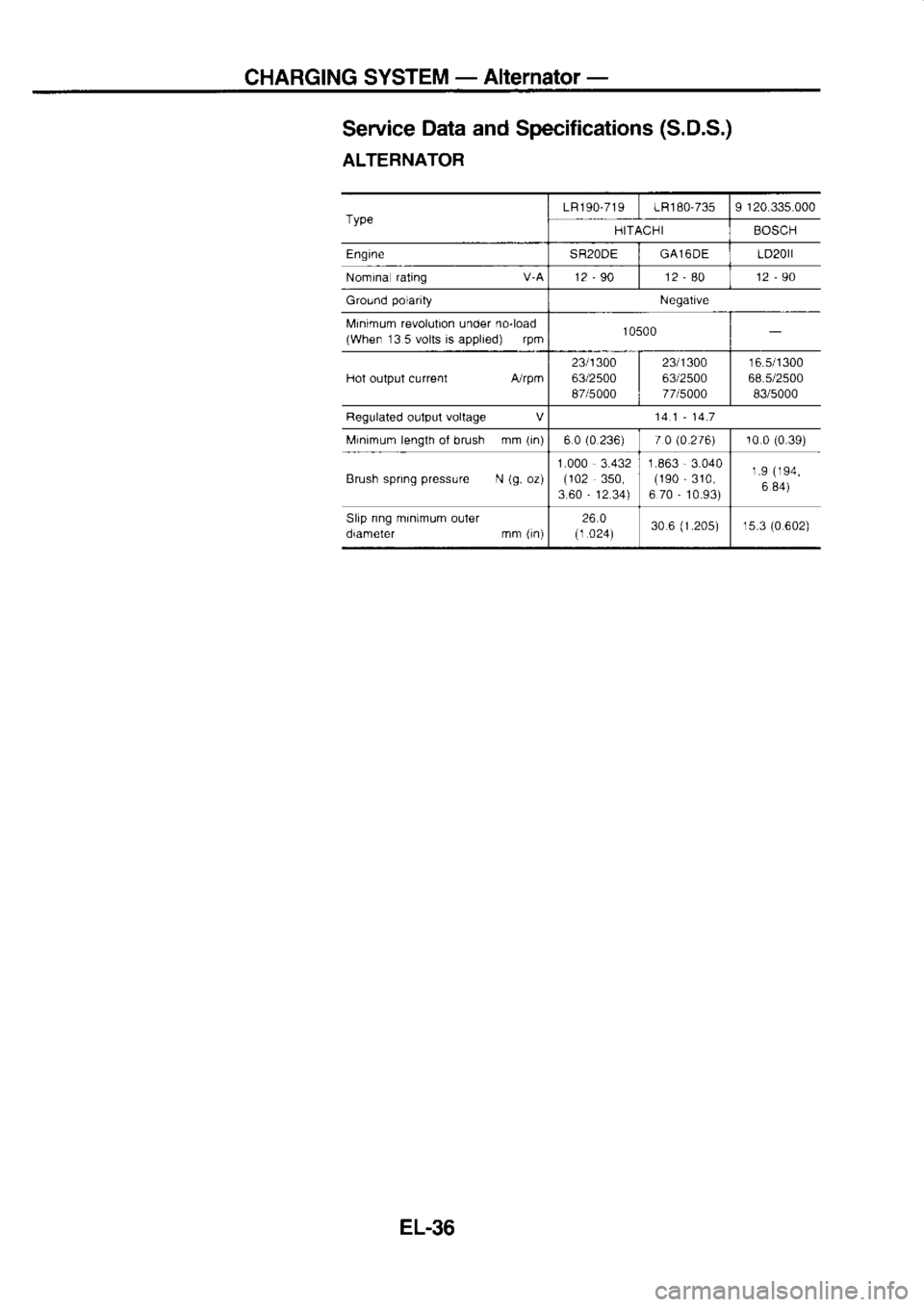

Page 1147 of 1254

CHARGING

SYSTEM -

Alternator -

Service Data

and Specifications (S.D.S.)

ALTERNATOR

Type LR190-719

1R180-735I 120.335.000

HITACHI BOSCH

Engine SR2ODEGAl6DE LD20rl

Nomina rating

V-A12-90 12 -

80 12-90

Ground polarity

Negalrve

l\,4inimum revolution

under no-load

(When 13 5 volts

is

applred) rpm 10500

Hot output current A./rpm234300

63/2500

87/5000 2311300

63/2500

77l5000 16.5/1300

68.5/2500 B3/5000

Regulated oulpul vollage

V 14.114.7

Minimum length ot brush mm (in)

6 0 (0

236) t

010.276) 10

0

{0.39)

Brush spring pressure

N (9,

oz) 1.000

3.432

(102 350,

3.60 -

12.34) 1.863

3.040

(1S0 -

310,

6 70 -

10.93) 1.9

(194,

6 84)

Slip nng

minimum

outer

orameler mm (1n) 26.0

(1 024) 30

6 (1.20s)

1s.3 (0

602)

E1.36